Heat exchanger

a technology of heat exchanger and insert, which is applied in the direction of heat exchange apparatus safety devices, lighting and heating equipment, and stationary conduit assemblies, etc., can solve the problems of tube in the neighborhood of the root being broken, the difference in the amount of thermal expansion between the tubes and the insert is liable to generate thermal stress, and the effect of reducing the efficiency of heat exchang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

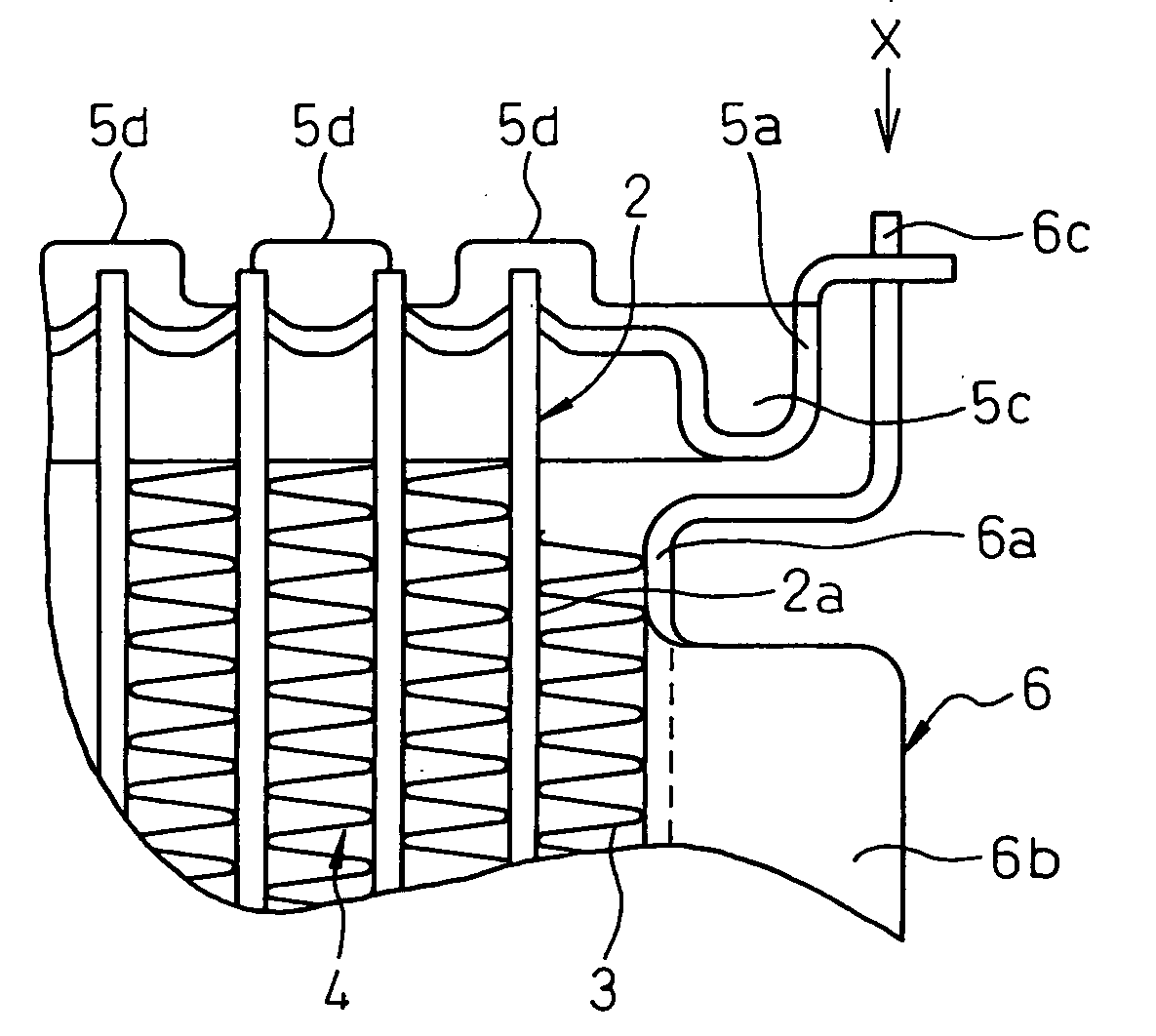

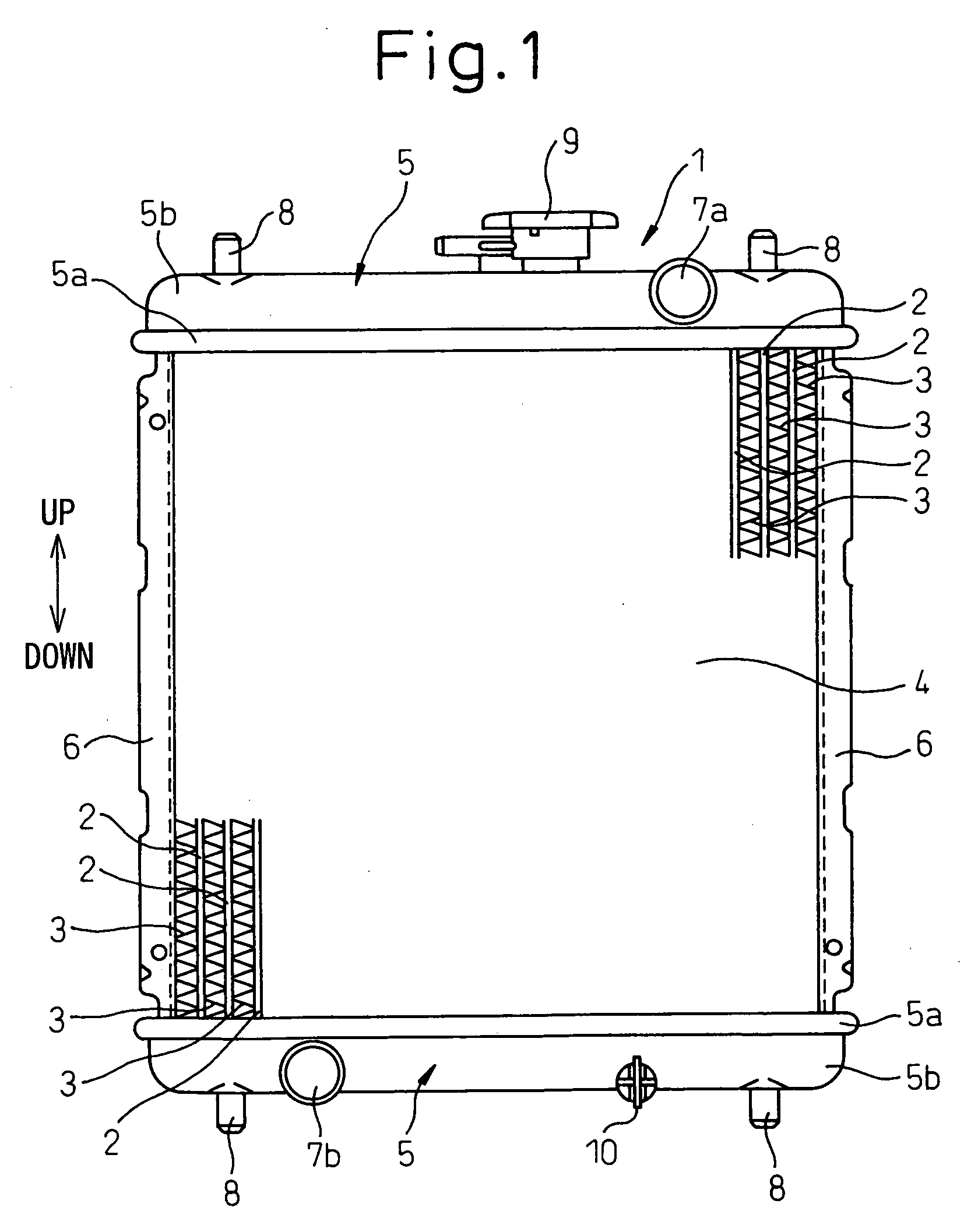

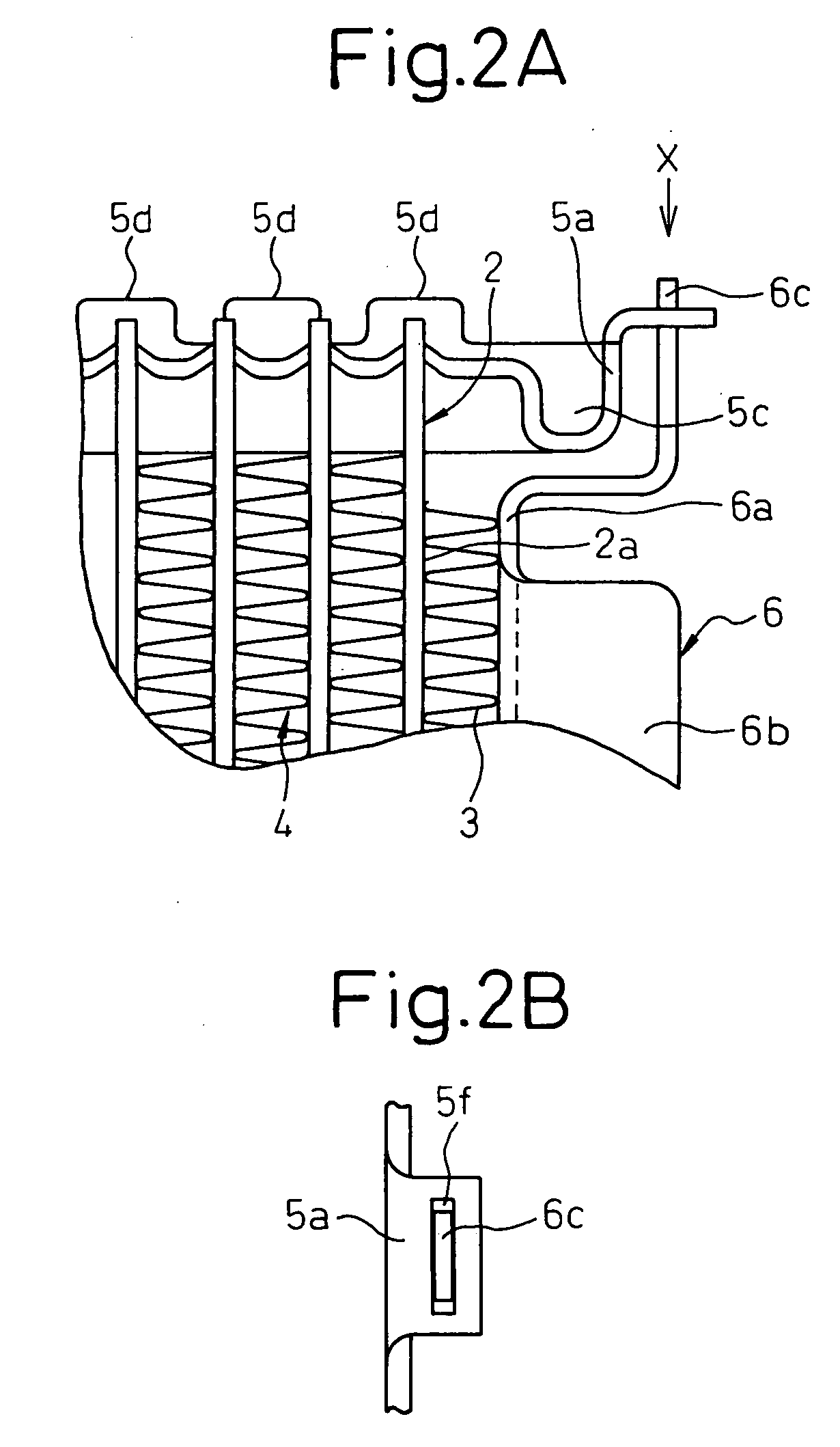

[0089] A header tank 5 extends in the direction horizontal direction in this embodiment) perpendicular to the length of the tubes 2 at each longitudinal end (upper and lower ends in this embodiment) of the tubes 2 and communicates with the plurality of the tubes 2. Each header tank 5 includes a core plate 5a with the tubes 2 coupled by insertion thereinto and a tank body 5b providing the internal space of the tank with the core plate 5a. the core plate 5a is formed of a metal (such as an aluminum alloy) and the tank body 5b is formed of resin.

