Rebar spacer and method

a technology of rebar spacers and rebars, applied in the direction of building reinforcements, constructions, building components, etc., can solve the problems of premature degradation, inability to achieve the desired structural characteristics of the structure, and considerable effort expended in the design of reinforced concrete structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

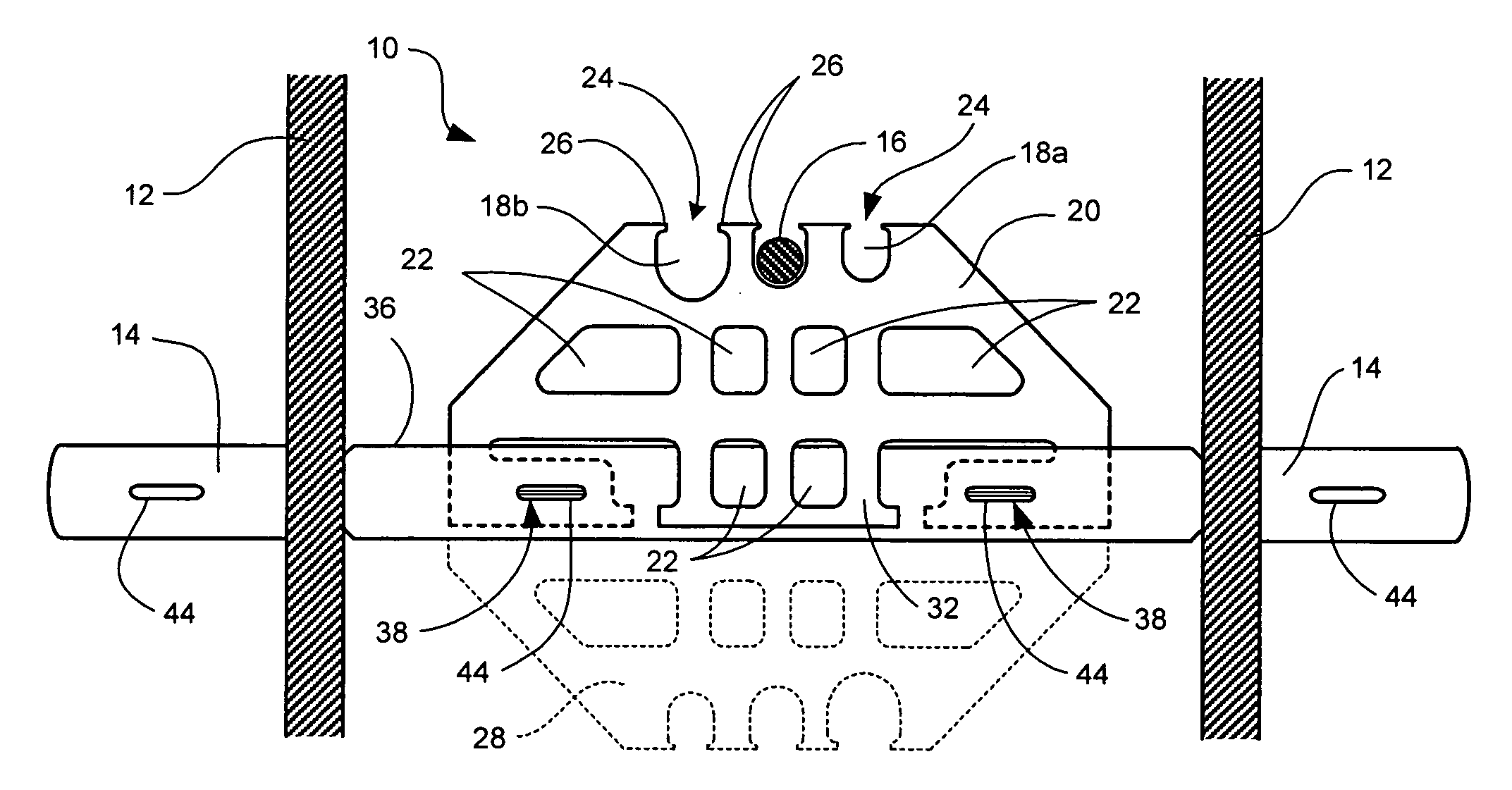

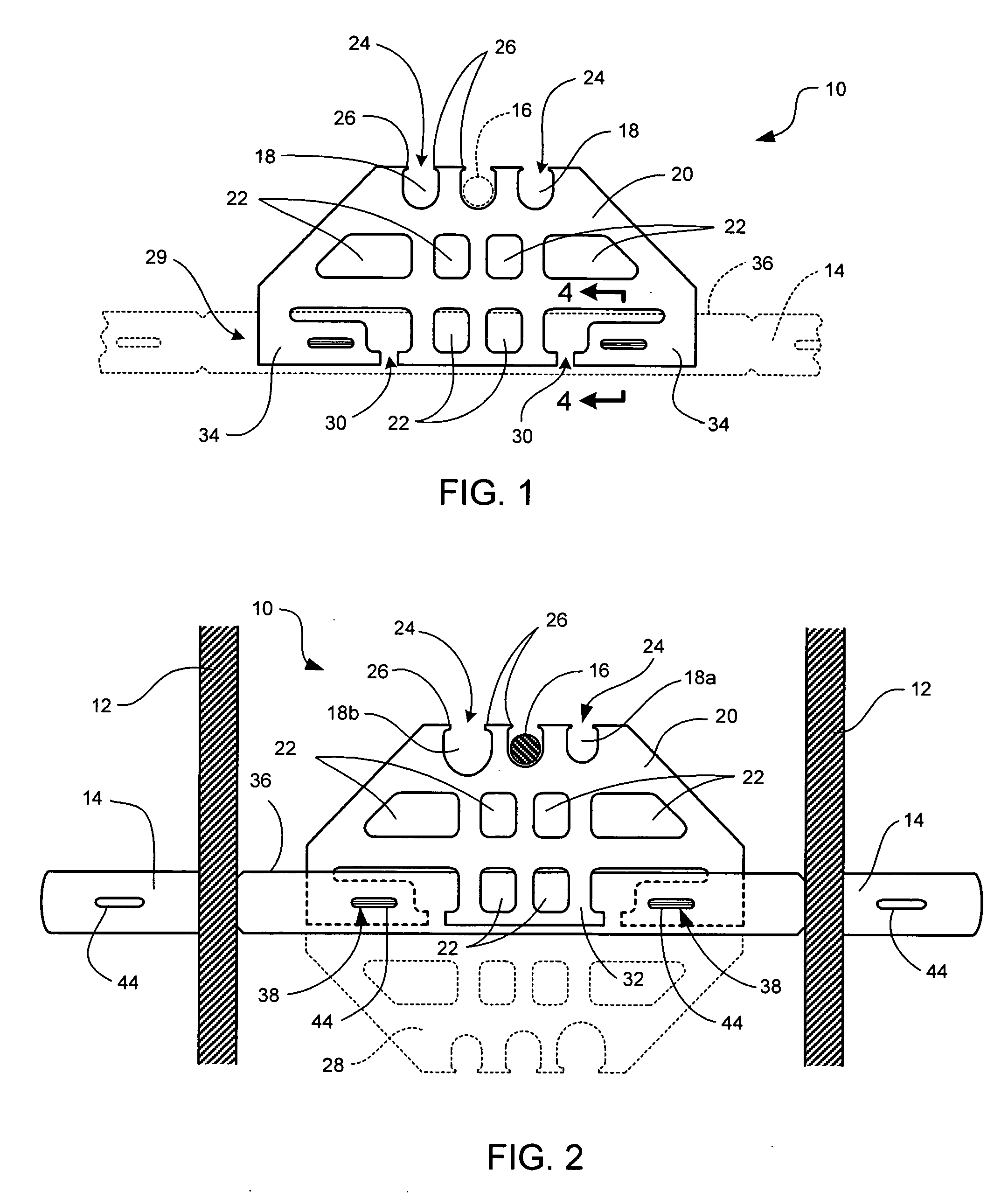

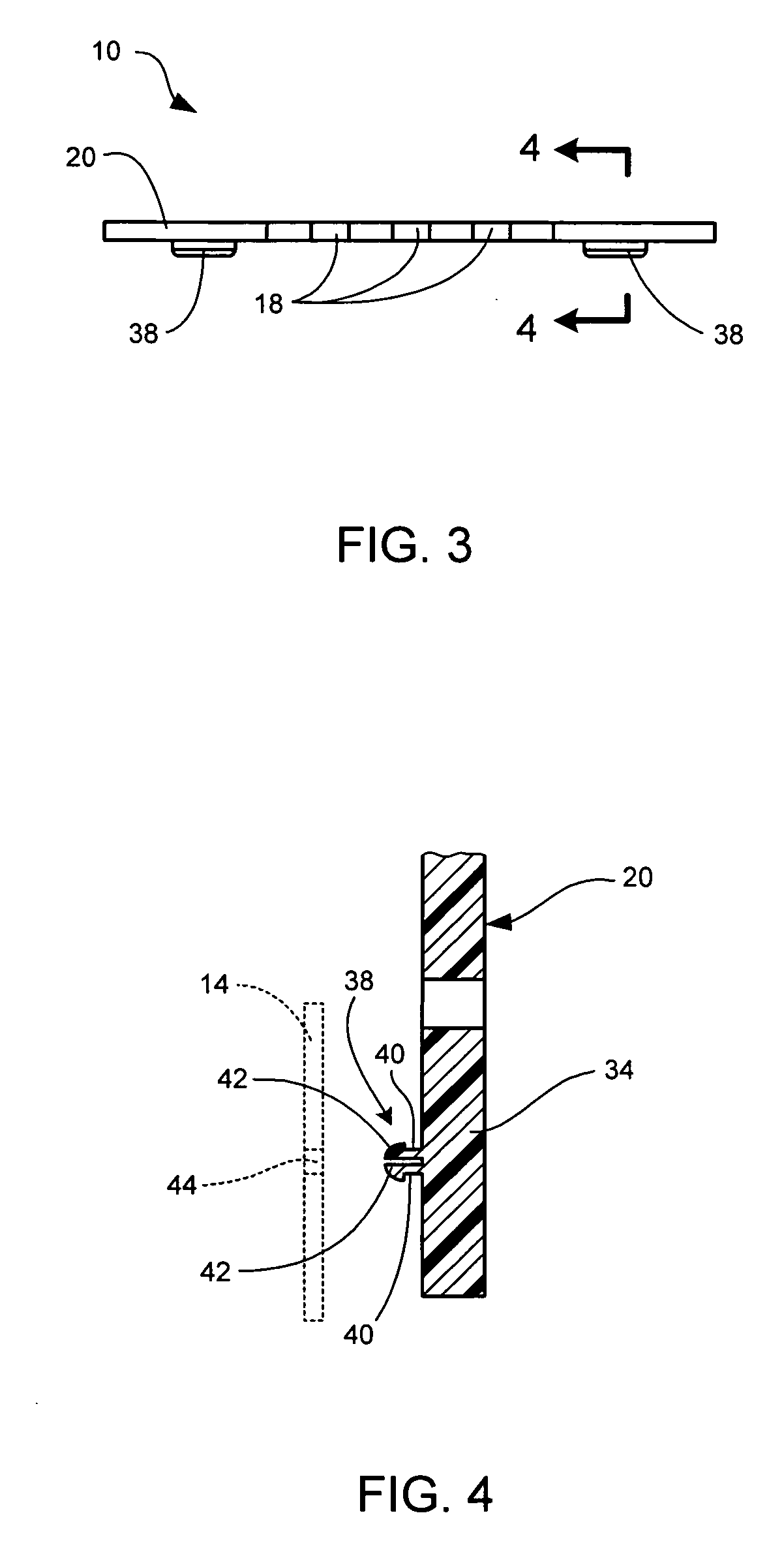

[0022] A front view of one embodiment of a rebar spacer 10 in accordance with the present invention is provided in FIG. 1, and a top view of the same is shown in FIG. 3. Shown in FIG. 2 is a cross-sectional view of opposing concrete forms 12 with a flat bar-type form tie 14 extending therebetween, and a rebar spacer disposed upon it. One piece of rebar 16 is shown in cross-section, disposed in one of the top slots 18 of the rebar spacer.

[0023] The rebar spacer 10 generally comprises a flat body 20 of non-metal material with a variety of openings formed in it. In the embodiment of FIG. 1, the top of the body includes several rebar apertures 18 that are open rounded slots designed to receive and support rebar 16 (shown in hidden lines in cross-section in FIG. 1) that is oriented substantially transverse to the body of the rebar spacer. Other openings 22 are also formed in the body. These openings perform several functions. They allow liquid concrete to flow through the body, so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com