Hole plugs

a technology of hole plugs and plugs, which is applied in the field of hole plugs, can solve the problems of excessive expansion of the sealing area of the cover portion, inability to provide sufficient sealing performance of the hole plug of this type, and inability to readily insert the fixing portion into the through-hol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

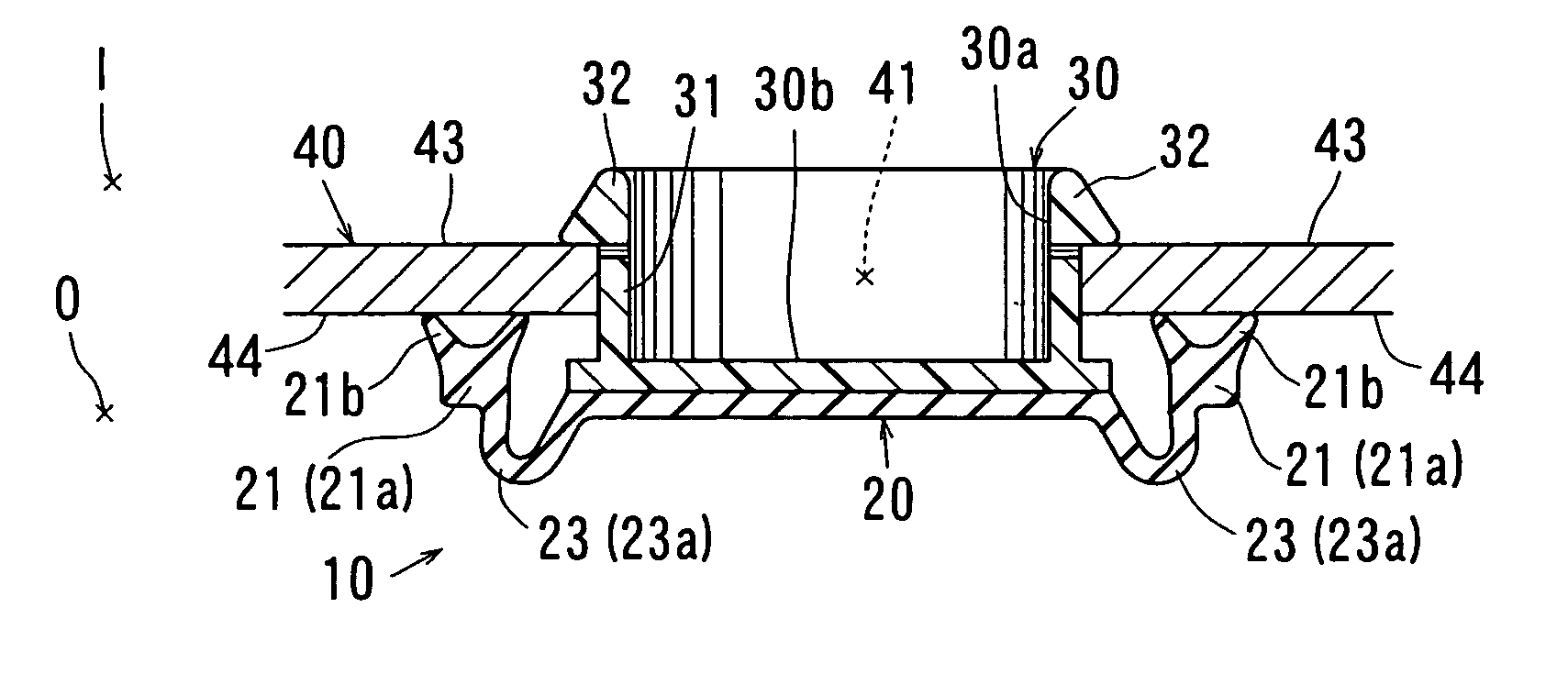

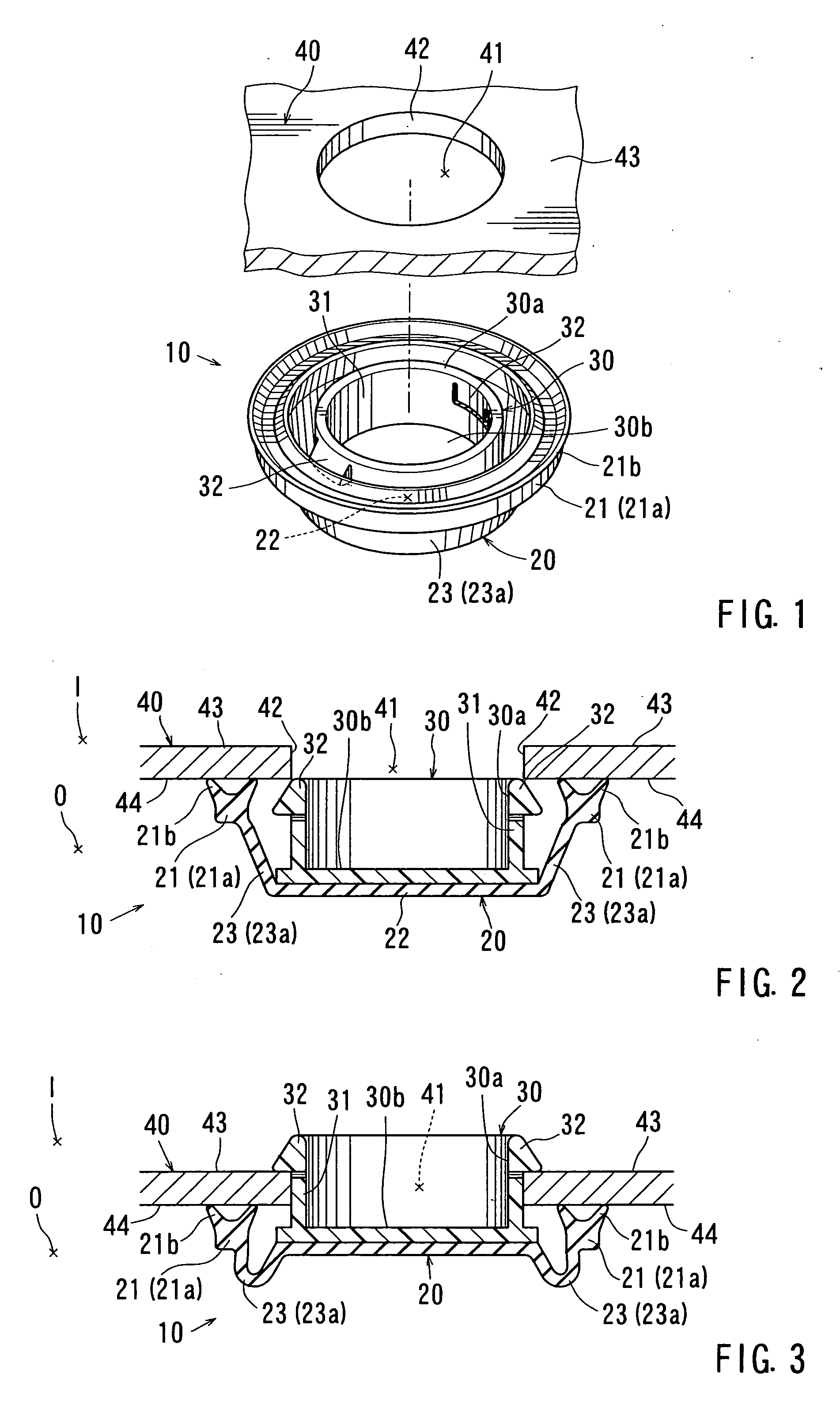

[0033] Detailed representative embodiments of the present invention are described with reference to the drawings. FIGS. 1 to 3 show a hole plug 10 according to the present invention. FIG. 1 is a perspective view of the hole plug 10. FIG. 2 is a cross-sectional view of the hole plug 10, which illustrates a condition before the hole plug 10 is inserted into a through-hole 41 formed in a compartment wall or panel 40. FIG. 3 is a cross-sectional view of the hole plug 10, which illustrates a condition after the hole plug 10 is inserted into the through-hole 41 formed in the compartment panel 40. Further, in FIGS. 2 and 3, references I and O respectively indicate inner and outer sides of the compartment panel 40.

