Continuous culture apparatus with mobile vessel, allowing selection of fitter cell variants and producing a culture in a continuous manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

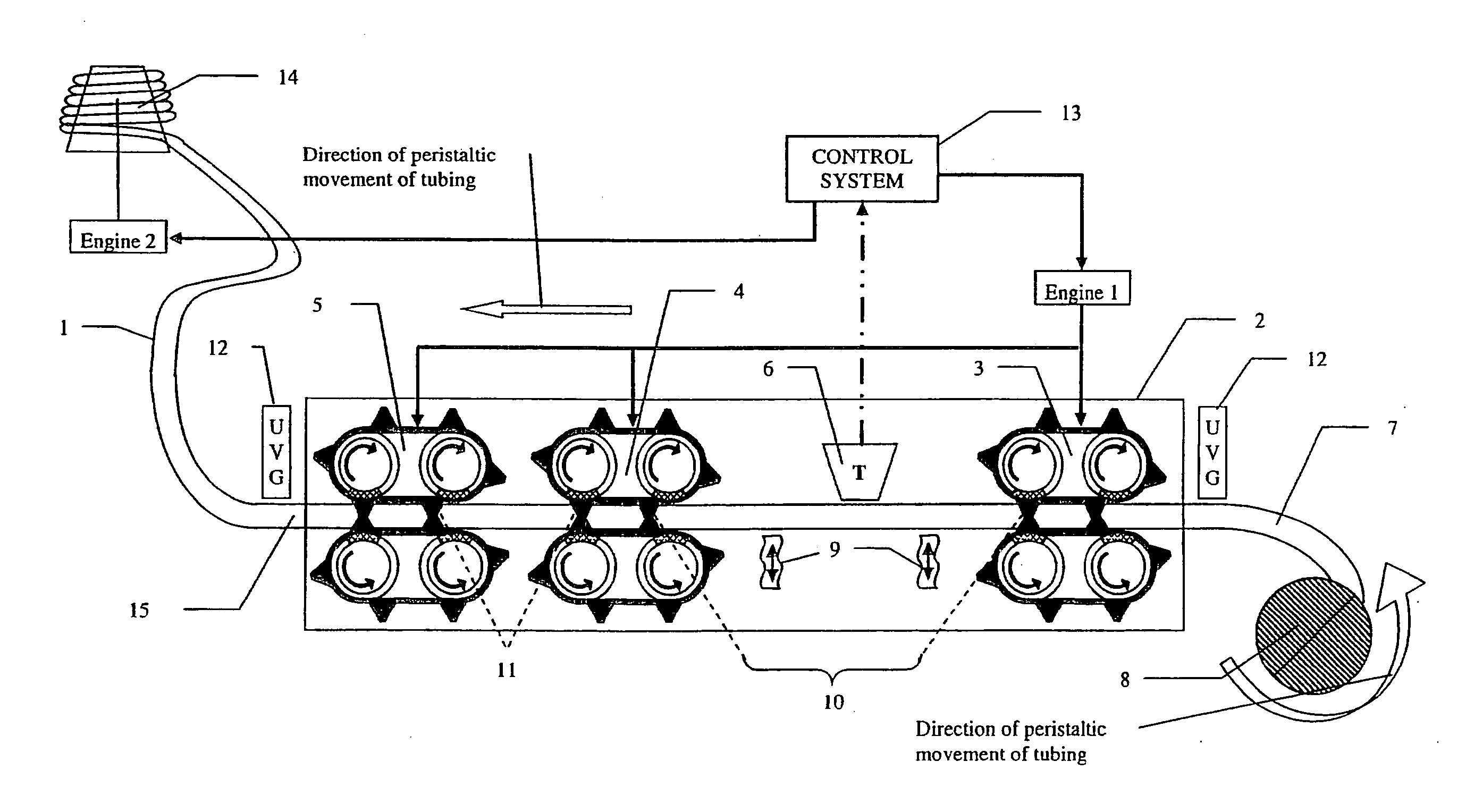

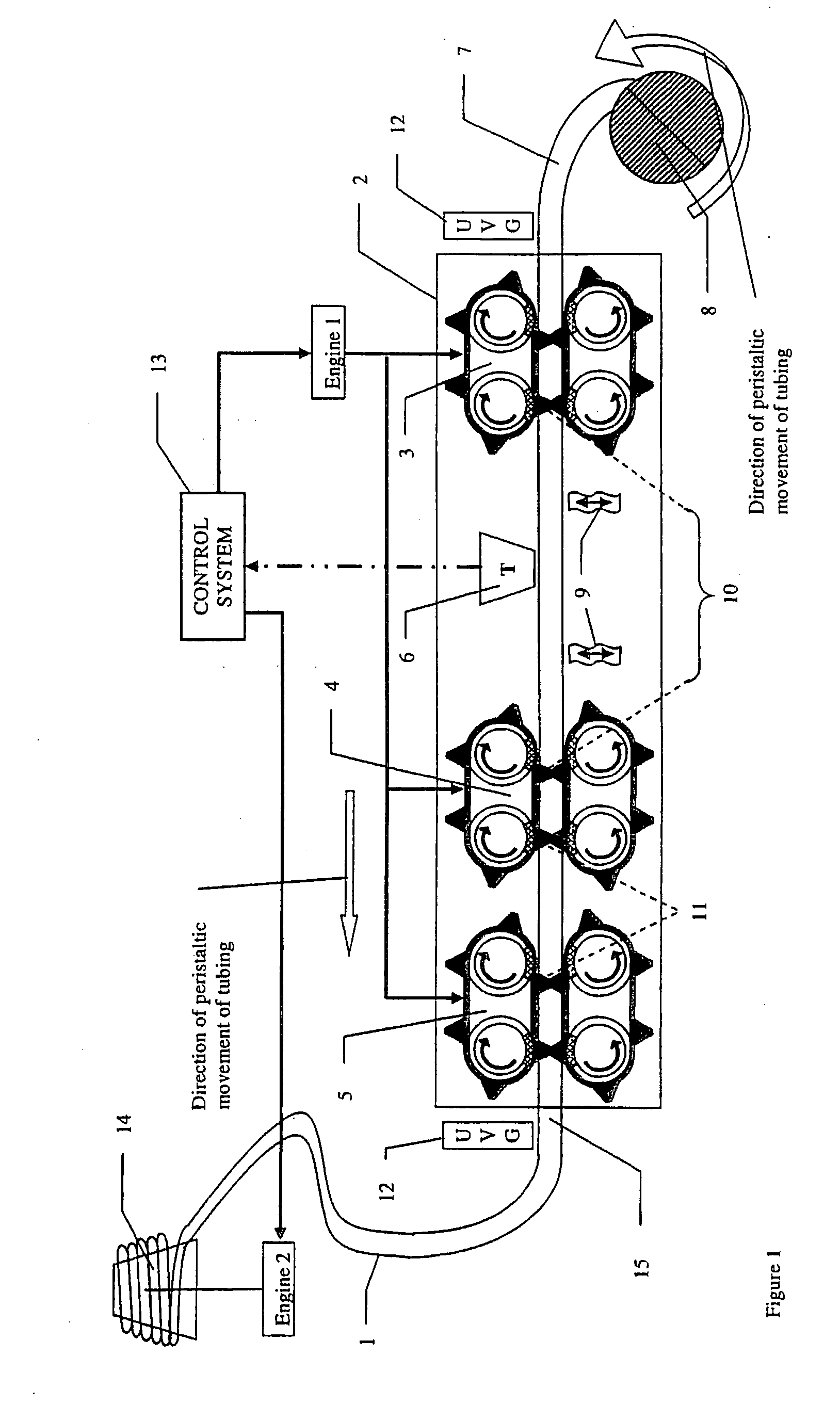

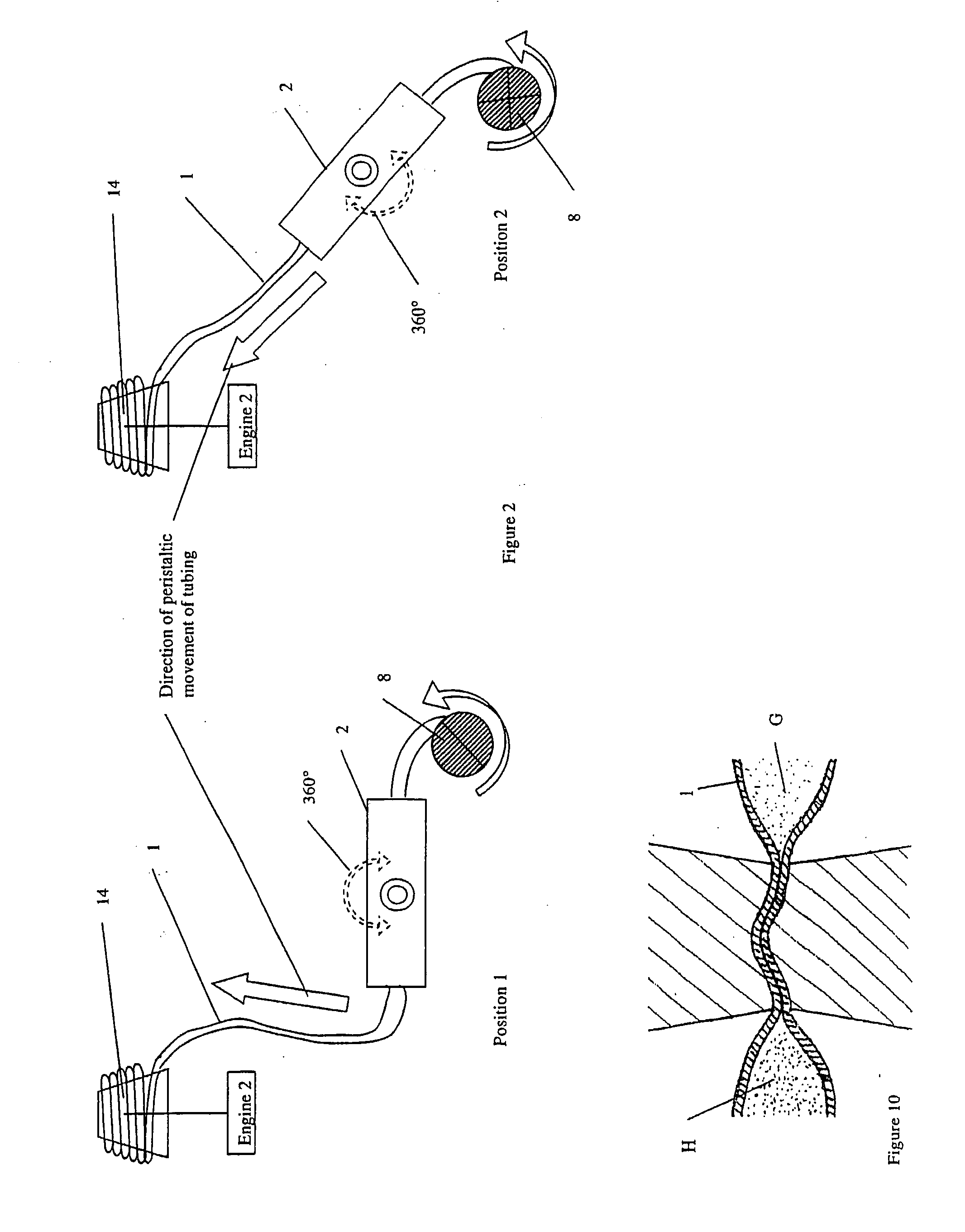

[0048] The basic operation of the device is depicted in FIGS. 3 through 9.

[0049] One potential configuration for the present device is shown in FIG. 1, as it appears after having been loaded with a fresh tube of sterile medium (shown divided into regions A-H by said gates (3), (4) and (5)).

[0050] Inoculation of the device with the chosen cell could be achieved by introduction of the cell into the growth chamber (FIG. 3), through injection (FIG. 4, region B). The culture would then be allowed to grow to the desired density and continuous culture would begin (FIG. 5).

[0051] Continuous culture would proceed by repetitive movements of the gated regions of tubing. This involves simultaneous movements of the gates, the tubing, the medium, and any culture within the tubing. The tubing will always move in the same direction; unused tubing containing fresh medium (and hereafter said to be ‘upstream’ of the growth chamber (7)) will move into the growth chamber and mix with the culture rema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com