Papermachine fabric

a technology of papermachine fabric and fabric, which is applied in the field of papermachine fabric, can solve the problems of high cost and limit of batt structure production, and achieve the effect of producing more cost-effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

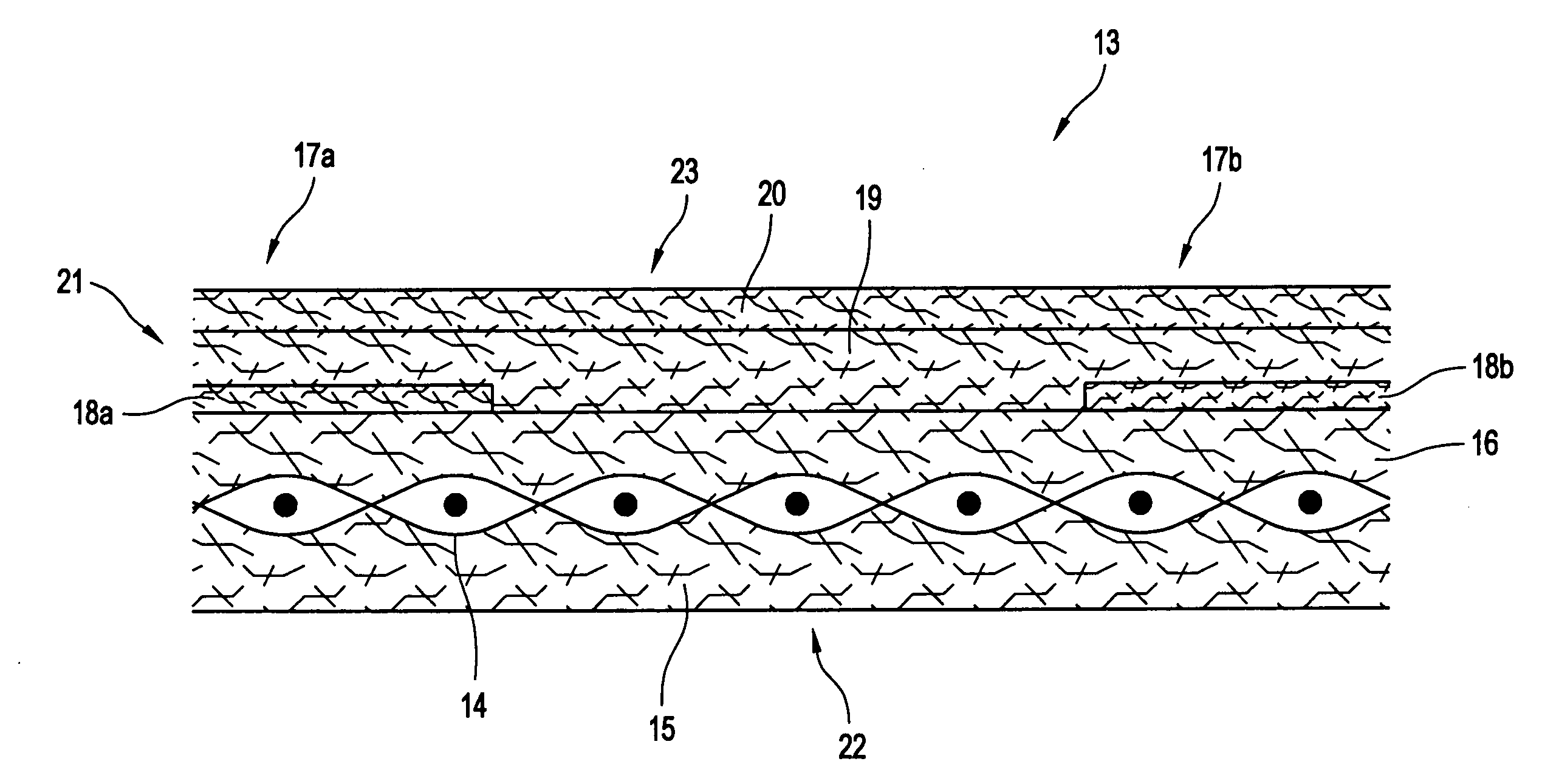

[0043]FIG. 1 shows in cross-section over its entire width a papermachine fabric according to the invention, formed as a dryer fabric 1.

[0044] The dryer fabric 1 has a carrier structure 2 which is formed by a perforated film 2 having openings 3. In the FIG. 1, above the perforated film, there is arranged a first ultrathin fiber batt 4, which is formed by ultrathin batt sections 5a, 5b, 6a, 6b and 7a, 7b.

[0045] The batt sections 6a and 7a and the batt sections 6b and 7b are in each case arranged flatly on one another and form a first laminate 8a and a second laminate 8b. The two laminates 8a and 8b are in each case arranged in the edge region 11a and 11b of the dryer fabric 1, the ultrathin batt sections 5a and 5b being arranged in the central region of the dryer fabric 1.

