Rebar positioner for masonry construction

a positioner and masonry technology, applied in the field of masonry construction, can solve the problems of unstable positioner, difficulty in rebar positioning, and numerous problems, and achieve the effect of increasing the attachment strength and widthwise stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

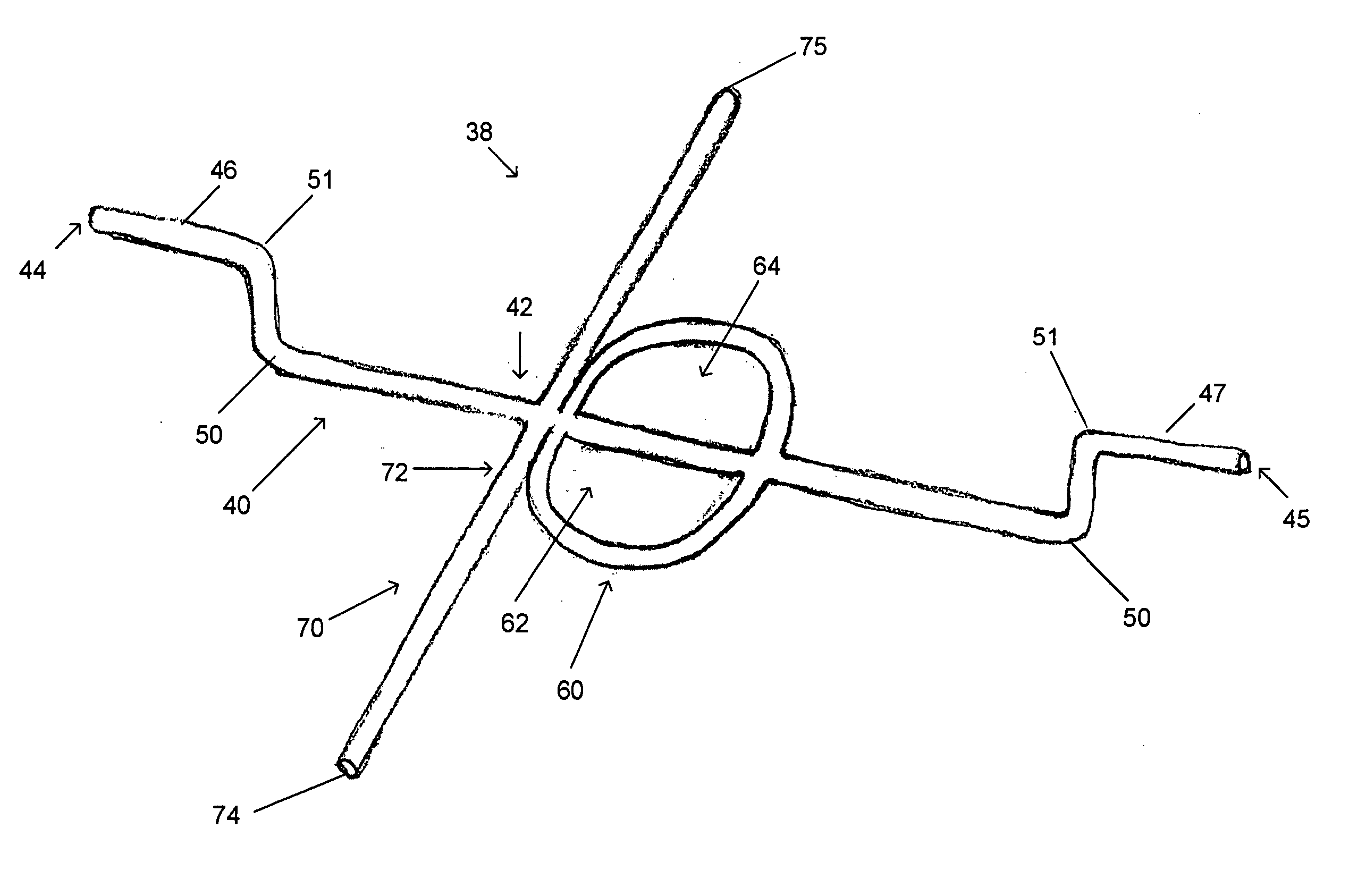

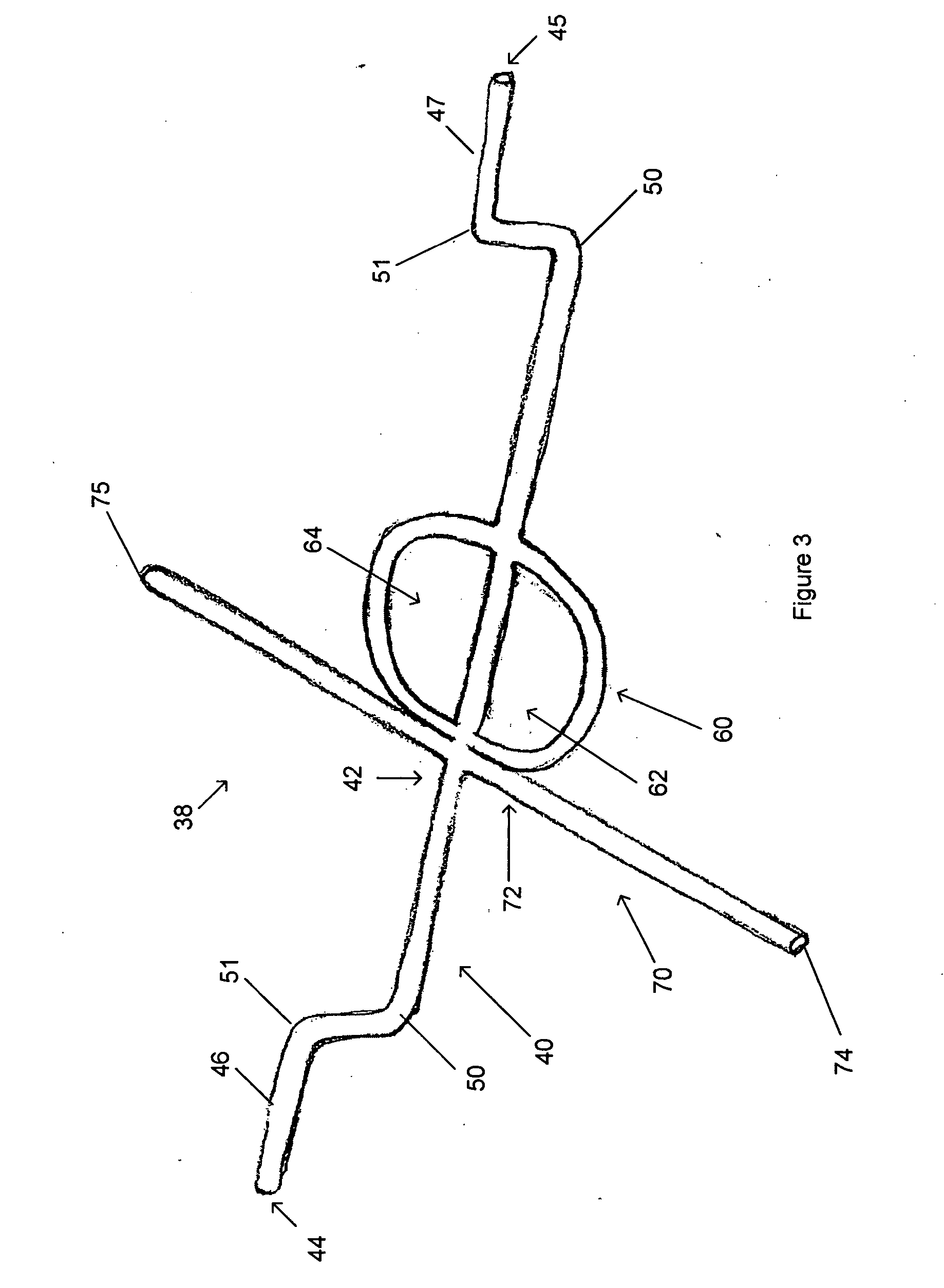

[0020]FIG. 3 shows a rebar positioner 38 according to a preferred embodiment of the present invention. Positioner 38 comprises a spine 40 having a spine midsection 42, a first spine end 44, and a second spine end 45. Positioner 38 includes a first spine rest 46 located at first spine end 44 and a second spine rest 47 located at second spine end 45.

[0021] In the depicted embodiment, both spine rests 46 and 47 are integral with spine 40. While spine 40 could be constructed of numerous materials, e.g. various ceramics, plastics, metals and woods, preferably, spine 40 of the present embodiment is constructed of nine gauge steel wire. Such wire is ideal because it facilitates the shaping of the spine and provides the requisite durability needed for construction. For example, as represented by FIG. 3, spine 40 is bent at points 50 and 51 to form the spine rests 46 and 47 and to offset spine rests 46 and 47 from spine 40. While the integral formation of the spine rests 46 and 47 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com