Fin field effect transistors (FinFETs) and methods for making the same

a technology of field effect transistor and finfet, which is applied in the field of sineconductor devices, can solve the problems of limited ability to tailor the structure of sineconductor resulting from such conventional methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

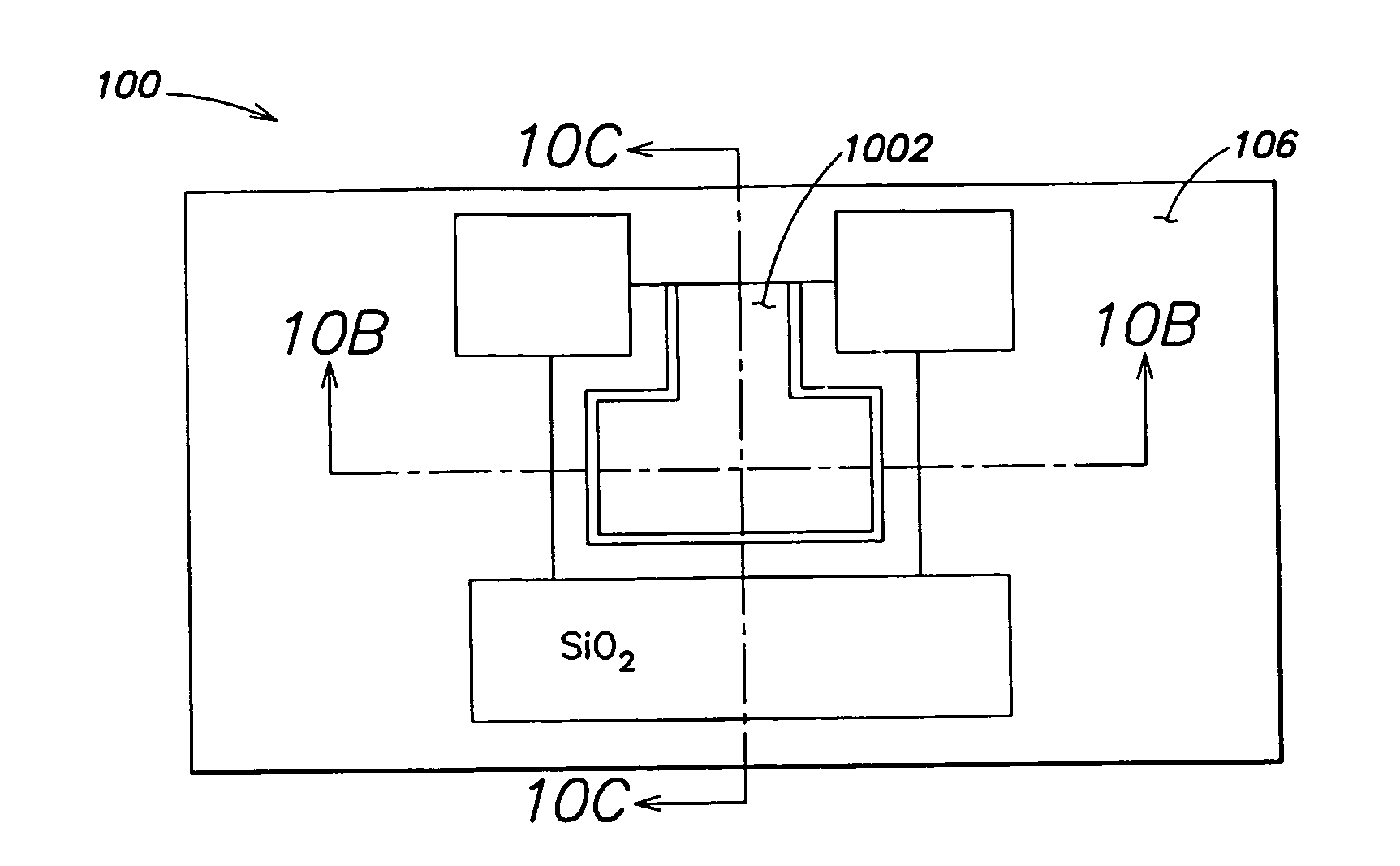

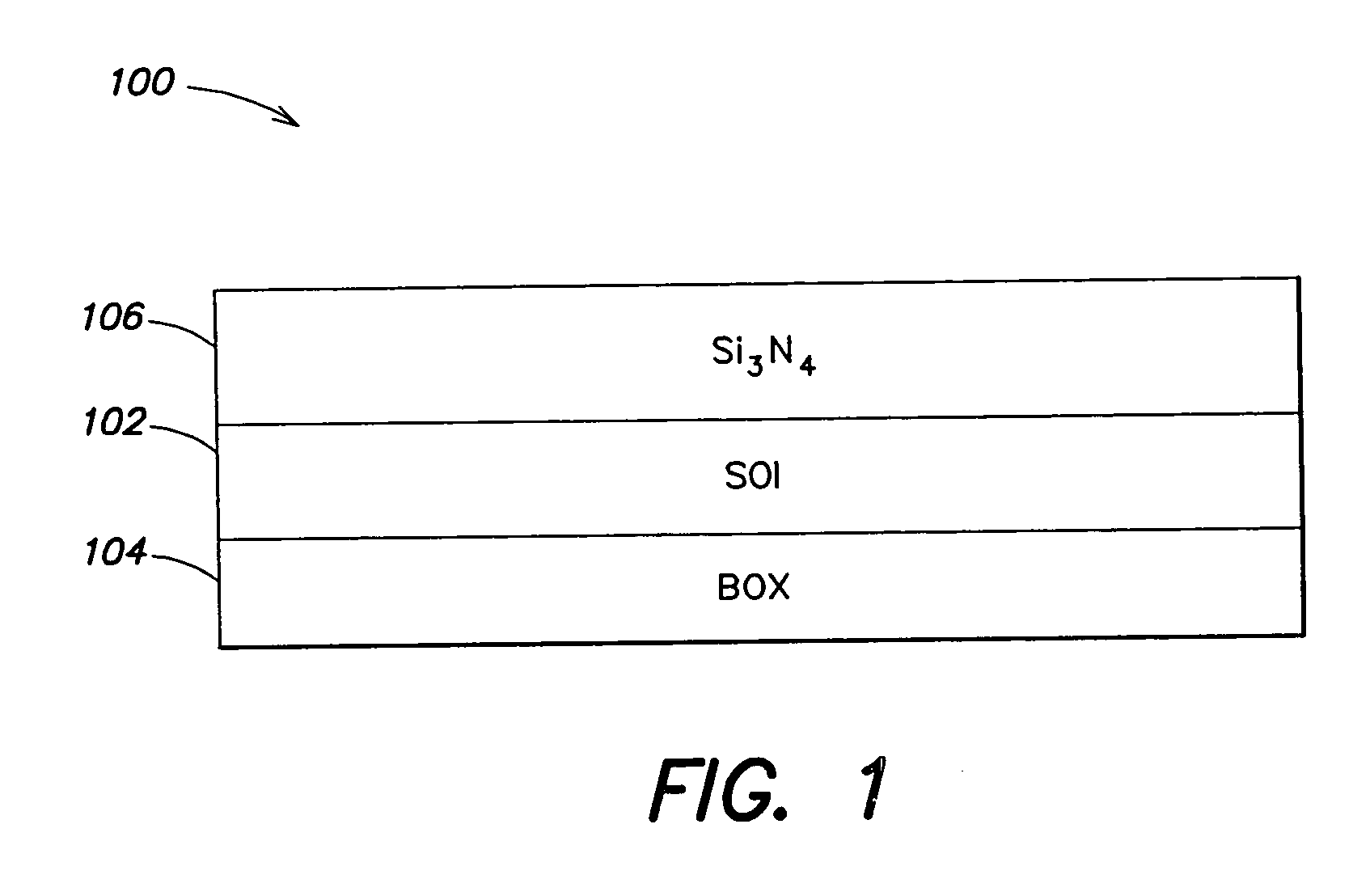

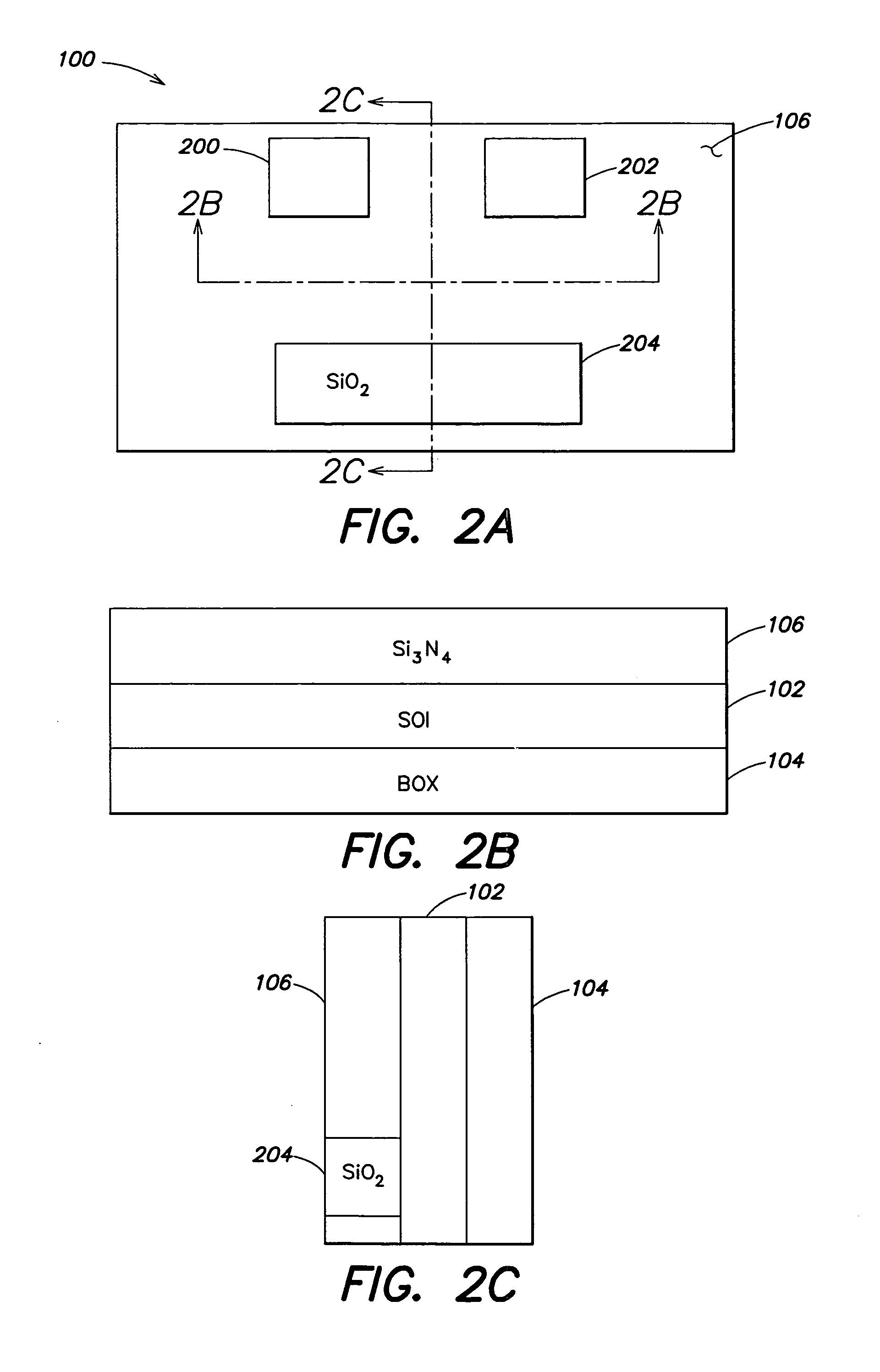

[0048] The present invention provides improved semiconductor devices and methods for making the same. More specifically, the present invention provides improved fin field effect transistors (FinFETS) and methods for making the same. The present methods of manufacturing FinFETs provide support (e.g., on one or more sides) to silicon which ultimately forms a fin during (e.g., throughout) manufacturing. In this manner, damage to the fin while manufacturing a FinFET may be reduced and / or eliminated, and therefore, a semiconductor device manufacturing yield may be improved.

[0049] Further, in contrast to conventional methods, the variability of a structure of a FinFET resulting from the present methods is not limited. For example, a FinFET in accordance with the present methods and apparatus may include a first gate conductor, which has a first work function, coupled to a first gate of the FinFET, and may include a second gate conductor, which has a different (e.g., a second) work functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com