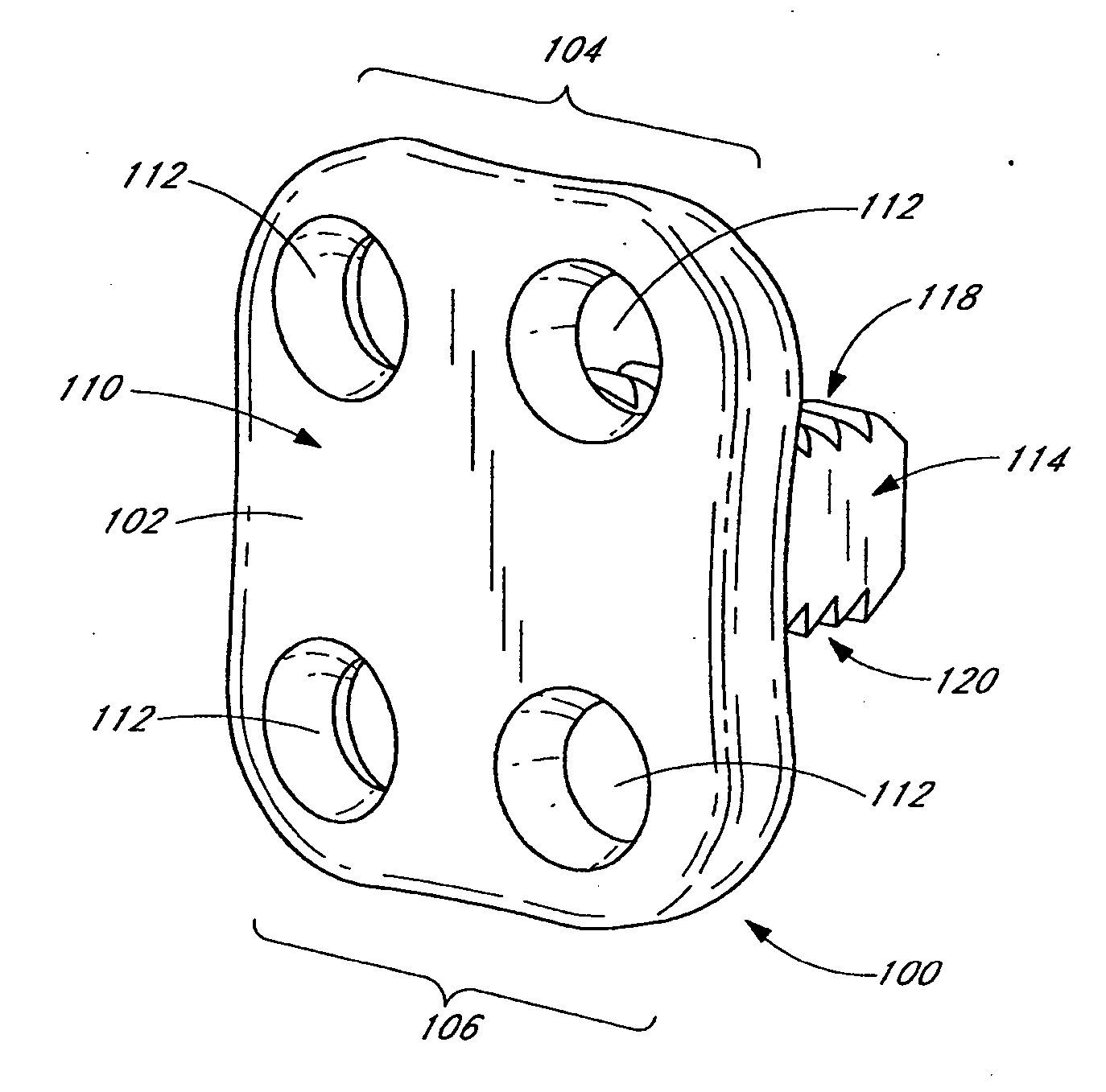

Flanged interbody fusion device with oblong fastener apertures

a fusion device and fusion device technology, applied in the field of spinal fixation systems and methods, can solve the problems of degenerative changes in bones, spine instability, pain and instability,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