[0034] It is noted that an example of the compartment panel 40 is a door panel of a vehicle. Also, the through-hole 41 corresponds to one of the through-holes that are formed in the compartment panel 40 at the time of the production thereof and the through-hole is otherwise left o...

second embodiment

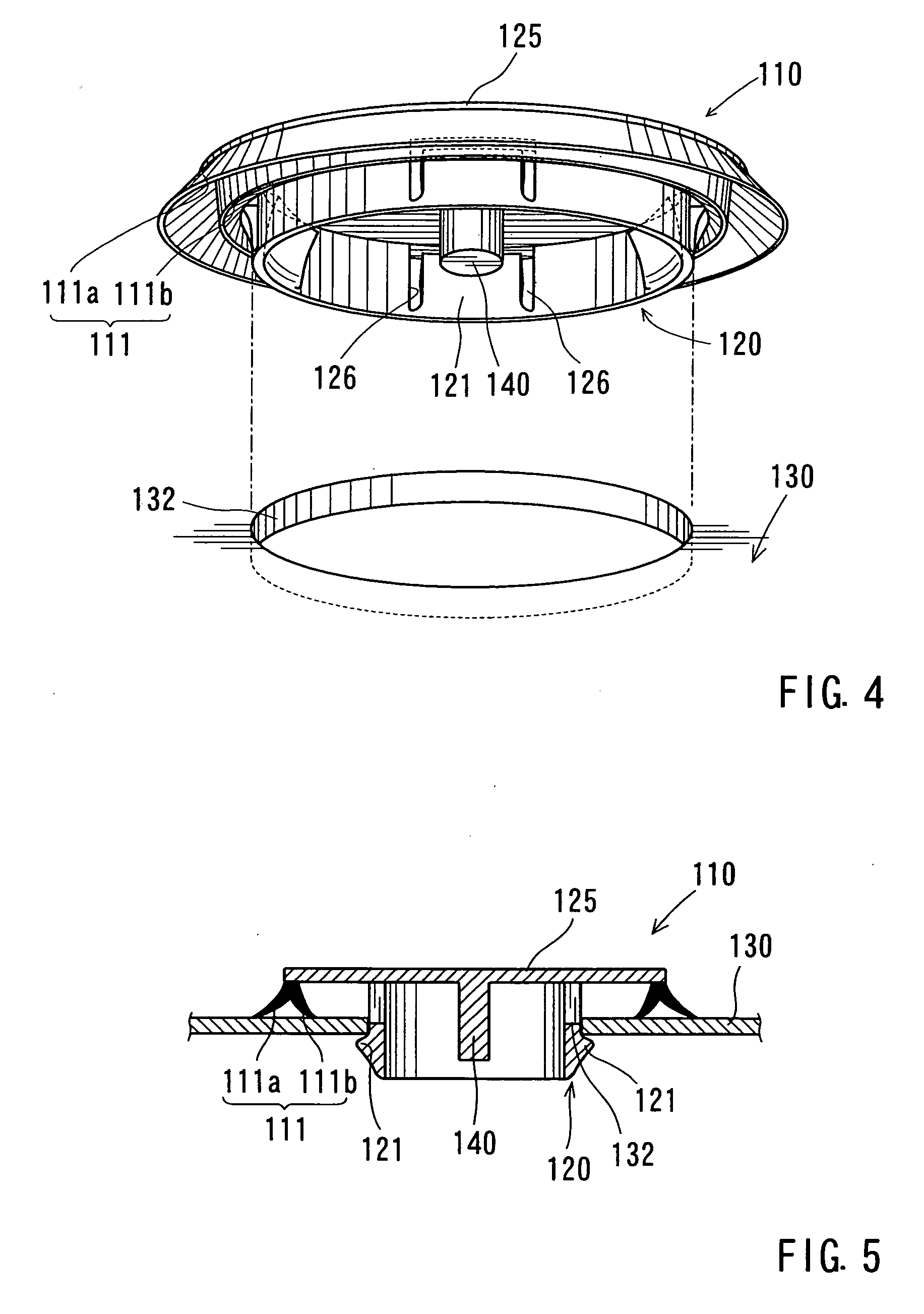

[0079] Moreover, in the second embodiment, the hole 132 formed in the body member 130 has a circular shape. However, the hole 132 may have a rectangular shape. Similarly, the seal members 111a and 111b of the seal member 111 have a circular shape. Naturally, the seal members 111a and 111b can be modified so as to correspond to the shape of the hole 132. Further, it should be noted that the seal members must be continuously formed regardless of the shape thereof.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com