[0046] In order to form the ultrathin fiber batt 4 extending over the entire width of the fabric 1, the fiber batts 5a and 5b and the first and the second laminate 8a, 8b are arranged adjoining one another in their...

second embodiment

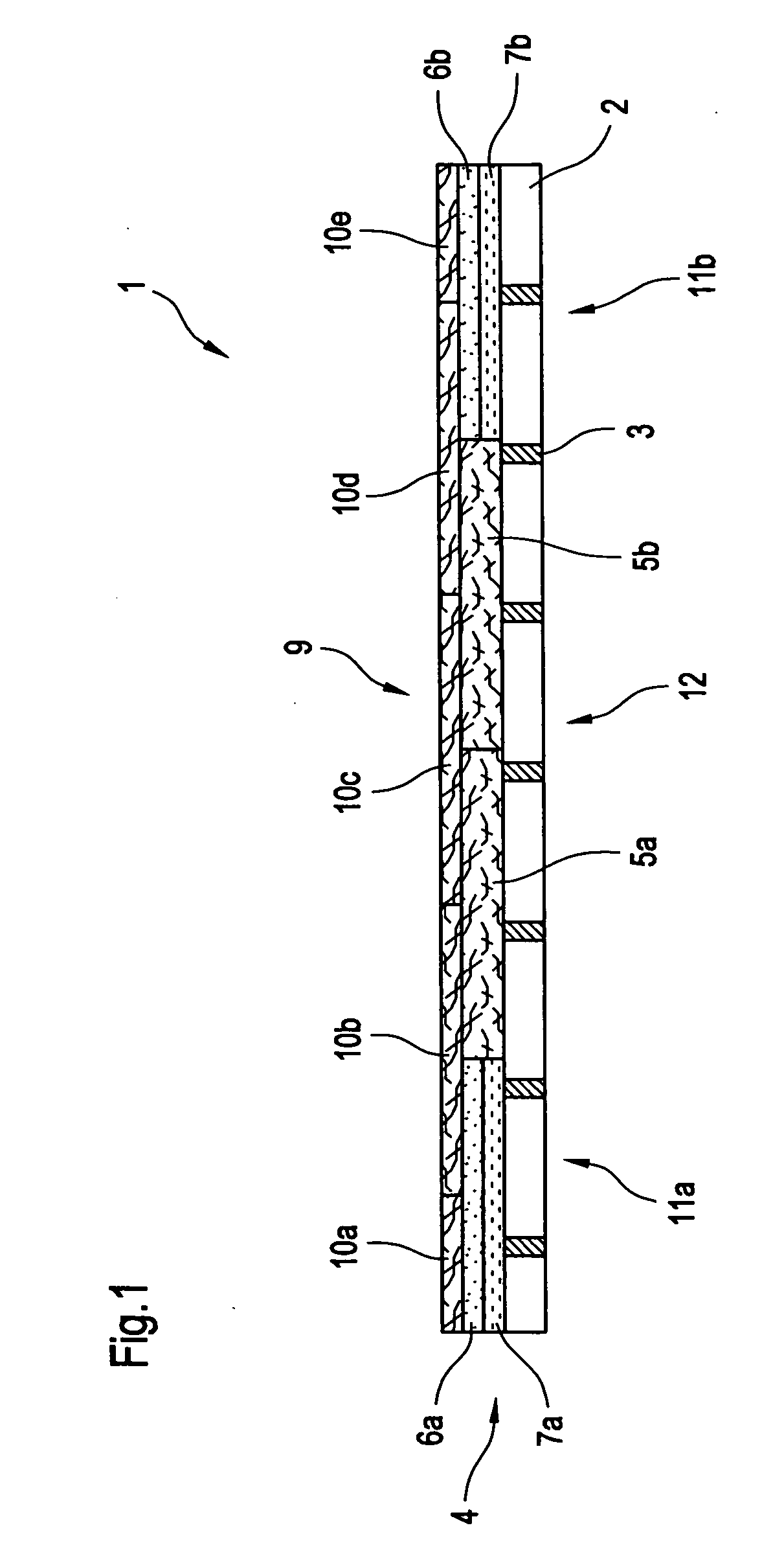

[0052]FIG. 2 shows in a cross section over its entire width a paper machine fabric according to the invention, formed as a press felt 13.

[0053] The press felt 13 has a carrier structure 14 which is formed by a woven fabric 14 known in the papermachine fabric sector. Furthermore, the press felt 13 has a batt structure 21.

[0054] The batt structure 21 has conventional fiber batts 15 and 16 which, in FIG. 2, are arranged above and below the woven fabric 14 and are joined flatly to the latter.

[0055] Furthermore, the batt structure 21 has conventional fiber batts 19 and 20 and ultrathin batt sections 18a and 18b according to the invention. The ultrathin batt sections 18a, 18b are in each case arranged in one of the edge regions 17a and 17b of the press felt 13, between the fiber batts 16 and 19.