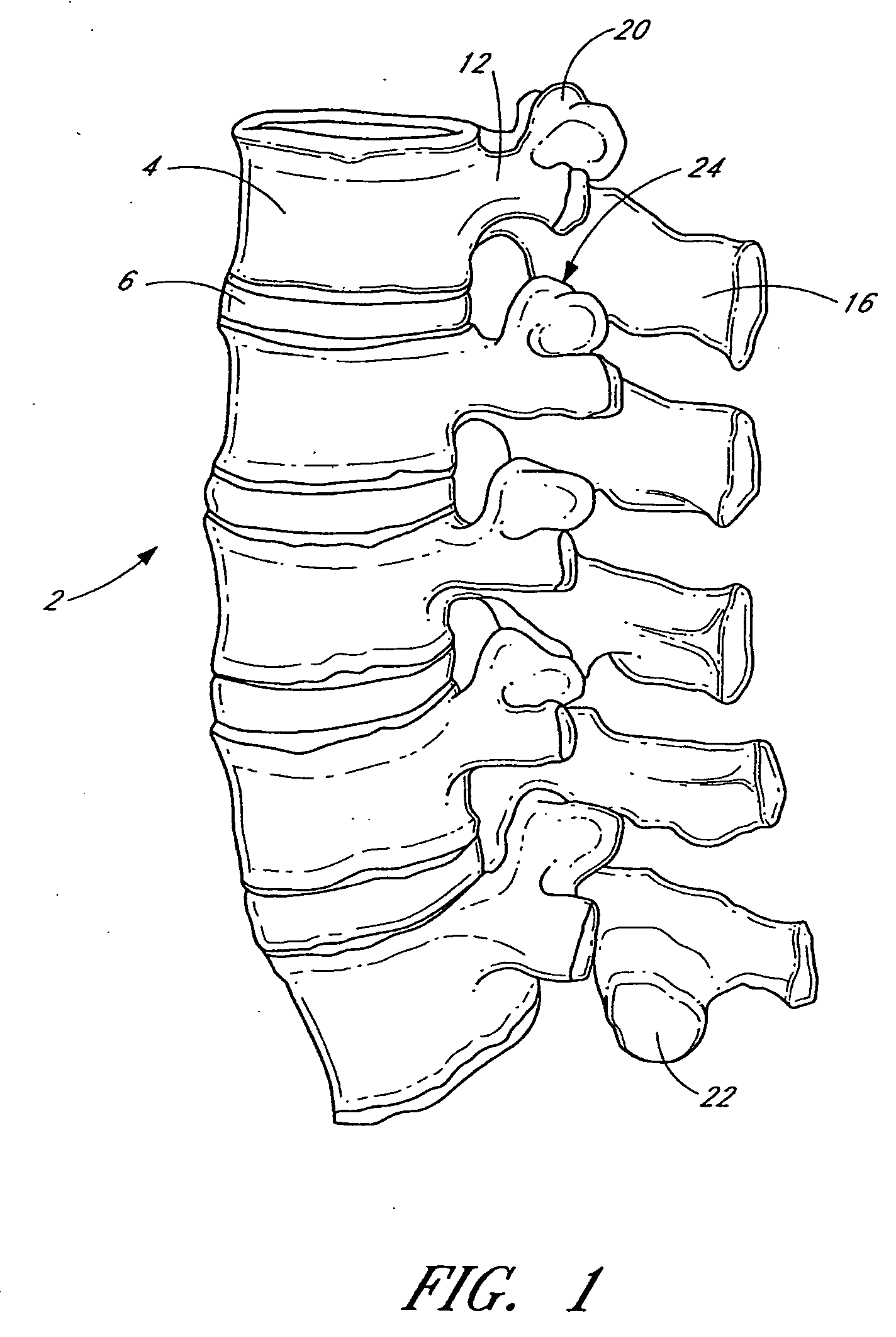

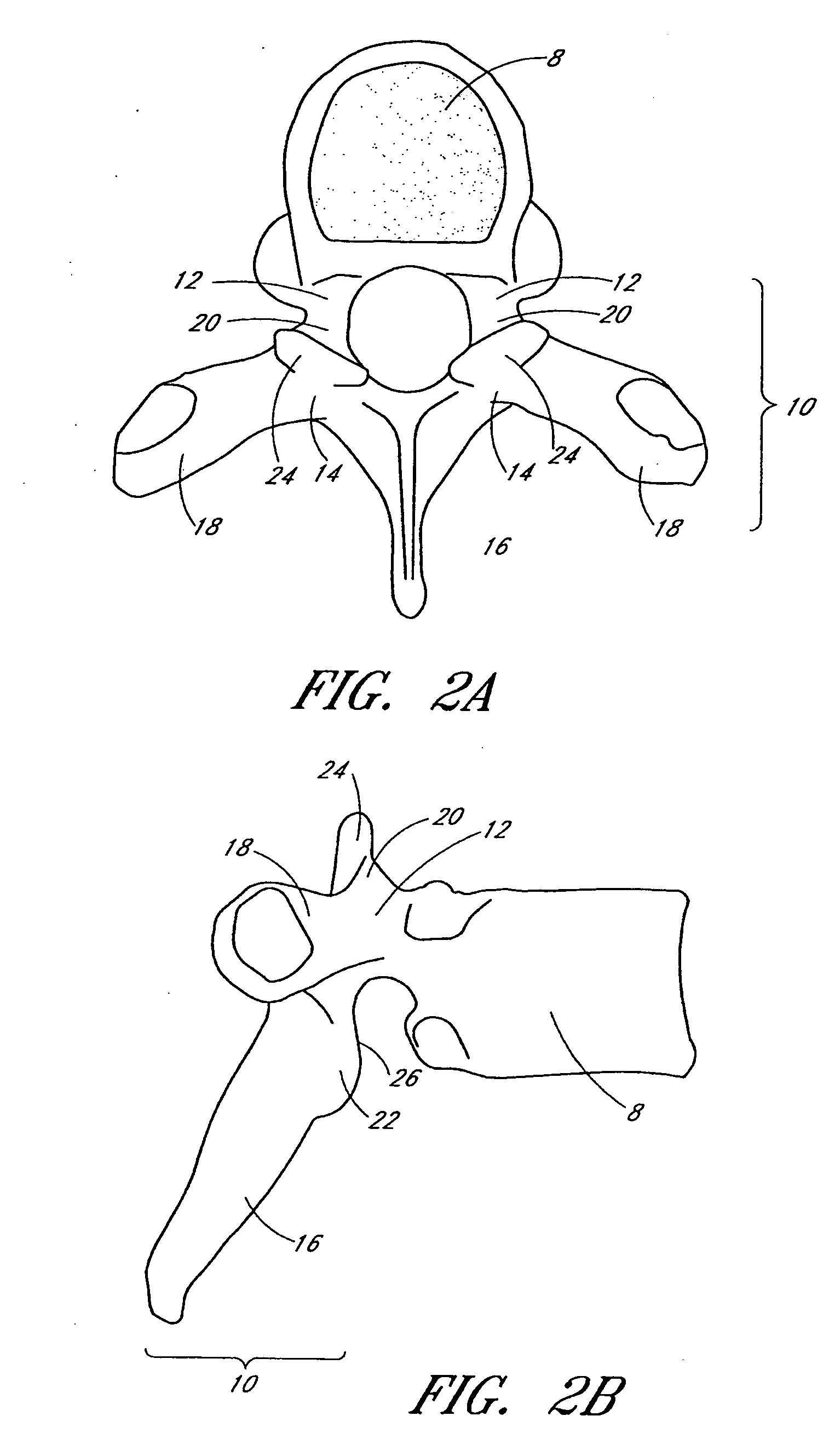

[0096] Advancing age, as well as injury, can lead to degeneration in the bones, discs, joints, and ligaments of the spine producing pain from nerve root compression. Under certain circumstances, alleviation of pain can be provided by performing a spinal fusion. Spinal fusion is a procedure that involves joining two or more adjacent vertebrae so that they no longer are able to move relative to each other.

[0097] In existing spinal fusion implants there have also been problems with loosening and backing out of screws into the patient's throat area. Backout is the exhibited tendency of bone screws, which affix the bone plate to the bone(s), to loosen with respect to both the plate and bone, resulting in poor fixation, fusion and ultimately, healing. Essentially, this loosening of the bone screw causes the screw to work itself out of the bone into which it is implanted. This results in the bone plate being poorly fixed in place thus becoming devoid of its fixation capabilities. Usually,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com