[0090] As shown in FIG. 2A, packing (not shown), made of an elastic material such as rubber, is arranged in a groove 5c formed along the whole peripheral edge of the core plate 5a thereby to close the gap between the tank body 5b and the core plate 5a in liquid tight fashion. A plurality of hooks 5d are erected on the peripheral edge of the core plate 5a. By fixedly caulking the hooks 5d on the flange formed on the outer peripheral edge of the...

fifth embodiment

[0114]FIG. 6A is an enlarged view of the essential parts of the radiator 1 and FIG. 6B an enlarged plan view of the fitting between the tank body 5b and the insert 6 taken from the X direction in FIG. 6A. As shown in FIG. 6A, each longitudinal end of the tank body 5b is formed with a protrusion 12 outside of the tank body 5b. The protrusion 12 is formed of resin and is molded integrally with the tank 5b.

[0115] The protrusion 12 is formed with a through hole 12a. The through hole 12a is configured to be fitted on the core plate 5a with the insert end portion 6a inserted in the through hole 5f.

[0116] As described above, by fitting the insert end portion 6c in the protrusion 12 of the tank body 5b of resin, the fitting between the insert 6 and the tank body 5b is prevented from being brazed and, therefore, effects similar to the first embodiment are achieved.

[0117] Next, a sixth embodiment of the invention will be explained with reference to FIGS. 6A, 6B. The sixth embodiment is di...

sixth embodiment

[0118] the tank body 5b and the protrusion 12 are formed of a metal (such as aluminum alloy), and the protrusion 12 is formed integrally with the tank body 5b. Also, the brazing material on the fitting between the tank body 5b and the insert 6, i.e. the inner wall portion of the through hole 12a and the portion of the insert end portion 6c corresponding to the through hole 12a is cut off.

[0119] As described above, the insert 6 is fitted in the protrusion 12 of the tank body 5b and the brazing material on the fitting between the tank body 5b and the insert 6 is cut off thereby to prevent the brazing. Thus, effects similar to those or the first embodiment are achieved.

[0120] Next, a seventh embodiment of the invention is explained with reference to FIGS. 7, 8. The seventh embodiment is different from the first embodiment in that both the fins 3 and the inserts 6 are formed of a bare material. In FIGS. 7, 8, component parts similar or identical to those of the first embodiment are de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com