[0056] The two ultrathin batt sections 18a, 18b each have a thickness of 0.1 mm, whereas the conventional fiber batts 16 and 19 have thicknesses in the range from 1.2 mm to 1.8 mm with thickness...

third embodiment

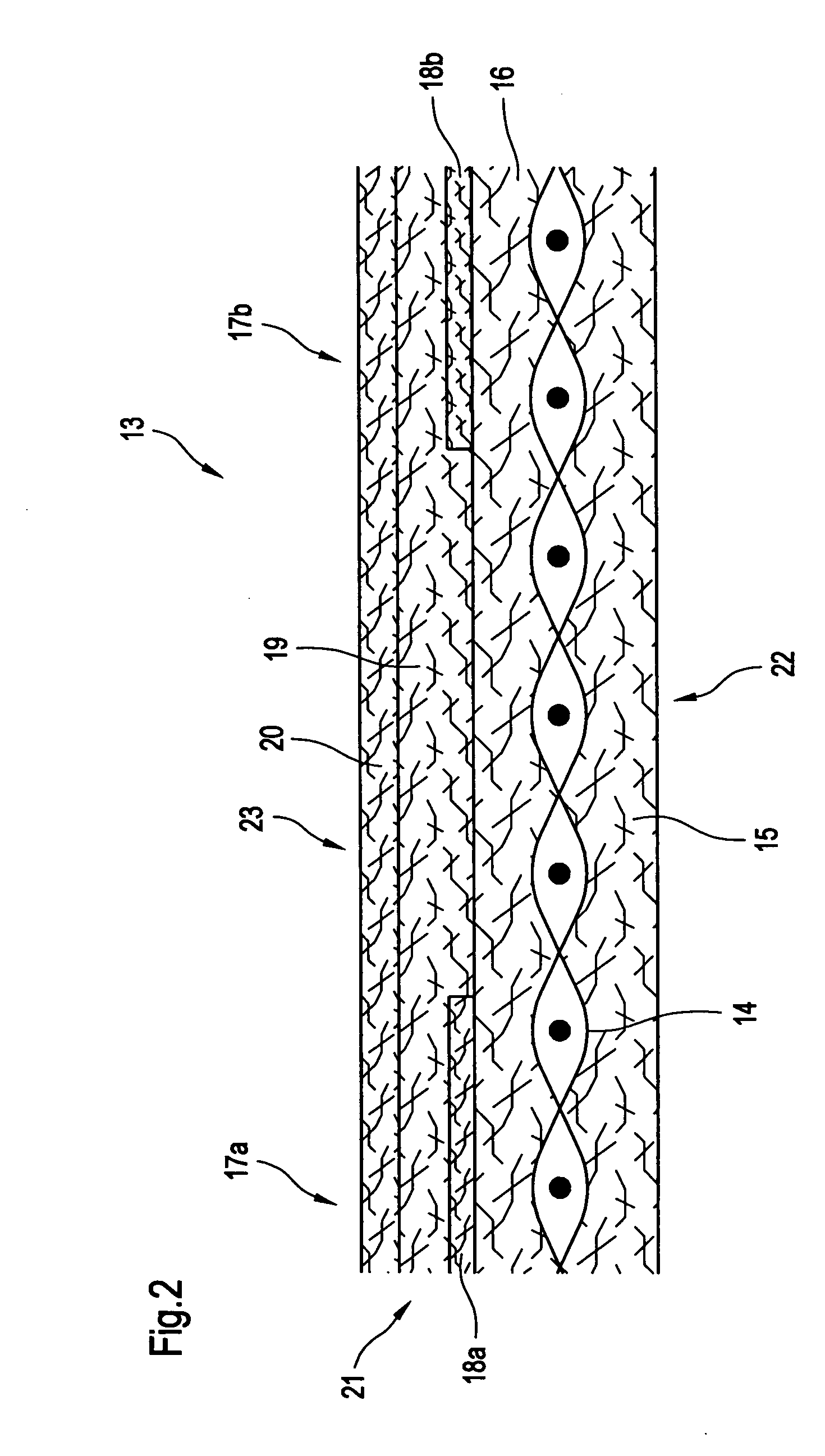

[0058]FIG. 3 shows in a cross section over its entire width a paper machine fabric according to the invention, formed as a press felt 24.

[0059] The press felt 24 has a carrier structure 25 which is formed by a laid scrim having filaments 27 extending in the machine direction. In FIG. 3, above the carrier structure 25, there is arranged a batt structure 26 which is joined flatly to the carrier structure 25.

[0060] The batt structure 26 has ultrathin fiber batts 28, 29, 30, 31 and 32 which are ranged above one another flatly from bottom to top in FIG. 3.

[0061] In the two edge regions 33a and 33b of the press felt 24, ultrathin batt sections 35a and 35b are, moreover, arranged between the two ultra thin fiber batts 30 and 31. Furthermore, two ultrathin batt sections 36a and 36b adjoining one another in their width extent are arranged in the central region 34 between the two fiber batts 31 and 32.

[0062] Each of the ultrathin fiber batts 28, 29, 30, 31 and 32 is formed by a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com