Pilot controlled pulse valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

.

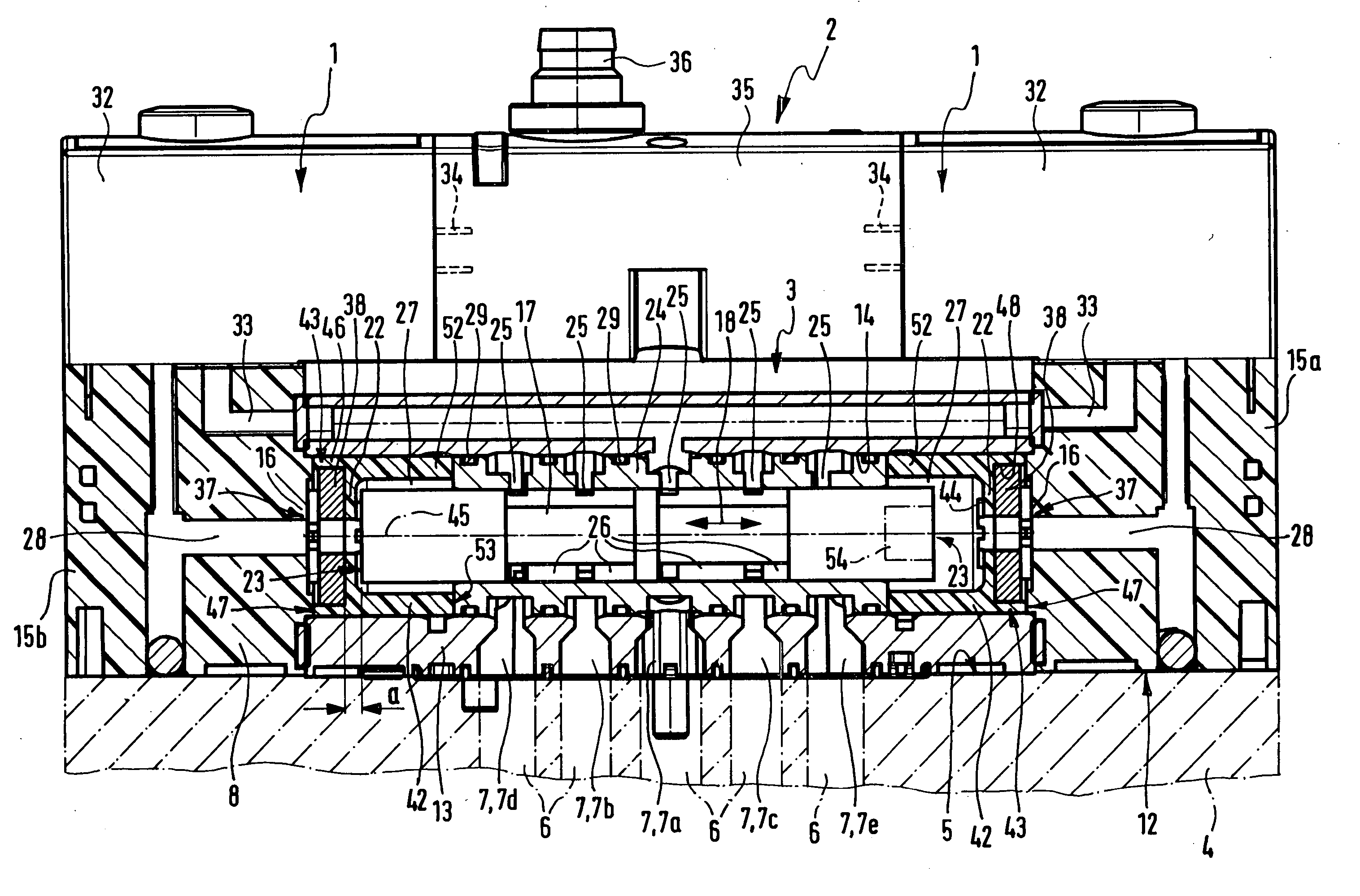

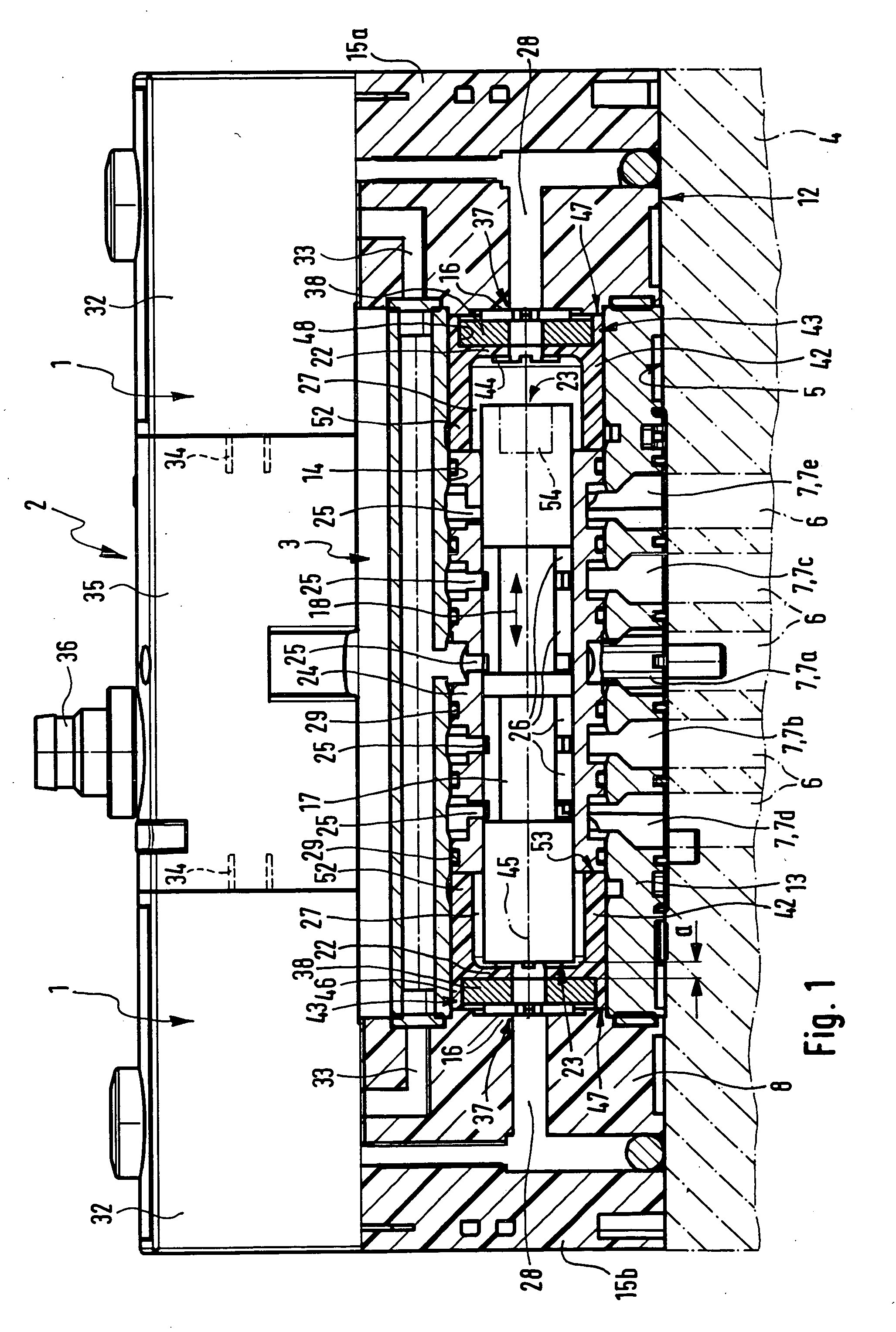

[0021] The drawing shows a pulse valve 2 which is pilot controlled by means of an electrically actuated pilot control means 1, comprising a principal fluid operated valve 3 by way of the pilot valve means 1, such principal valve 3 being assembled together with the pilot valve means 1 in the form of a uniformly handled sub-assembly.

[0022] The pulse valve 2 is mounted on a base plate 4 indicated in chained lines. At the corresponding component mounting face 5 of the base plate 4 base plate ducts 6 open, which communicate with flush valve ducts 7 extending in the valve housing 8 of the principal valve 3 and open opposite to the base plate ducts 6 at the mounting face 12, of the valve housing 8.

[0023] The valve housing 8 of the working example comprises an elongated middle part 13, which exhibits a cavity extending through in the longitudinal direction and which serves as a valve spool socket 14. At the end on either side of the middle part 13 a respective terminal part 15a and 15b i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap