Patents

Literature

38results about How to "Kept very reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

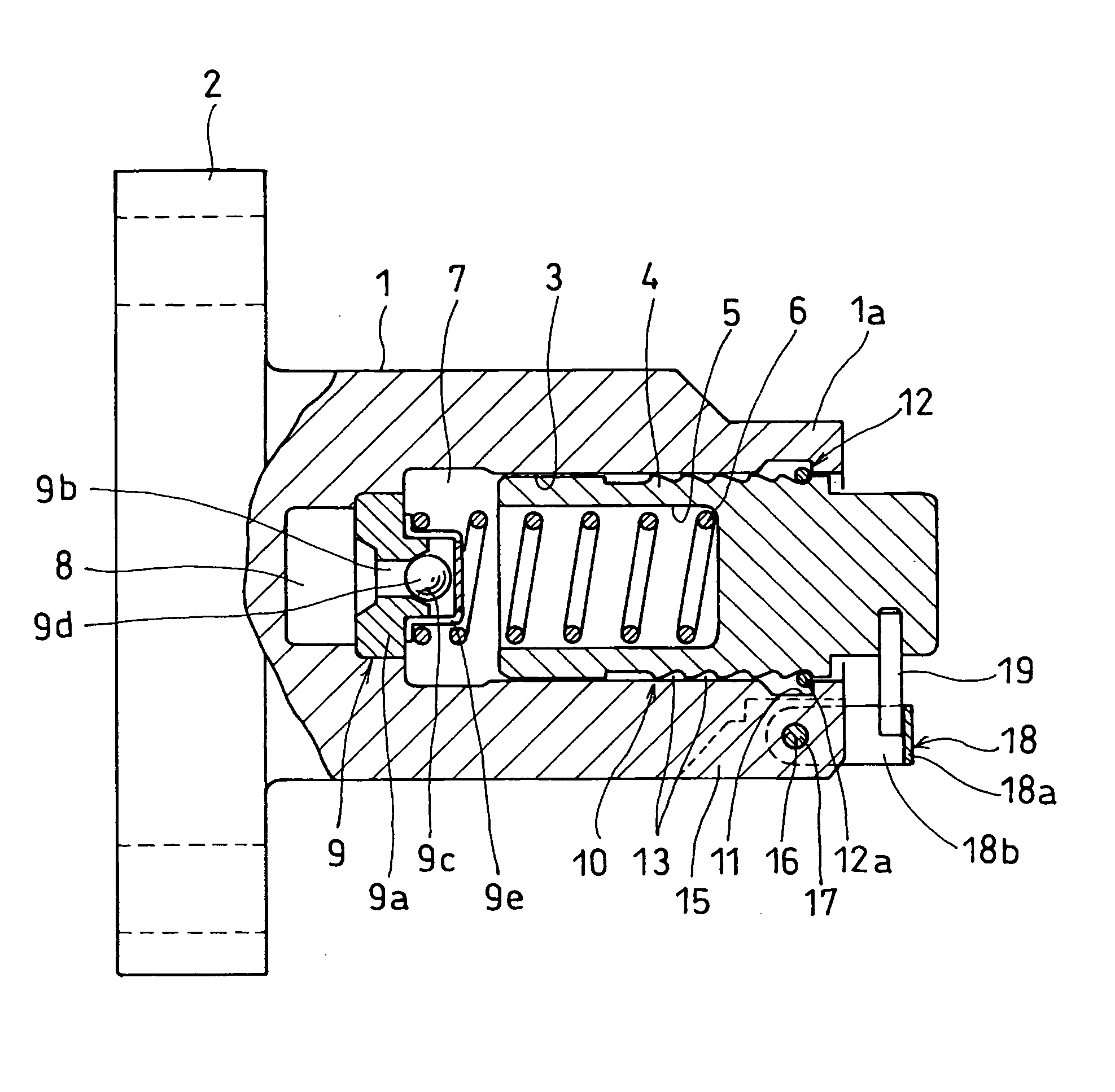

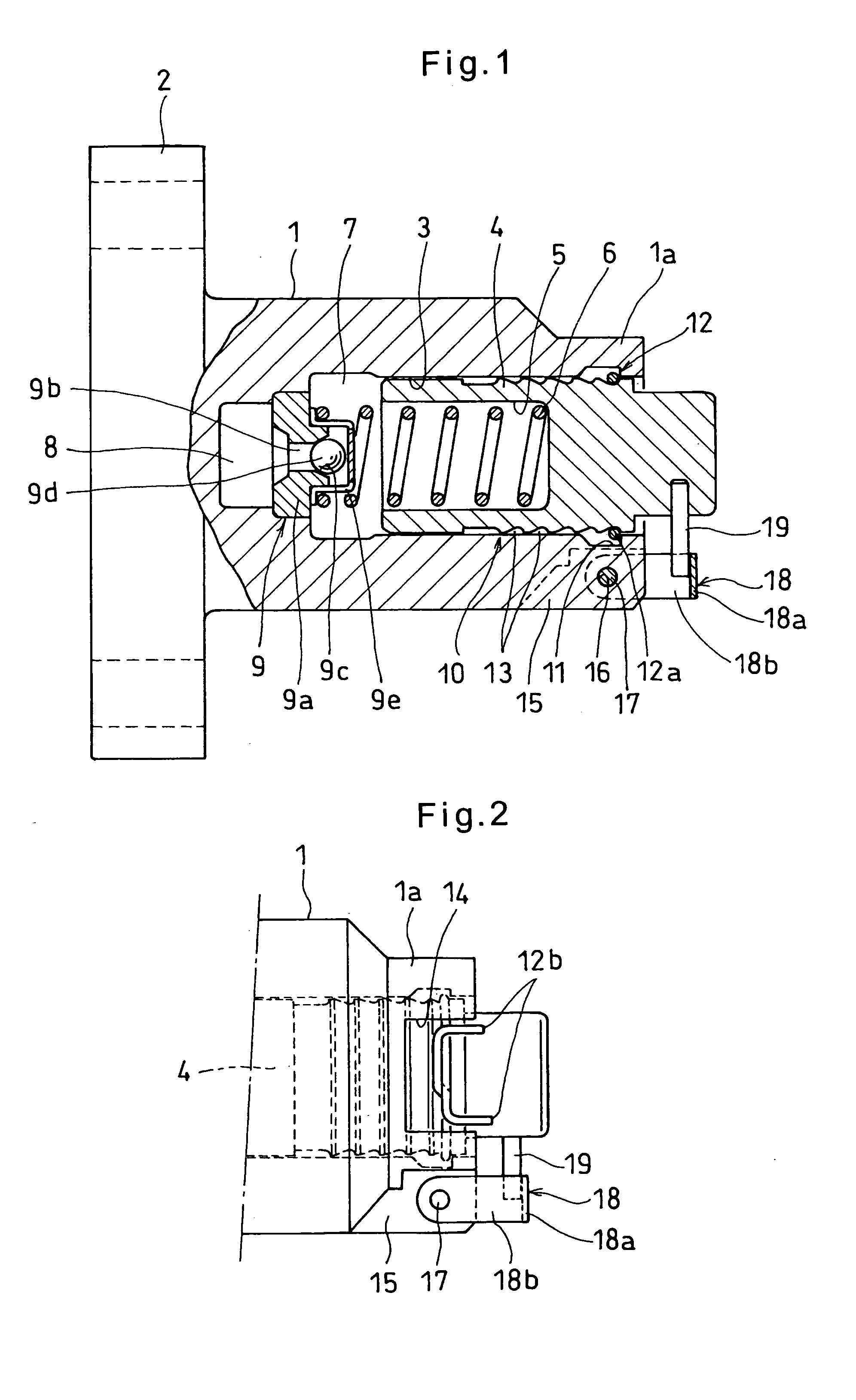

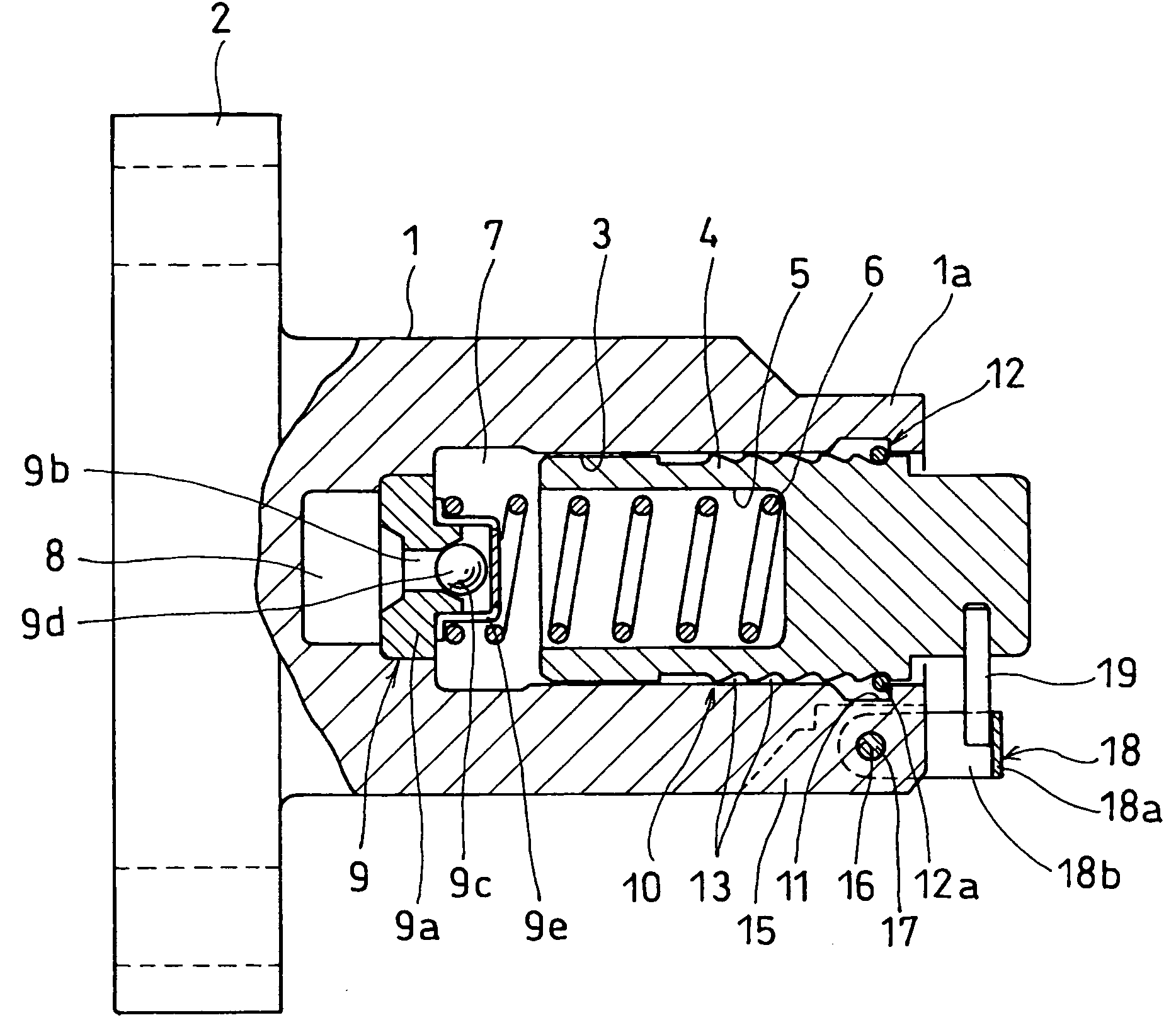

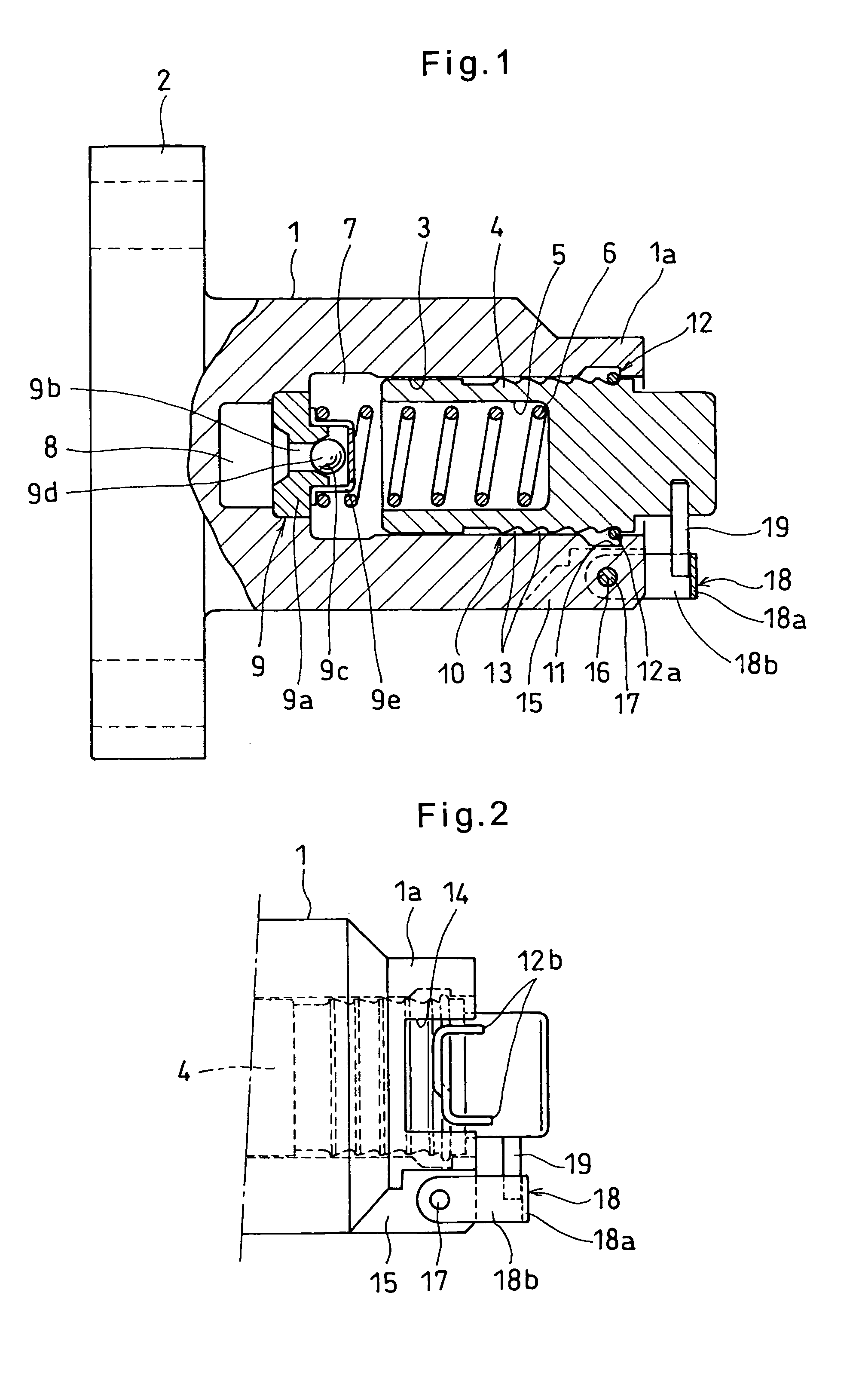

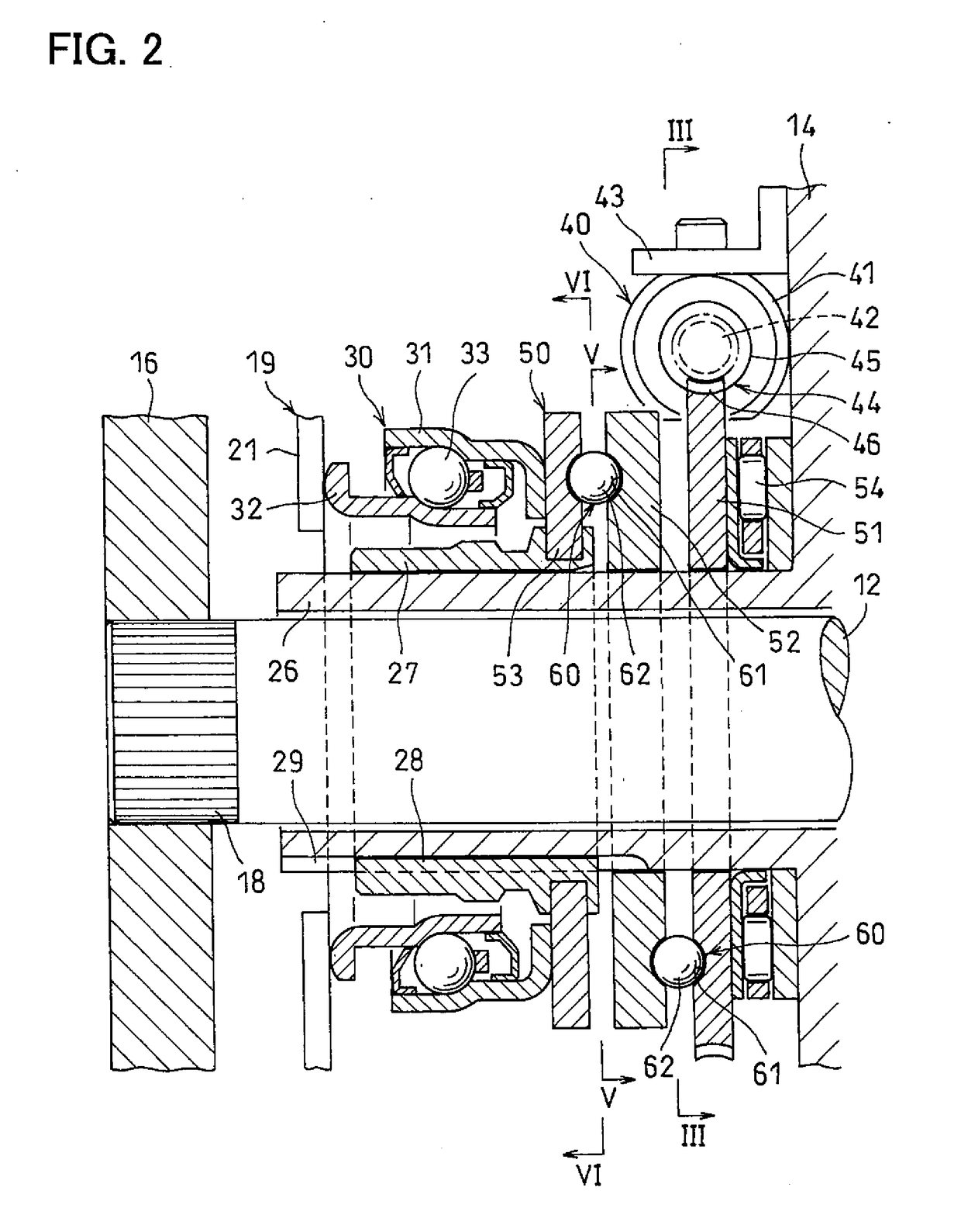

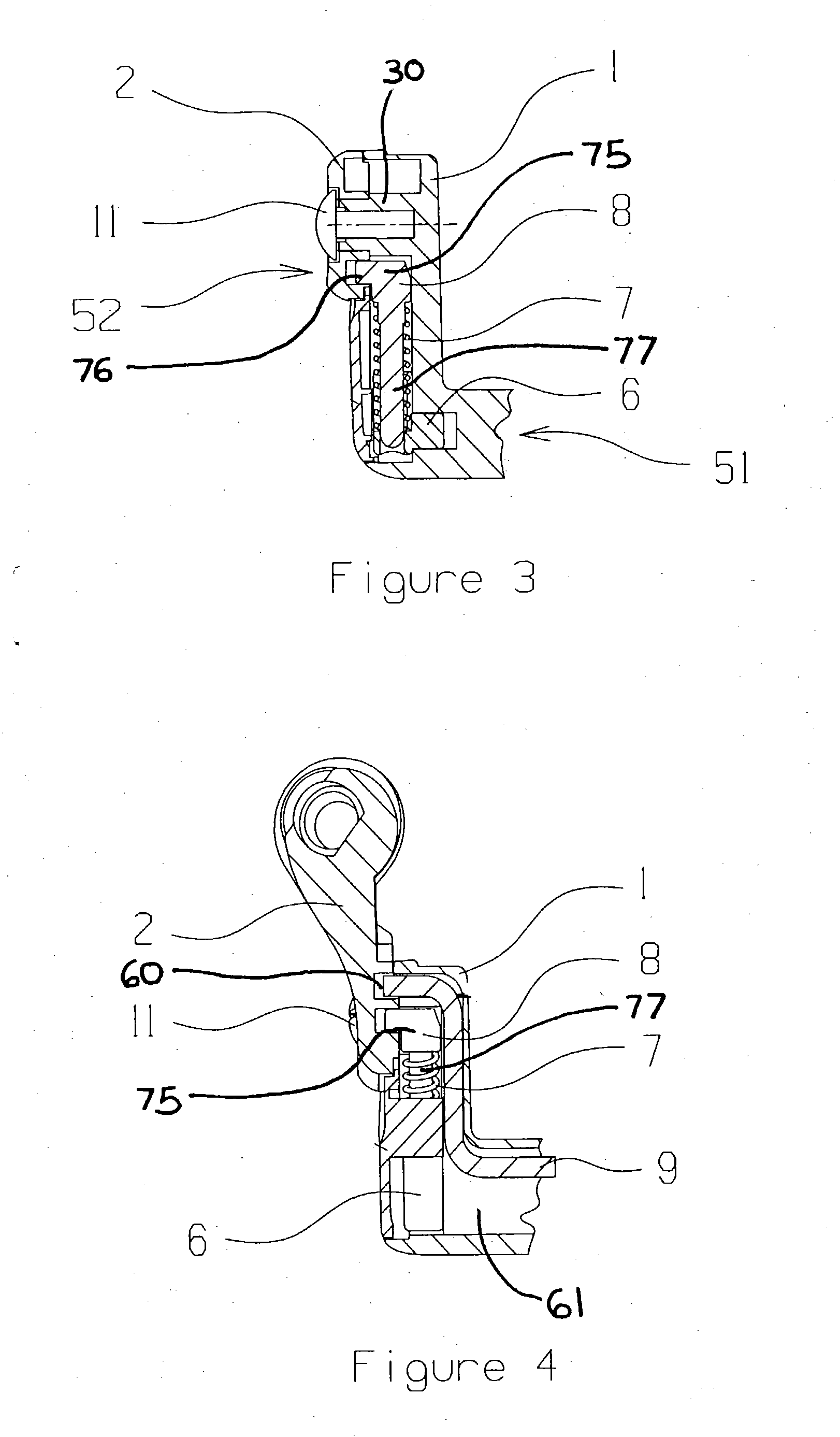

Chain tensioner

A chain tensioner includes a housing having a cylinder chamber. A plunger is slidably mounted in the cylinder chamber. A spring is mounted in the cylinder chamber to bias the plunger outwardly of the cylinder chamber. The plunger has a radially extending locking pin at its lower portion near its front end. The housing is formed with a pin hole extending substantially perpendicular to an axis of the cylinder chamber near the front end of the housing and under the cylinder chamber. The chain tensioner further includes a support pin inserted in the pin hole, and a locking lever supported on the support pin so as to be pivotable about the support pin. The locking lever can engage the locking pin when the plunger is sufficiently pushed into the cylinder chamber, thereby keeping the plunger pushed in the cylinder chamber.

Owner:NTN CORP

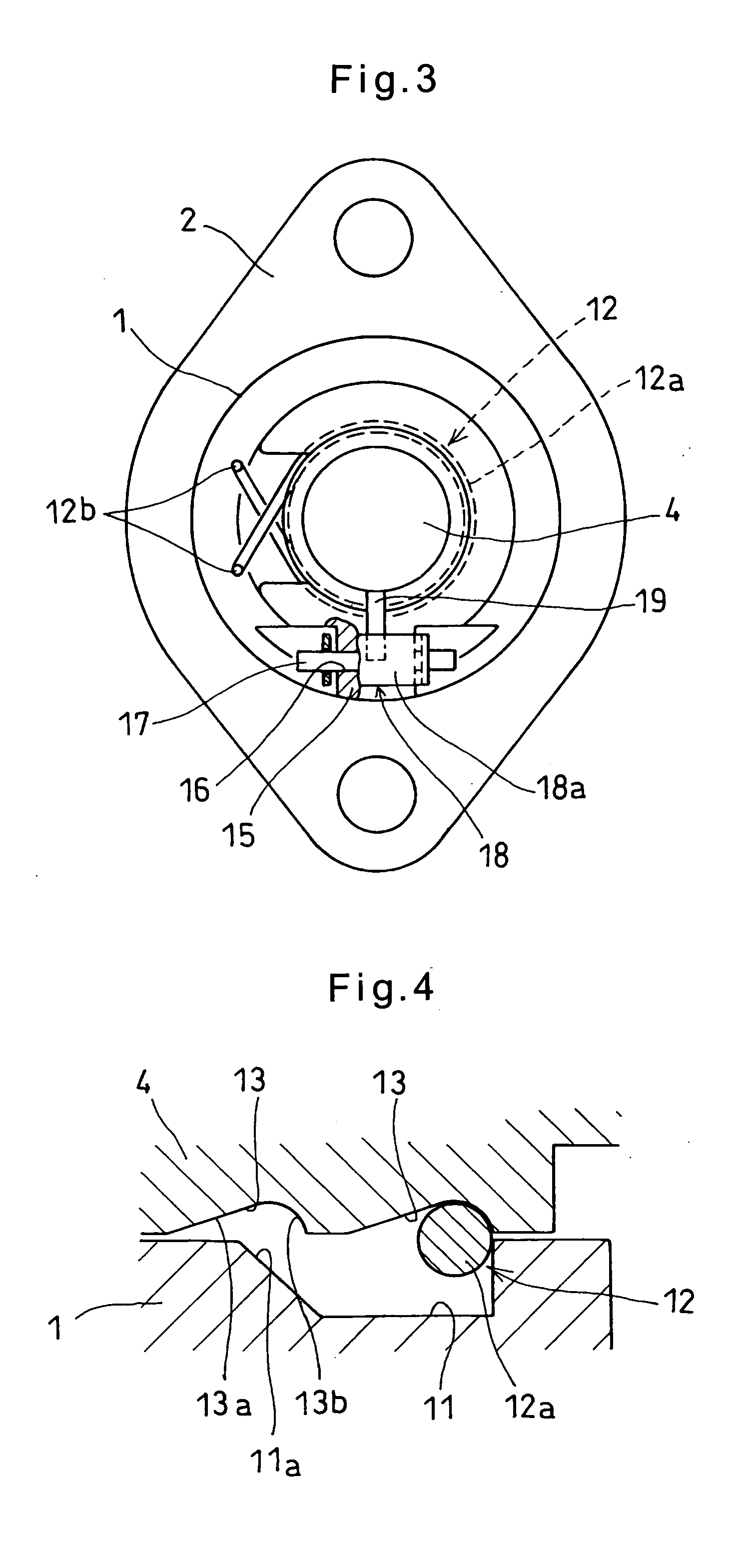

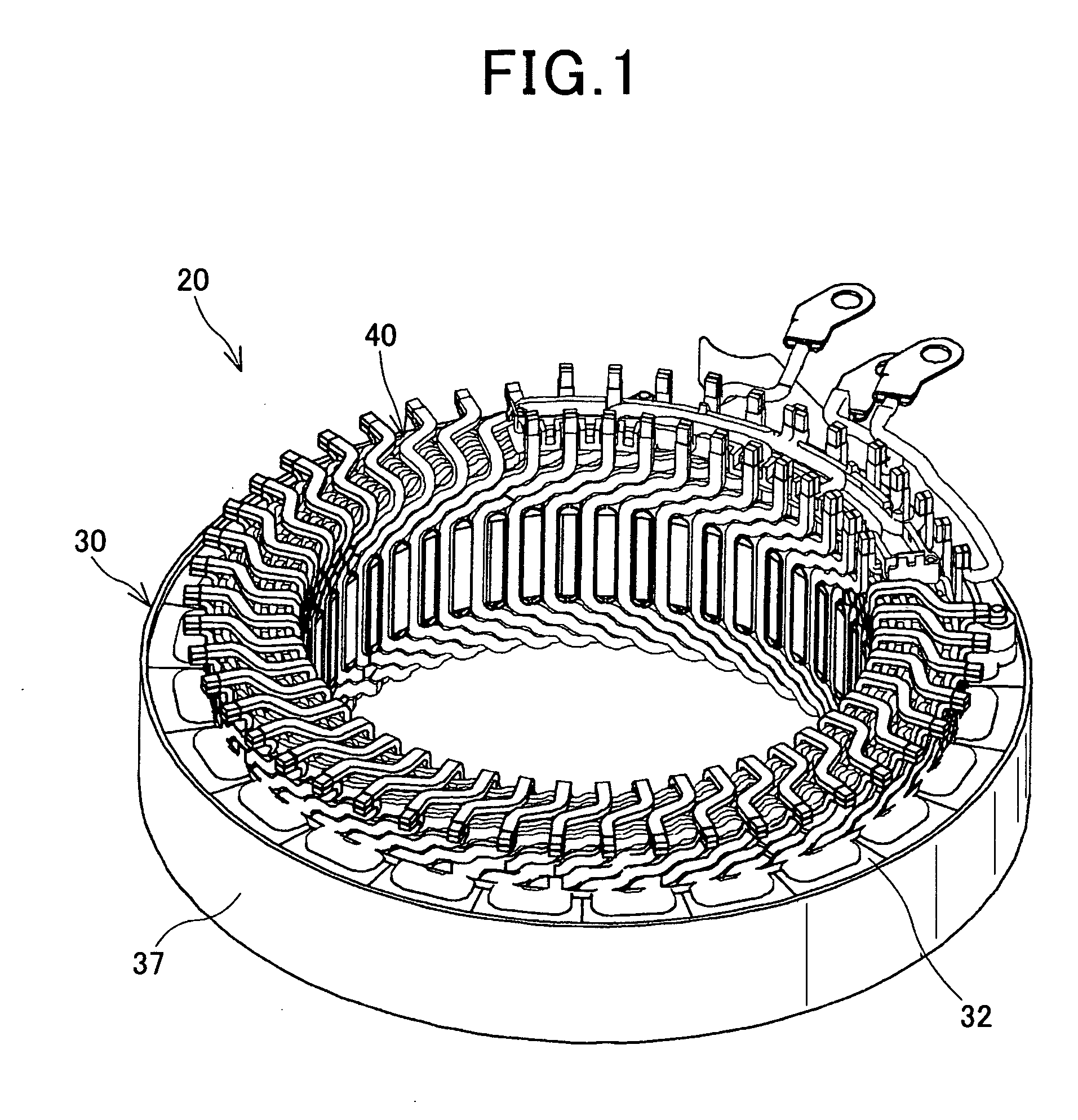

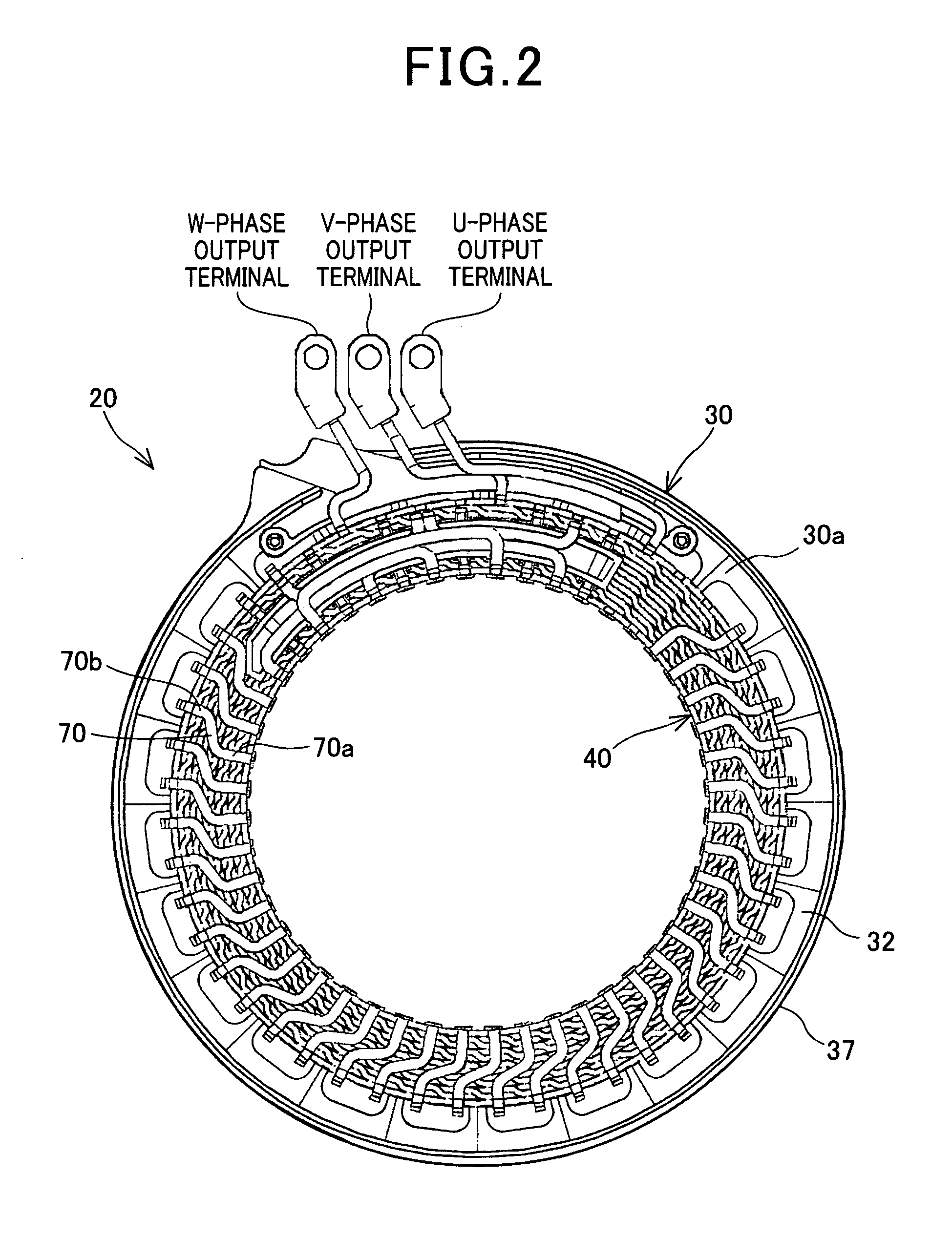

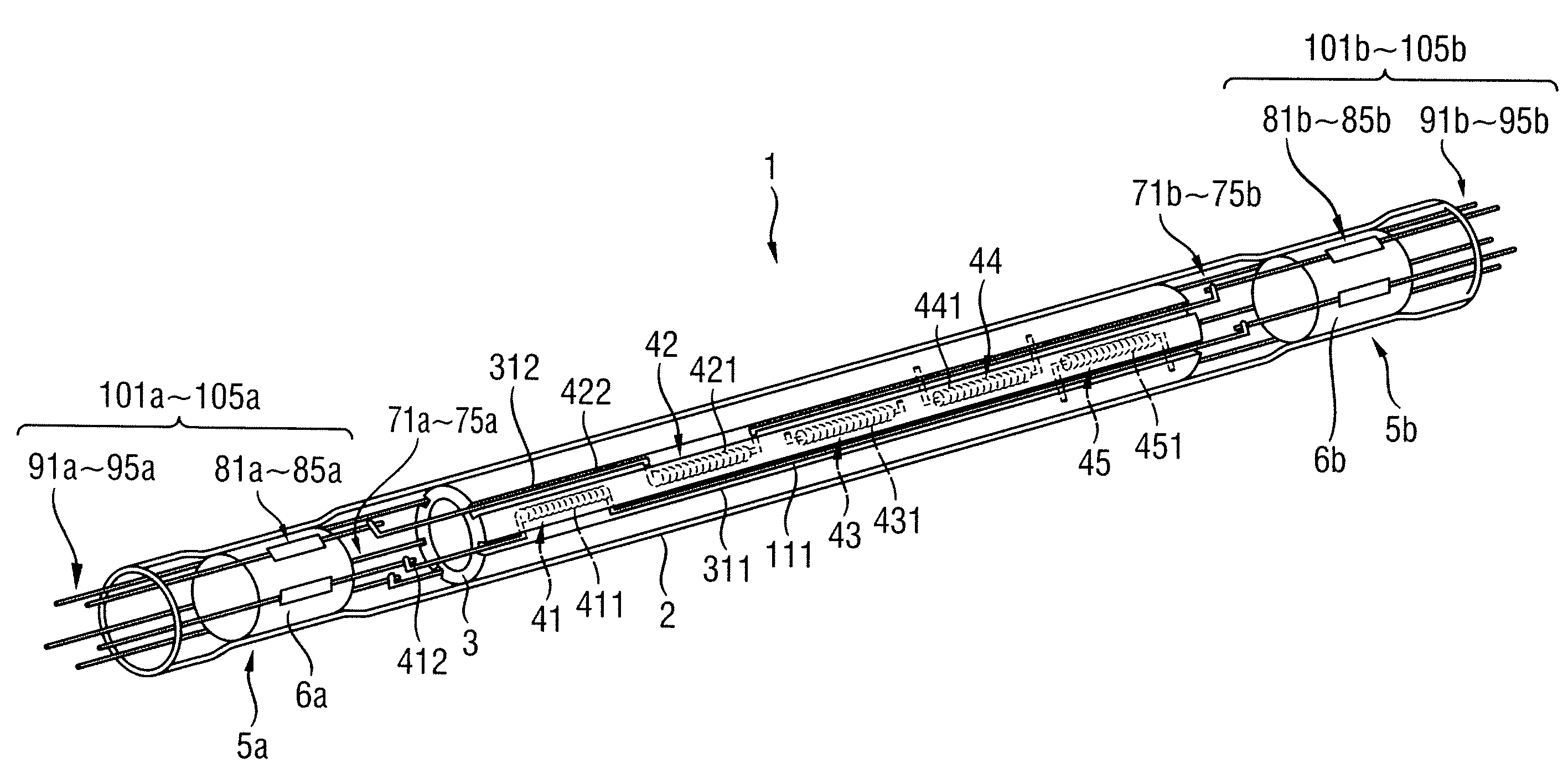

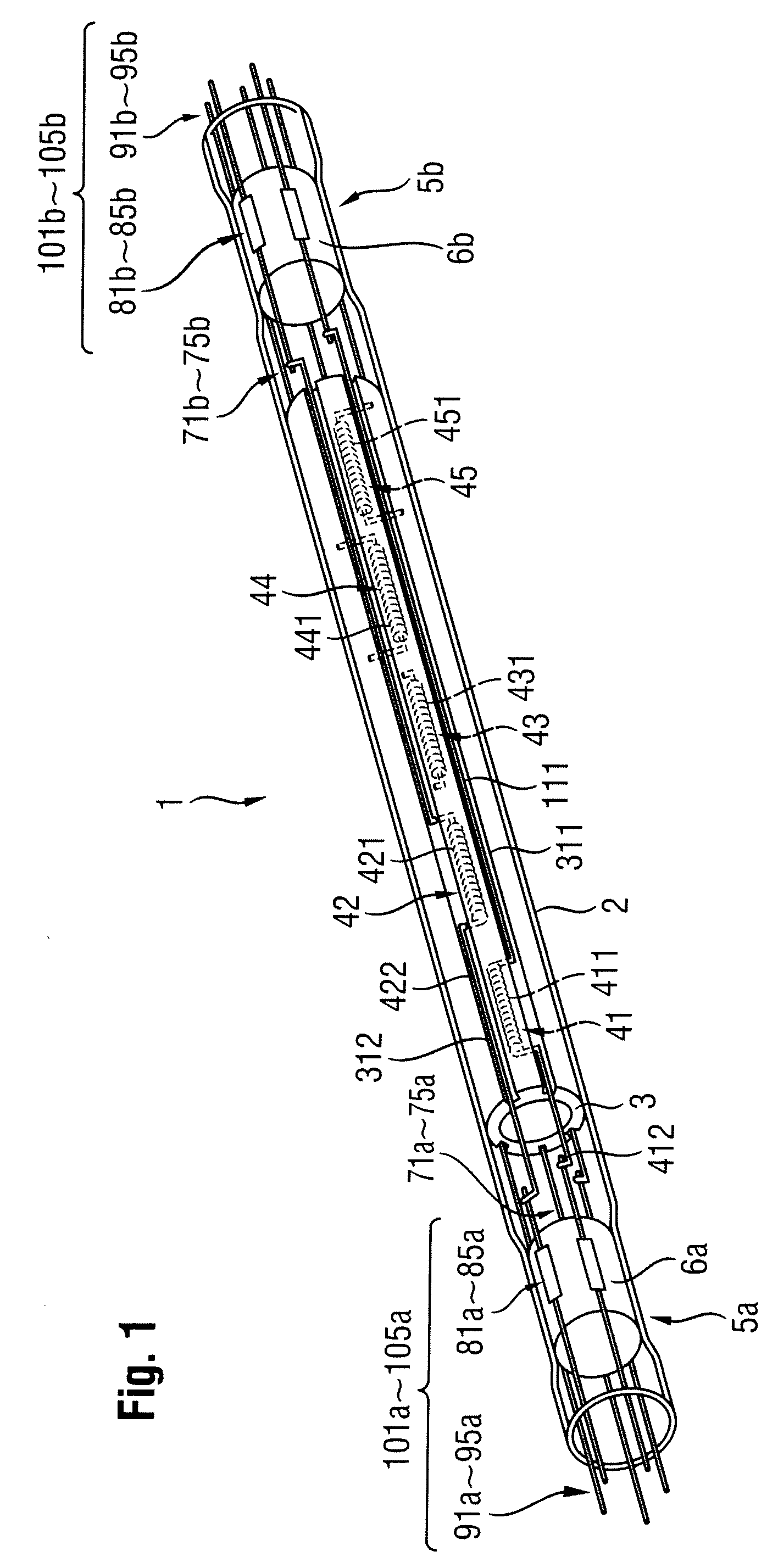

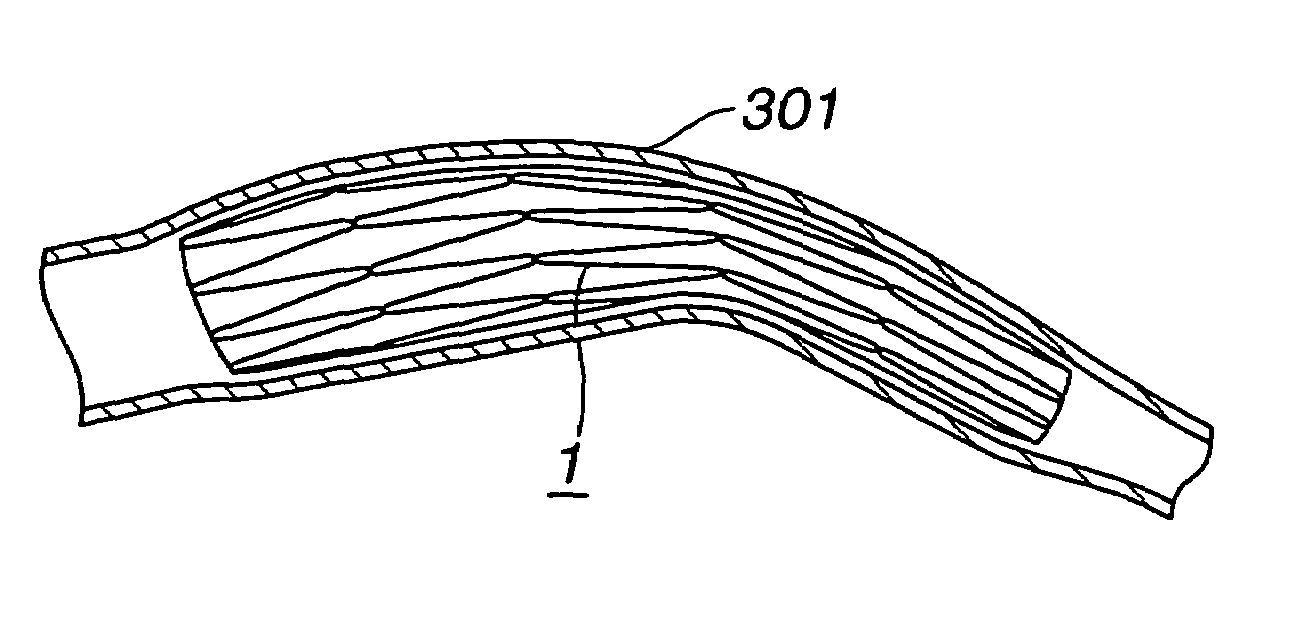

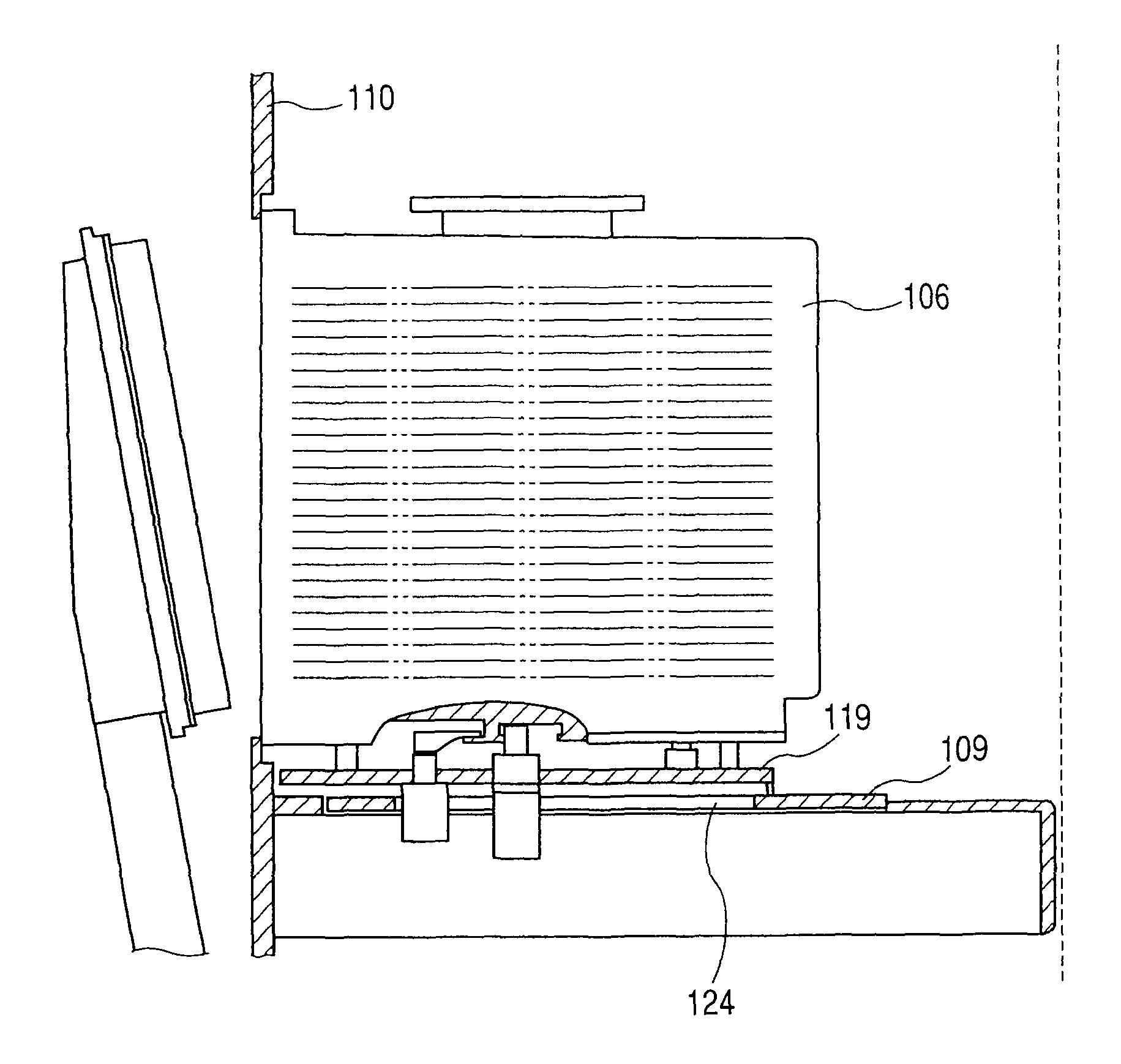

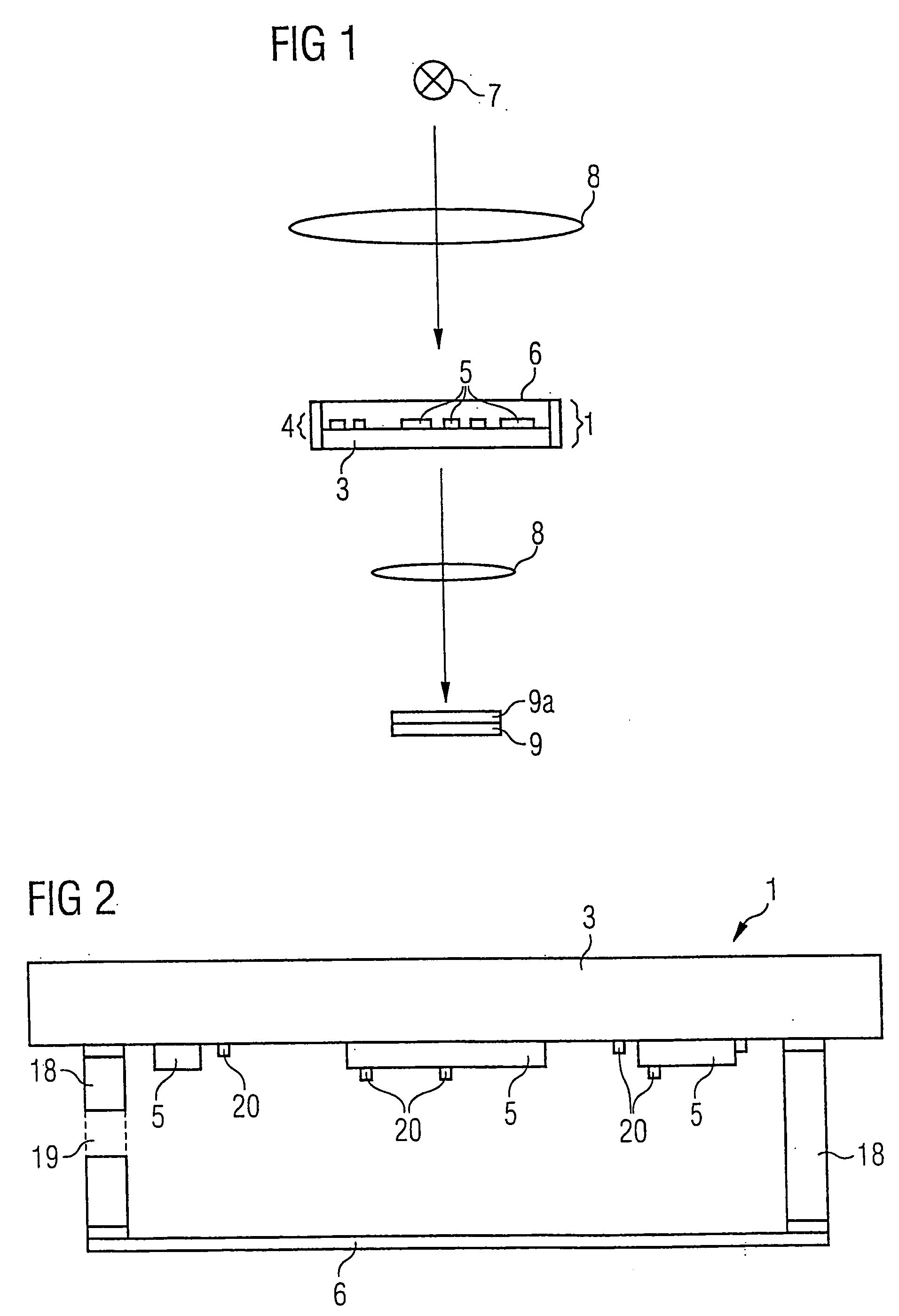

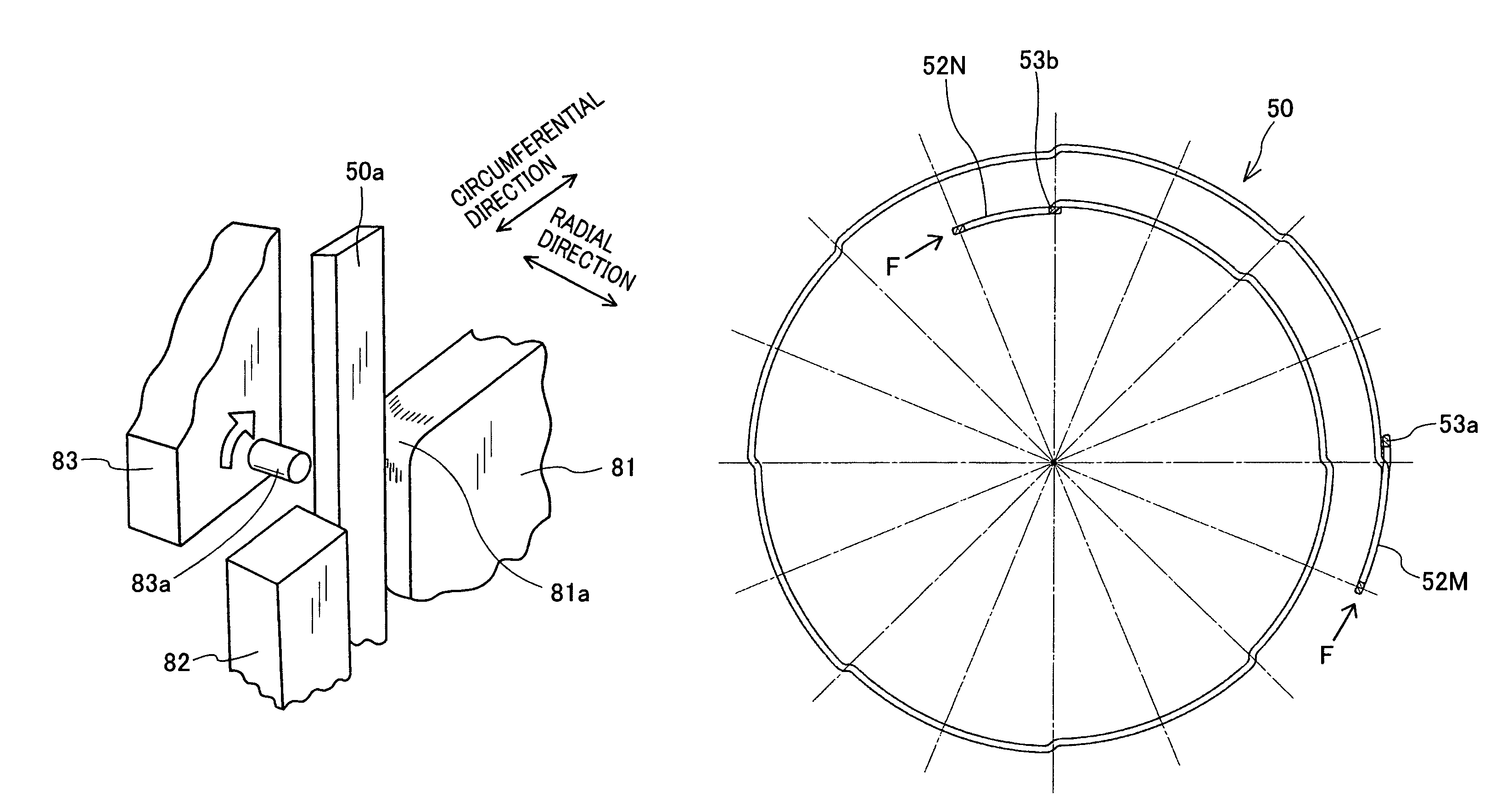

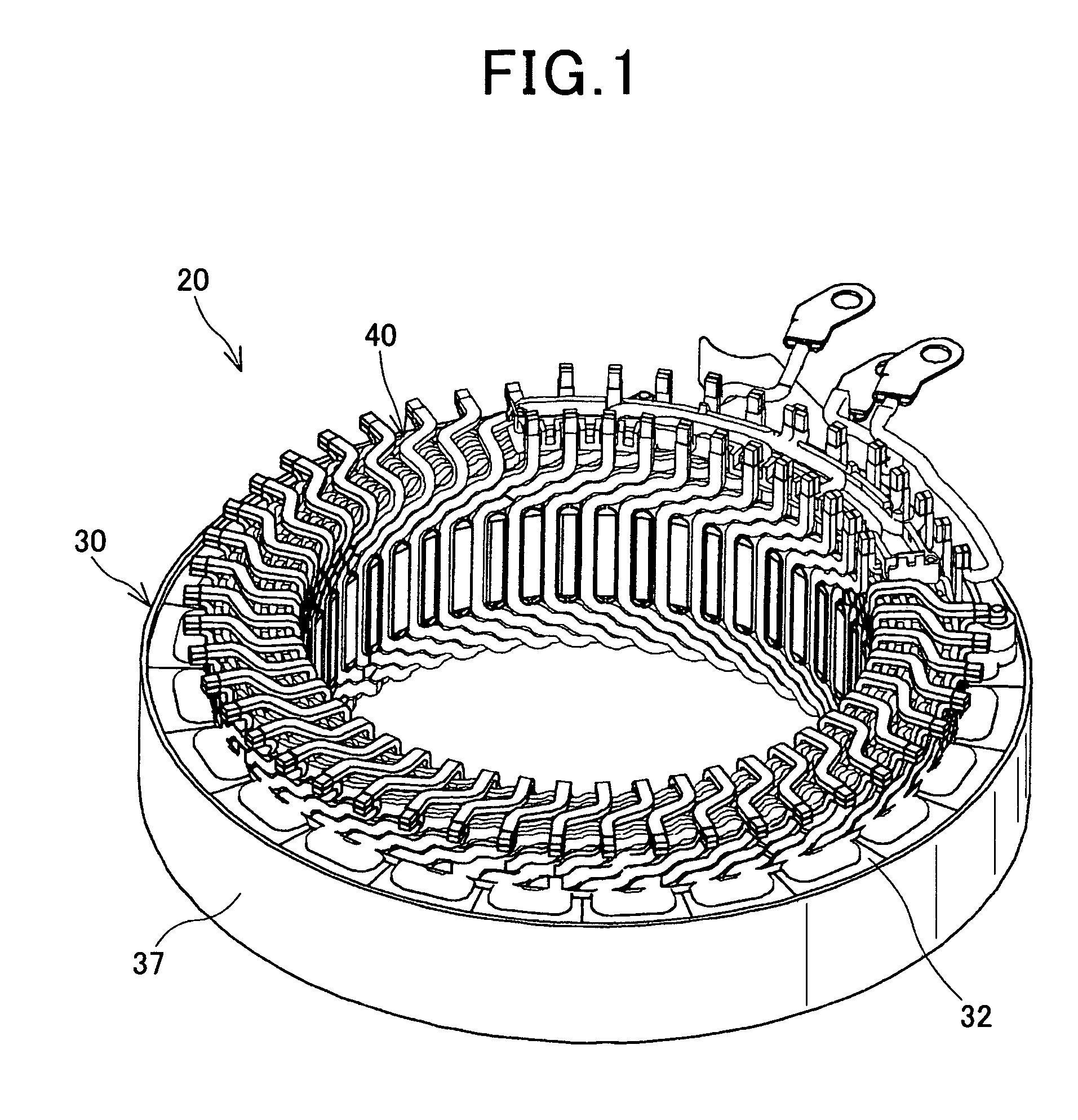

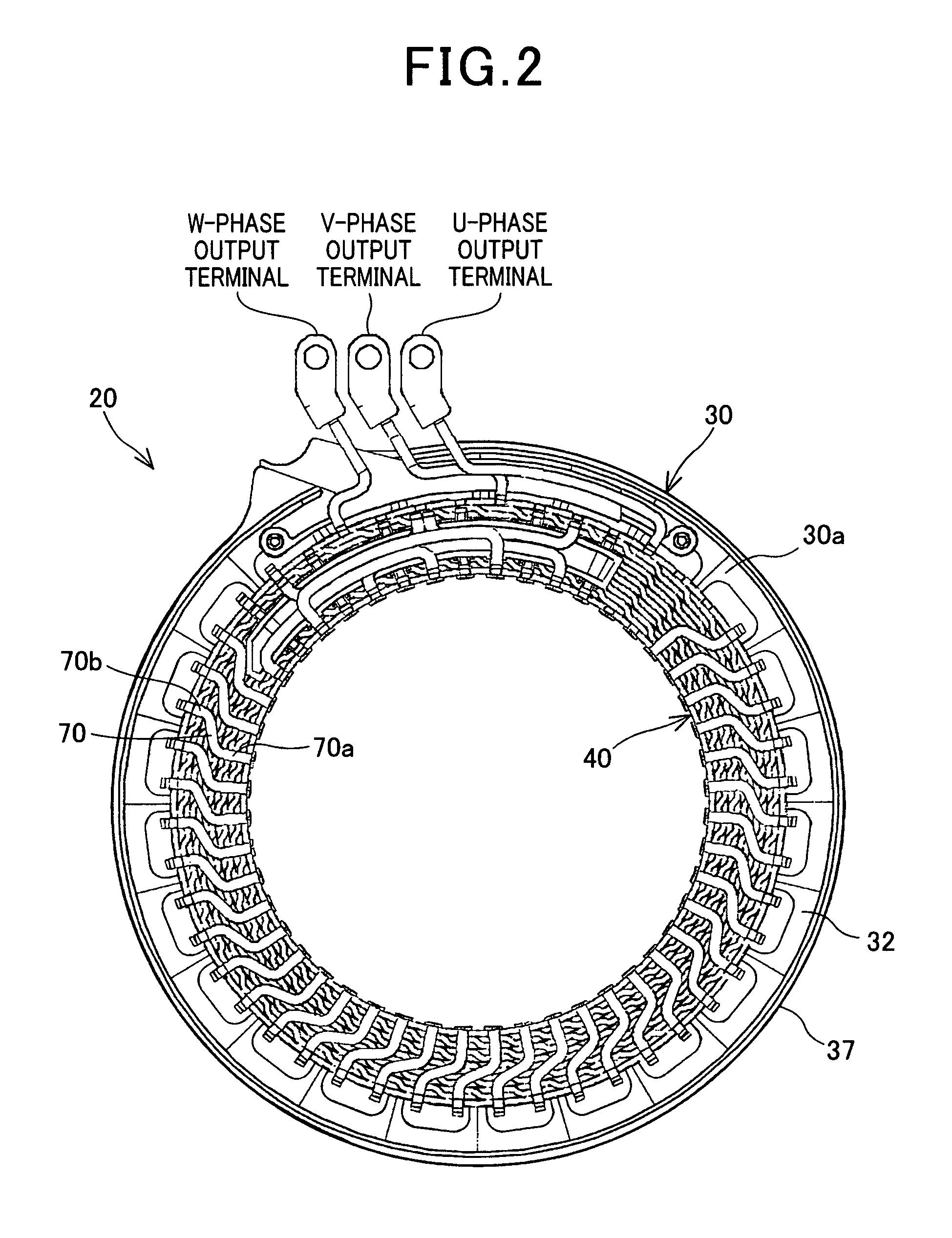

Stator for electric rotating machine and method of manufacturing the same

ActiveUS20110095639A1Facilitate assemblyEasily and accurately operateWave amplification devicesMagnetic circuitExternal connectionEngineering

Disclosed is a method of manufacturing a stator for an electric rotating machine. The method includes the steps of: (1) forming a plurality of planar electric wires, each of the planar electric wires including a plurality of in-slot portions to be received in slots of a stator core and a plurality of turn portions to be located outside of the slots to connect the in-slot portions; (2) rolling each of the planar electric wires through plastic deformation into a spiral or circular-arc shape; (3) forming a hollow cylindrical stator coil by assembling the rolled electric wires through operations of making relative axial movement therebetween; and (4) assembling the stator core and the stator coil together to form the stator.

Owner:DENSO CORP

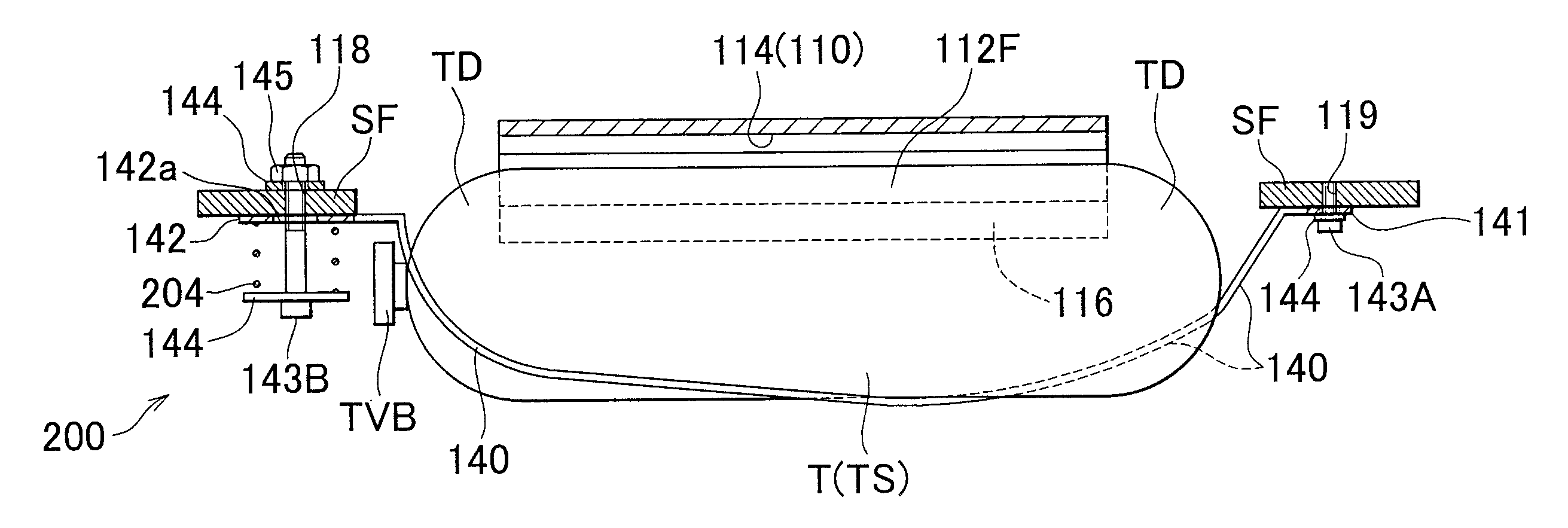

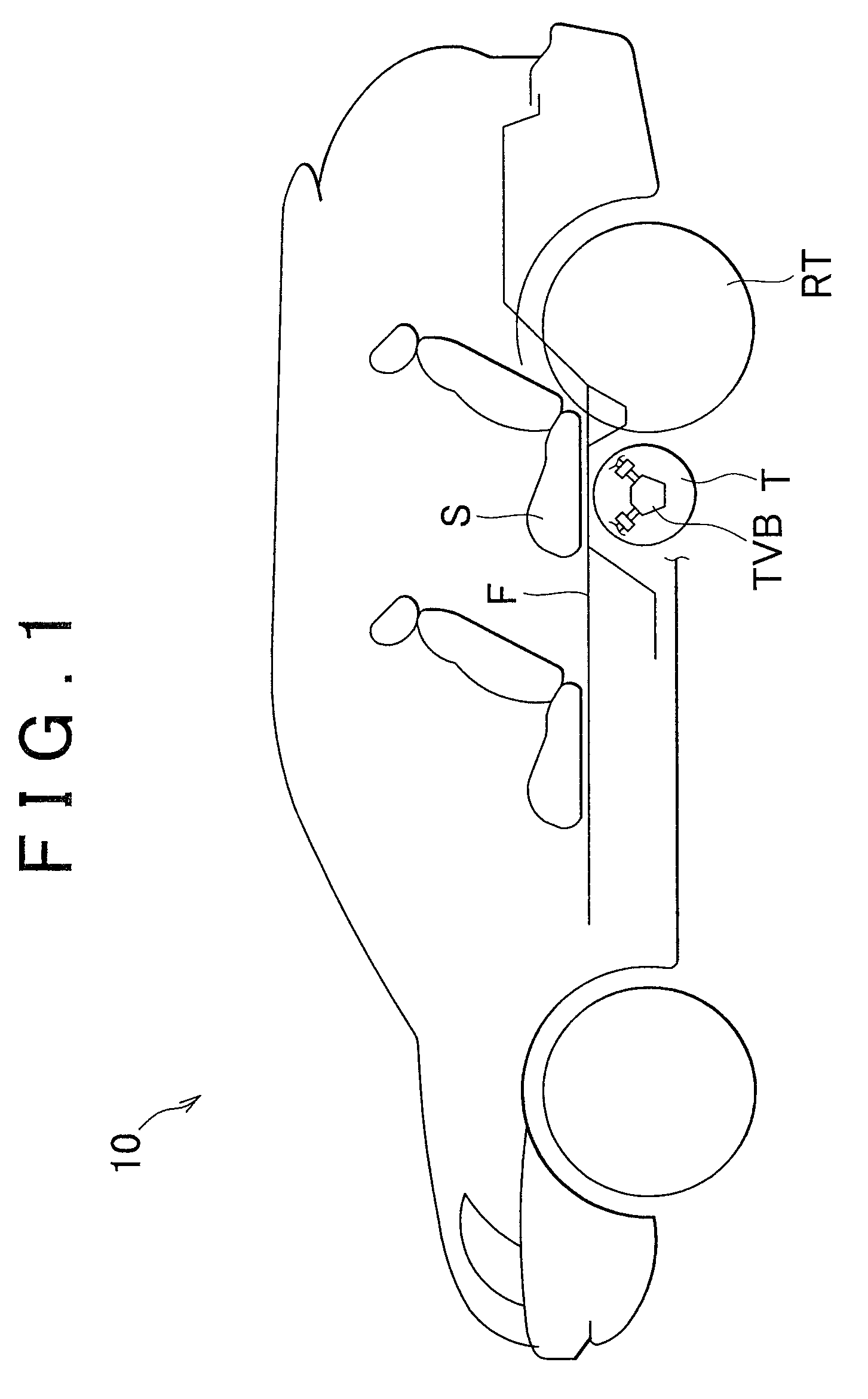

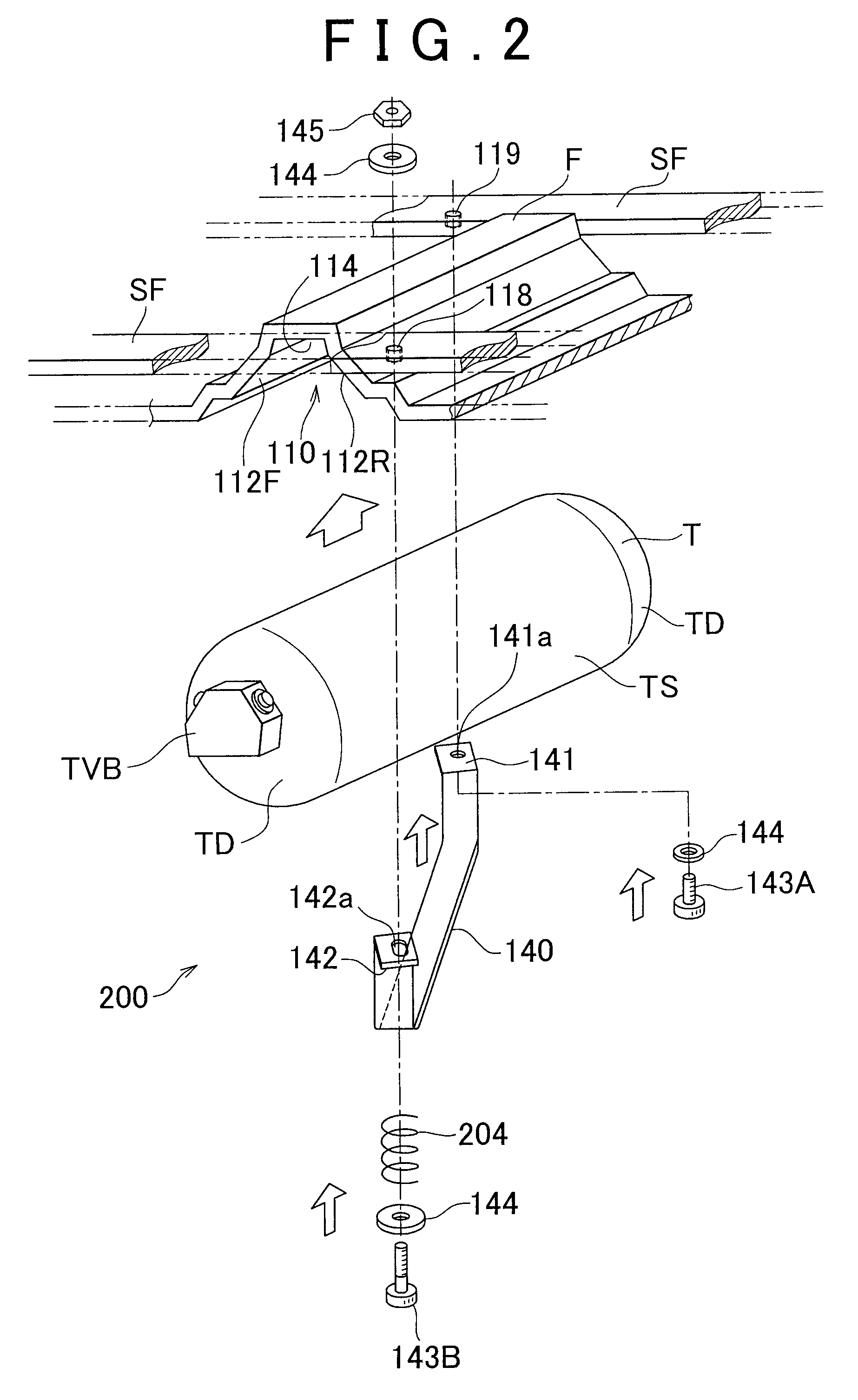

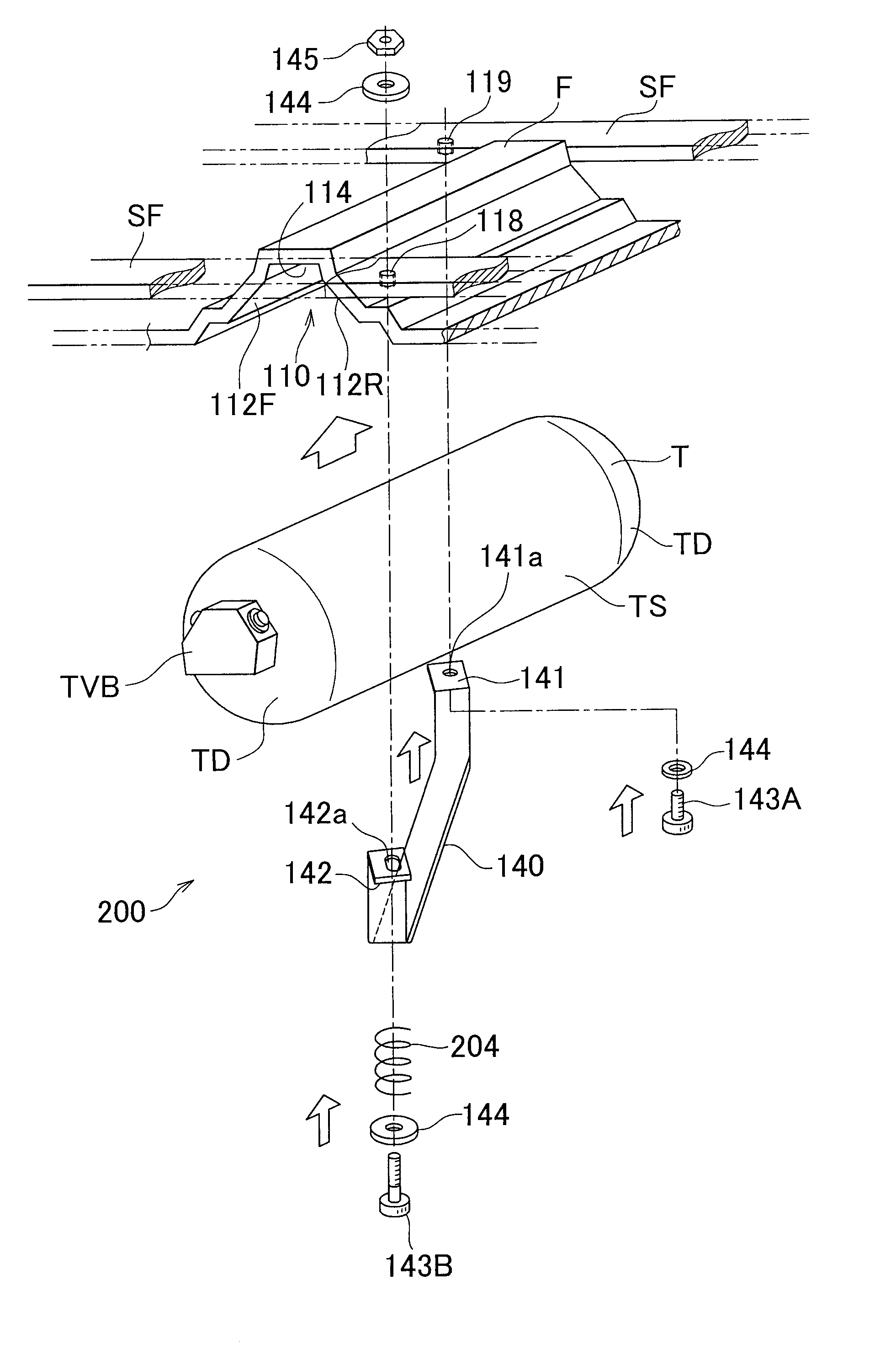

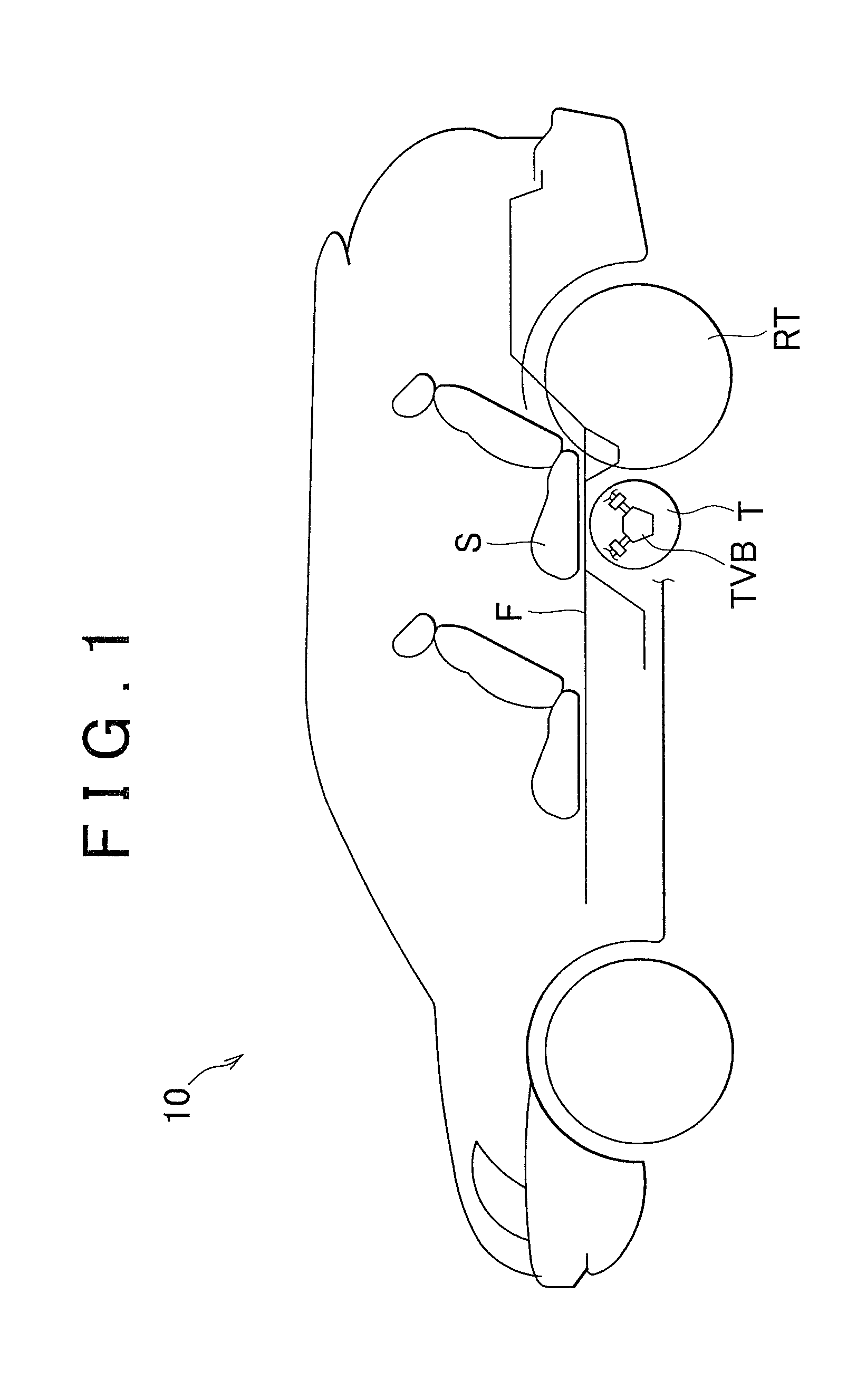

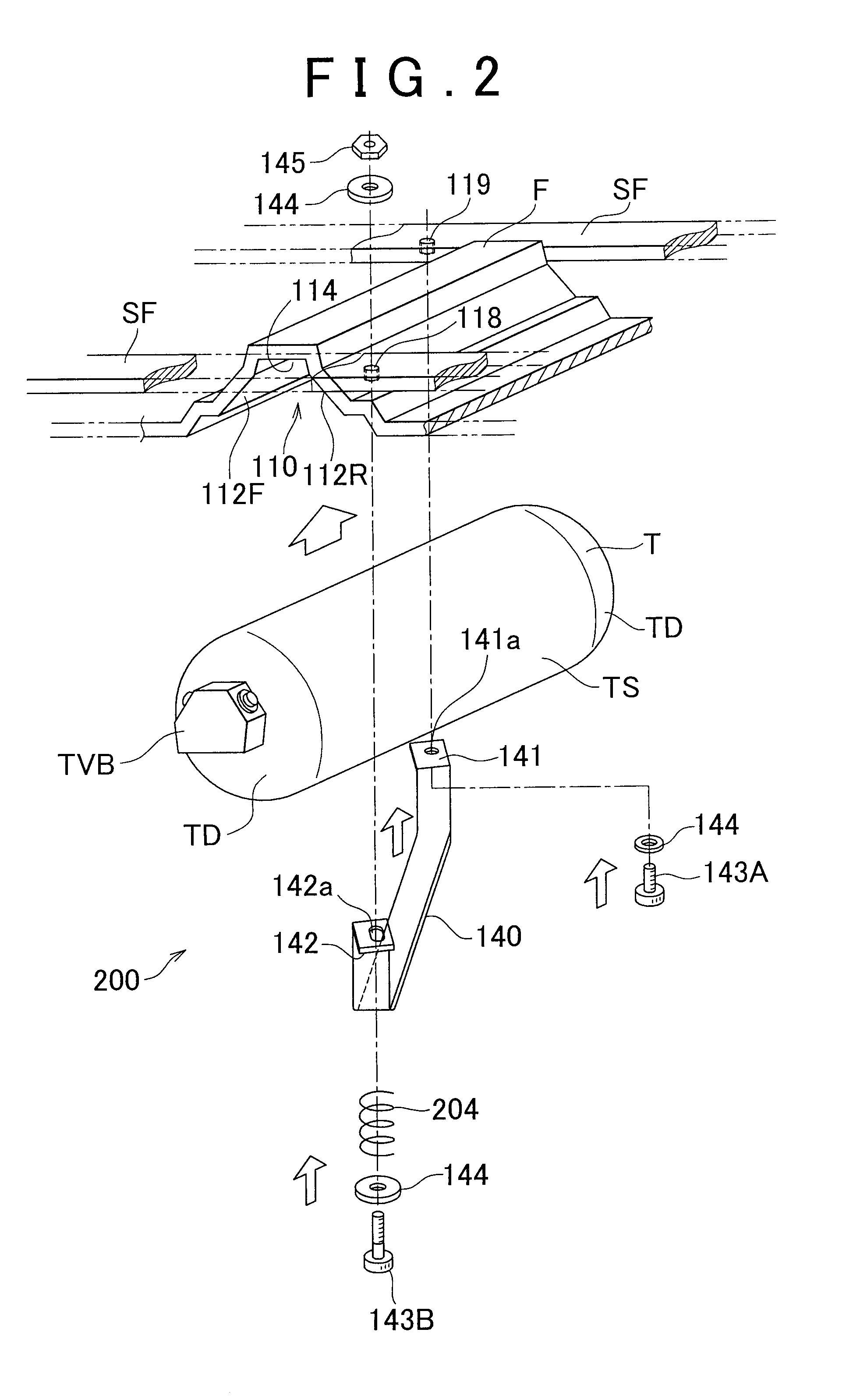

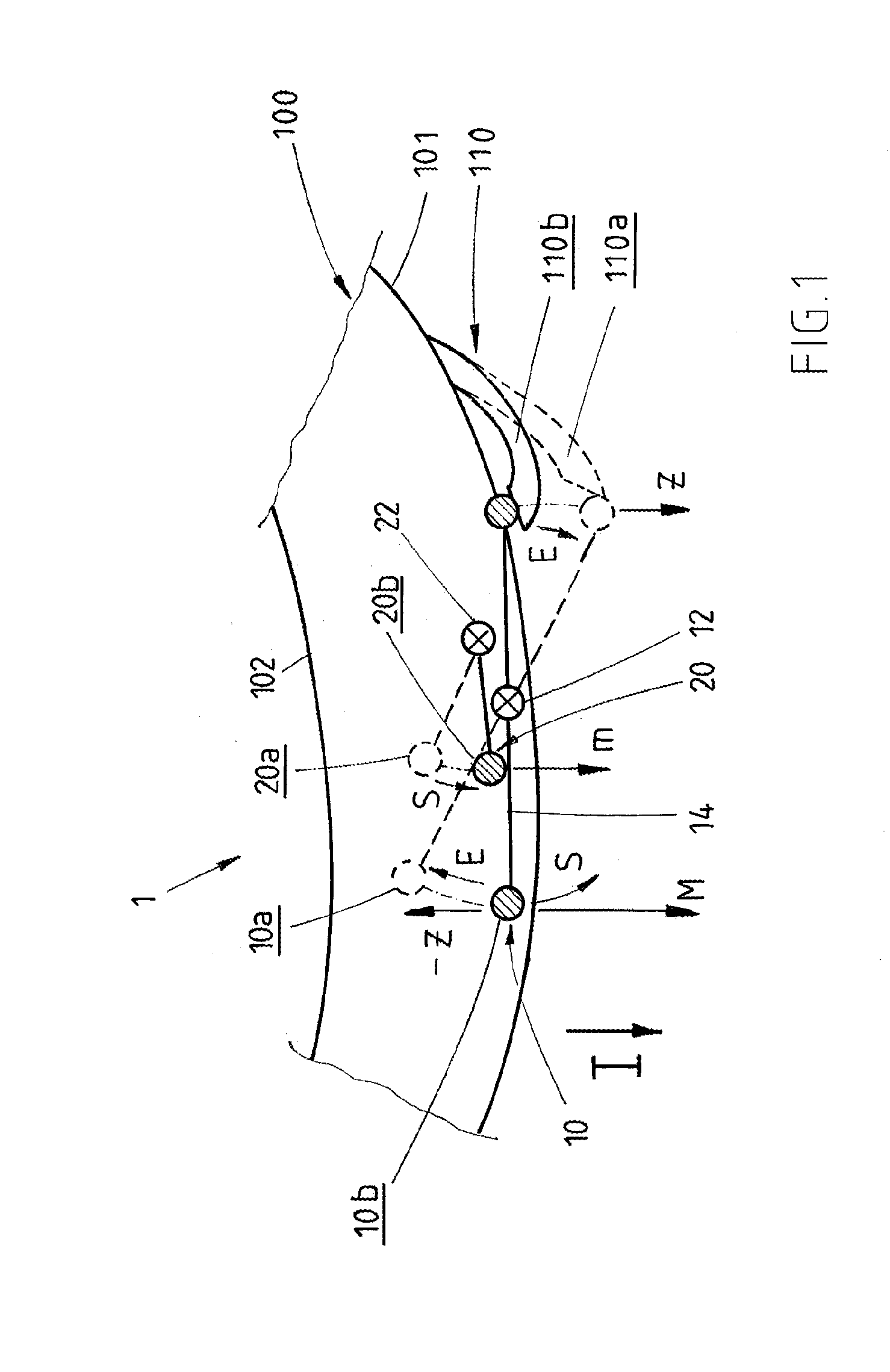

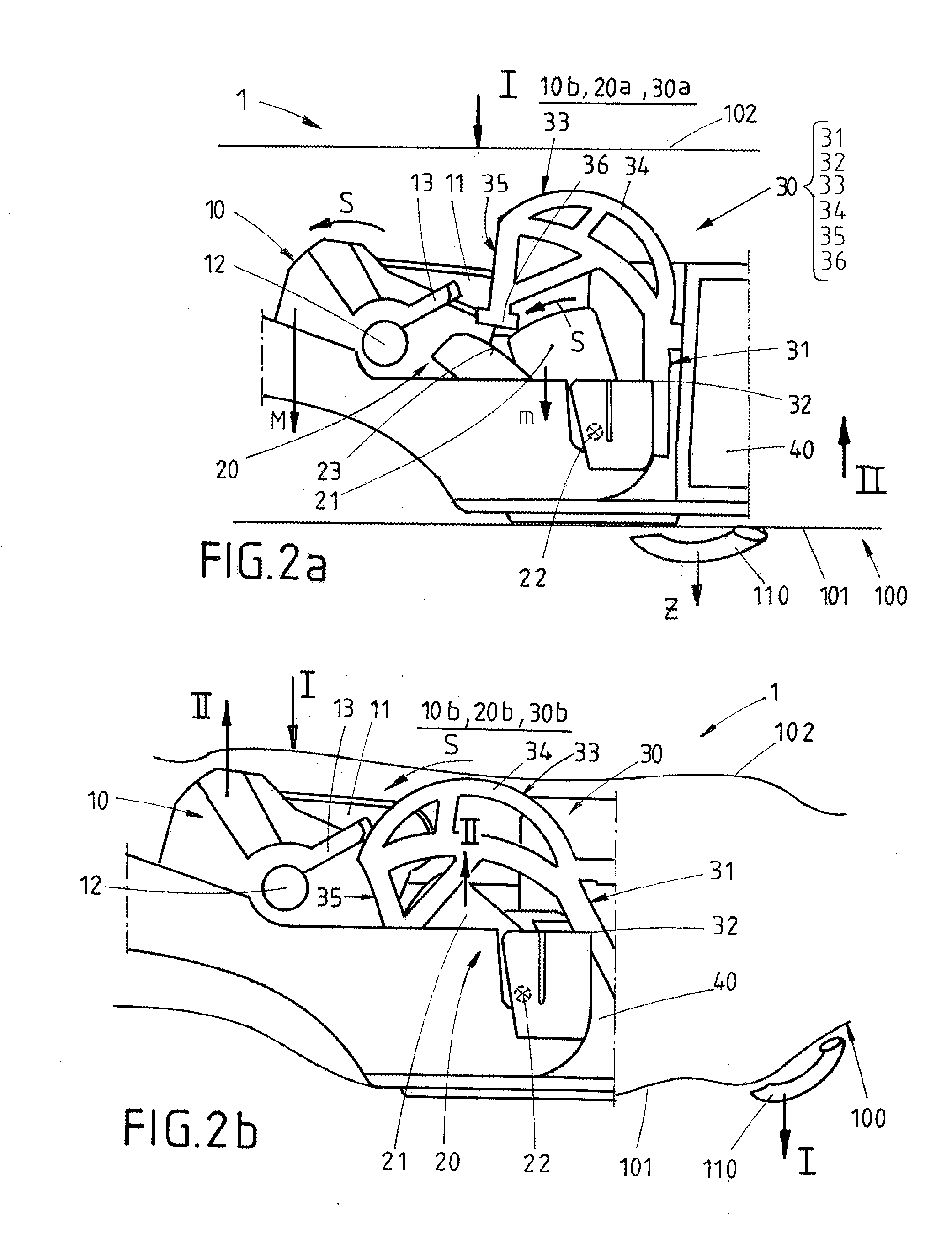

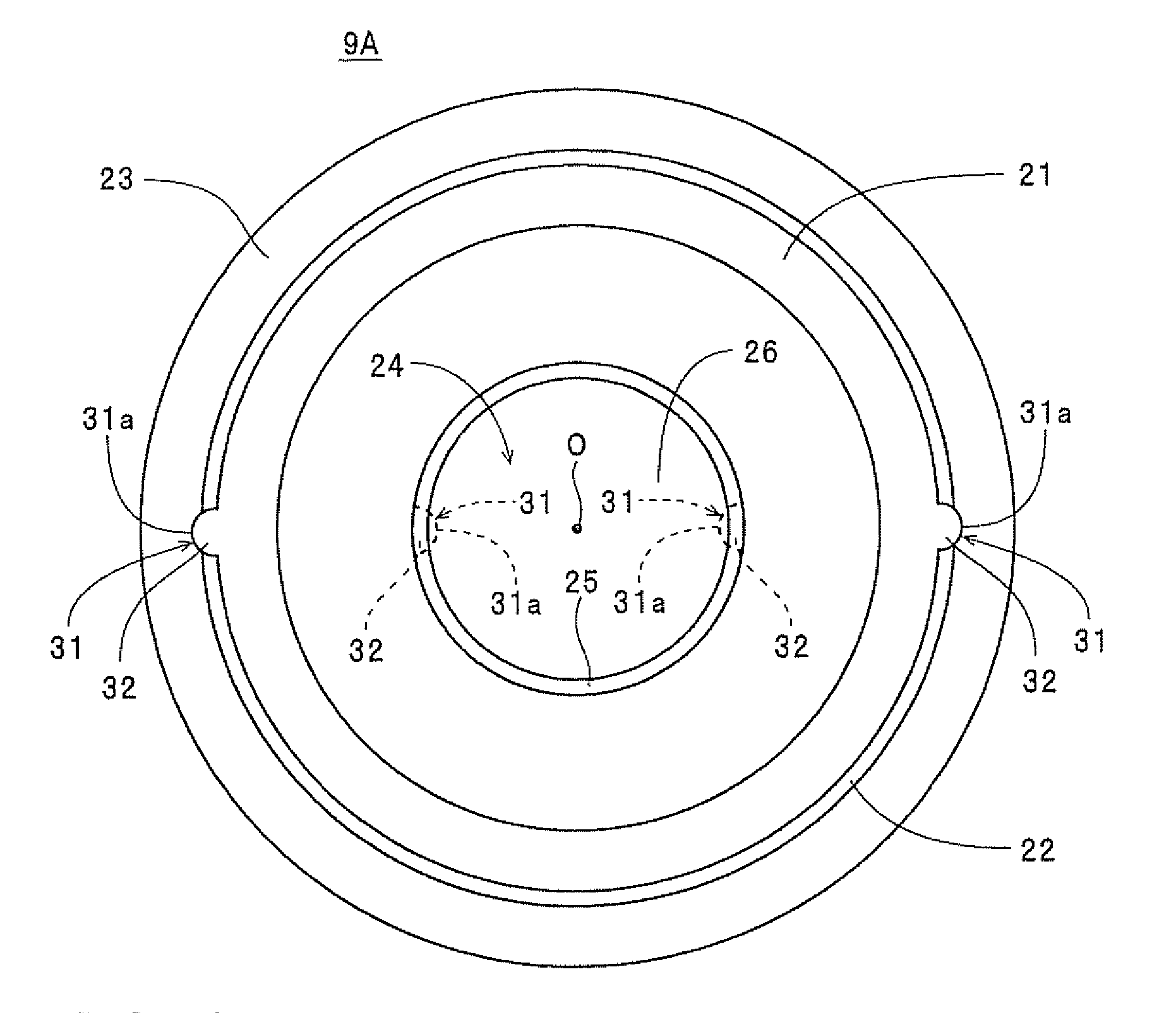

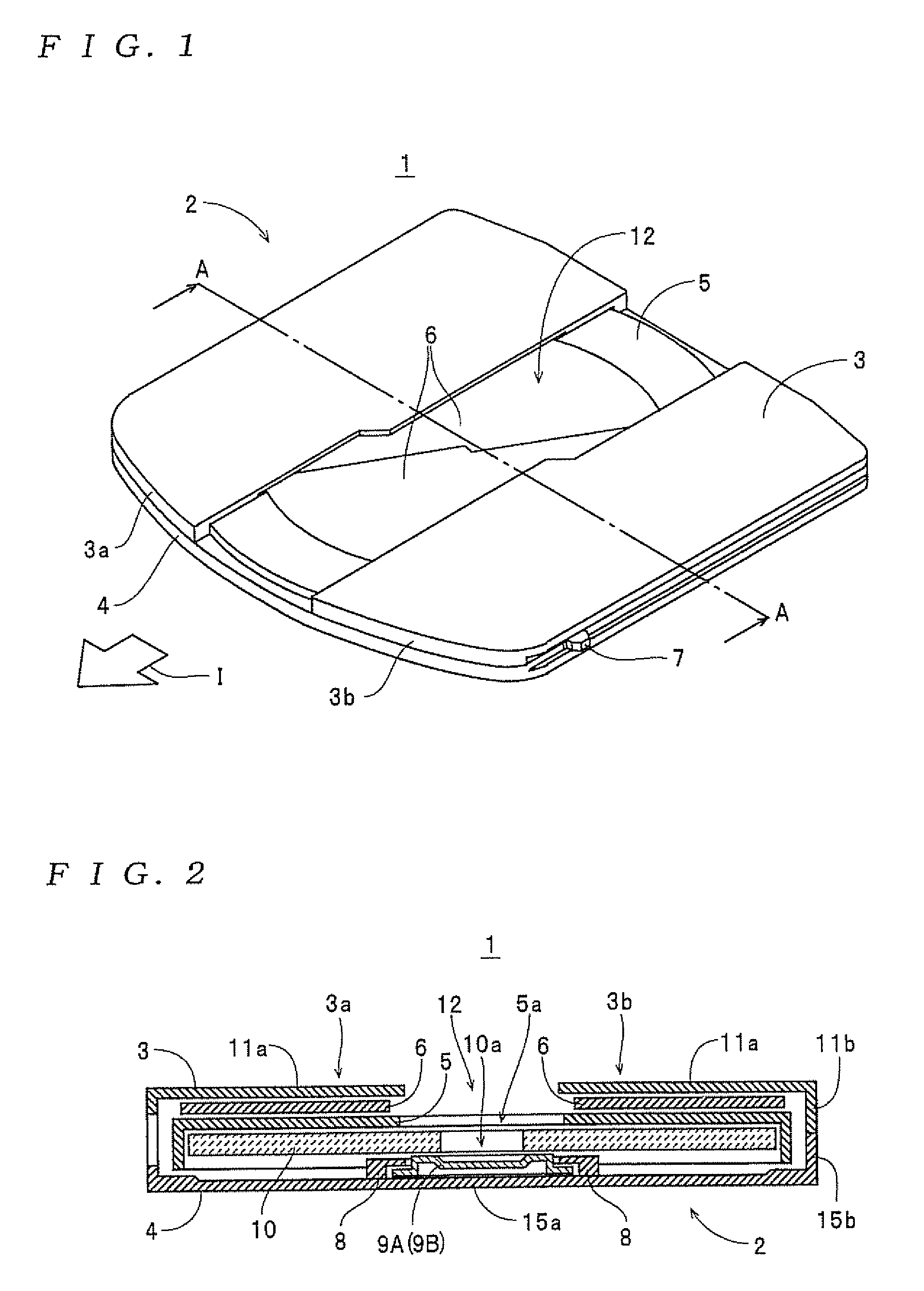

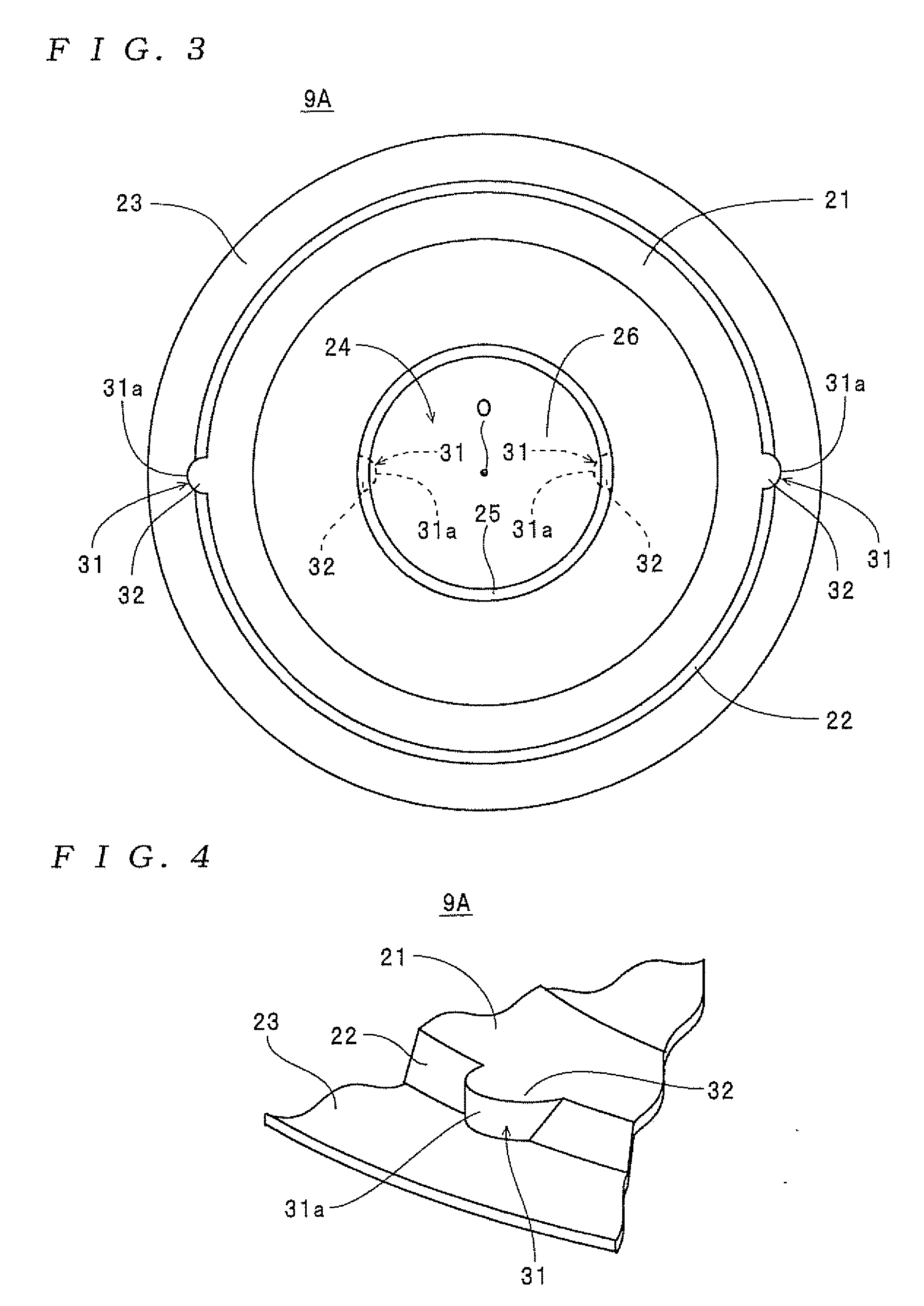

Tank holding mechanism for gas tank and vehicle in which gas tank is mounted using the same

A tank holding mechanism holds a gas tank that has a cylindrical portion and hemispherical-shaped domical portions formed on respective sides of the cylindrical portion. The tank holding mechanism includes: a tank accommodating portion that contacts a peripheral wall of the cylindrical portion of the gas tank; tank end-side members provided near respective ends of the gas tank; a tank band that pushes the gas tank against the tank accommodating portion; and band securing portions that secure end portions of the tank band to the respective tank end-side members. The tank band is routed from one of the domical portions through the cylindrical portion to the other domical portion. The tank band extends along a diagonal line of the gas tank over an outer face of the cylindrical portion, conforms to the outer face of the cylindrical portion, and conforms to hemispherical outer faces of both of the domical portions.

Owner:TOYOTA JIDOSHA KK

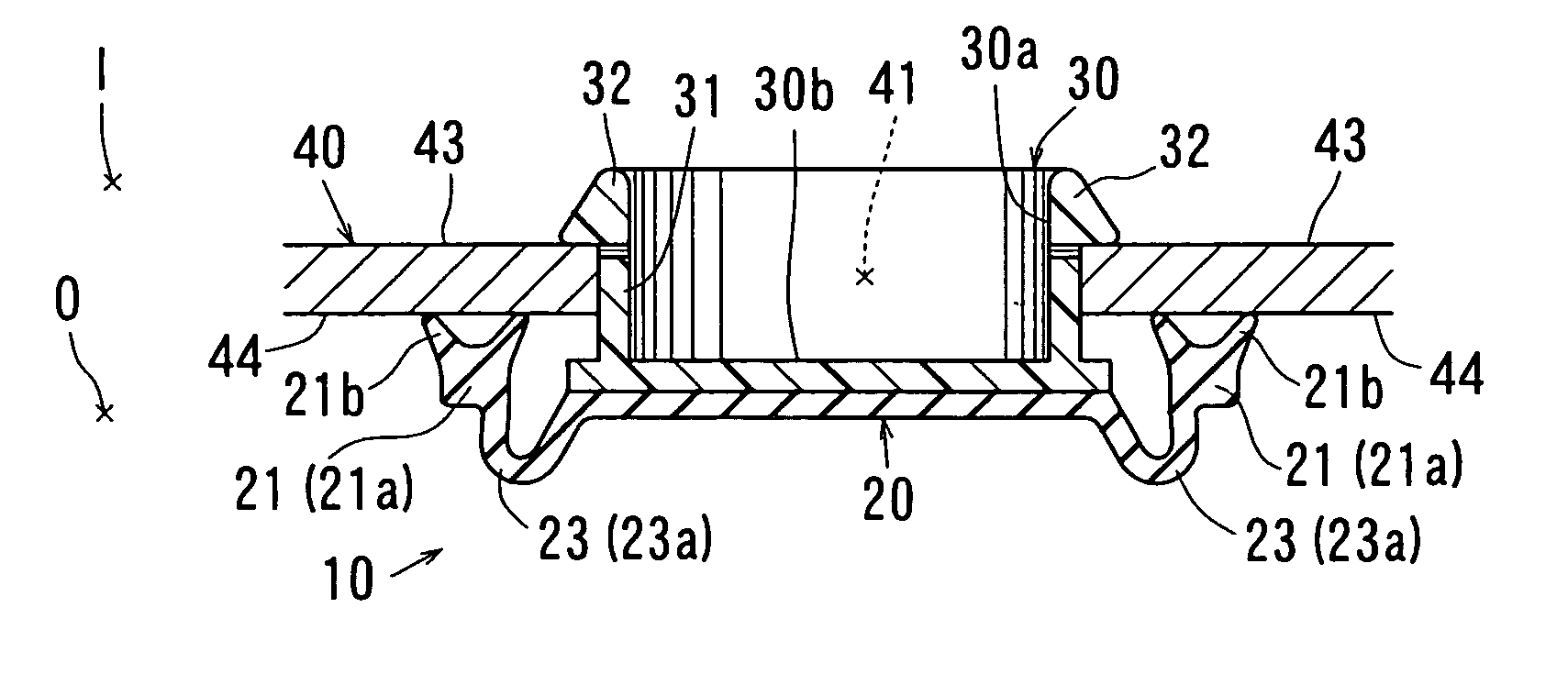

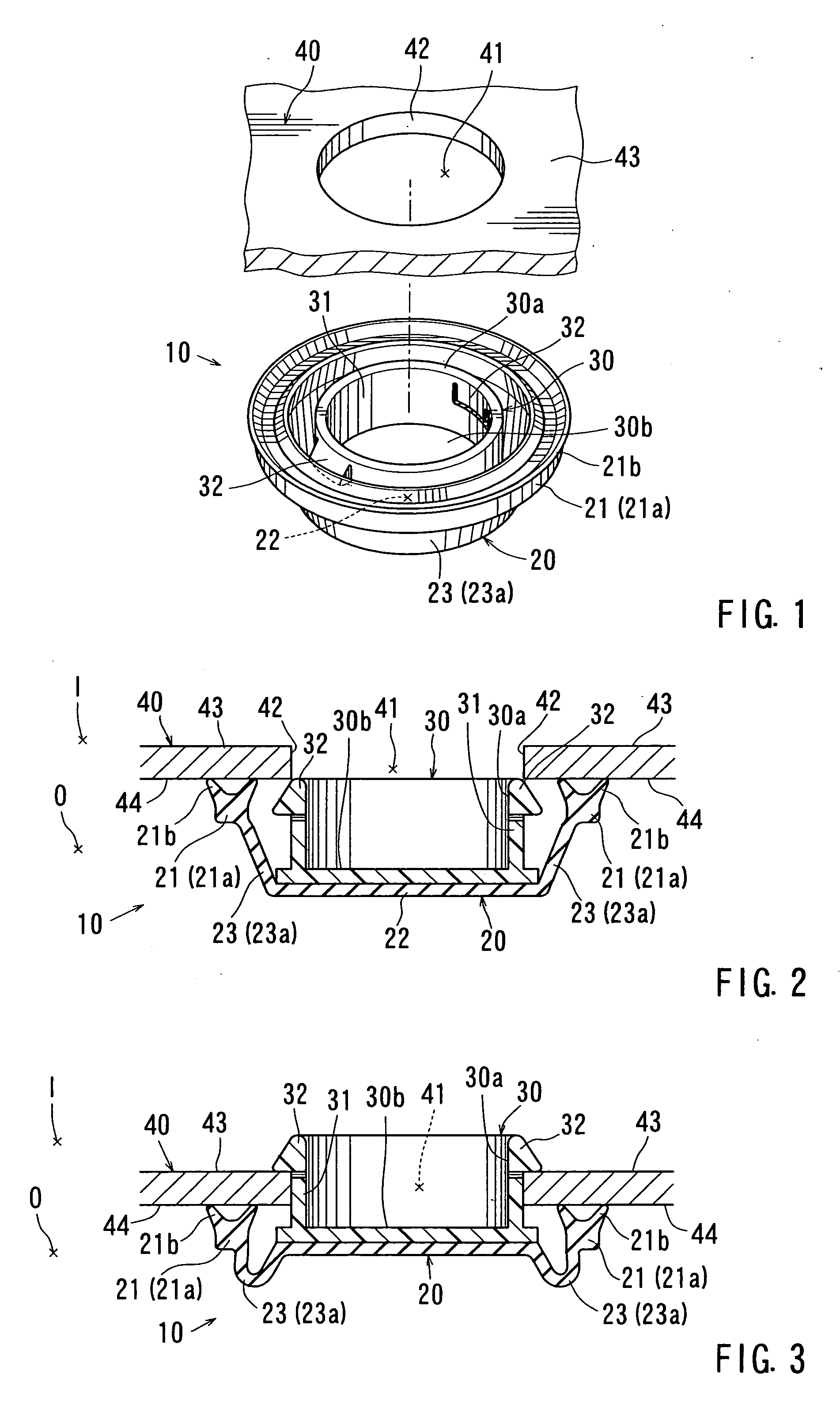

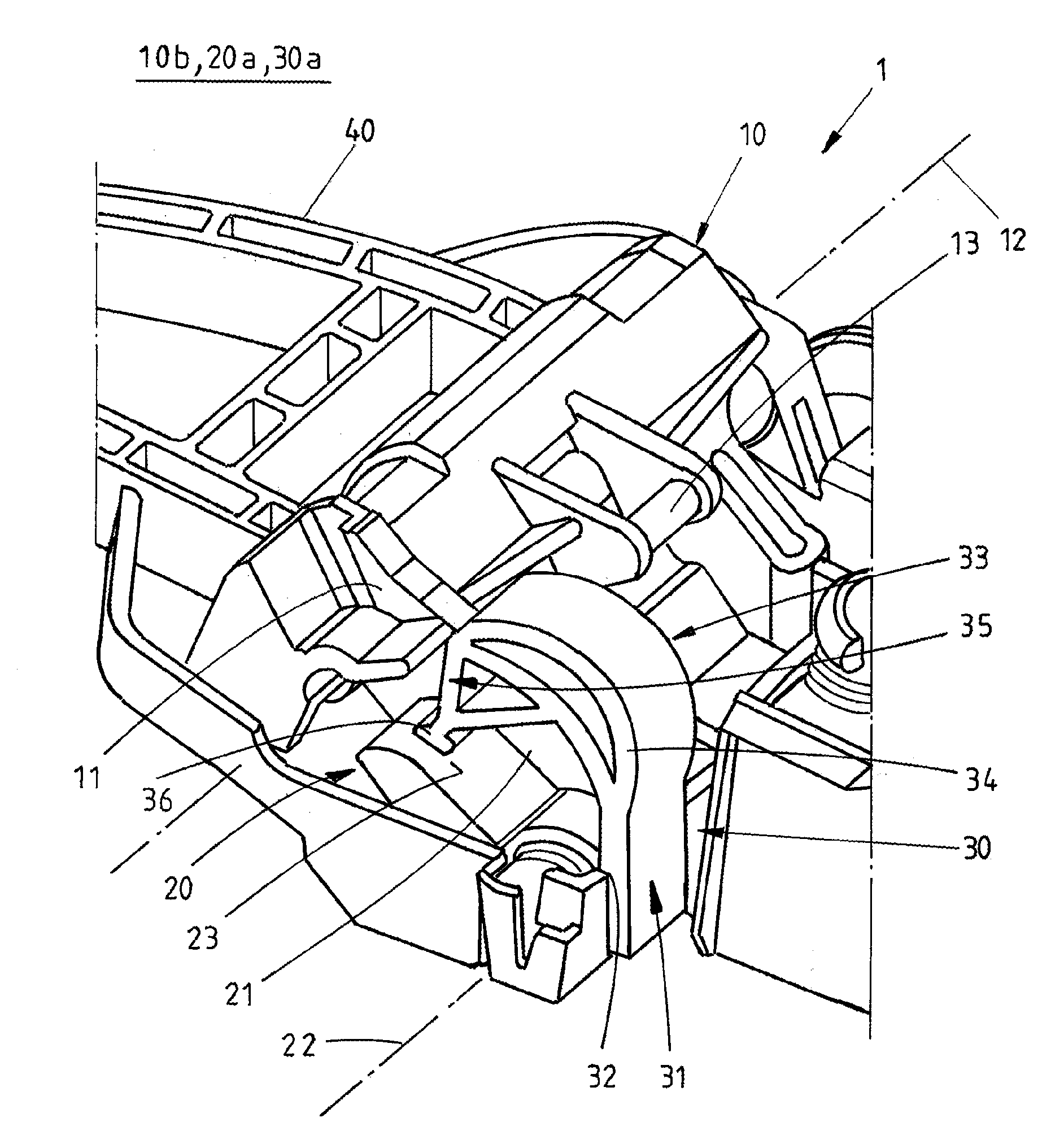

Hole plugs

InactiveUS20070062962A1Improve the immunityImprove stress conditionRemovable lids/coversElectric connection structural associationsEngineeringSynthetic resin

A hole plug for closing a through-hole formed in a compartment wall may include an attaching portion formed from a synthetic resin and a cover portion integrated with the attaching portion at a central portion thereof. The attaching portion can be inserted into the through-hole so as to engage the inner surface of the compartment wall. The cover portion has a size and shape that can enclose the through-hole and has a peripheral edge portion that can closely contact the outer surface of the compartment wall. The cover portion has a thickened portion that is formed in the peripheral edge portion thereof or in a vicinity of the peripheral edge portion and that can maintain a size and configuration of the peripheral edge portion when an external force is applied to the cover portion. The cover portion has a thinned portion that is formed between the thickened portion and the central portion integrated with the attaching portion and that can undergo elastic buckling deformation when an external force is applied thereto.

Owner:DAIWA KASEI IND CO LTD

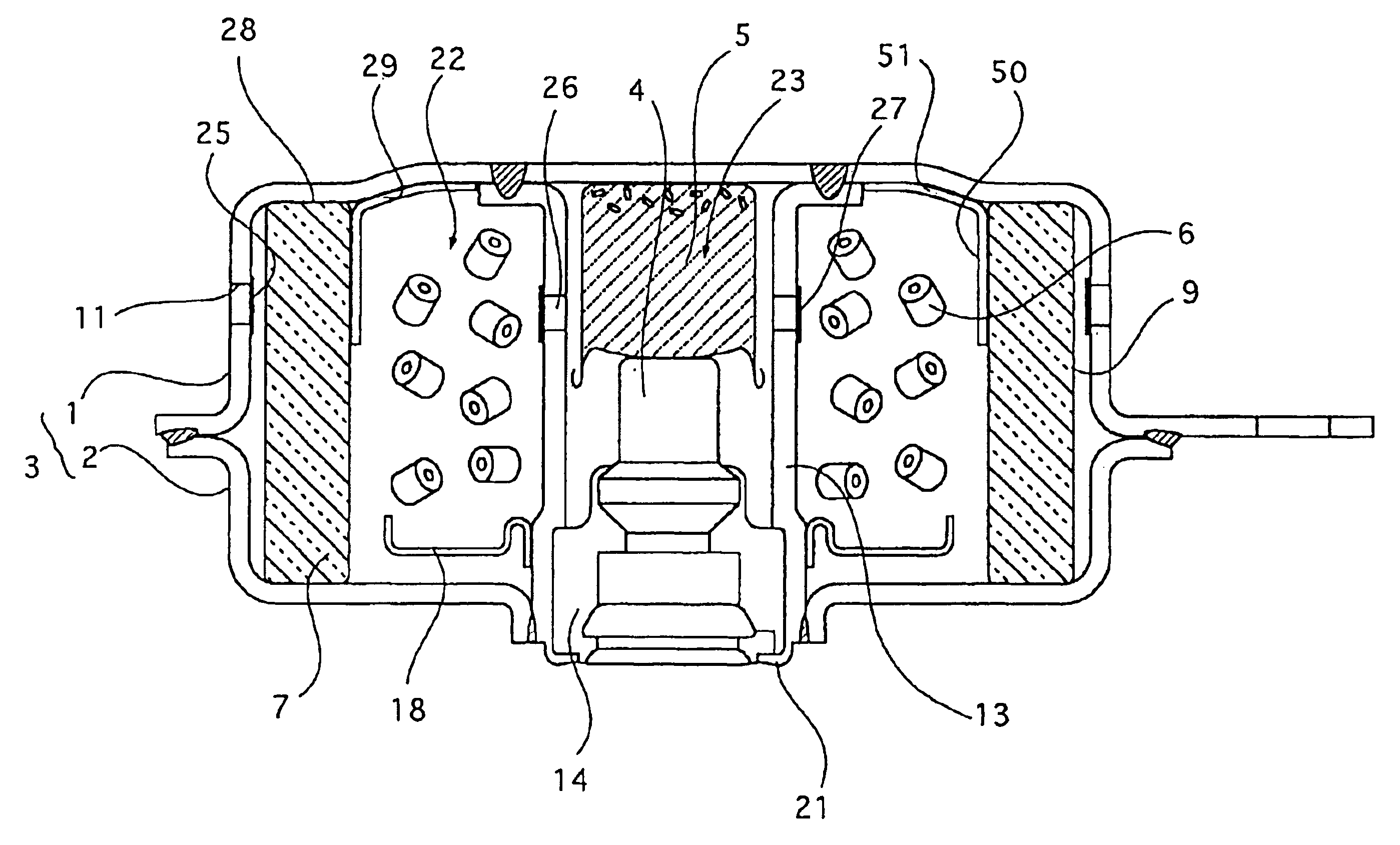

Chain tensioner

A chain tensioner includes a housing having a cylinder chamber. A plunger is slidably mounted in the cylinder chamber. A spring is mounted in the cylinder chamber to bias the plunger outwardly of the cylinder chamber. The plunger has a radially extending locking pin at its lower portion near its front end. The housing is formed with a pin hole extending substantially perpendicular to an axis of the cylinder chamber near the front end of the housing and under the cylinder chamber. The chain tensioner further includes a support pin inserted in the pin hole, and a locking lever supported on the support pin so as to be pivotable about the support pin. The locking lever can engage the locking pin when the plunger is sufficiently pushed into the cylinder chamber, thereby keeping the plunger pushed in the cylinder chamber.

Owner:NTN CORP

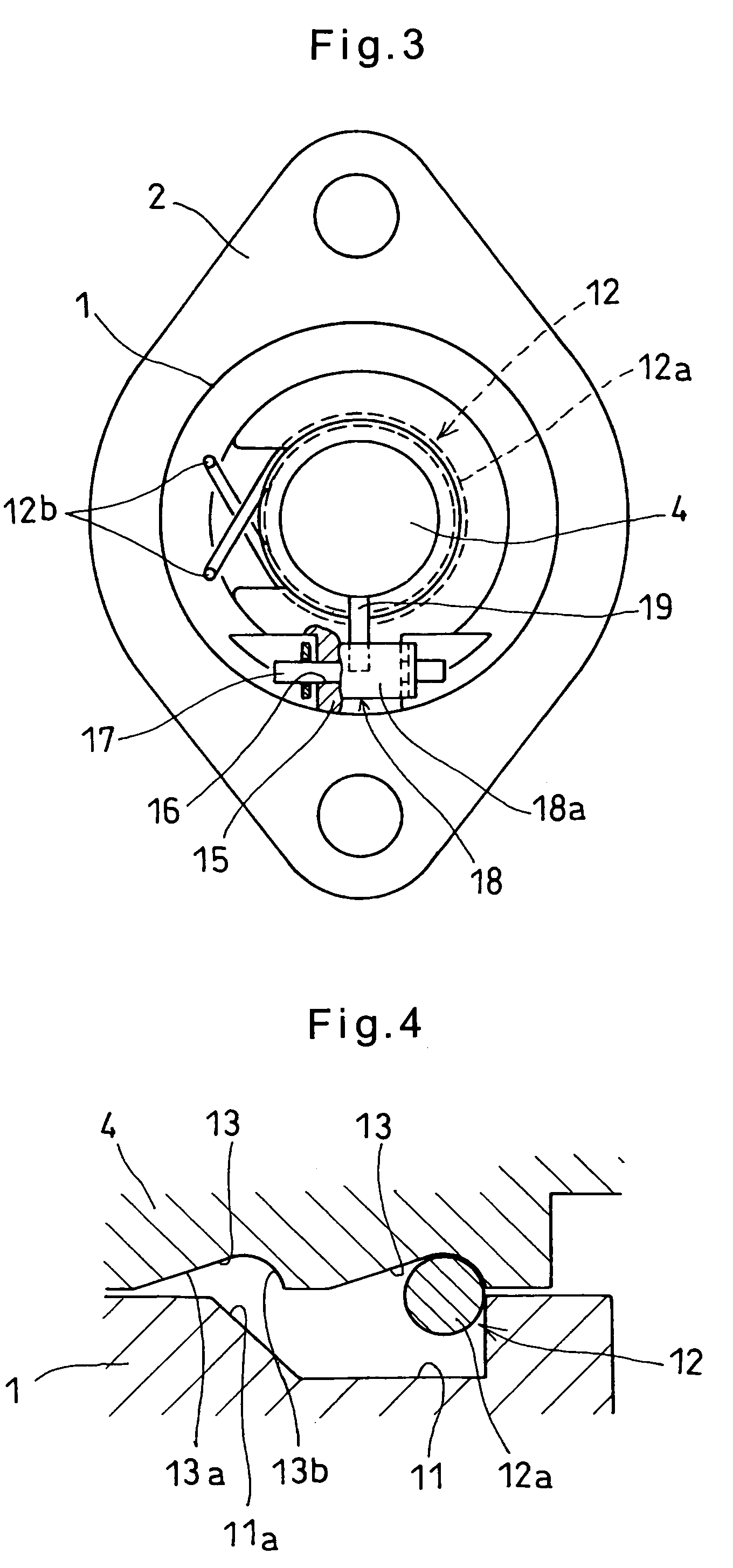

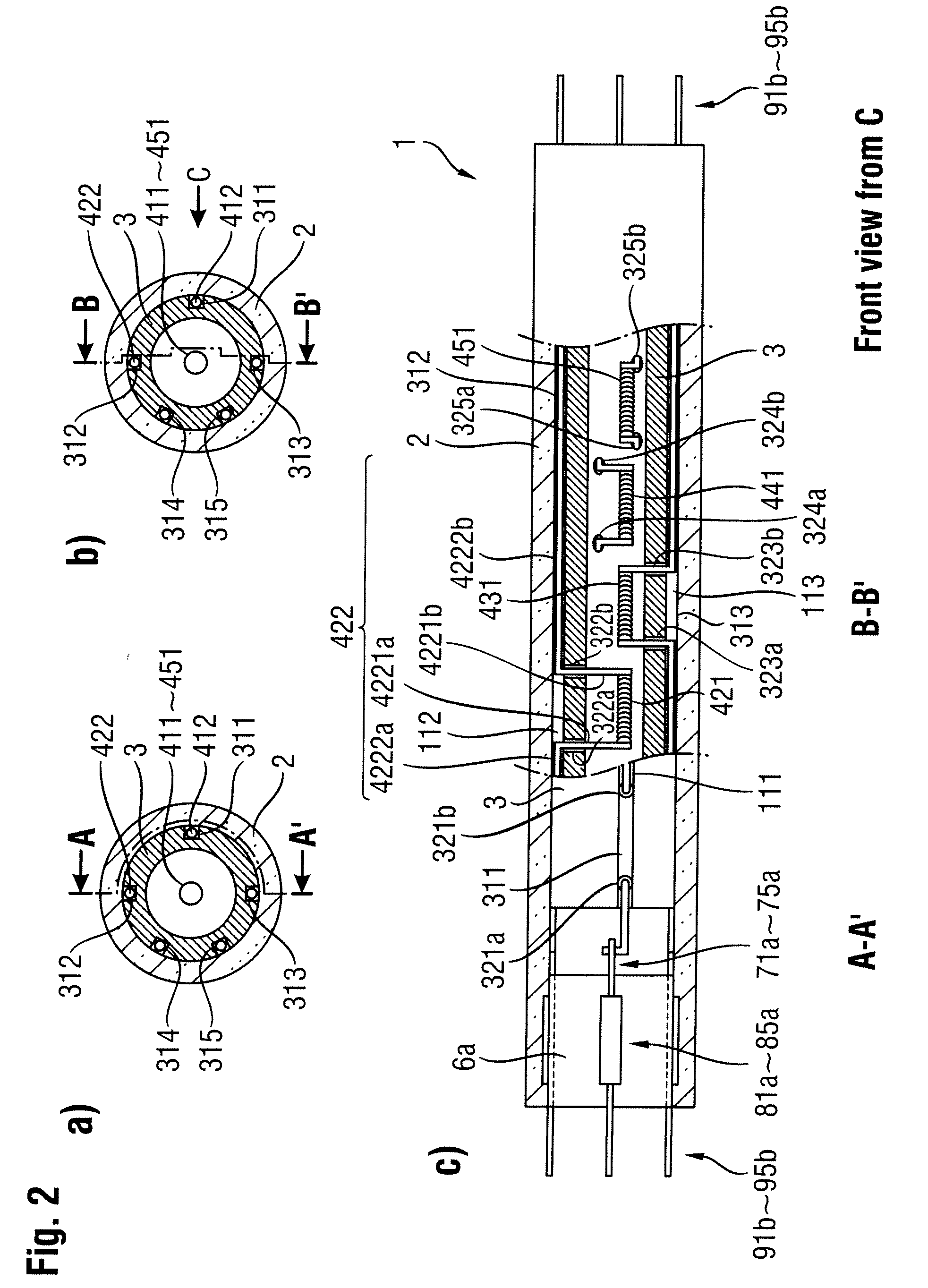

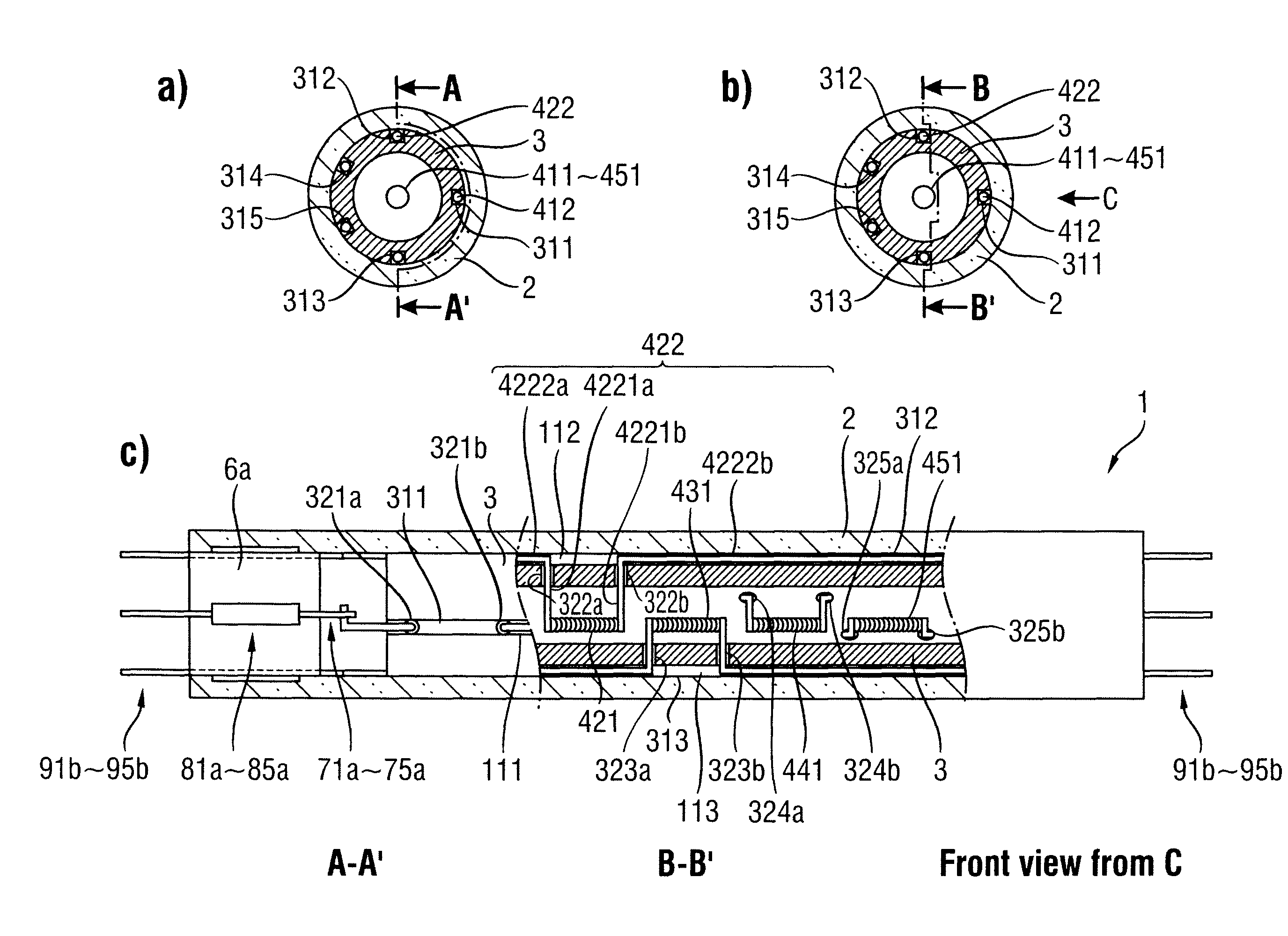

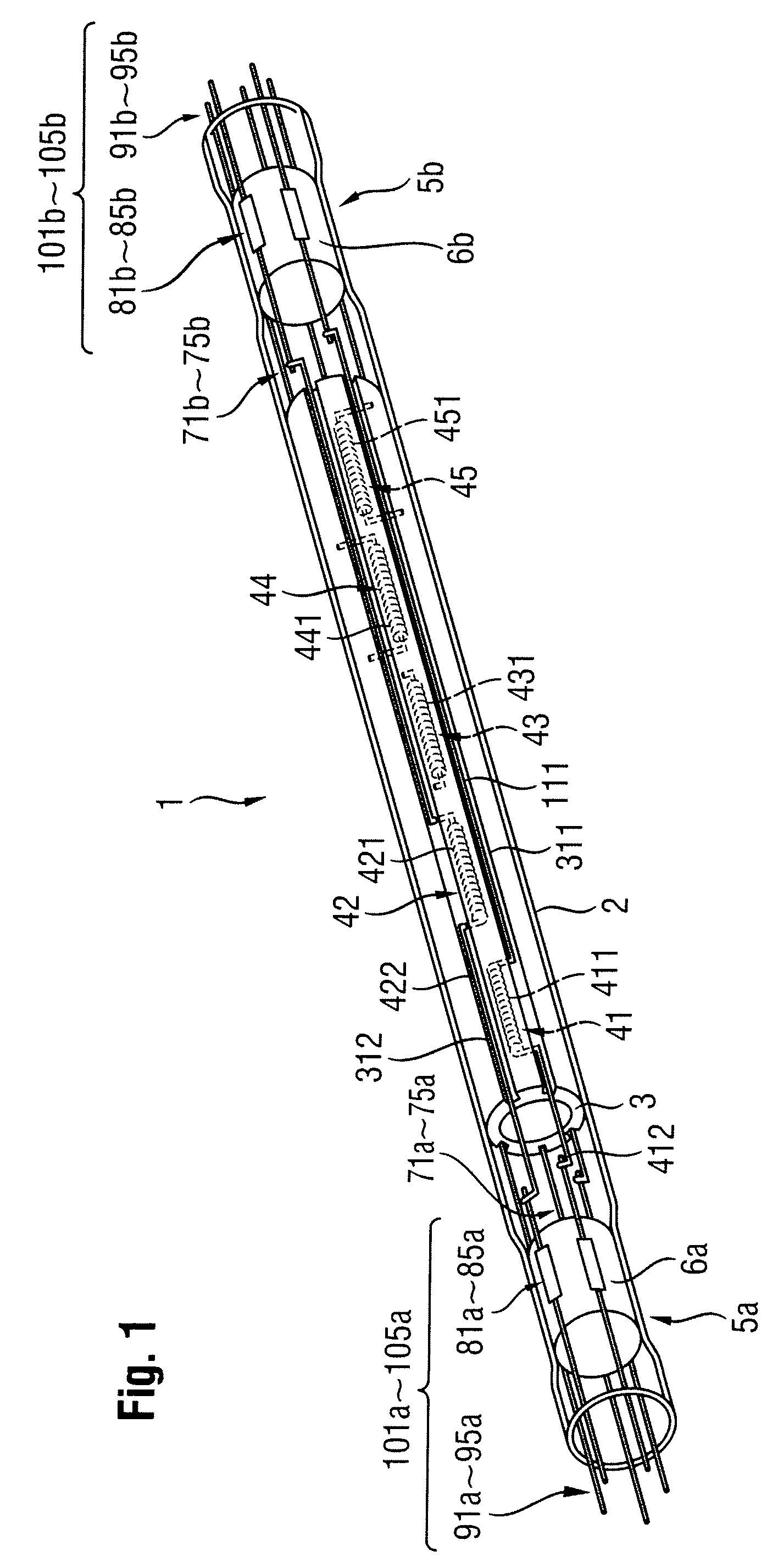

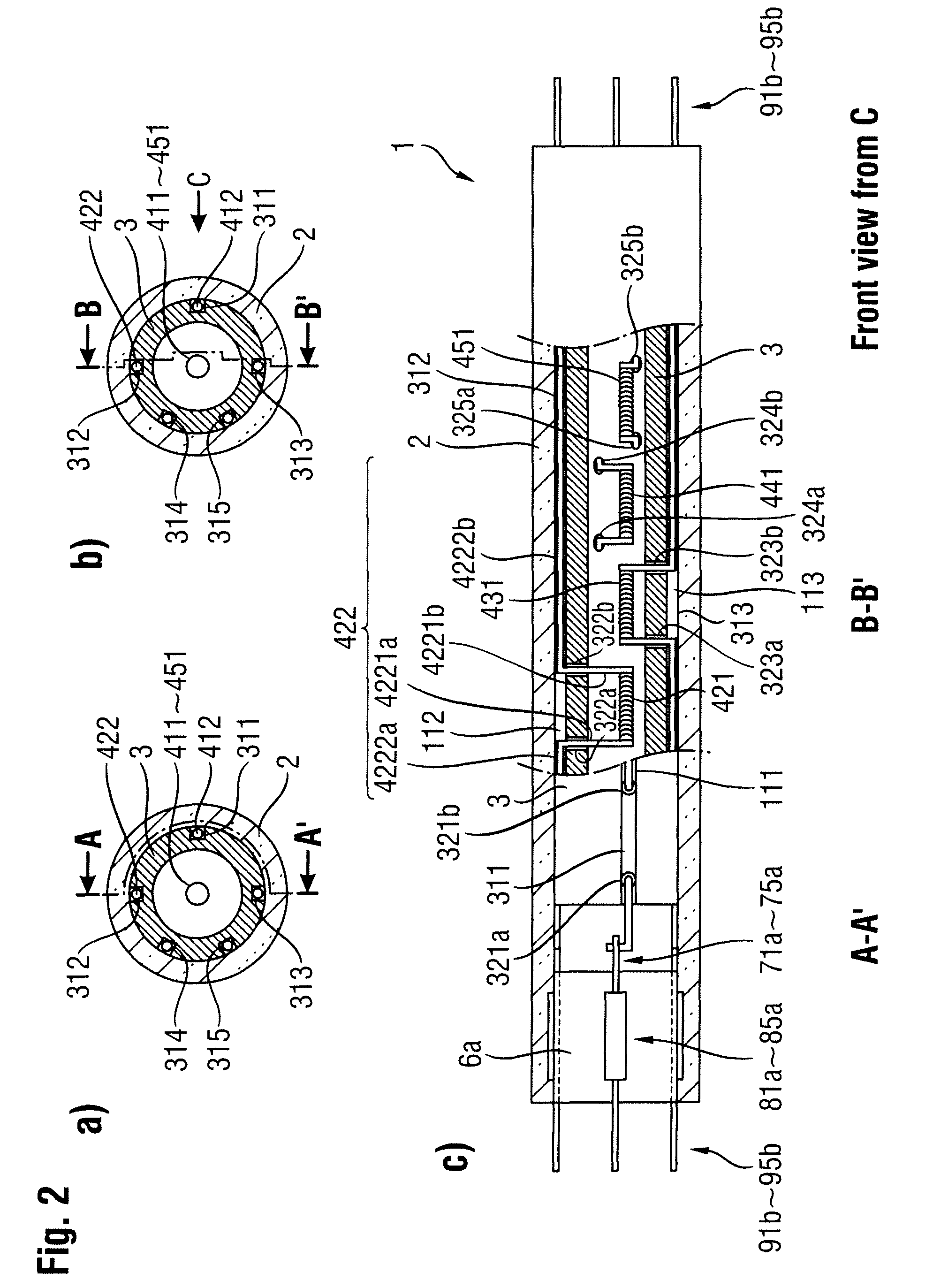

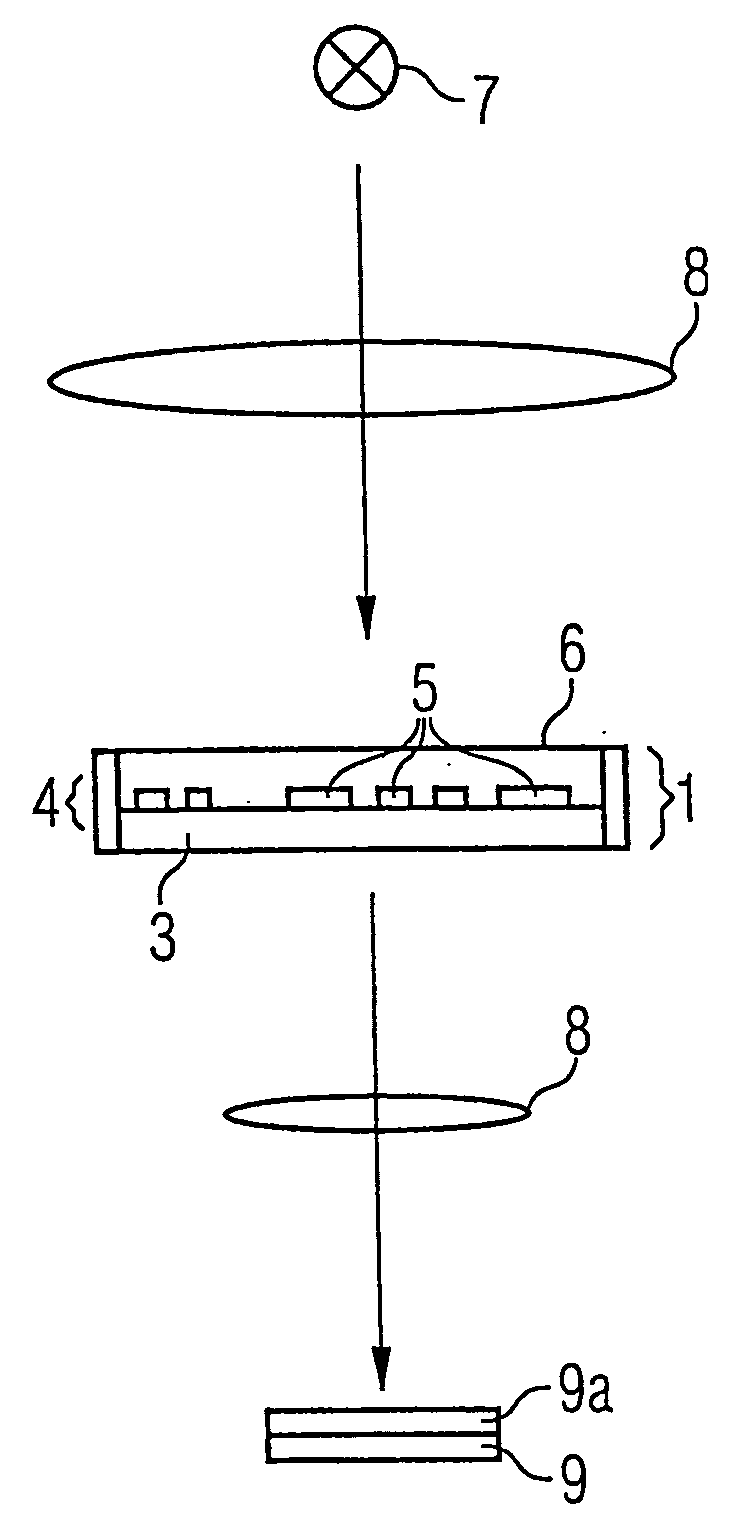

Filament lamp and light-irradiation-type heat treatment device

InactiveUS20080298787A1Suppress unwanted dischargePrecise positioningDomestic stoves or rangesDrying solid materials with heatElectricityLight irradiation

A filament lamp includes multiple filament assemblies having filaments connected to paired leads, arrayed in order within a light emitting tube and following a tube axis thereof. Each lead is electrically connected in a seal area. Each filament is powered independently. The light emitting tube includes insulating walls or inner tubes between the filaments and leads that have openings through which the leads pass, and located along the tube axis in proximity to the inner wall of the light emitting tube. Multiple lead accommodation spaces corresponding to the number of leads are provided in the light emitting tube by the insulating walls with each lead passing through an opening in the insulating wall and placed without short circuits in its lead accommodation space.

Owner:USHIO DENKI KK

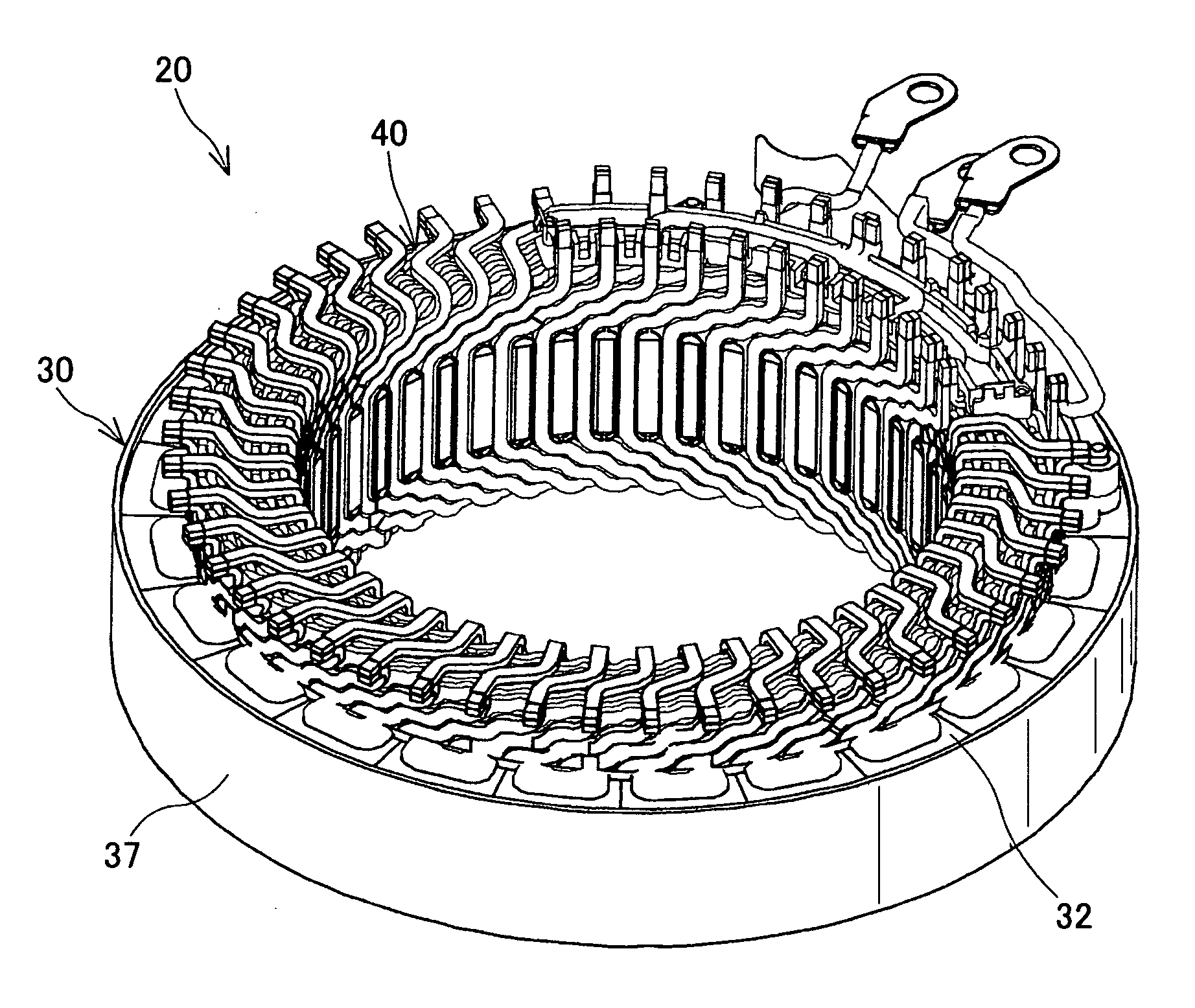

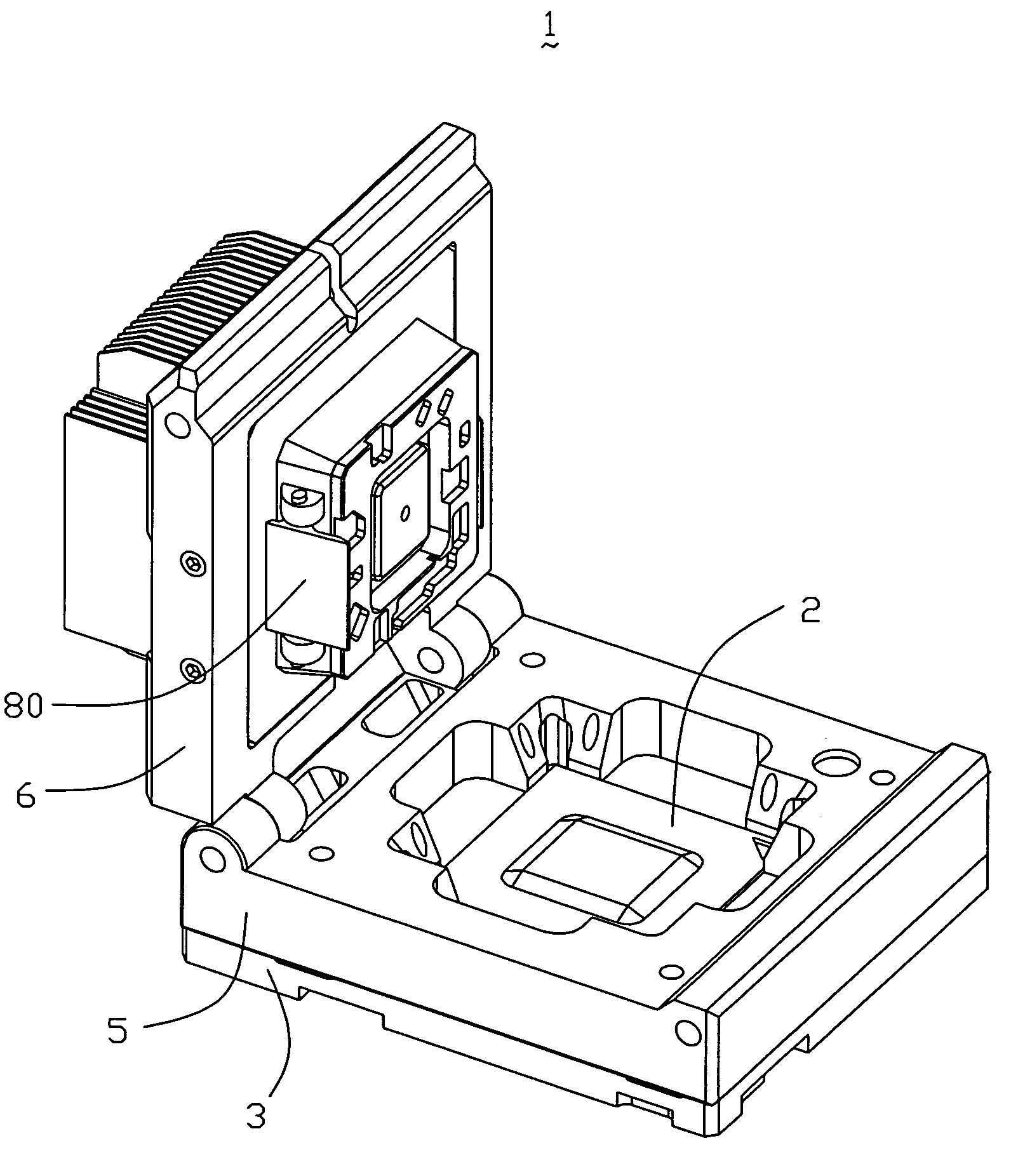

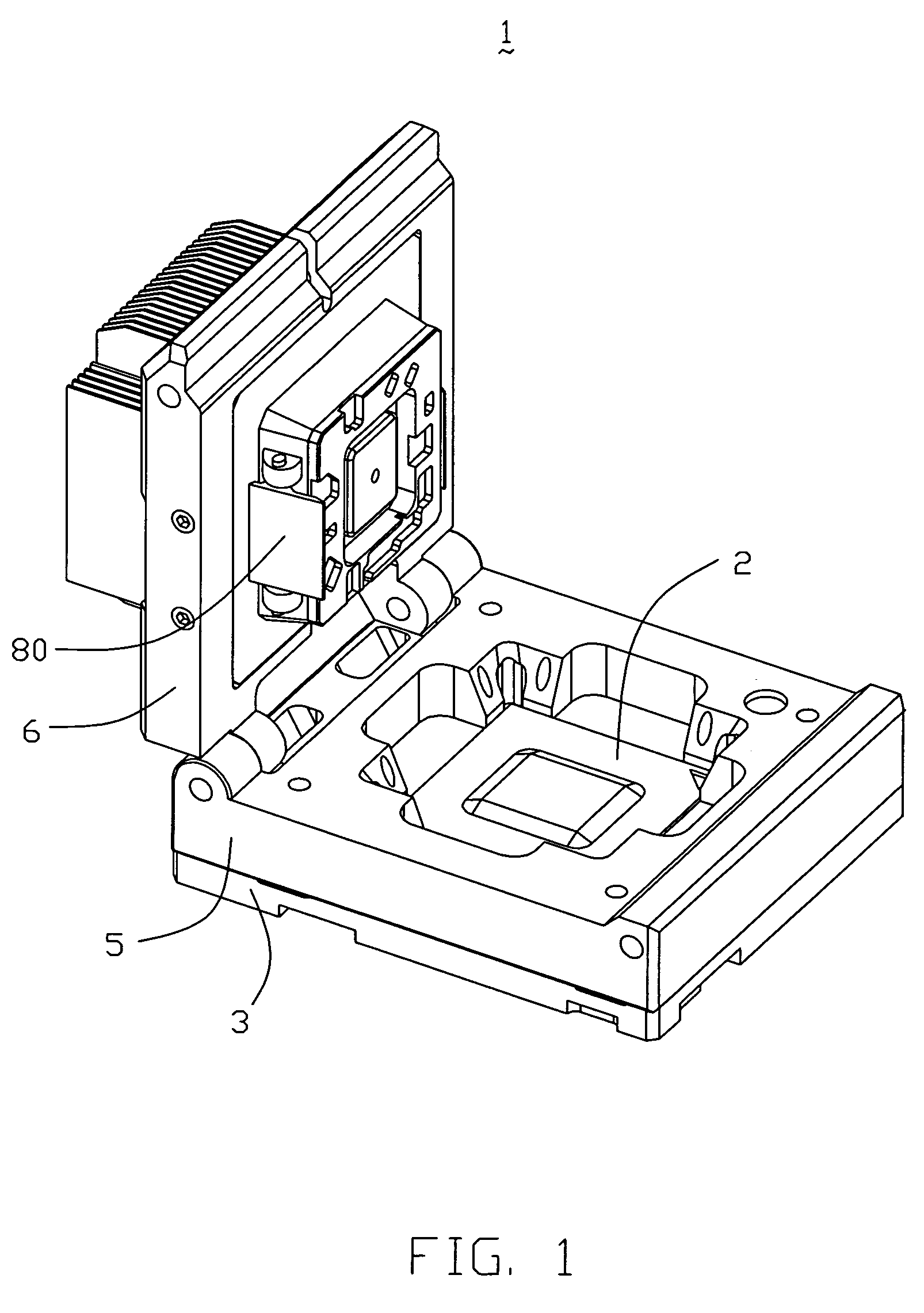

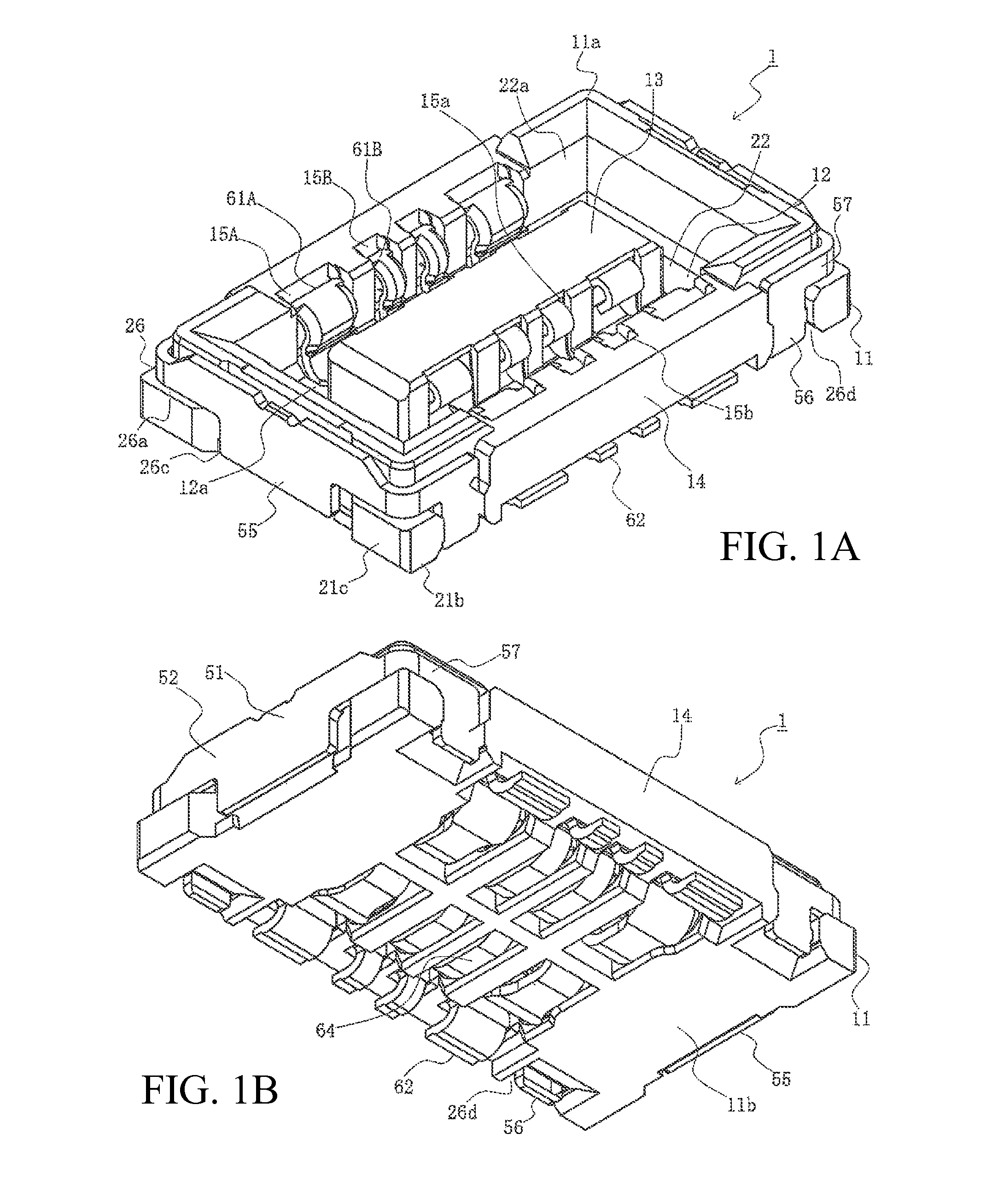

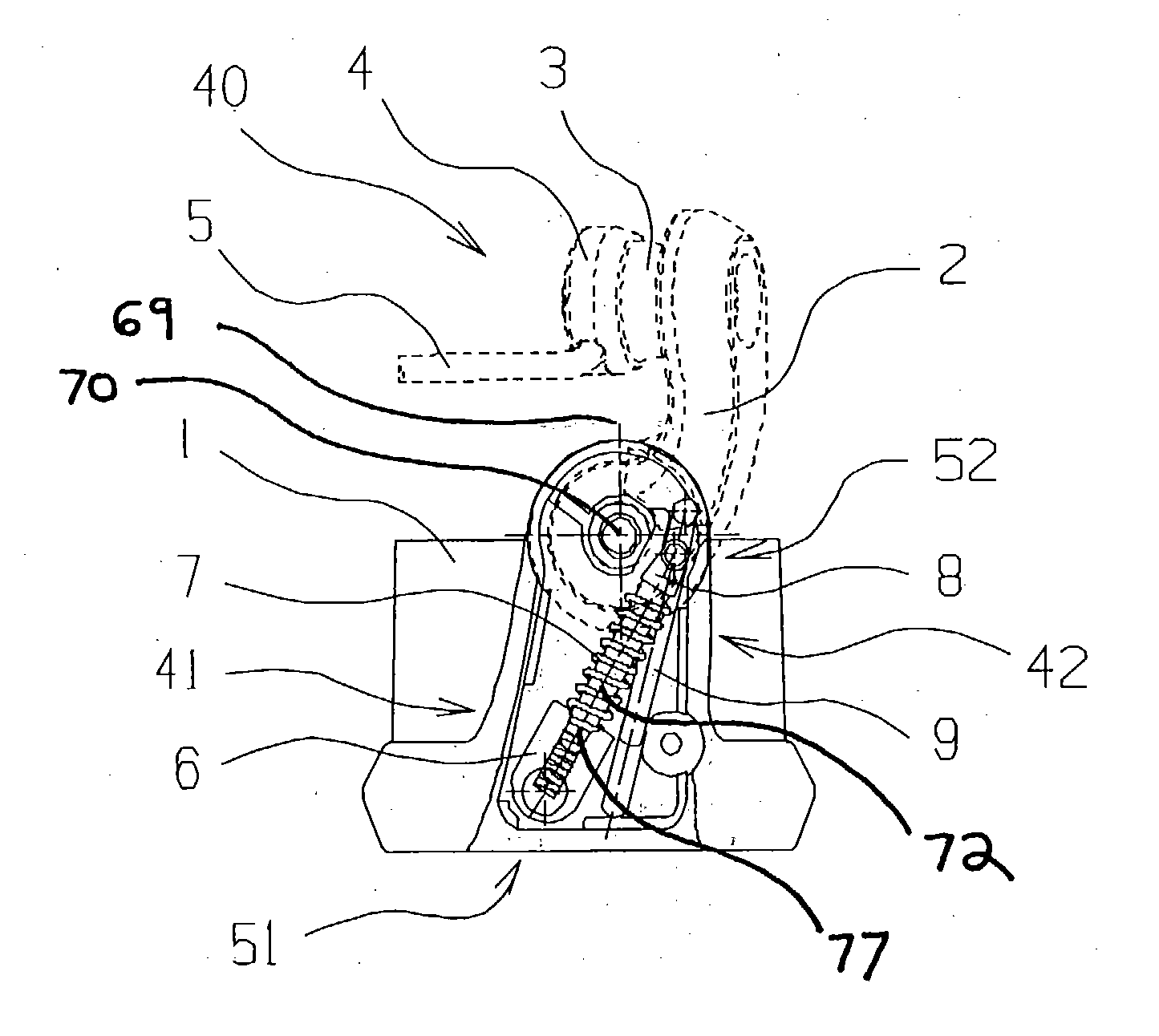

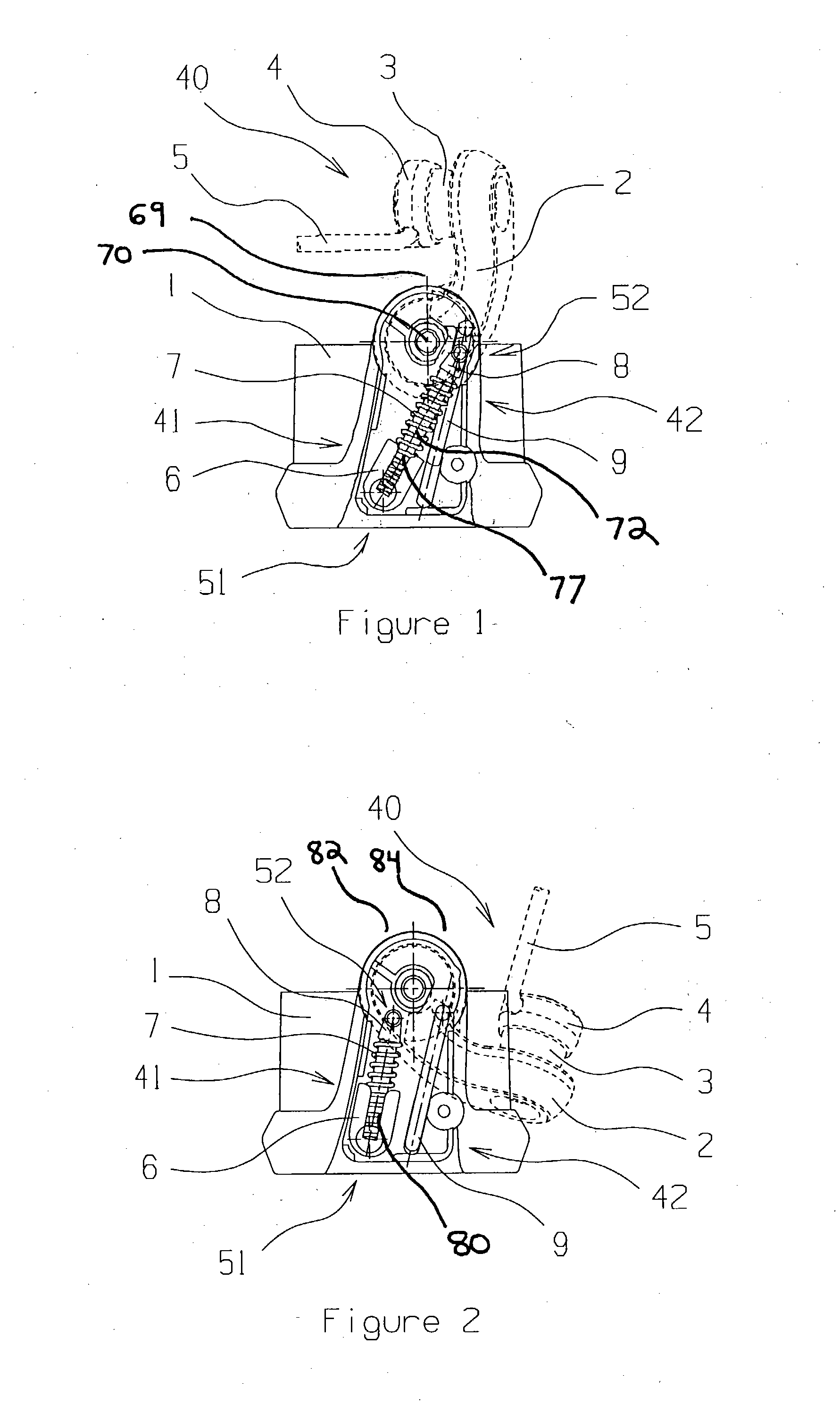

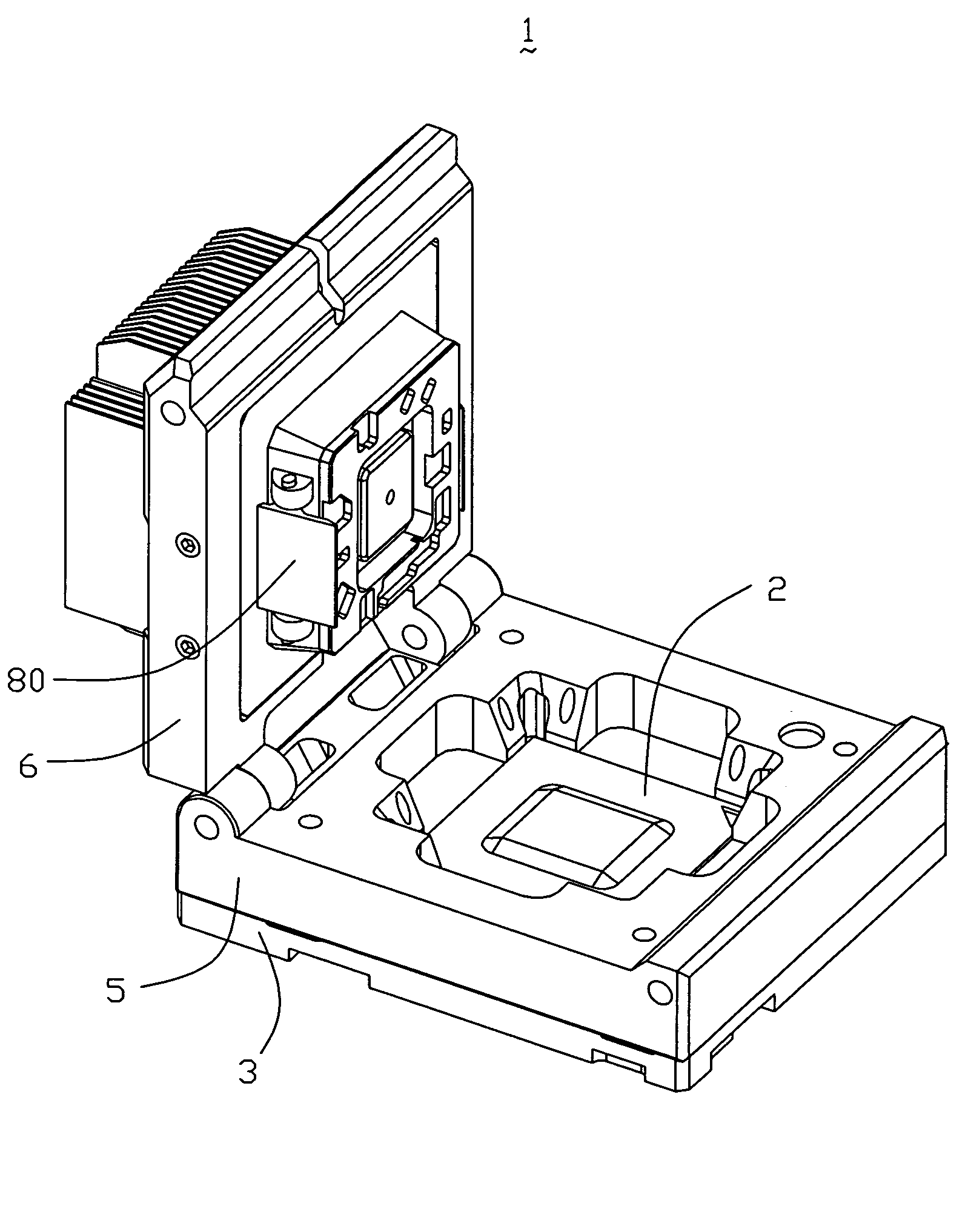

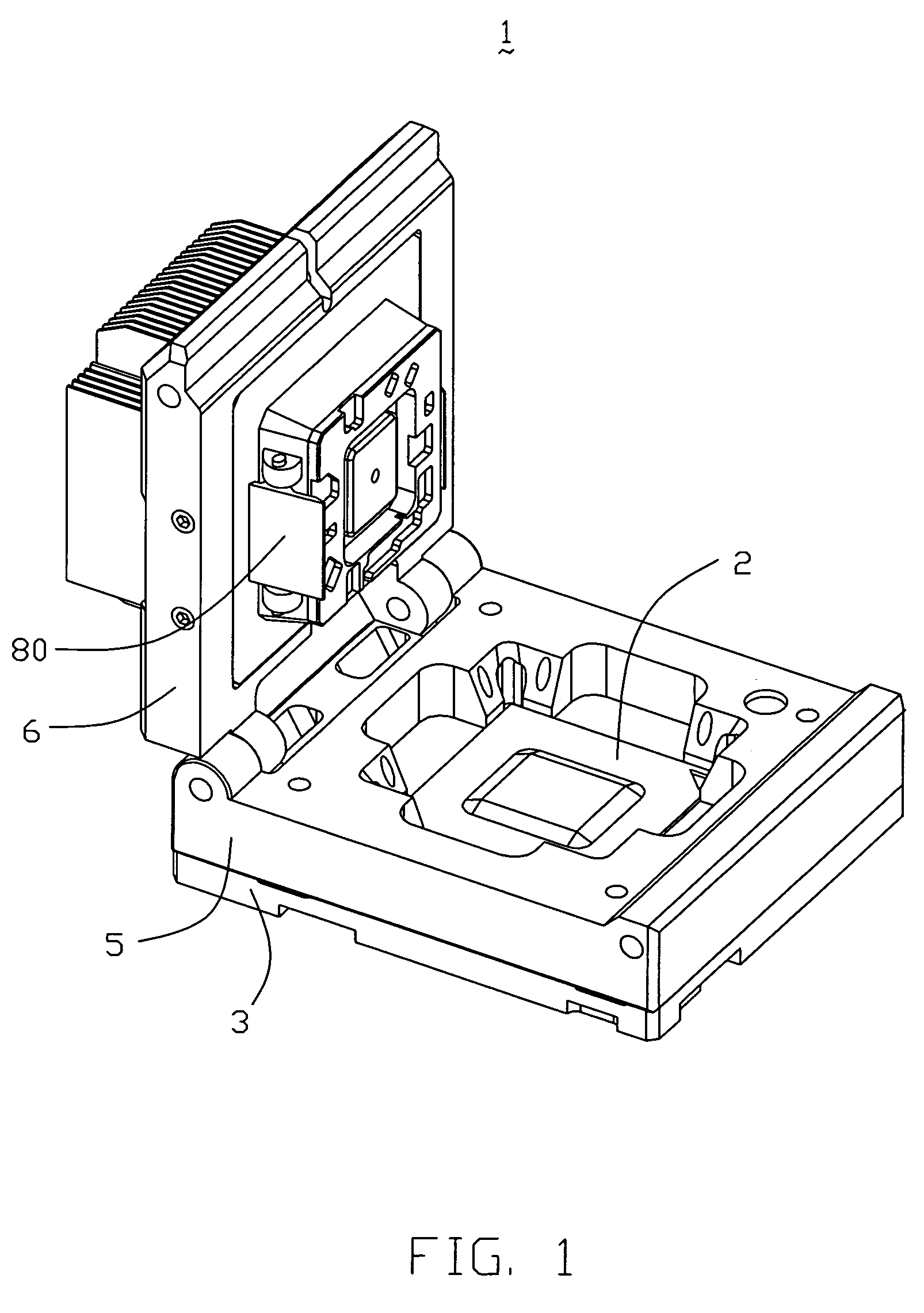

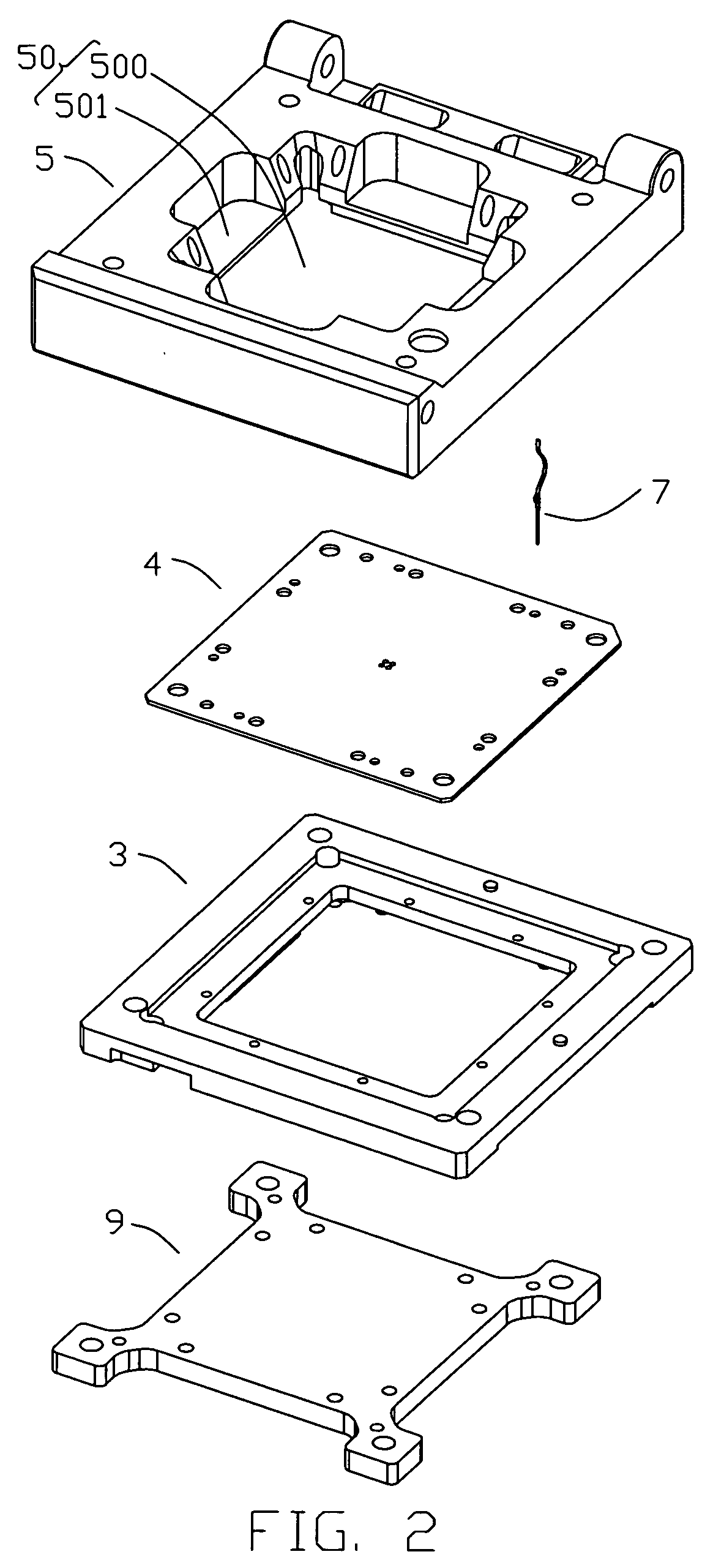

Burn-in socket having pick-up arrangement for quickly pick-up IC package after IC package is tested

InactiveUS7540745B2Kept very reliableEngagement/disengagement of coupling partsElectrical measurement instrument detailsBurn-inEngineering

A burn-in socket for receiving an IC package (2) is provided. The burn-in socket includes a socket body with a plurality of contacts (7) disposed therein and a cover (6) rotatablely coupled to the socket body. The socket body defines a receiving space (500) for receiving the IC package (2) to be tested therein. The cover (6) has a pushing portion (611) capable of pressing on the IC package (2) toward the socket body when the cover (6) is turned to a closed position. At least one pair of pick-up arrangements (8) are provided around the pushing portion (611) for automatic pick-up of the IC package (2).

Owner:HON HAI PRECISION IND CO LTD

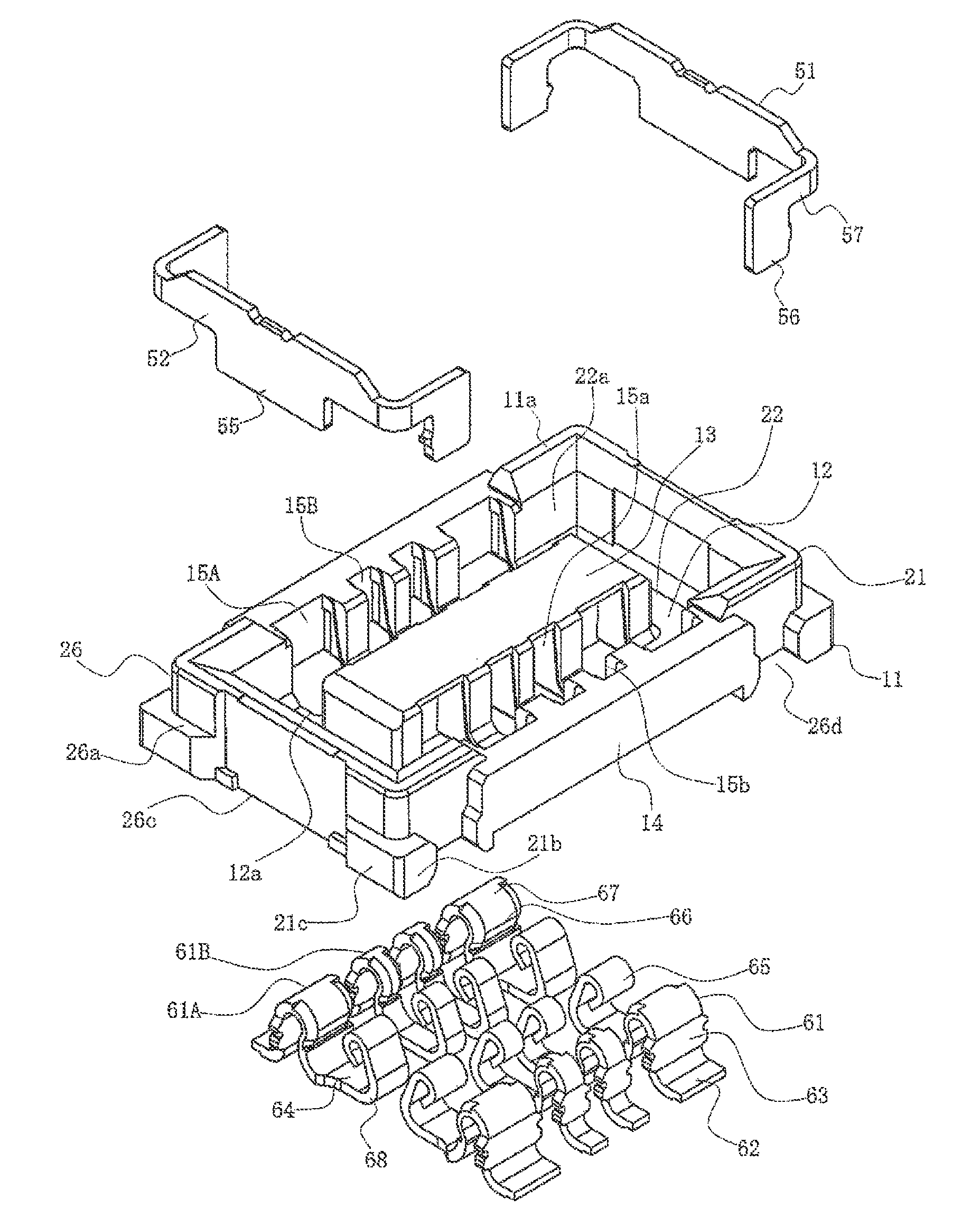

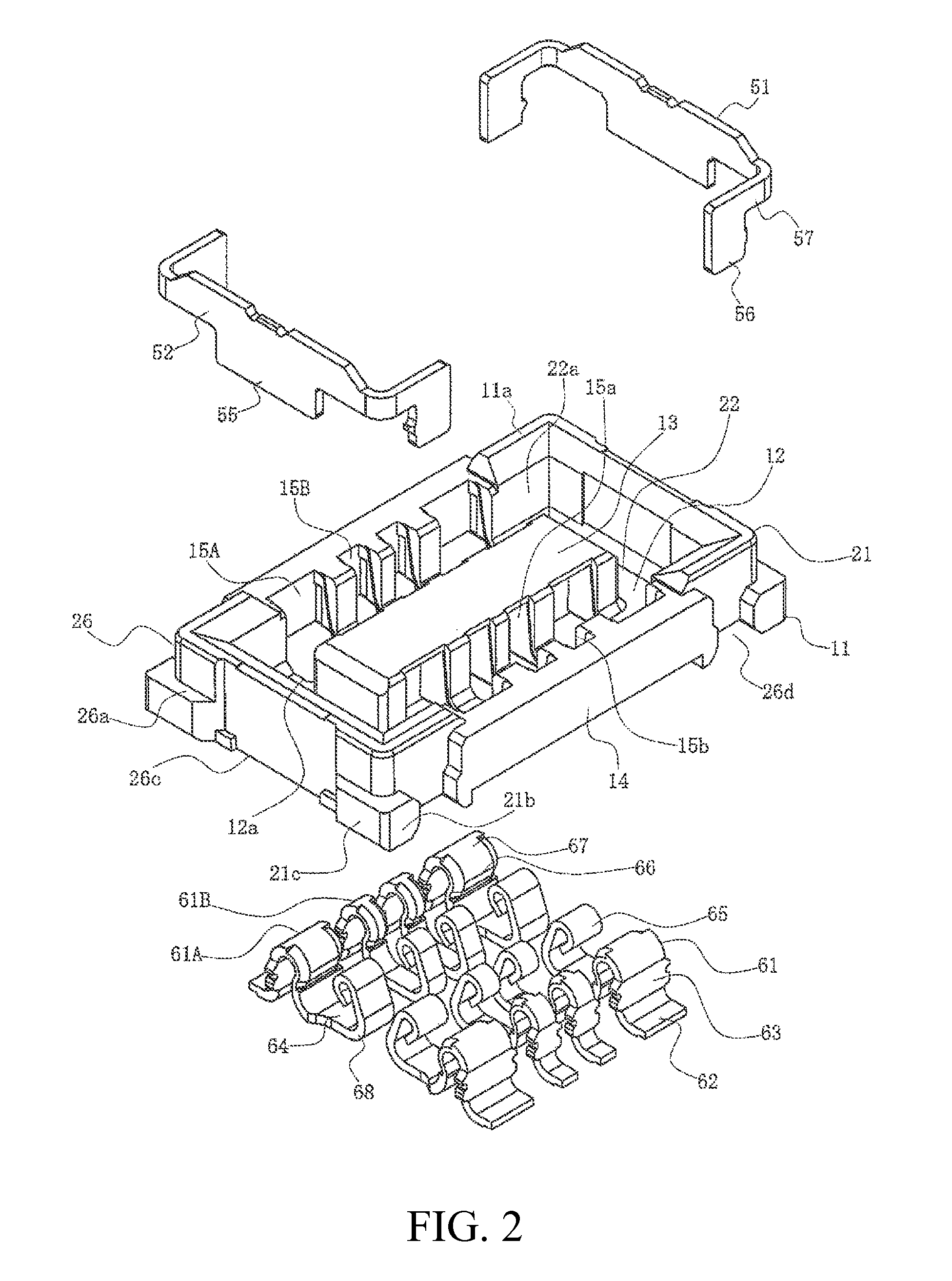

Connector

ActiveUS9356371B2Kept very reliableFirmly connectedNitrous oxide captureCoupling contact membersEngineeringMechanical engineering

A connector comprises a first connector and a second connector. The first connector includes a first connector main body and a plurality of first terminals mounted side by side in the longitudinal direction of the first connector main body on both sides in the transverse direction of the first connector main body. The second connector includes a second connector main body for mating with the first connector main body and a plurality of second terminals mounted side by side in the longitudinal direction of the second connector main body on both sides in the transverse direction of the second connector main body. Each first terminal includes a first contact portion and a second contact portion facing each other. The first contact portion and the second contact portion overlap the corresponding second terminal. The amount of overlap is greater than the amount of clearance in the transverse direction of the first connector main body. Each second terminal is inserted between the first contact portion and the second contact portion of the corresponding first terminal and contacting the first terminal when the first connector main body is mated with the second connector main body.

Owner:MOLEX INC

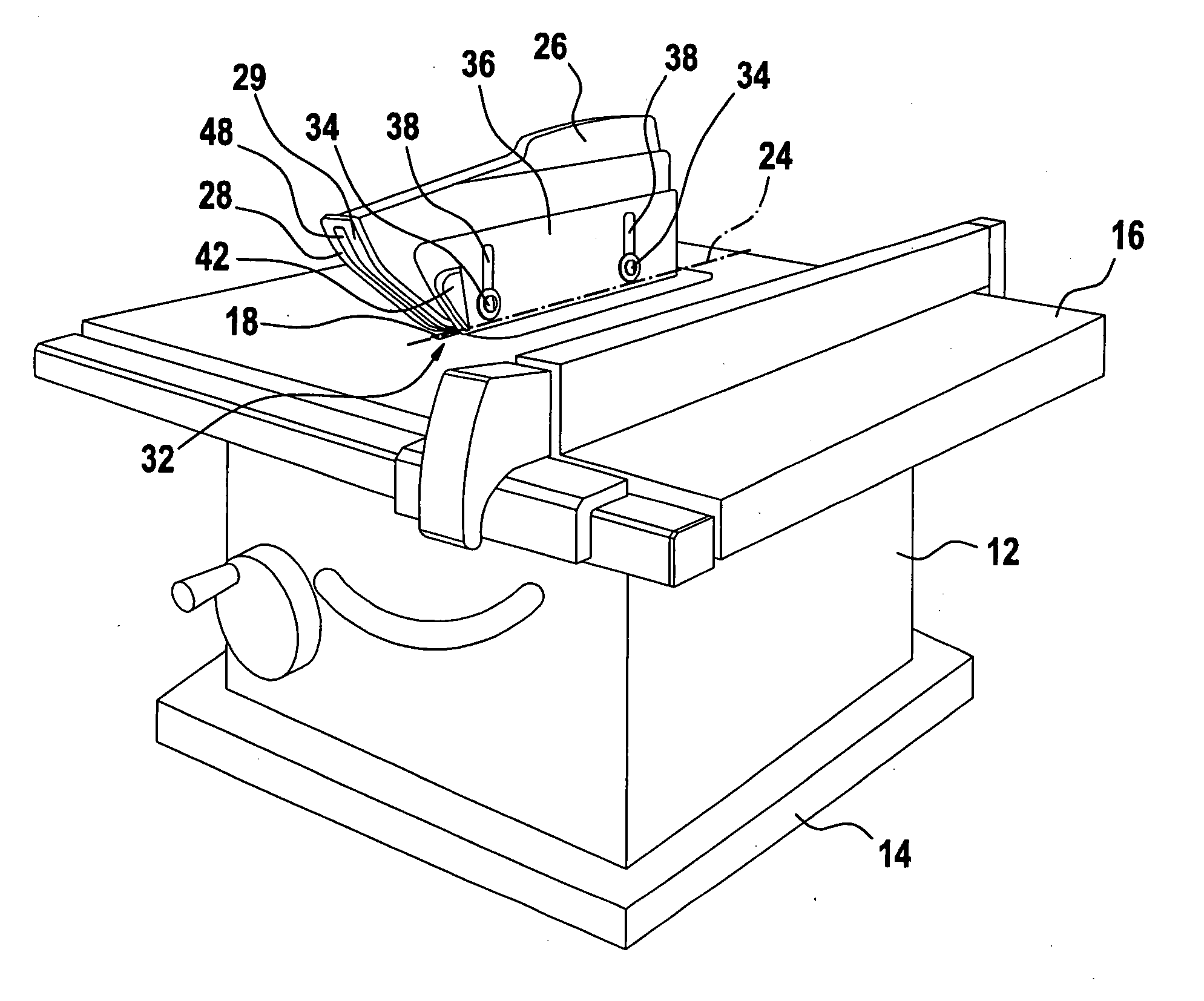

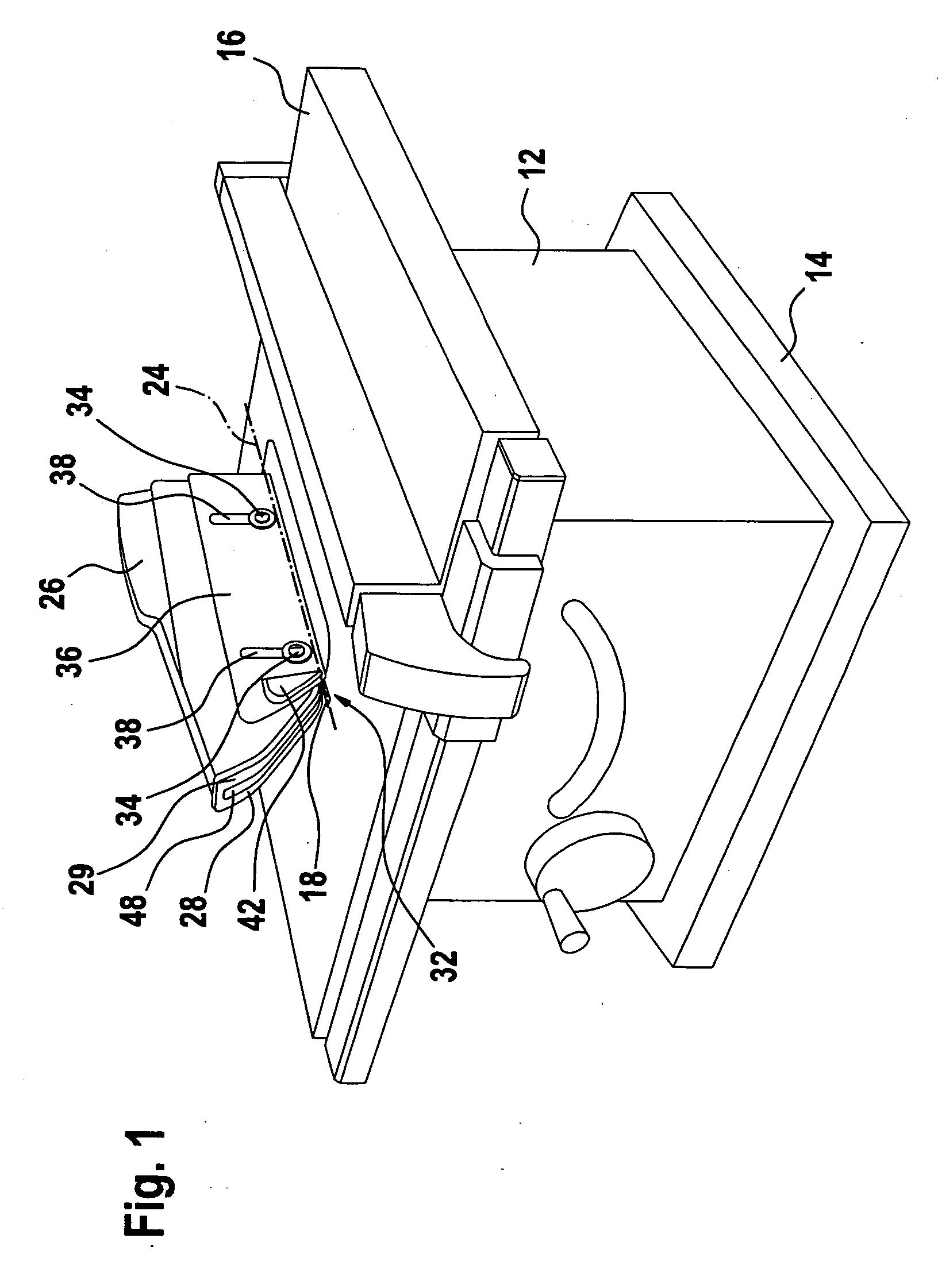

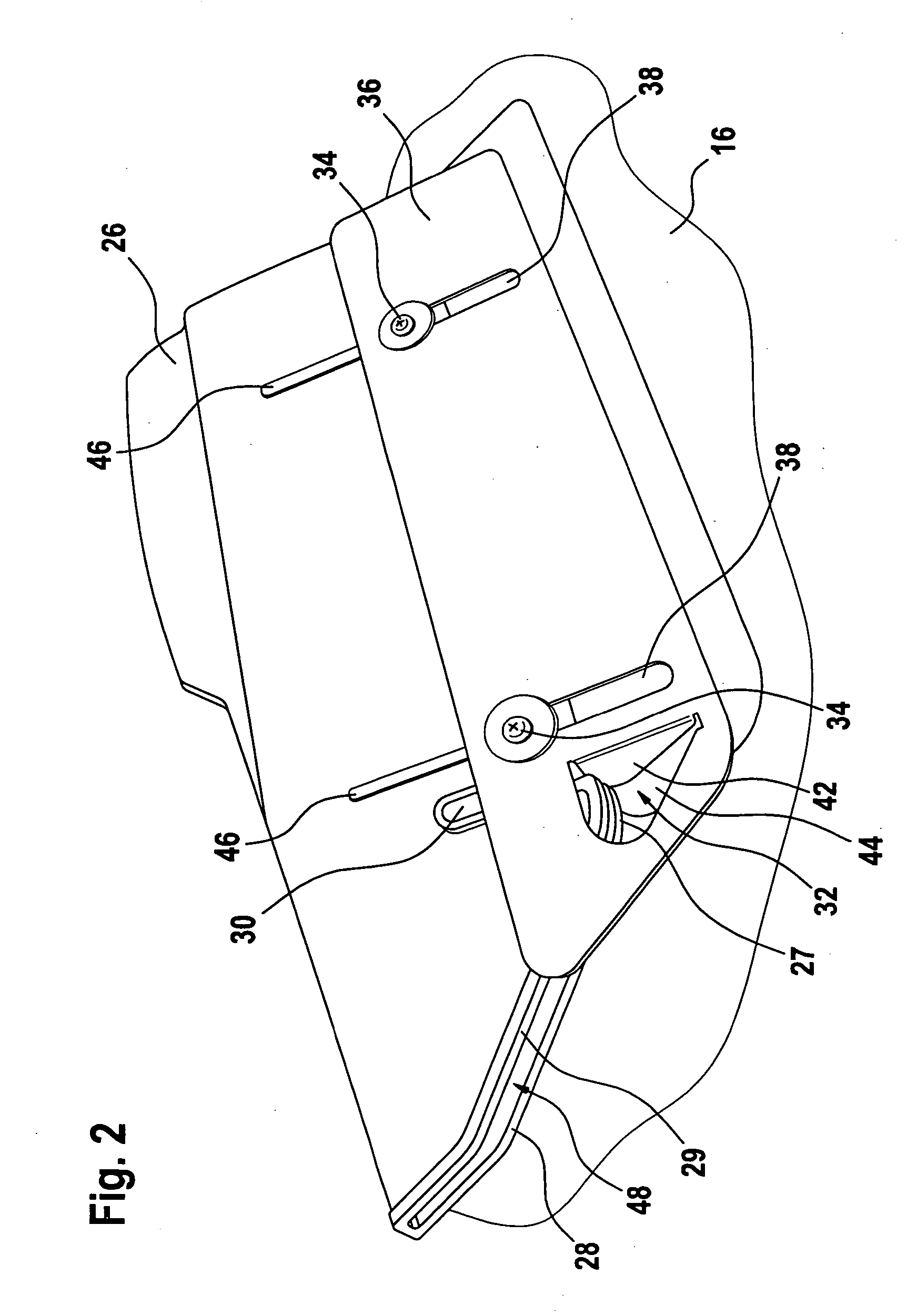

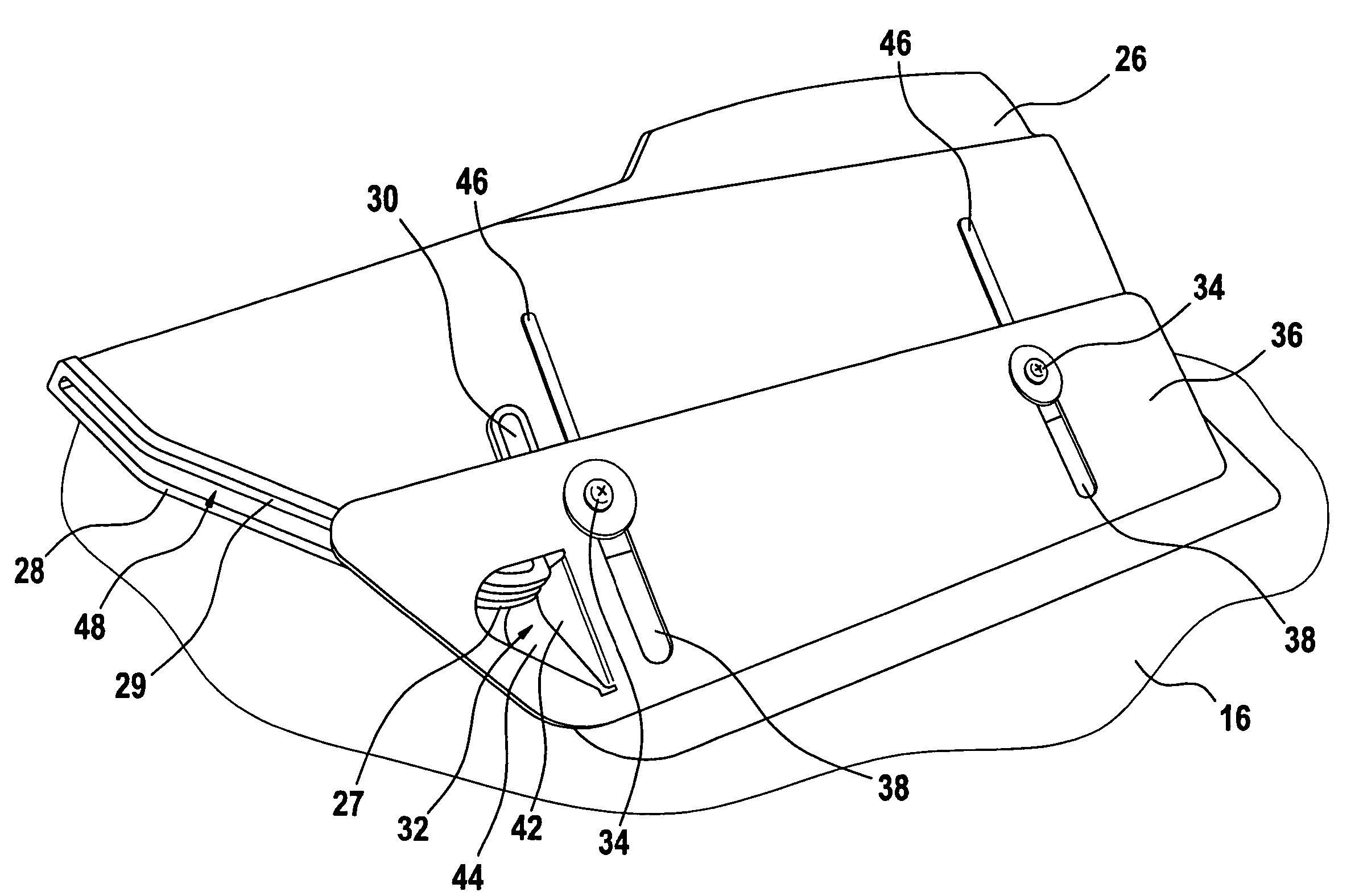

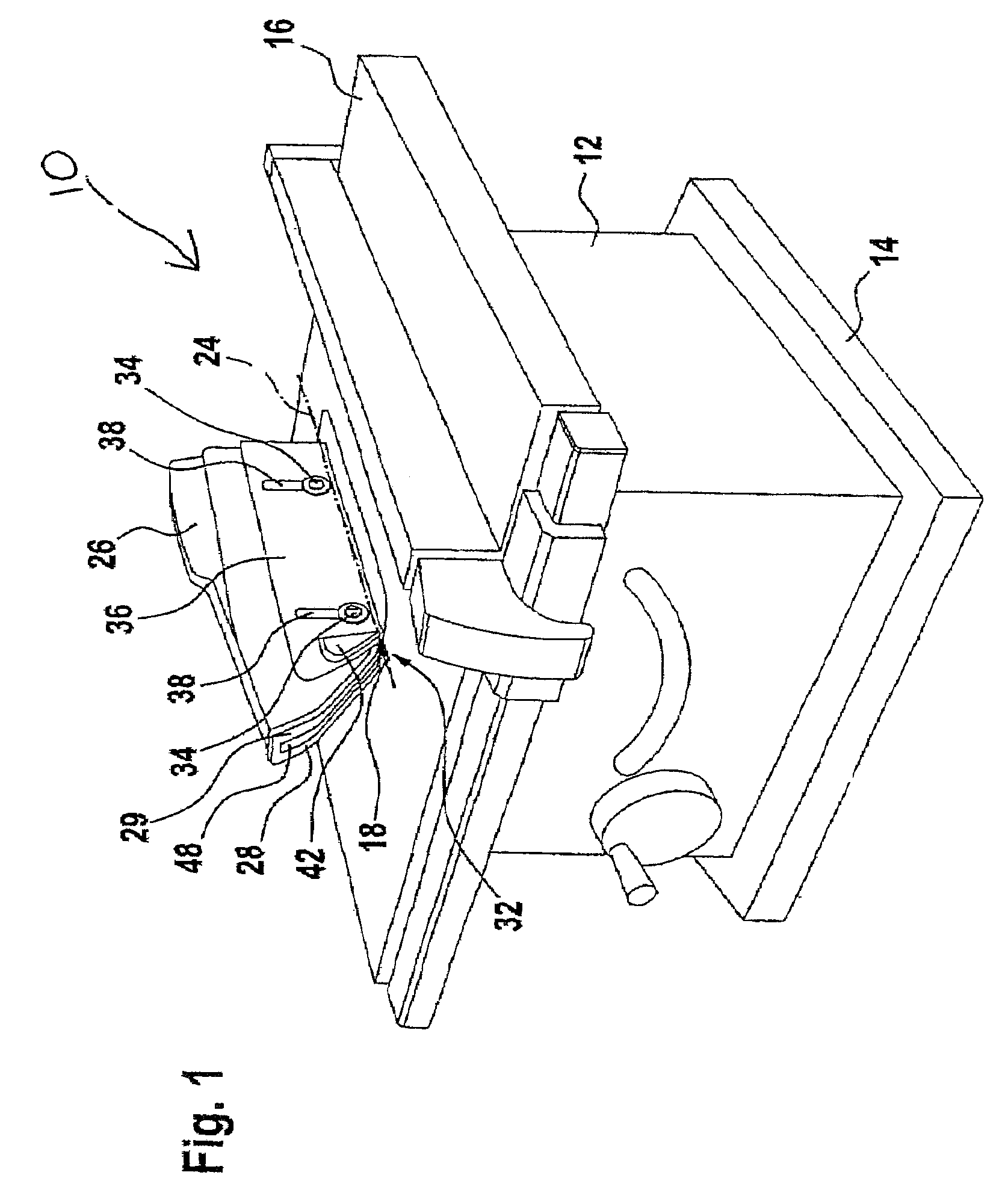

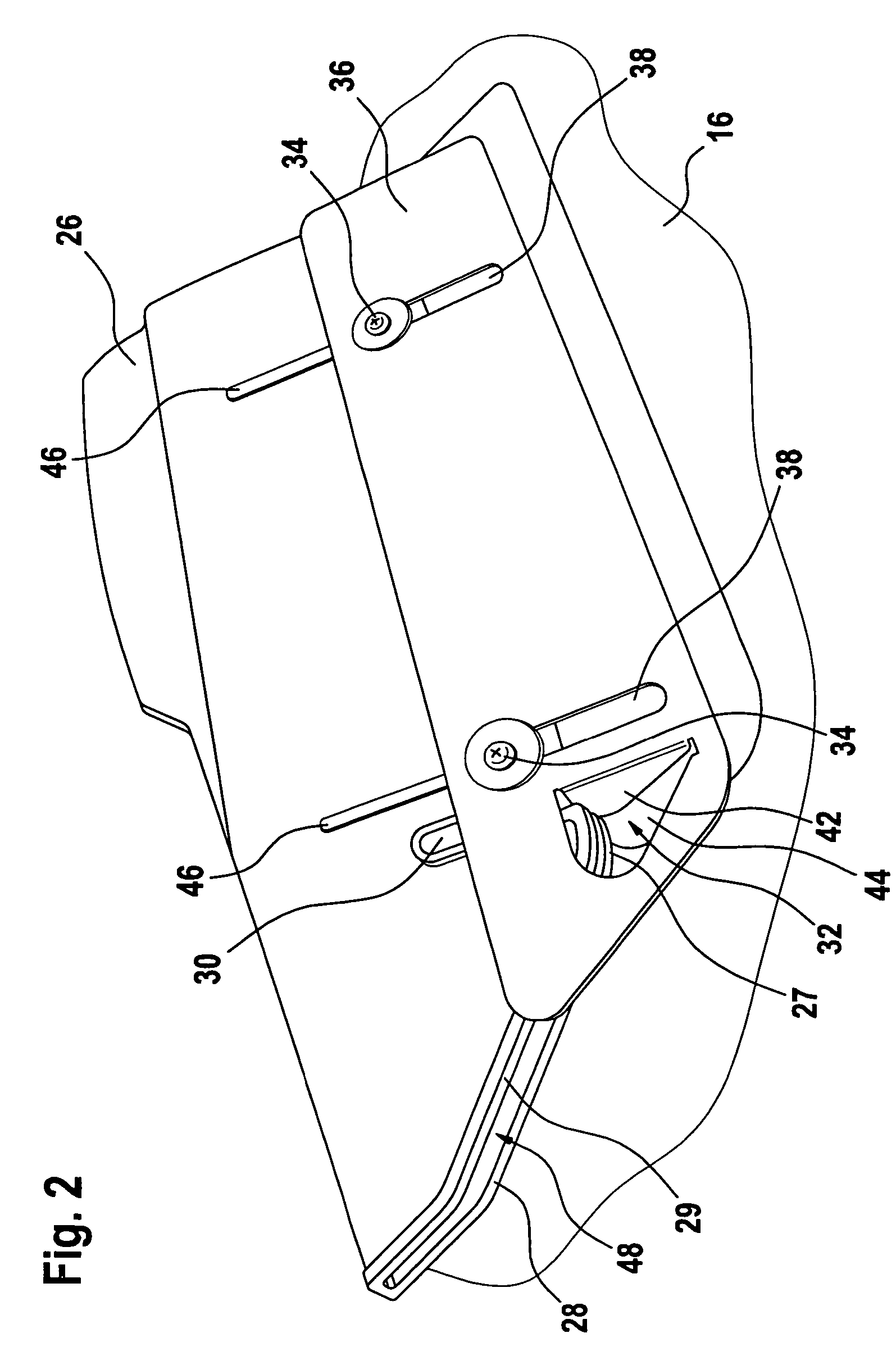

Circular saw bench

InactiveUS20060053993A1Kept very reliableImprove protectionGuide fencesShearing machinesCircular saw

A table saw (10) with a table top (16) over which a saw blade (20) is positioned, whereby the upper region is covered by a guard (26) which is height-adjustable relative to the saw blade (20) in particular, and whereby the saw blade (20) is angularly-displaceable relative to the table top (16), whereby a gap (30) is located between the guard (26) and the table top (16). The table saw is made safer to handle by the fact that the guard (26) includes a protective panel (36) which is movably supported relative to the guard (26) and closes the gap (30) in a manner in particular such that it cannot be penetrated by the operator's fingers.

Owner:ROBERT BOSCH GMBH

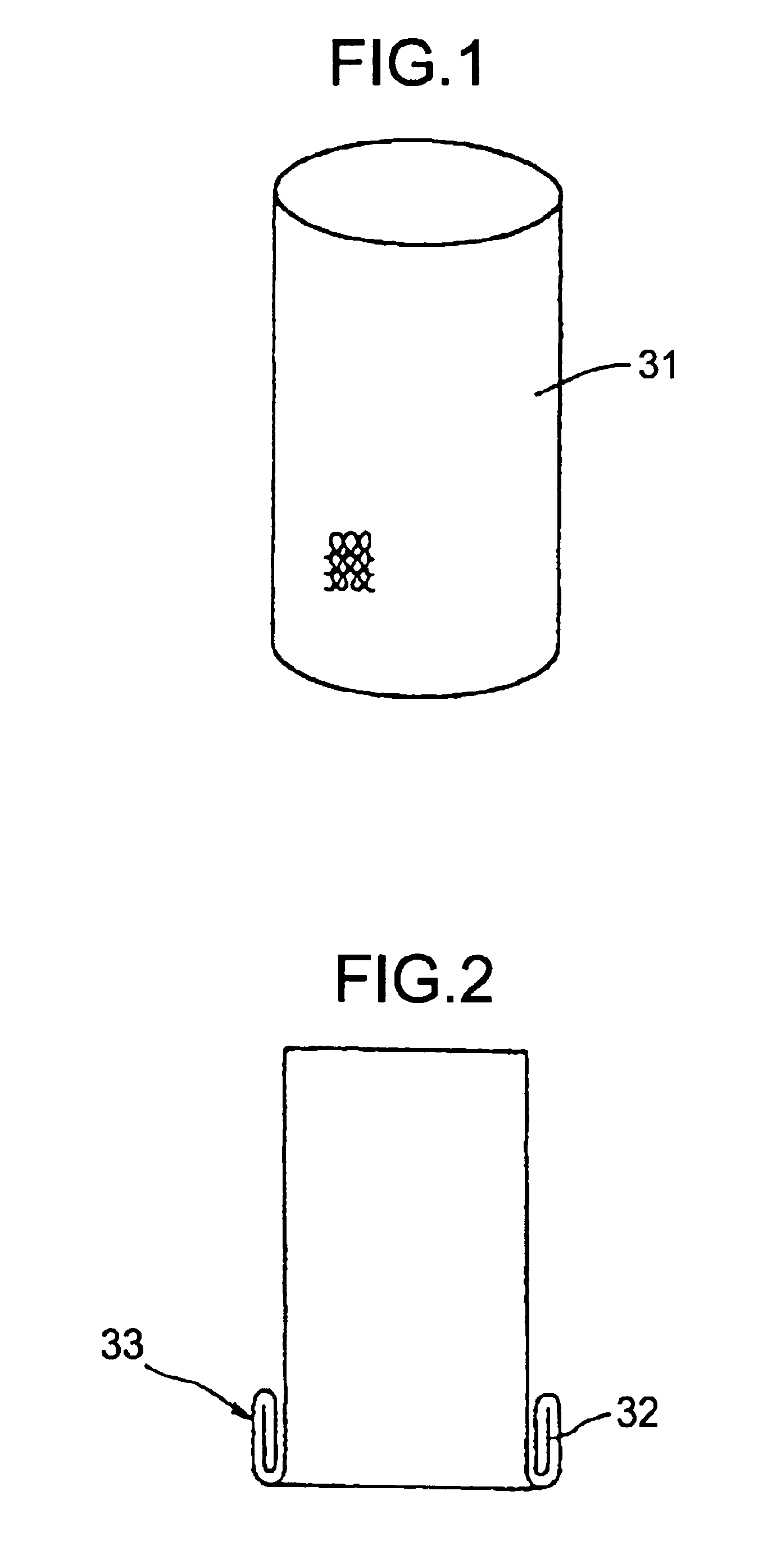

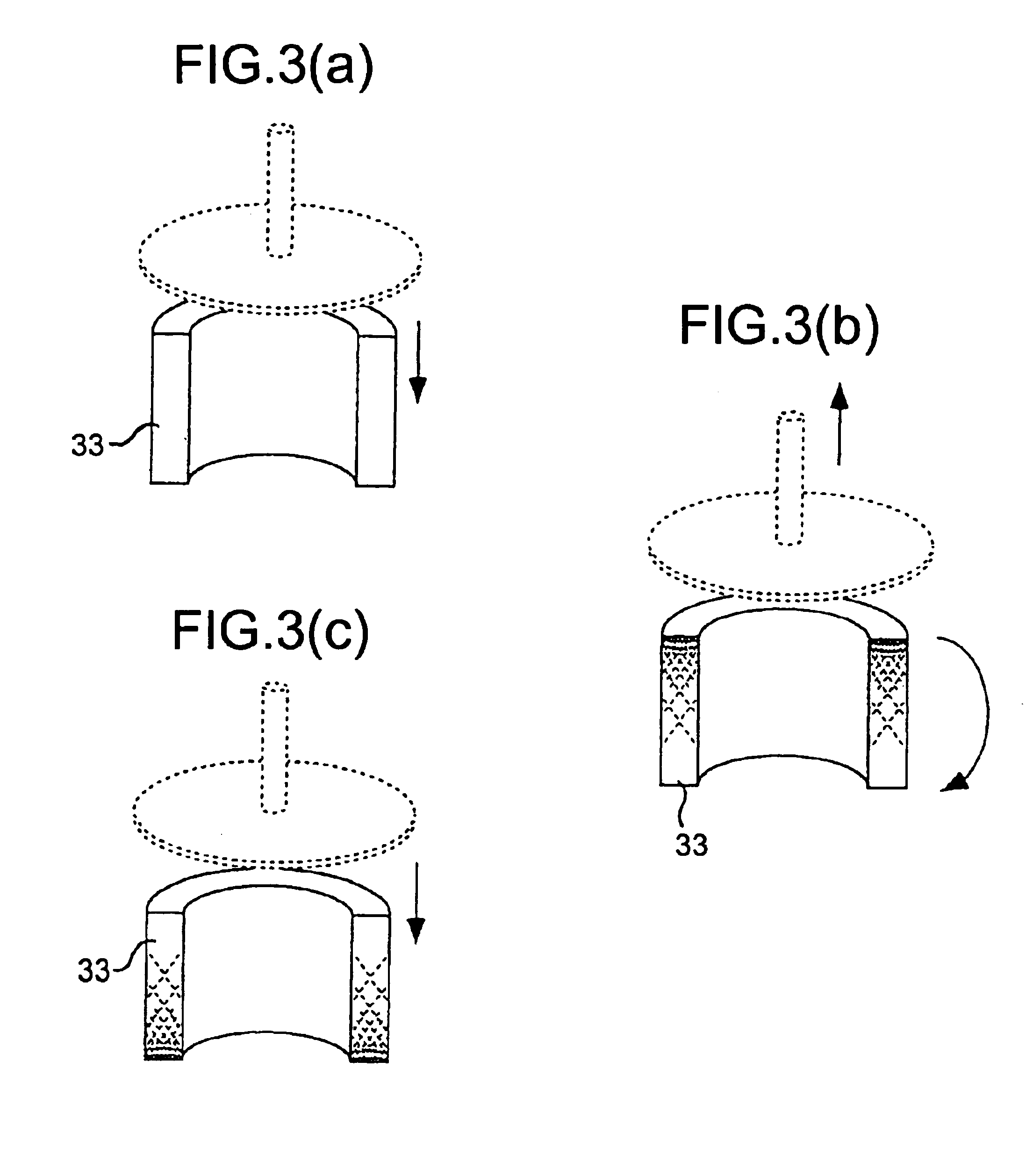

Tank holding mechanism for gas tank and vehicle in which gas tank is mounted using the same

ActiveUS20110174856A1Reliable holdLow costReactant parameters controlTank vehiclesFuel tankMount used

A tank holding mechanism holds a gas tank that has a cylindrical portion and hemispherical-shaped domical portions formed on respective sides of the cylindrical portion. The tank holding mechanism includes: a tank accommodating portion that contacts a peripheral wall of the cylindrical portion of the gas tank; tank end-side members provided near respective ends of the gas tank; a tank band that pushes the gas tank against the tank accommodating portion; and band securing portions that secure end portions of the tank band to the respective tank end-side members. The tank band is routed from one of the domical portions through the cylindrical portion to the other domical portion. The tank band extends along a diagonal line of the gas tank over an outer face of the cylindrical portion, conforms to the outer face of the cylindrical portion, and conforms to hemispherical outer faces of both of the domical portions.

Owner:TOYOTA JIDOSHA KK

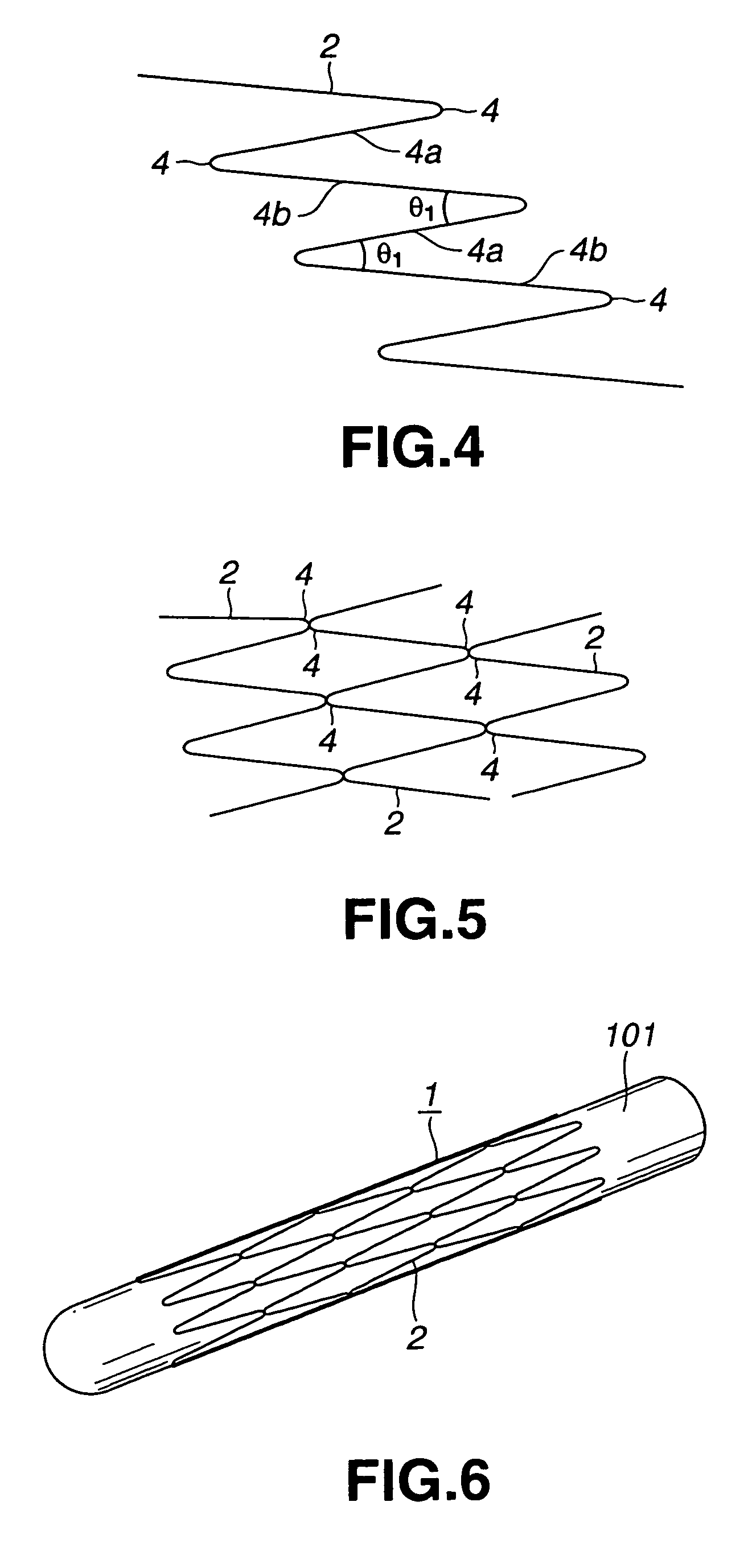

Stent for vessel

A stent for a vessel implanted in the vessel of the living body including a main body portion of the stent formed into a tube by a yarn formed of a biodegradable polymer exhibiting a shape memory function. The main body portion of the stent is shape-memorized to a size that can be inplanted in the vessel. The main body portion of the stent is implanted in the vessel of the living body as it is contracted in diameter by an external force, and is enlarged in diameter by being heated with the temperature of the living body. The main body portion of the stent is formed by winding a yarn formed of a biodegradable polymer in a tube form as the yarn is bent in a zigzag design. The main body portion of the stent is enlarged or contracted in diameter with the bends of the yarn as the displacing portions.

Owner:IGAKI IRYO SEKKEI

Filament lamp and light-irradiation-type heat treatment device

InactiveUS8014652B2Suppress unwanted dischargePrecise positioningDomestic stoves or rangesDrying solid materials with heatElectricityLight irradiation

Owner:USHIO DENKI KK

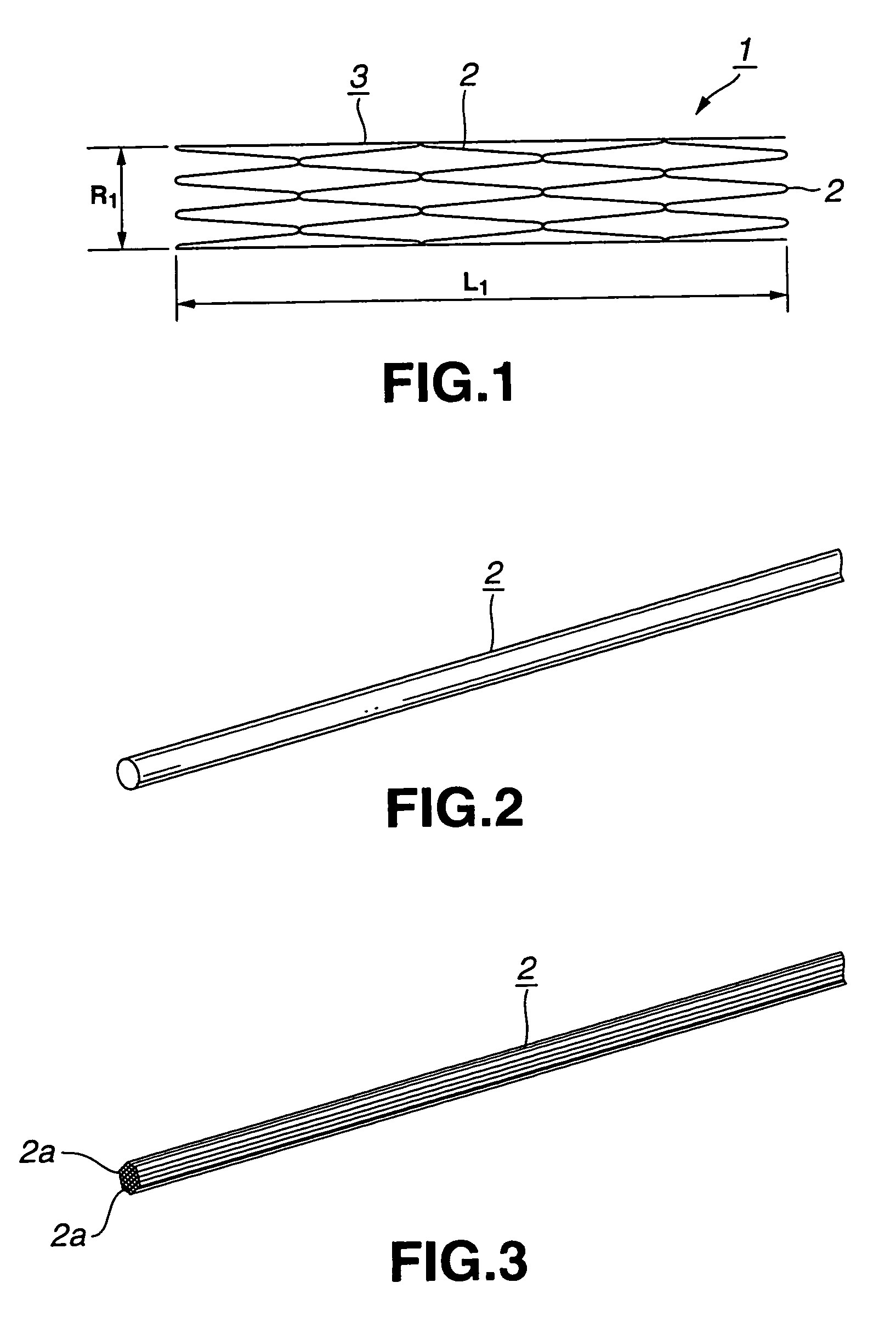

Coolant for air-bag gas generator and production method therefor

InactiveUS6840977B1Improve output performanceLow temperature generationCombination devicesAuxillary pretreatmentWire rodProduct gas

The present invention provides a coolant for an air bag inflator in which unevenness in density in the axial direction is reduced even though the coolant is compressed in its axial direction.The coolant is a molded product made of wire rods and compressed in its axial direction. An absolute value of a difference between a radial pressure loss of the axially upper half portion of the coolant and a radial pressure loss of the axially lower half portion of the coolant is 10 mm H2O or less at a flow rate of 250 liters / minute under the atmosphere of 20° C.

Owner:DAICEL CHEM IND LTD +2

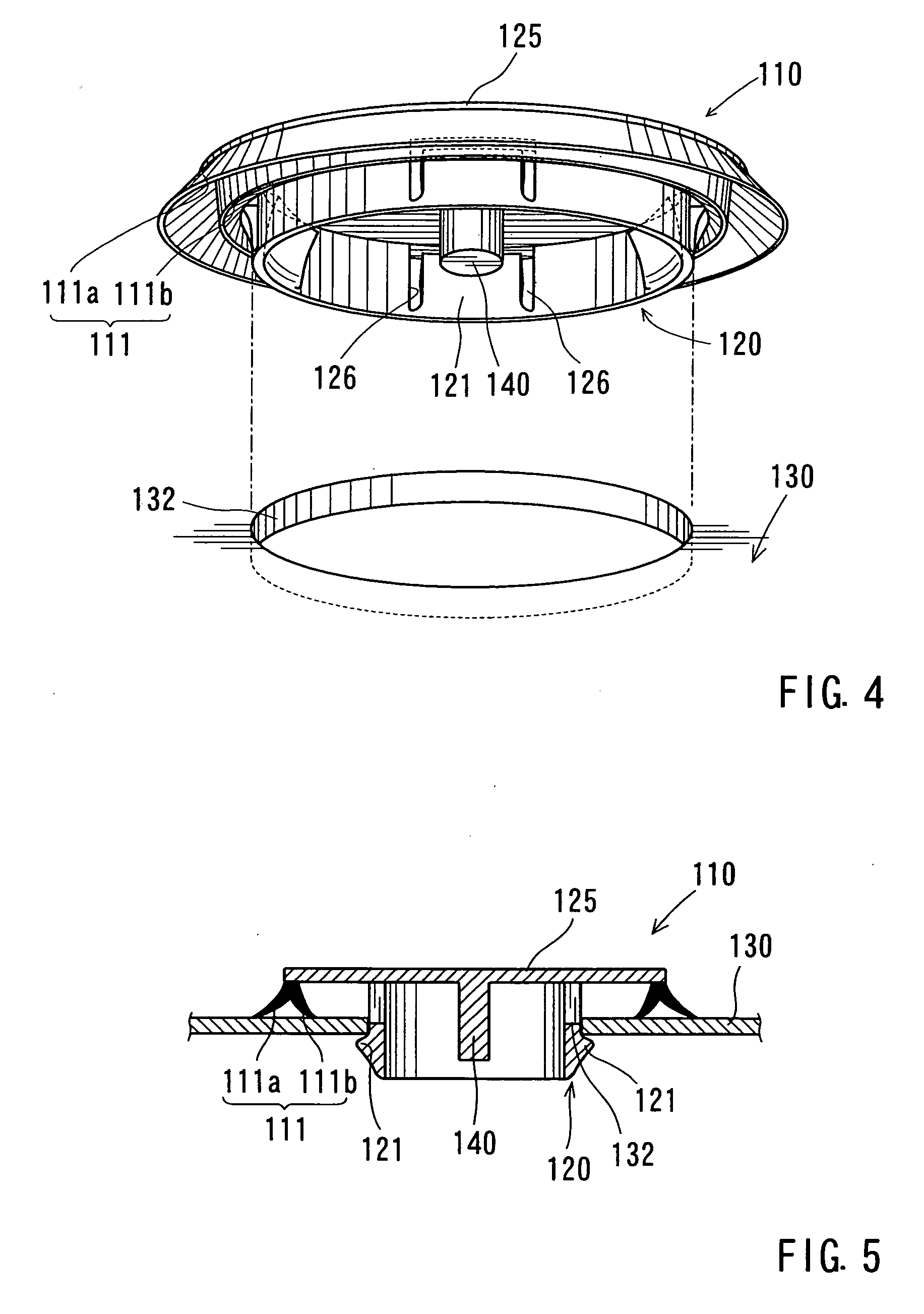

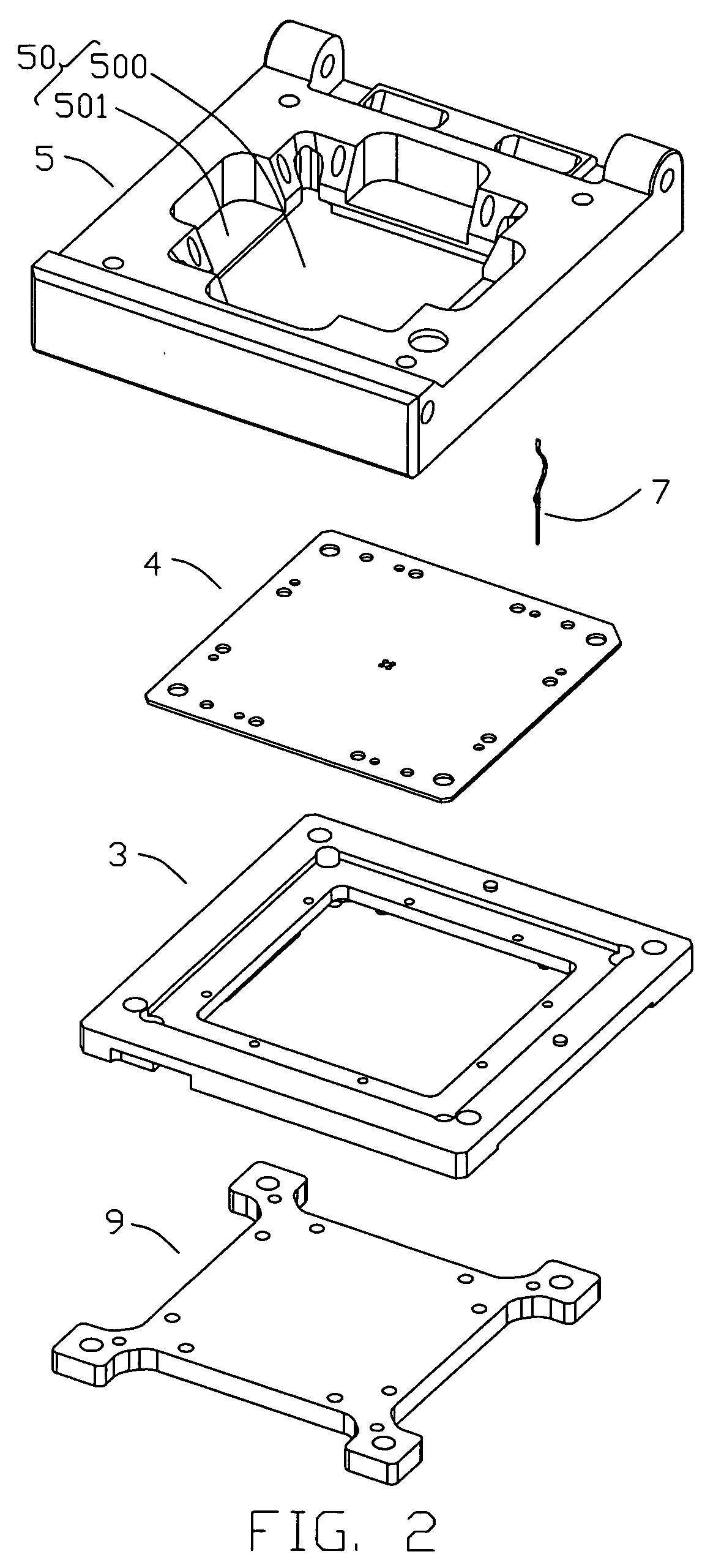

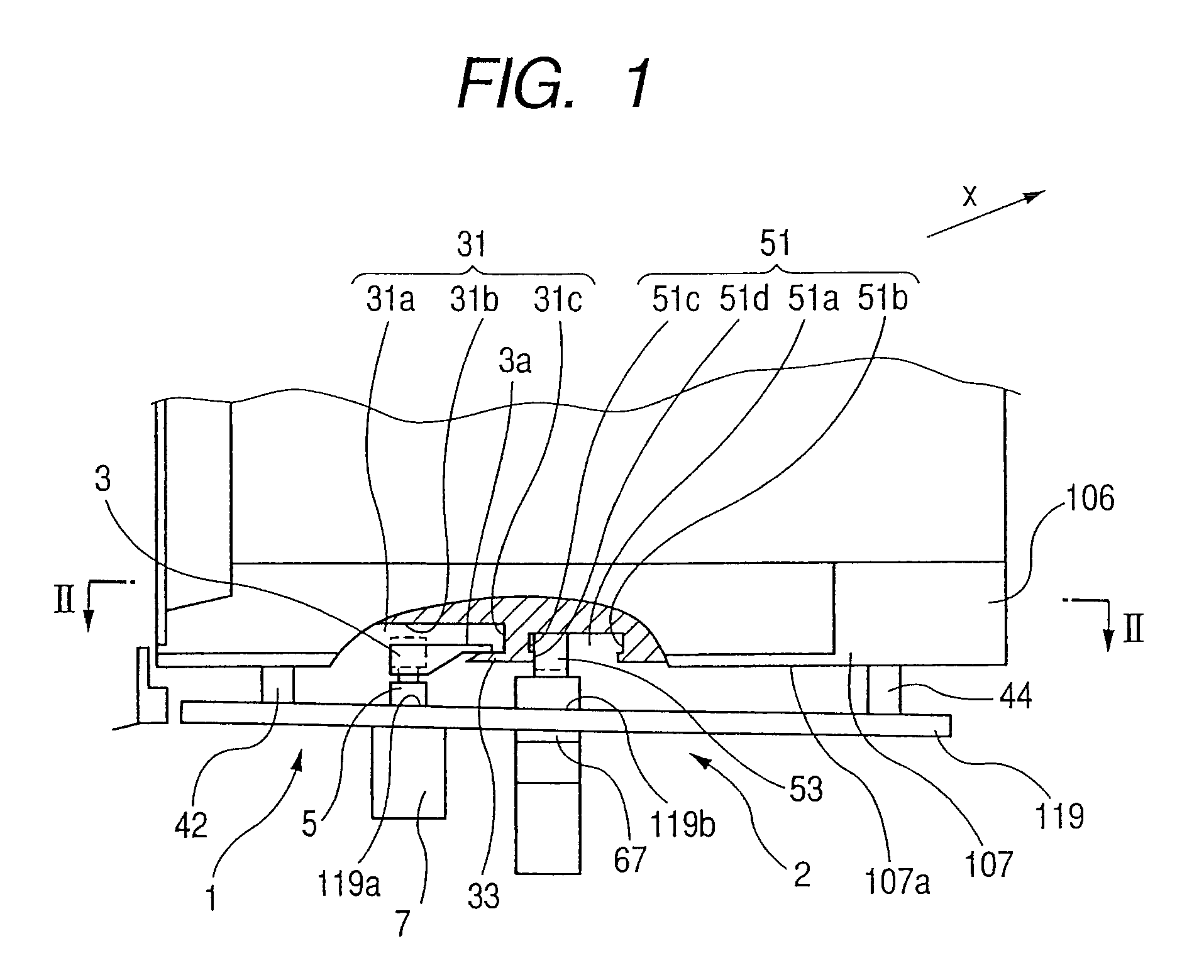

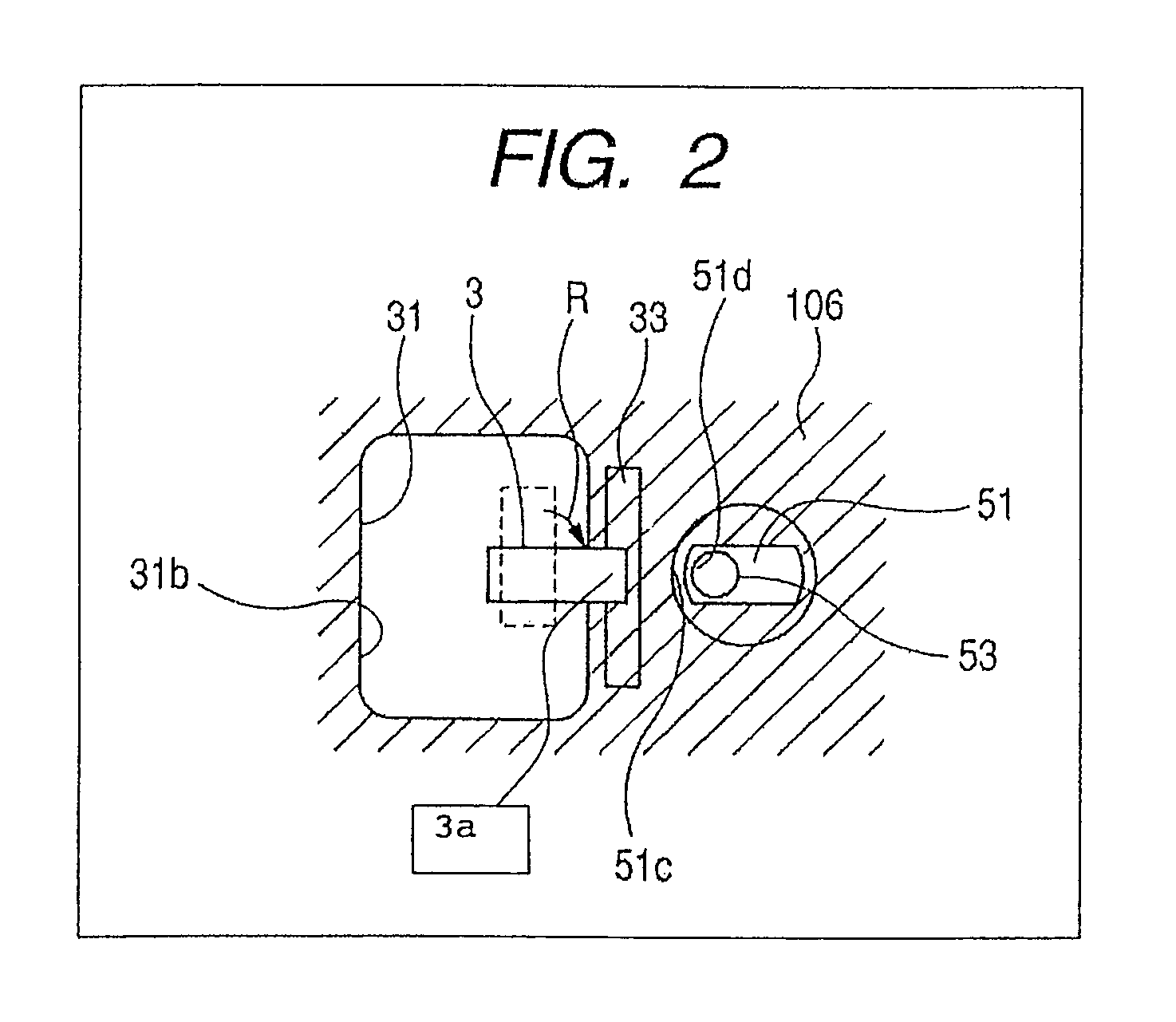

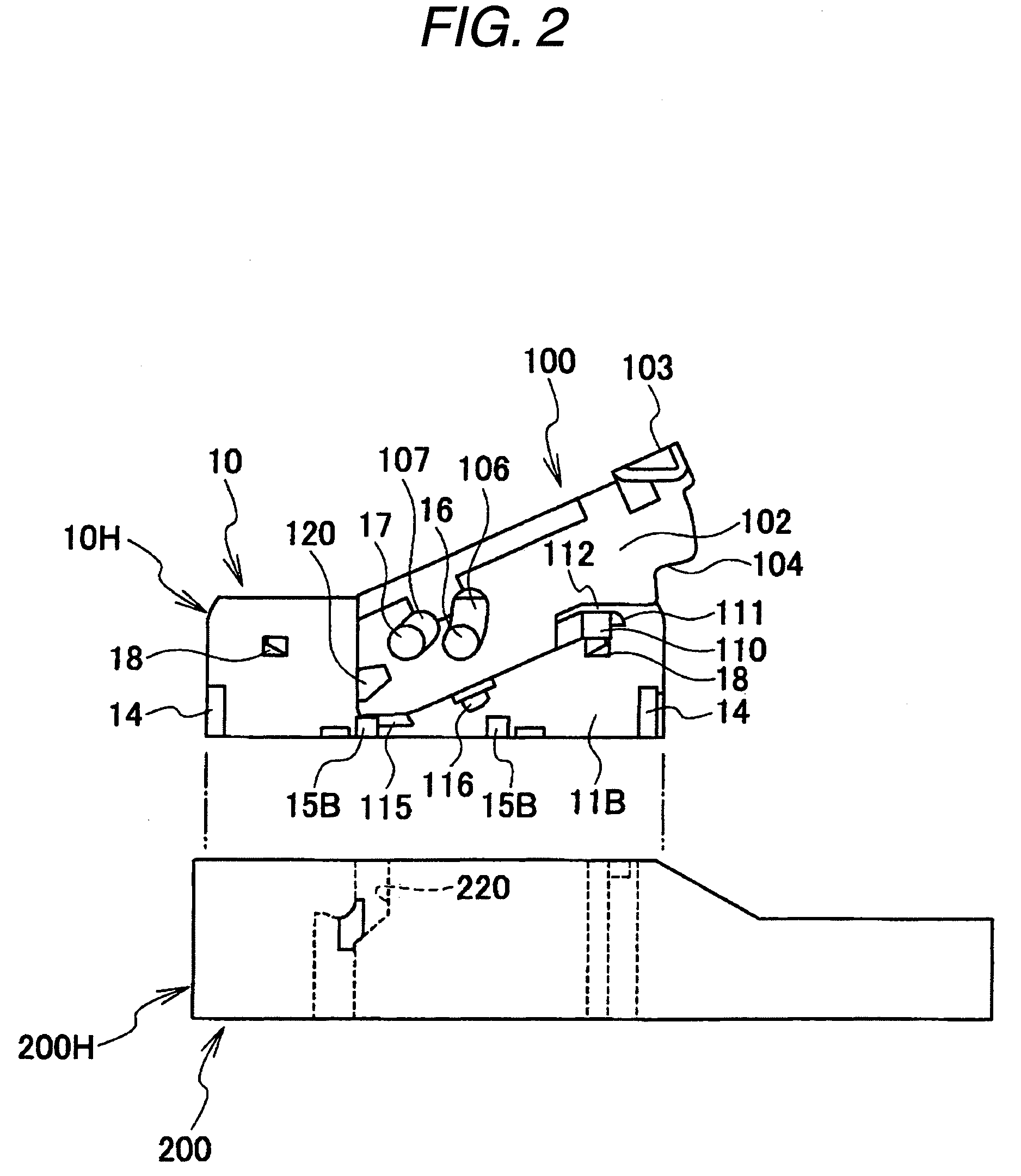

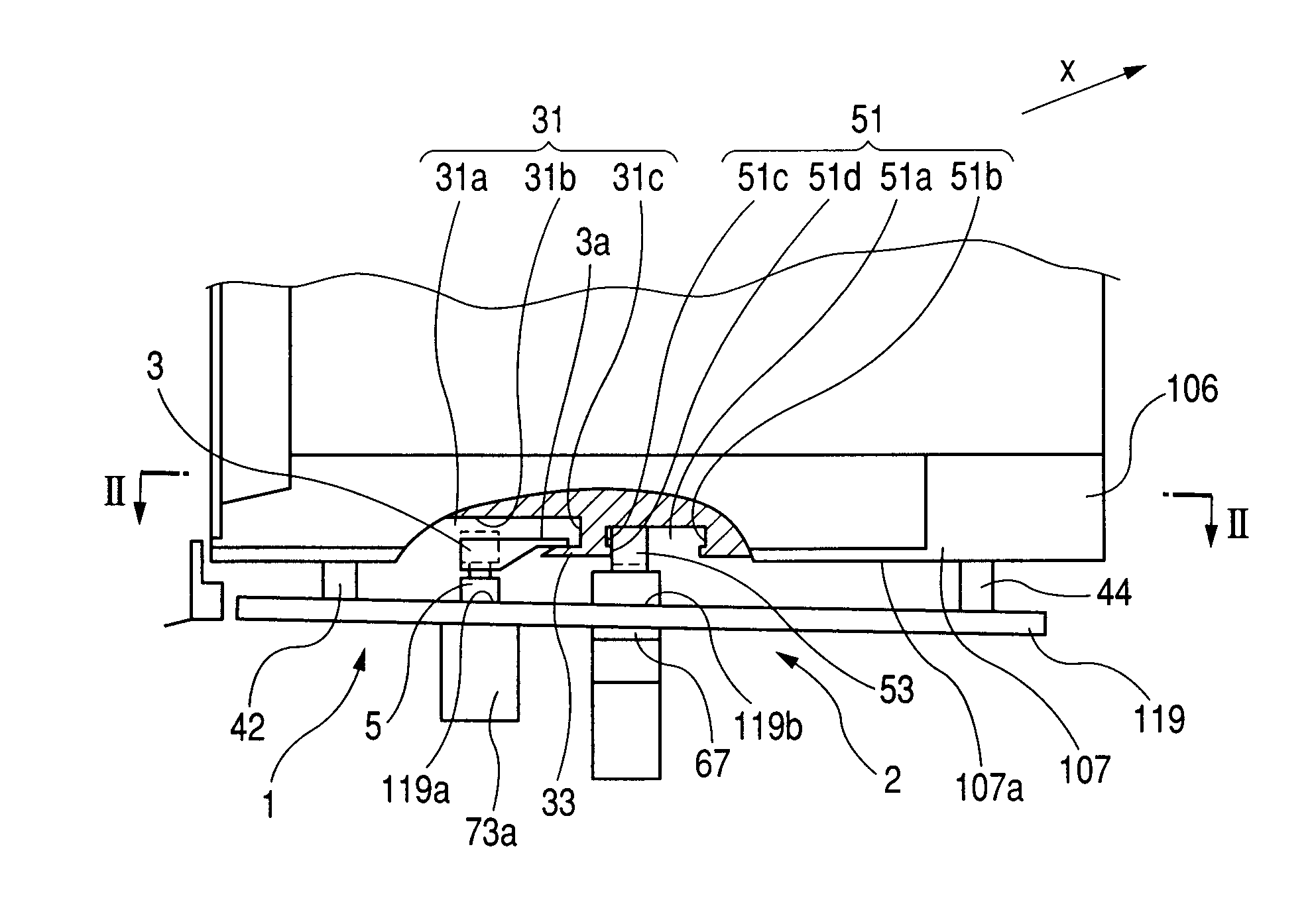

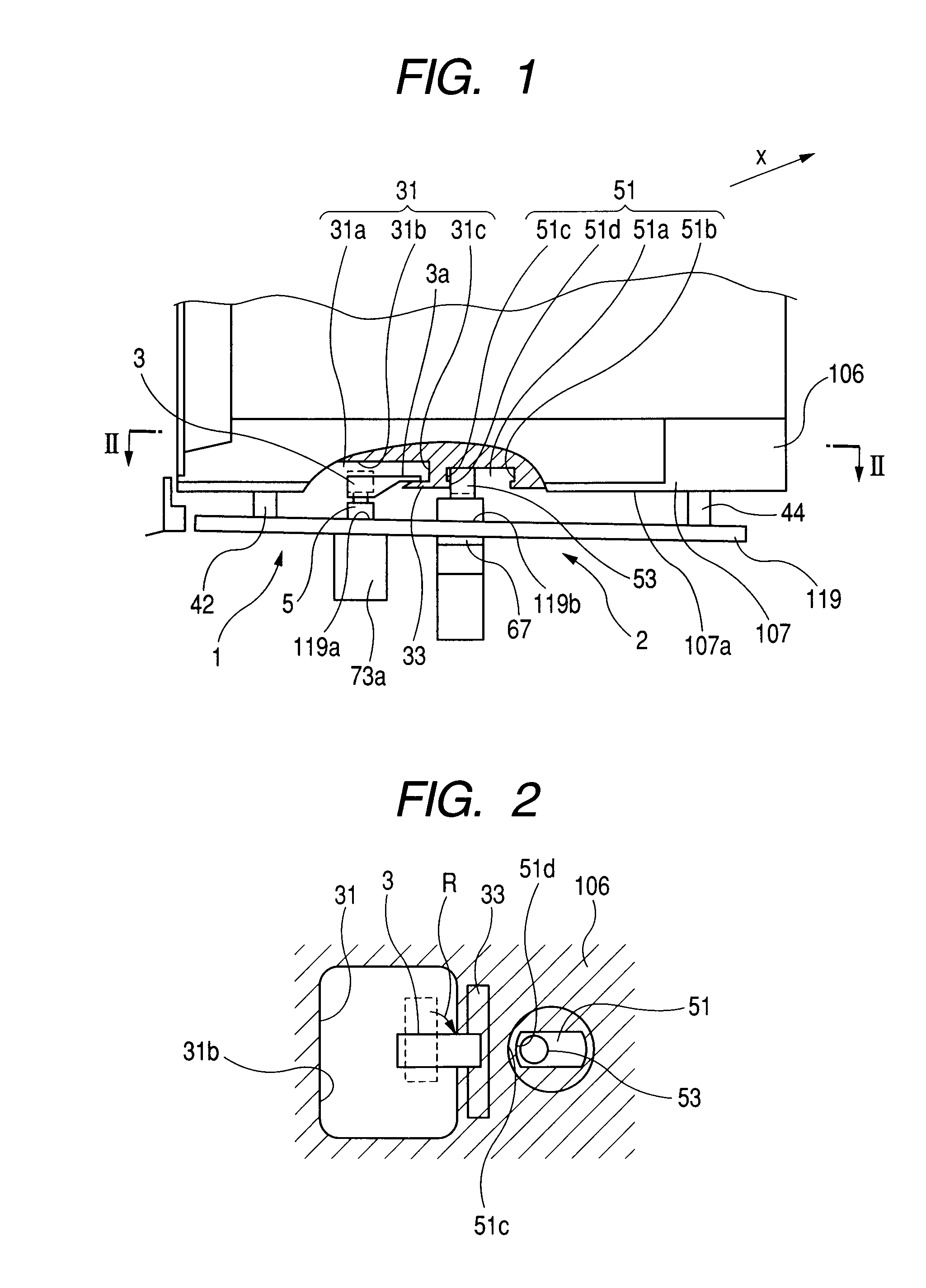

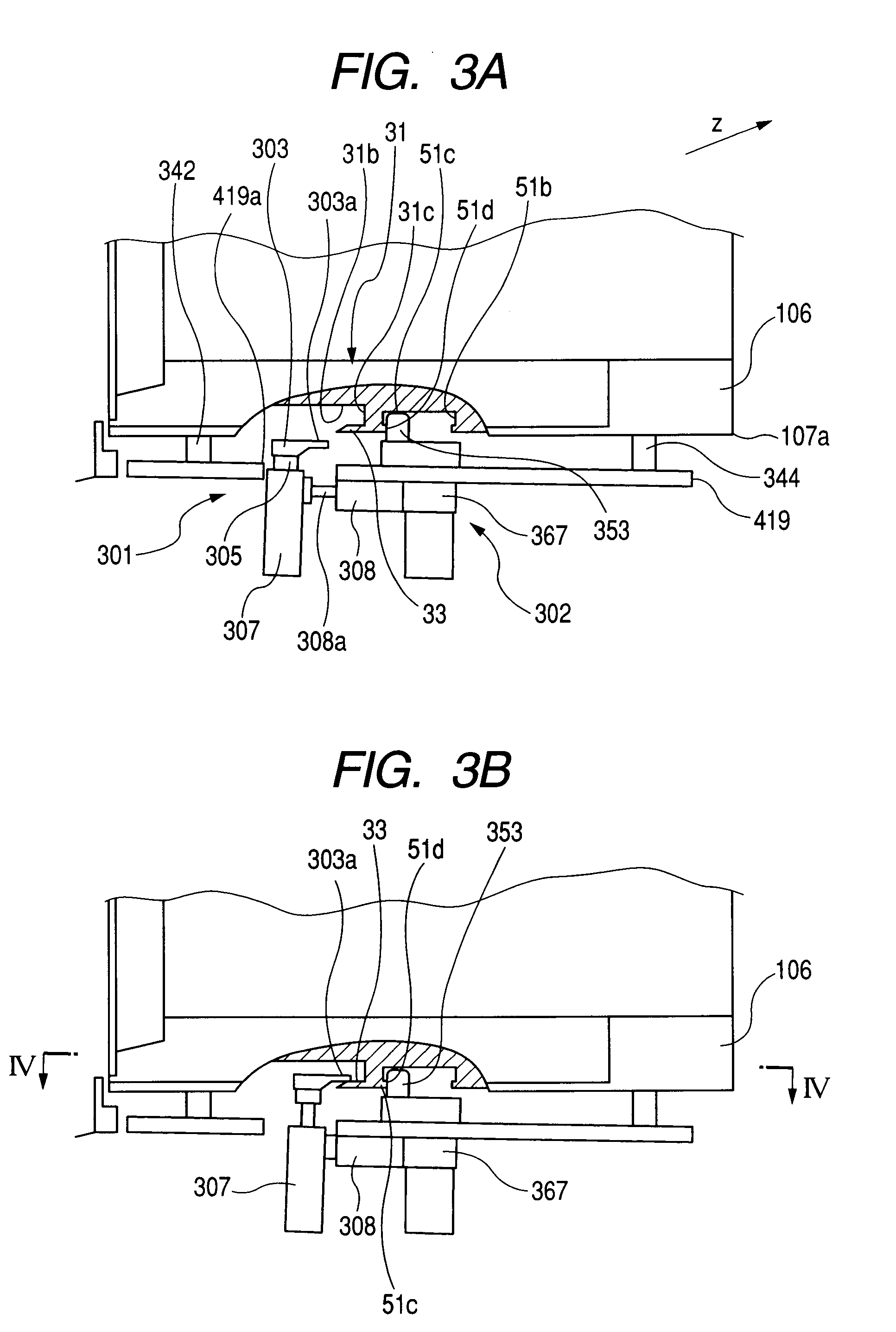

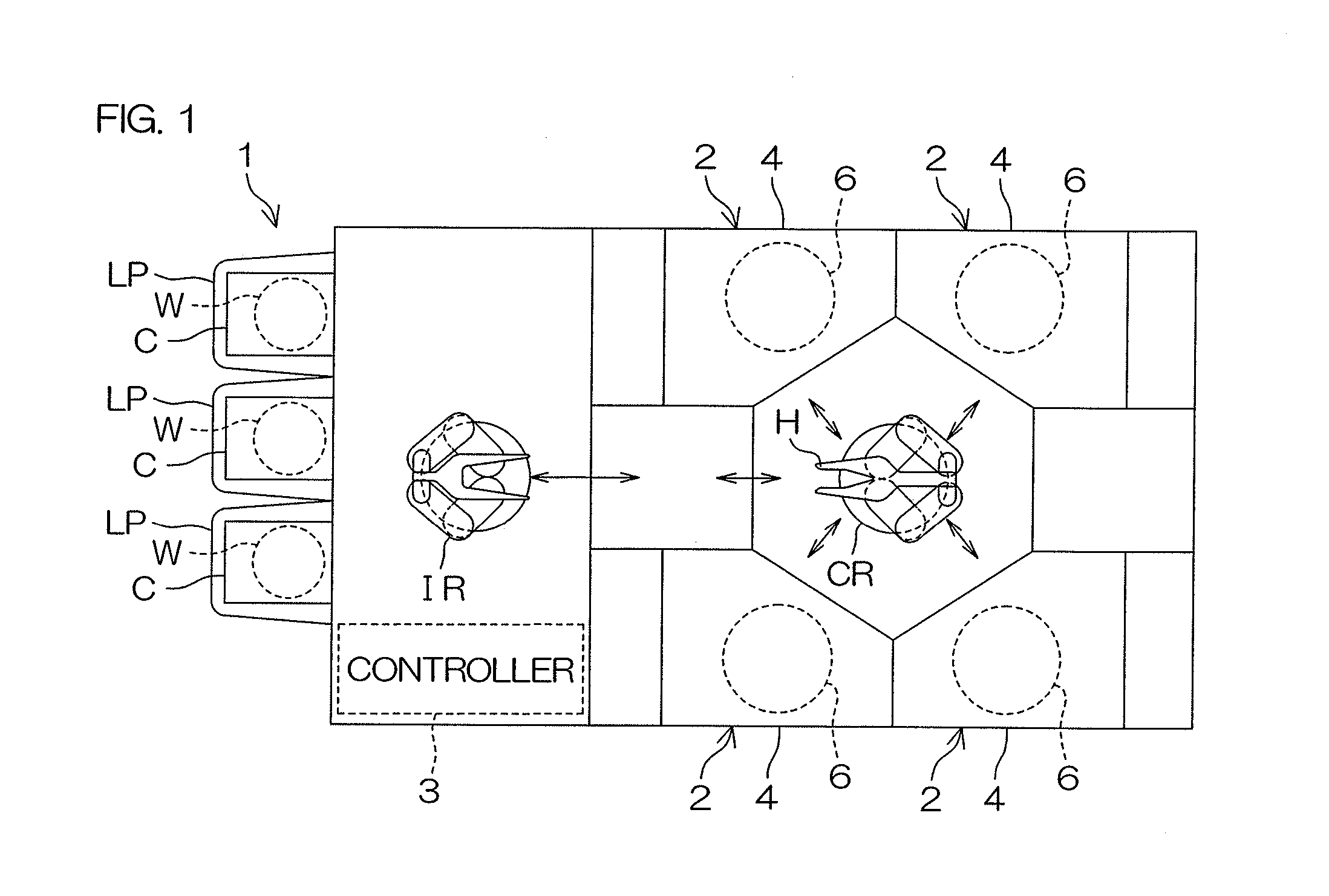

Pod clamping unit load port equipped with pod clamping unit and mini environment system including pod and load port

ActiveUS7927058B2Kept very reliableAvoid supportSemiconductor/solid-state device manufacturingArticle unpackingEngineeringMechanical engineering

The invention is directed to a pod clamping unit for fixing a pod to a support table in a load port, the pod including a pod body capable of storing a wafer in the interior thereof and a lid, the load port having a pod opener that opens / closes the lid. The pod clamping unit includes a clamp portion that is provided on the support table and adapted to engage with a first engagement portion provided on a lower surface of the pod body to restrict upward movement of the pod relative to the support table, a restriction pin that is movable upwardly and downwardly relative to the support table and adapted to engage with a second engagement portion provided on the lower surface of the pod body to restrict movement of the pod in a disengaging direction that causes disengagement between the first engagement portion and the clamp portion, and a vertically driving portion that moves the restriction pin up to / down from the second engagement portion.

Owner:TDK CORPARATION

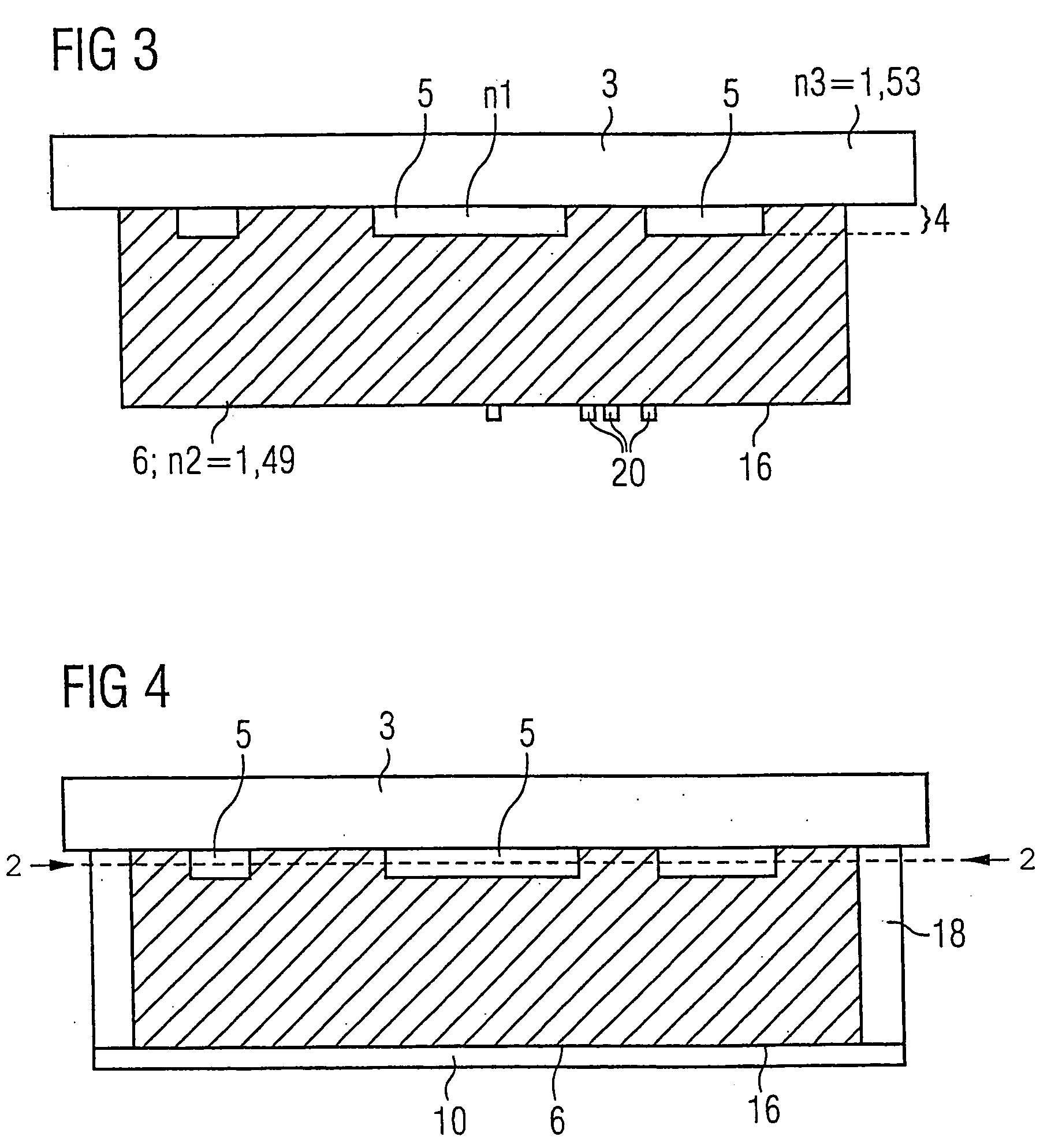

Lithographic mask, and method for covering a mask layer

InactiveUS20050106475A1Improve optical qualityAvoid impuritiesPicture framesPhotosensitive materialsLithographic artistLiquid state

A lithographic mask having a mask substrate (3) and a patterned mask layer (4) which includes mask structures (5) and can be transferred by lithography to a further substrate is disclosed. With masks of this type, it is customary for a protective layer to be provided in the form of a membrane positioned at a distance from the mask layer (4), in order to keep impurity particles or other impurities away from the focal plane of the mask layer (4). According to the invention, the protective layer (6) is applied in liquid form directly to the mask structures (5) and fills up spaces between the mask structures (4). Then, the protective layer (6), while it is still in the liquid state, is covered with a plane-parallel plate. The continuously dense protective layer (6) which is formed in accordance with the invention is even more reliable in preventing impurity particles or impurities (20) from penetrating into spacers between the structures (5) of the mask layer (4). The impurity particles or impurities (20) can only be deposited on the outer side (16) of the protective layer (6), at a still greater distance from the focal plane.

Owner:POLARIS INNOVATIONS

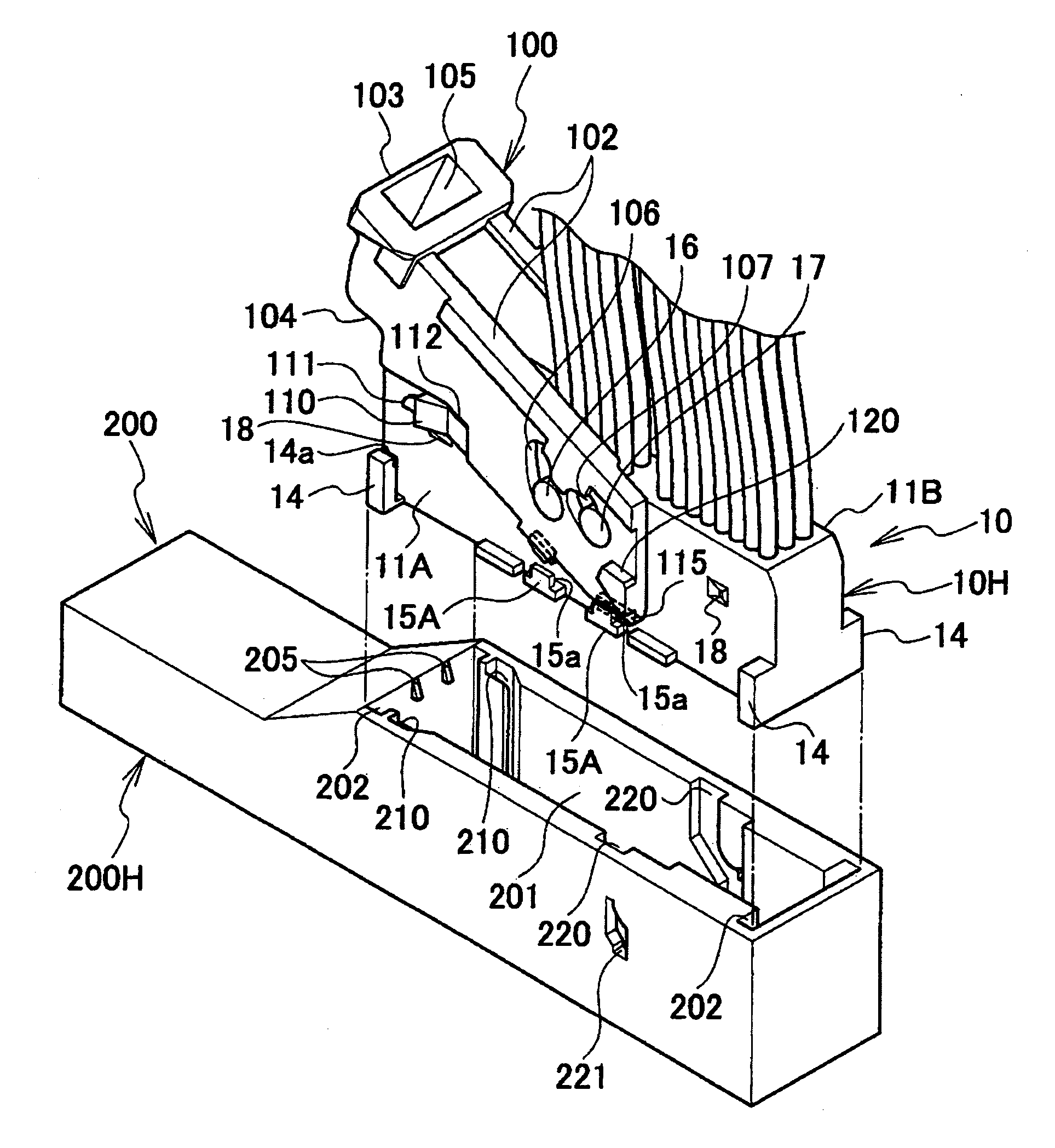

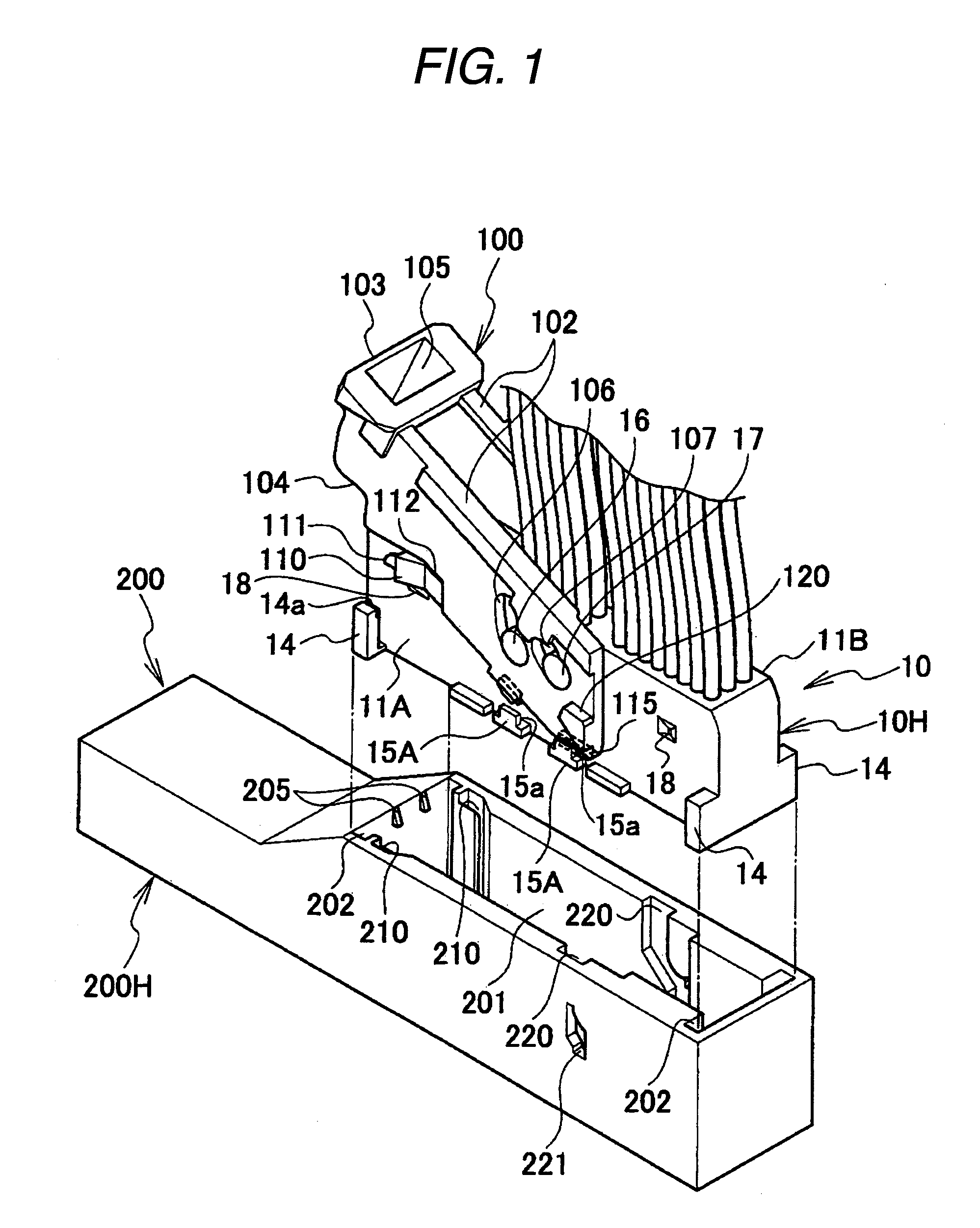

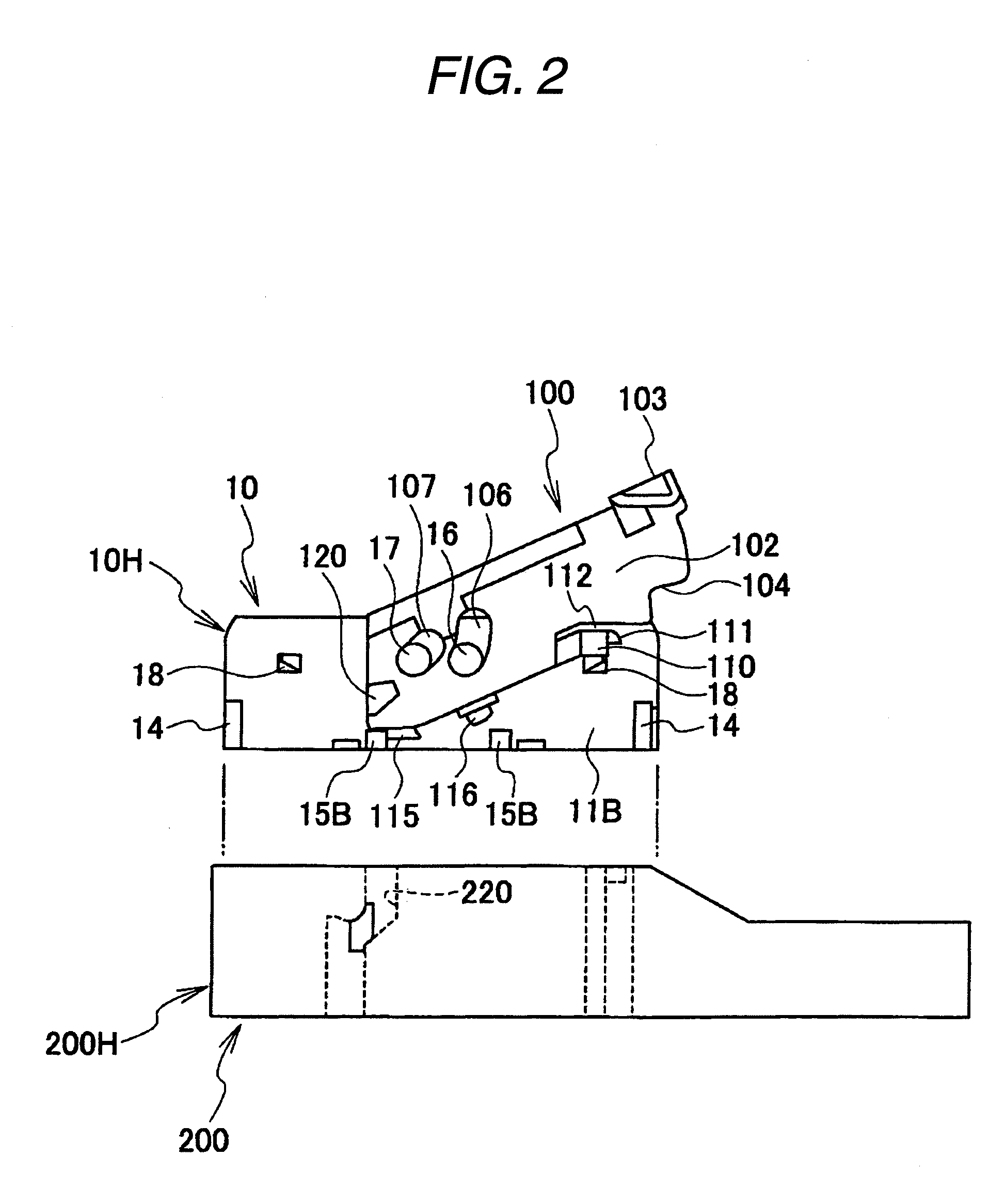

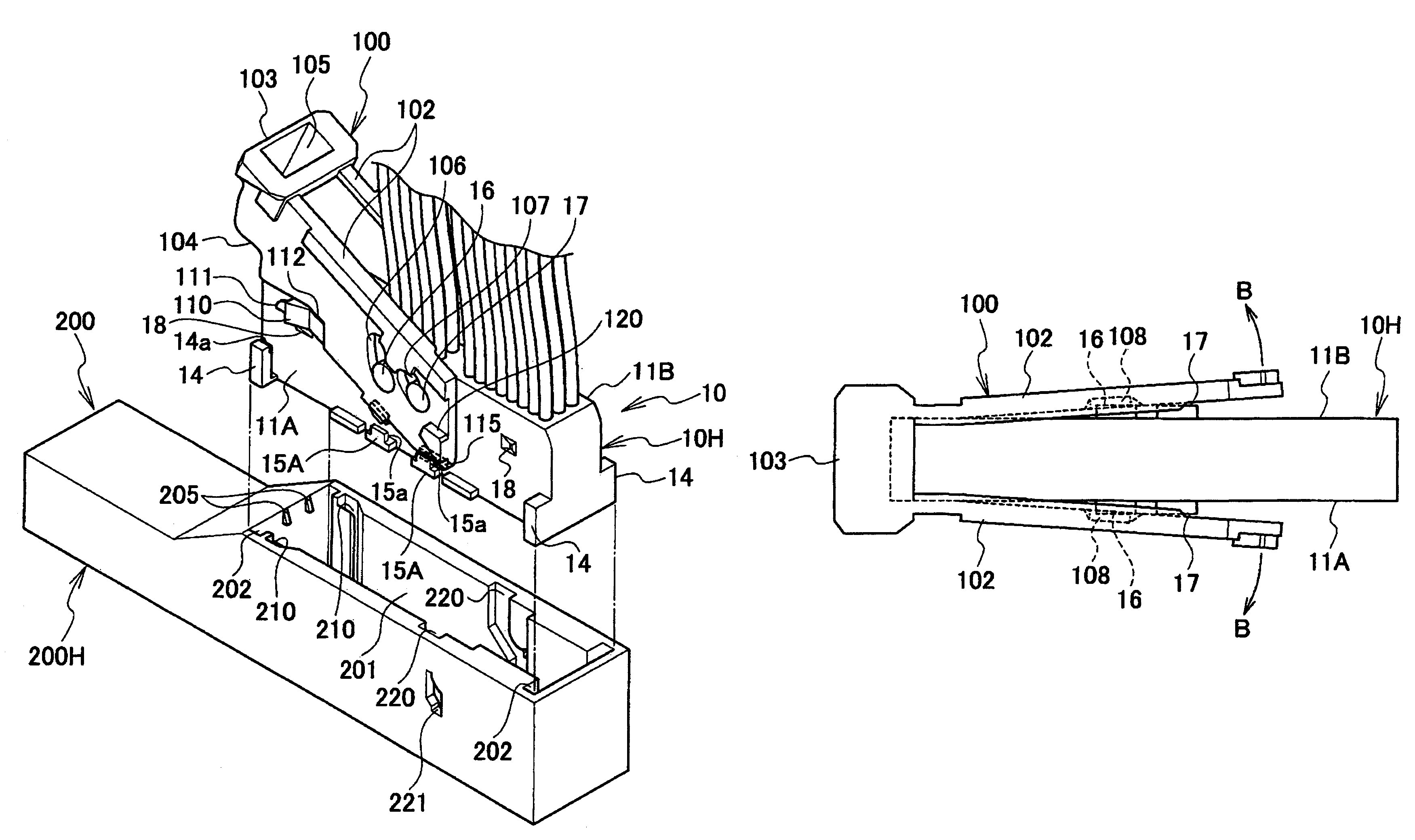

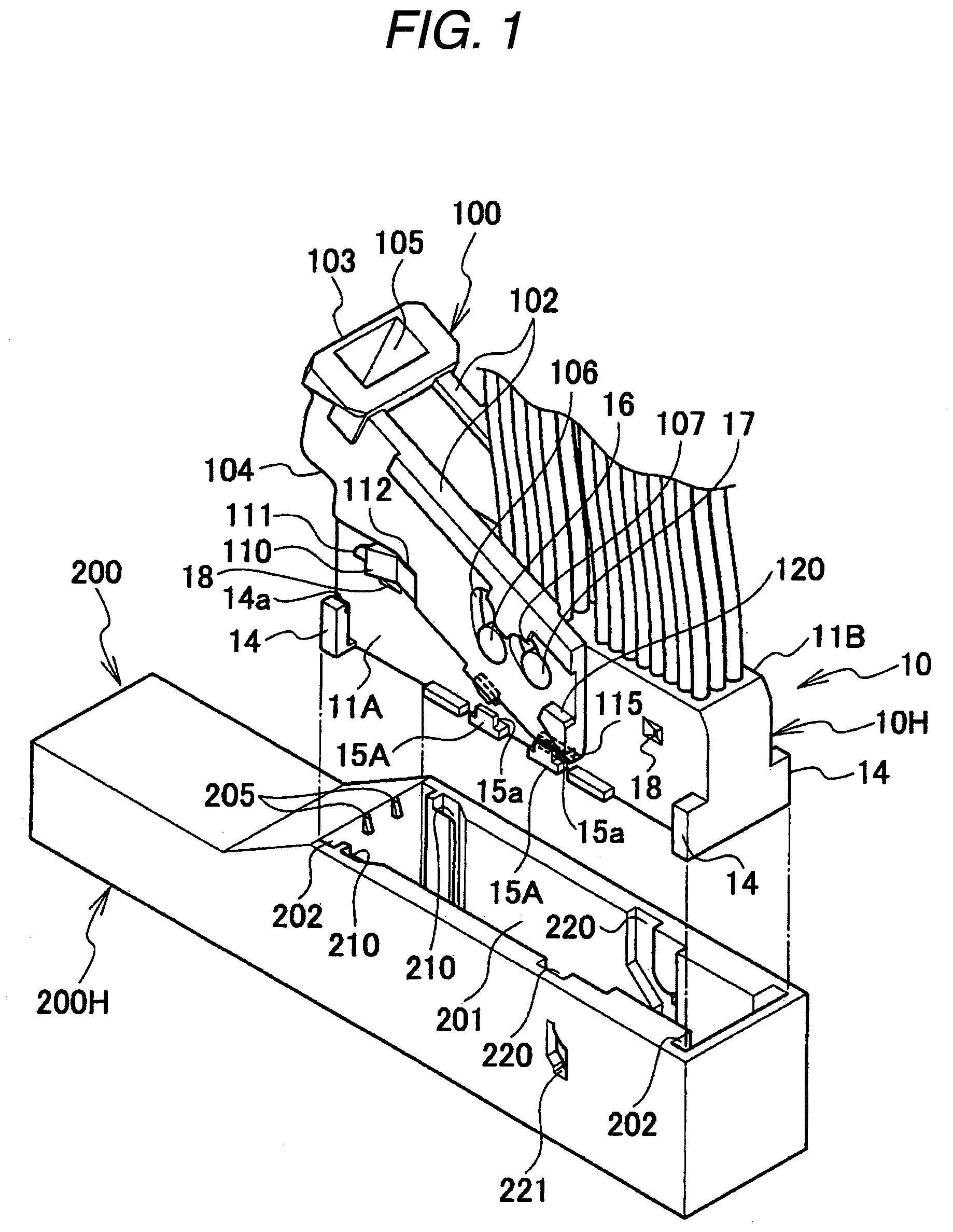

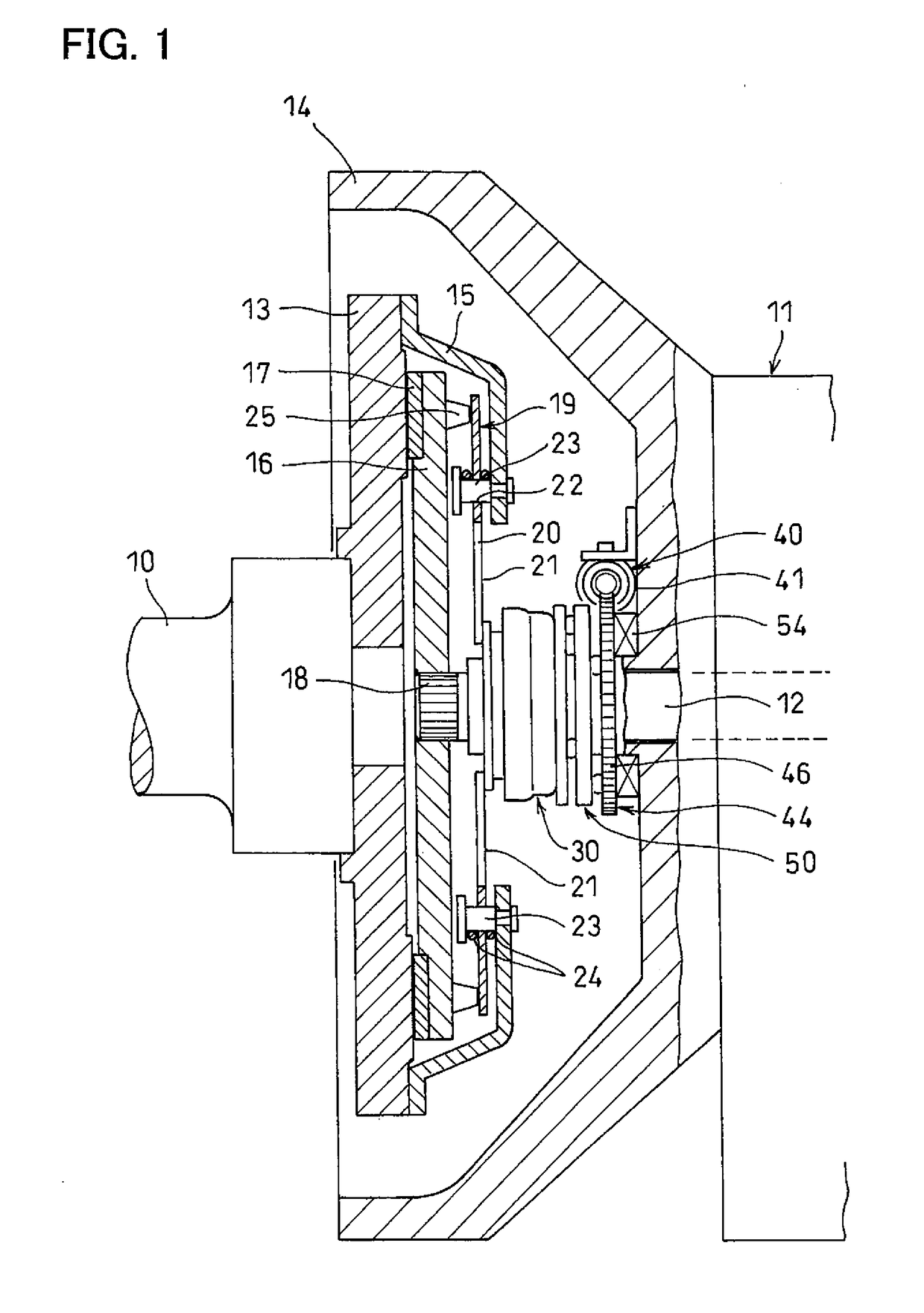

Lever type connector

ActiveUS20090163063A1Improve reliabilityKeep not can be separatedEngagement/disengagement of coupling partsIncorrect coupling preventionEngineeringMechanical engineering

Provided is a lever type connector for fitting connectors by swinging a lever 100, in which protrusions 115 and 116 are provided on an outer peripheral portion of the one end side of the lever side plate 102, a reception portion 15A for preventing the lever side plate from opening outward by engaging with the protrusions provided on the outer peripheral portion of the lever side plate in a male connector housing 10H for mounting the lever, and the protrusions 115 and 116 and the reception portion 15A are provided to engage with each other when the lever mounted on at least the male connector housing is set to a temporary locking position before connector fitting.

Owner:YAZAKI CORP

Methods of manufacturing a stator for an electric rotating machine

ActiveUS8413314B2Easily and accurately perform operationEasy to assembleWave amplification devicesMagnetic circuitStator coilElectric wire

Disclosed is a method of manufacturing a stator for an electric rotating machine. The method includes the steps of: (1) forming a plurality of planar electric wires, each of the planar electric wires including a plurality of in-slot portions to be received in slots of a stator core and a plurality of turn portions to be located outside of the slots to connect the in-slot portions; (2) rolling each of the planar electric wires through plastic deformation into a spiral or circular-arc shape; (3) forming a hollow cylindrical stator coil by assembling the rolled electric wires through operations of making relative axial movement therebetween; and (4) assembling the stator core and the stator coil together to form the stator.

Owner:DENSO CORP

Arresting element and handle

InactiveUS20160097222A1Reliable releaseKept very reliableLimiting/preventing/returning movement of partsAccident situation locksCar door

Owner:HUF HULSBECK & FURST GMBH & CO KG

Lever type connector

ActiveUS7811104B2Improve reliabilityKeep not can be separatedEngagement/disengagement of coupling partsIncorrect coupling preventionEngineeringMechanical engineering

Provided is a lever type connector for fitting connectors by swinging a lever 100, in which protrusions 115 and 116 are provided on an outer peripheral portion of the one end side of the lever side plate 102, a reception portion 15A for preventing the lever side plate from opening outward by engaging with the protrusions provided on the outer peripheral portion of the lever side plate in a male connector housing 10H for mounting the lever, and the protrusions 115 and 116 and the reception portion 15A are provided to engage with each other when the lever mounted on at least the male connector housing is set to a temporary locking position before connector fitting.

Owner:YAZAKI CORP

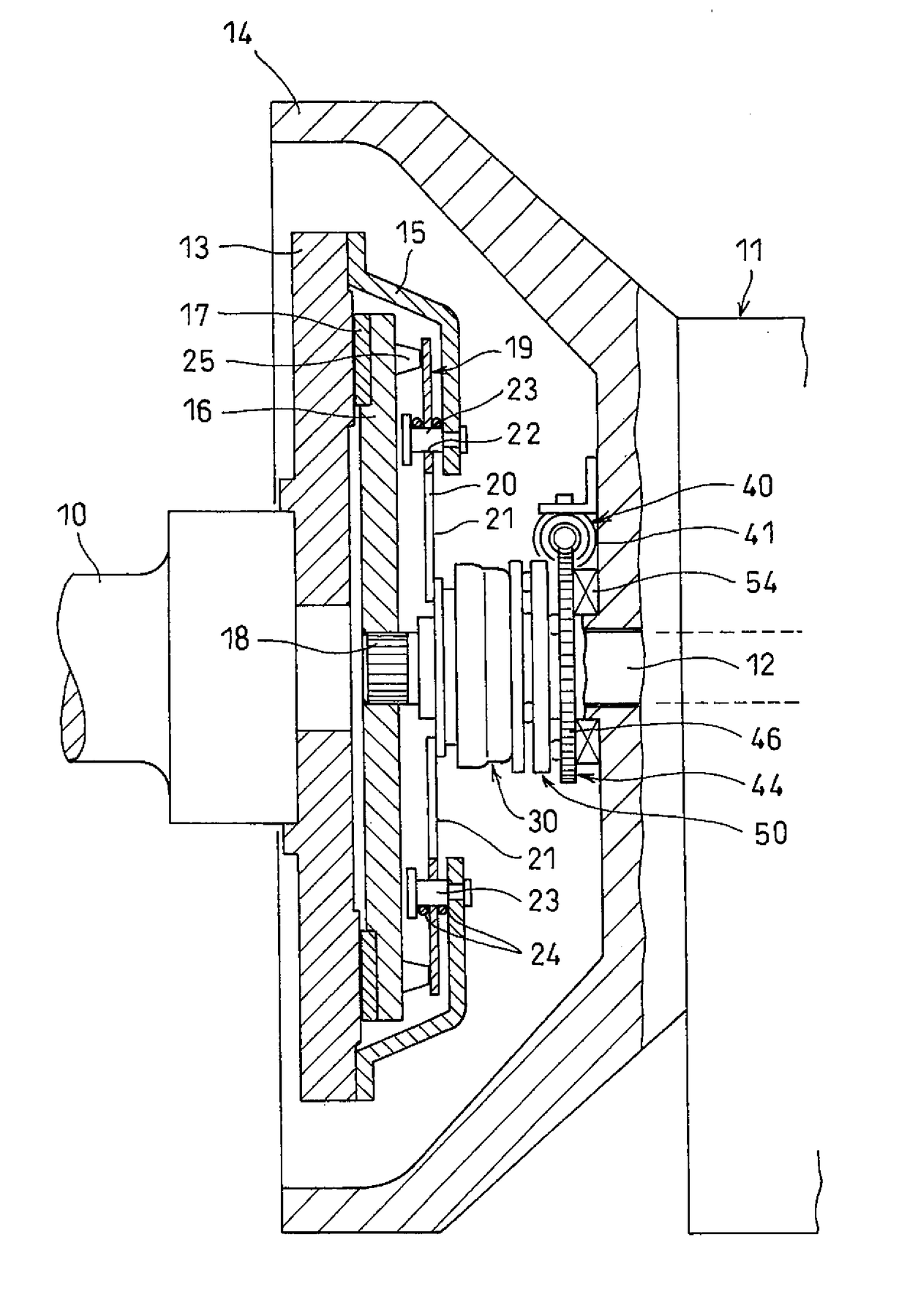

Automatic clutch device

ActiveUS20180238402A1Small sizeSmall installation spaceToothed gearingsFriction clutchesLinear motionReduced size

An automatic clutch device includes an axial force generating mechanism including an electric motor arranged adjacent to the outer periphery of an end of an input shaft of a transmission, and a rotation-linear motion conversion mechanism for converting the rotation of the rotor of the electric motor to a linear motion of a release bearing. The rotation-linear motion conversion mechanism includes plural annular cam plates arranged in tandem on the input shaft, and torque cam mechanisms each disposed between each opposed pair of cam plates, for reduced size and improved responsiveness of the automatic clutch device.

Owner:NTN CORP

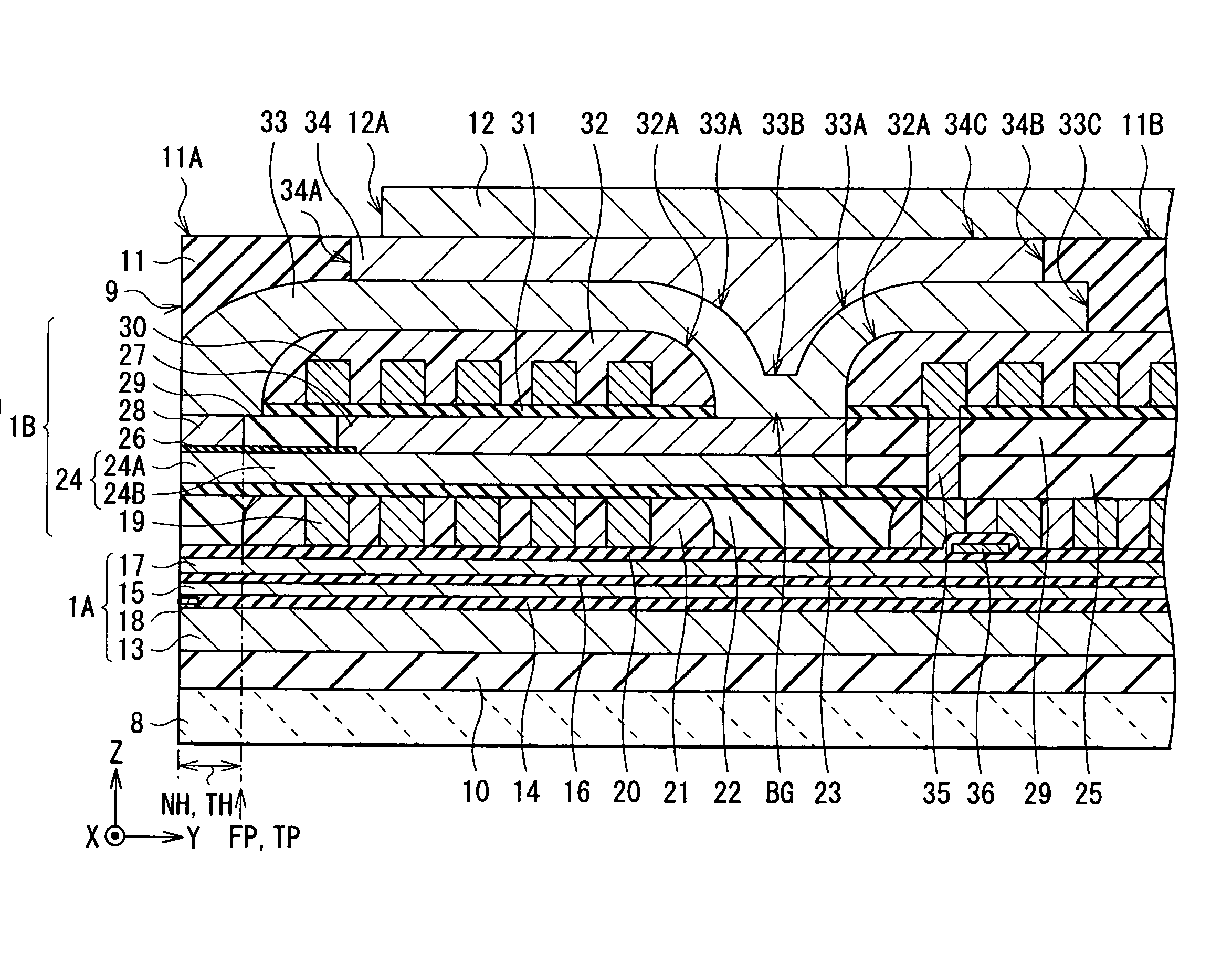

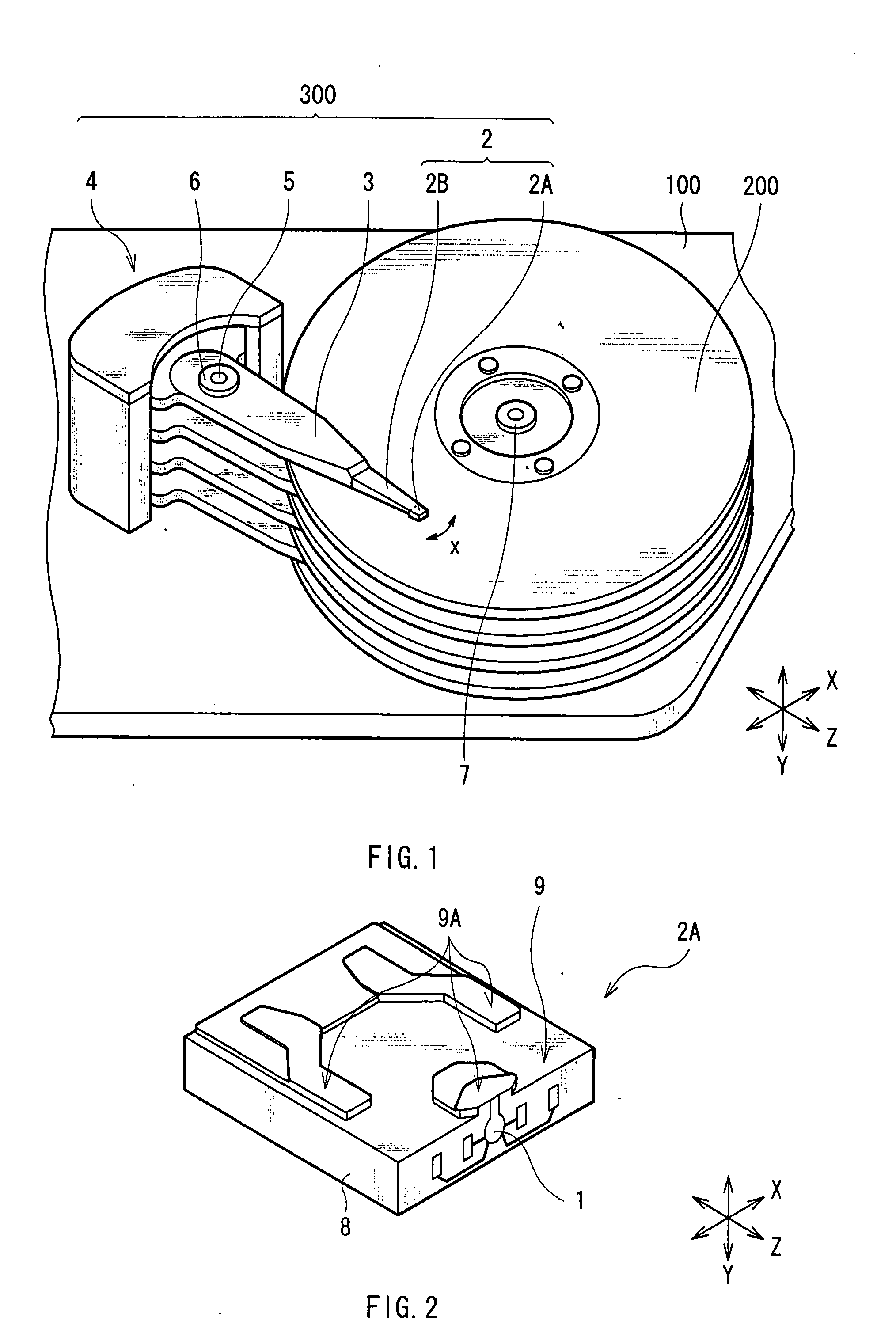

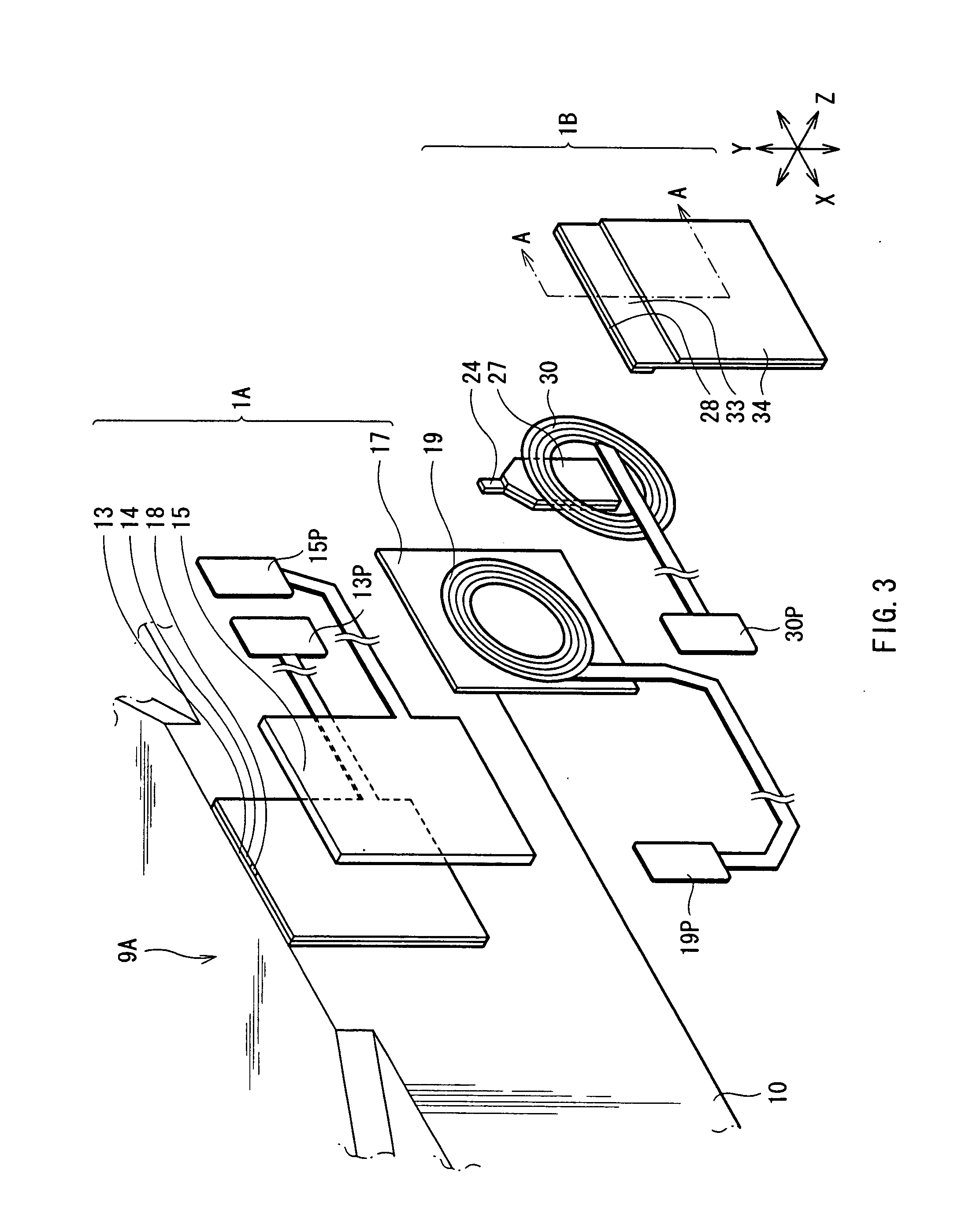

Thin film magnetic head, head gimbal assembly, head arm assembly, magnetic disk device and method of forming thin film magnetic head

ActiveUS20080253032A1Low reliabilityRule out the possibilityRecord information storageManufacture of flux-sensitive headsMagnetic polesThermal expansion

A thin film magnetic head is provided, in which thermal protrusion can be suppressed. The thin film magnetic head includes a main magnetic pole layer which conducts a magnetic flux into the recording medium so that the recording medium is magnetized in a direction perpendicular to a surface of the recording medium, a first return yoke layer provided in a trailing side of the main magnetic pole layer, and has a recess in a top surface, a second return yoke layer provided so as to fill at least the recess of the first return yoke layer, and a thermal expansion suppression layer provided in a trailing side of the second return yoke layer. Thus, since the thermal expansion suppression layer can be provided on a surface having no recess, a possibility of a crack in the thermal expansion suppression layer can be eliminated.

Owner:TDK CORPARATION +1

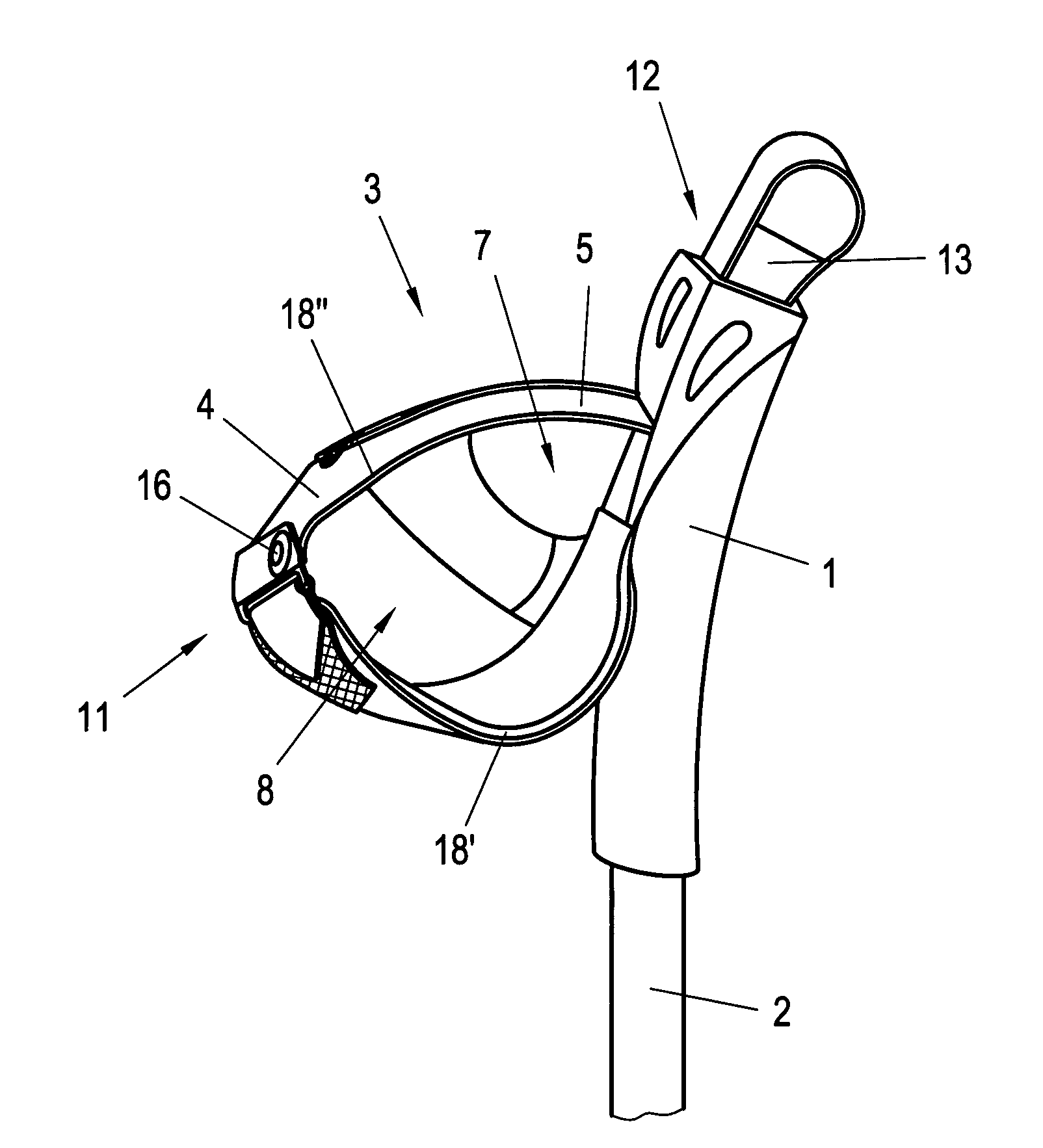

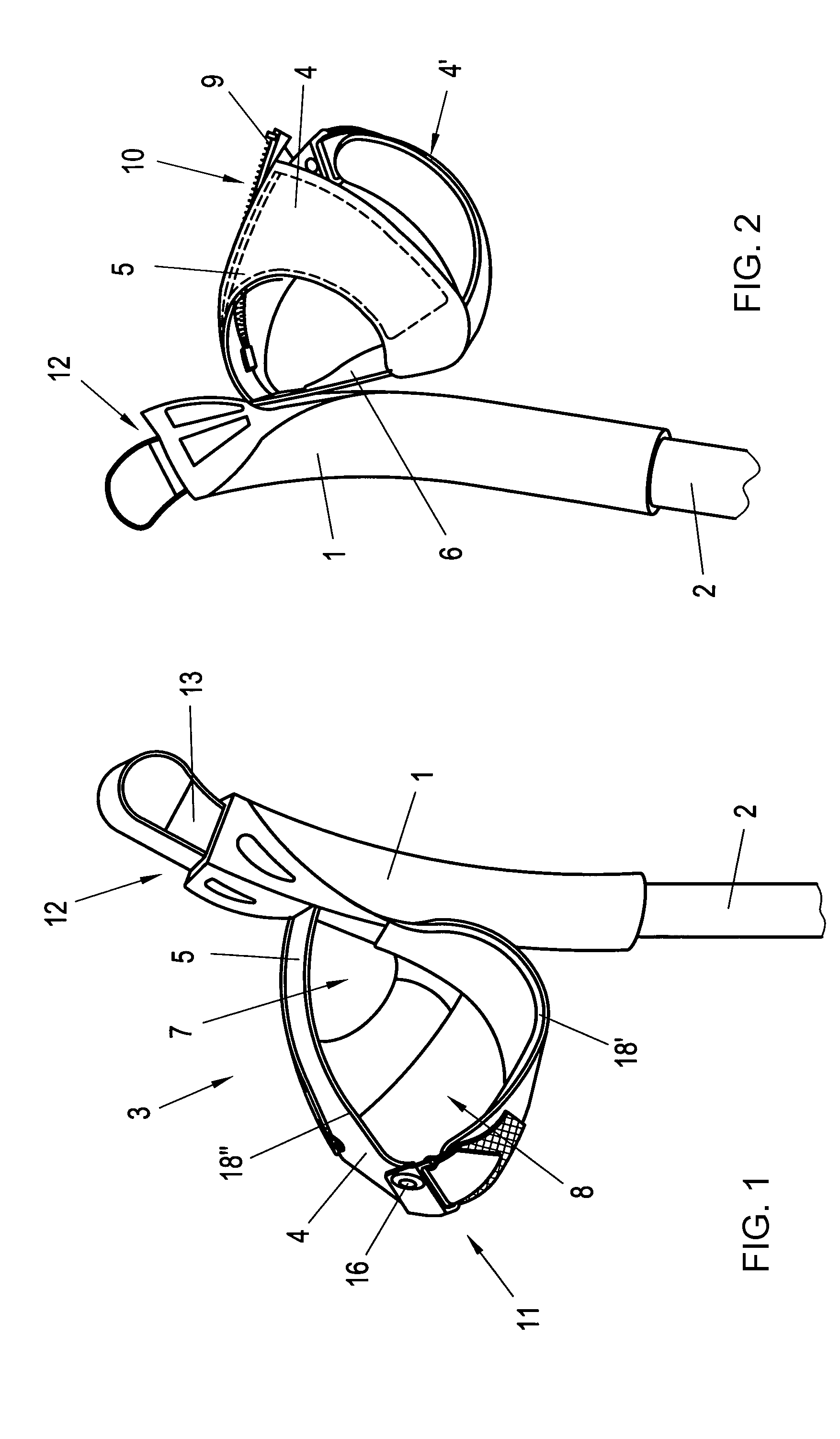

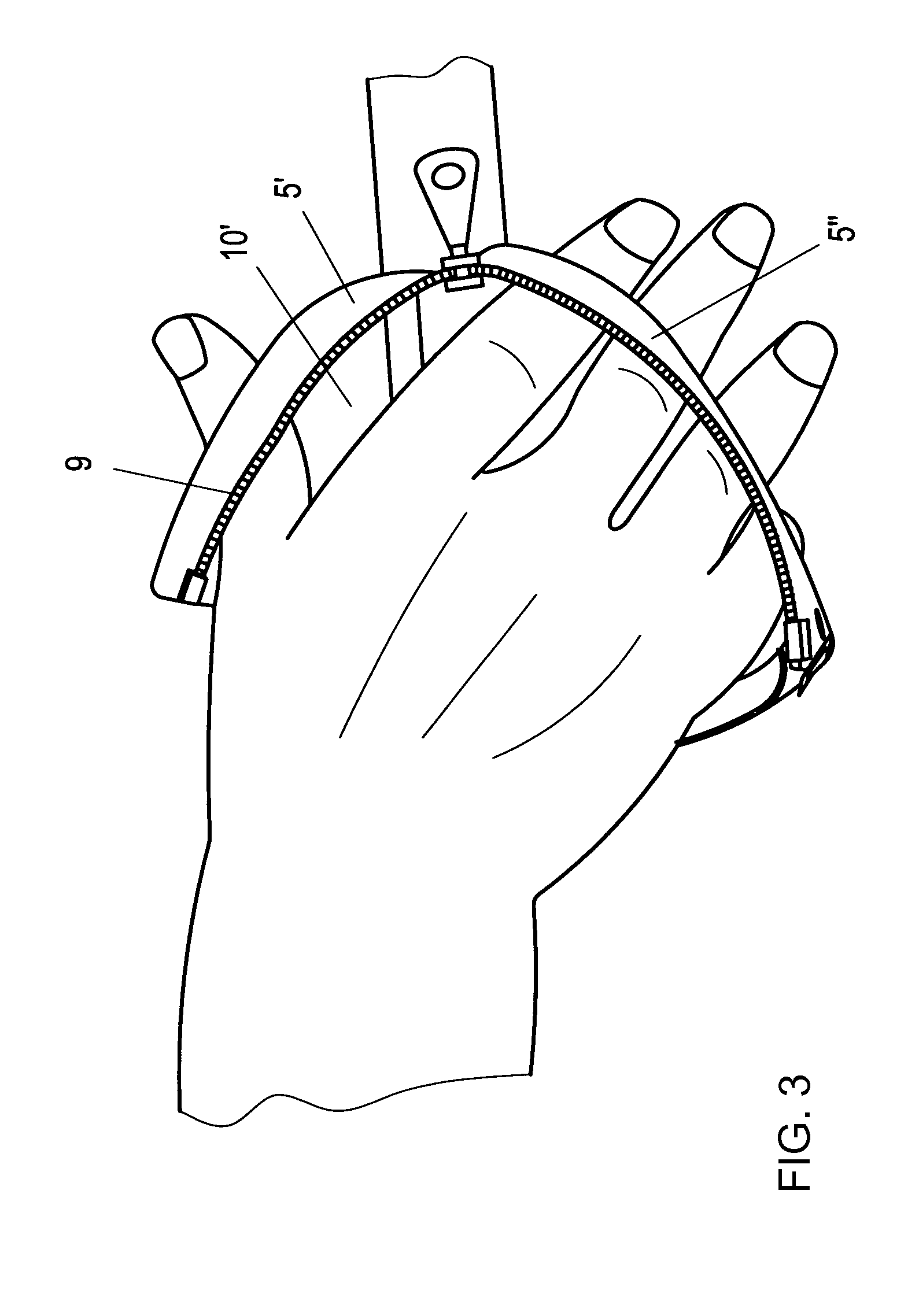

Holding apparatus having adjustment apparatus and separate closing apparatus, attachable to a handle

InactiveUS8579328B2Easy to removeReliably guarantee quick opening and closingWalking sticksSnowboard bindingsEngineeringMechanical engineering

A handle for a cane has a holding apparatus for a hand. The apparatus is attached or can be attached to a handle and includes an attachment section, which encloses the hand at the side of the back of the hand at least in the region between the thumb and index finger, and a wrist section, which is connected to the attachment section and substantially encloses the wrist or the back of the hand and which is connected to the handle by another attachment section on the side of the palm. The wrist section has an adjustment apparatus so that the circumference of an opening defined by the wrist section can be varied. A closing apparatus is provided separate from the adjustment apparatus which, when open, allows the hand to be removed from the holding apparatus and inserted into the holding apparatus.

Owner:FISCHER SPORTS

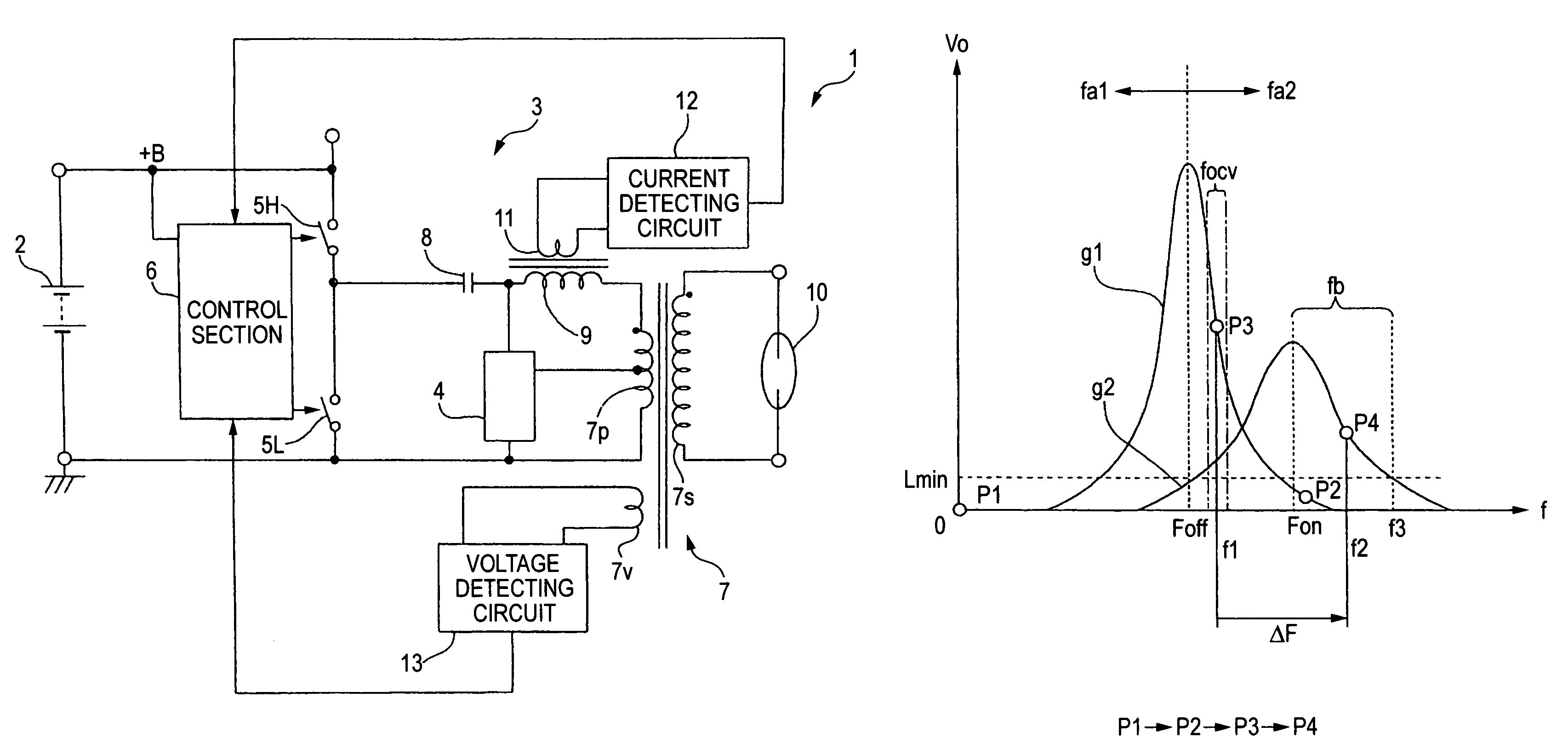

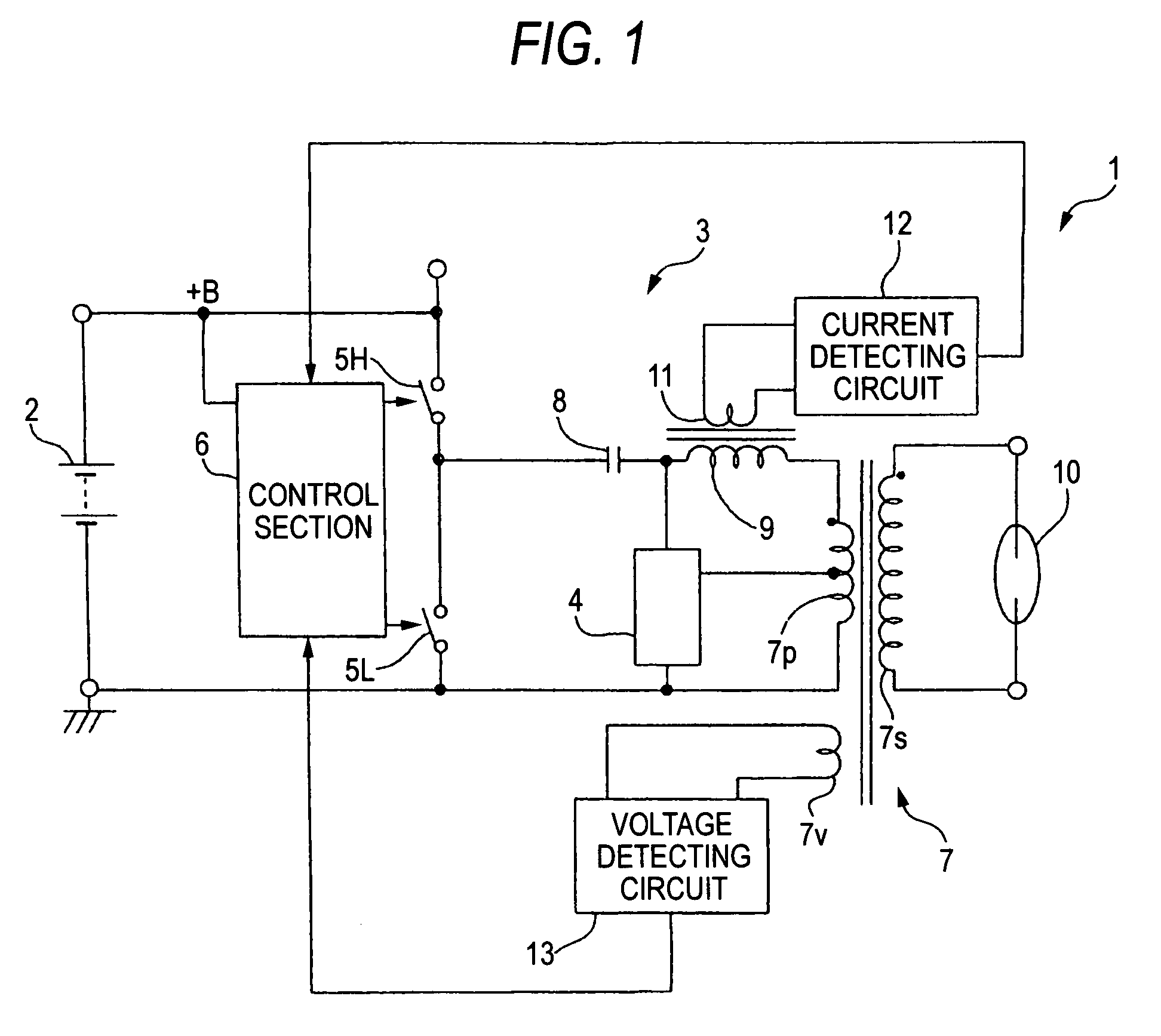

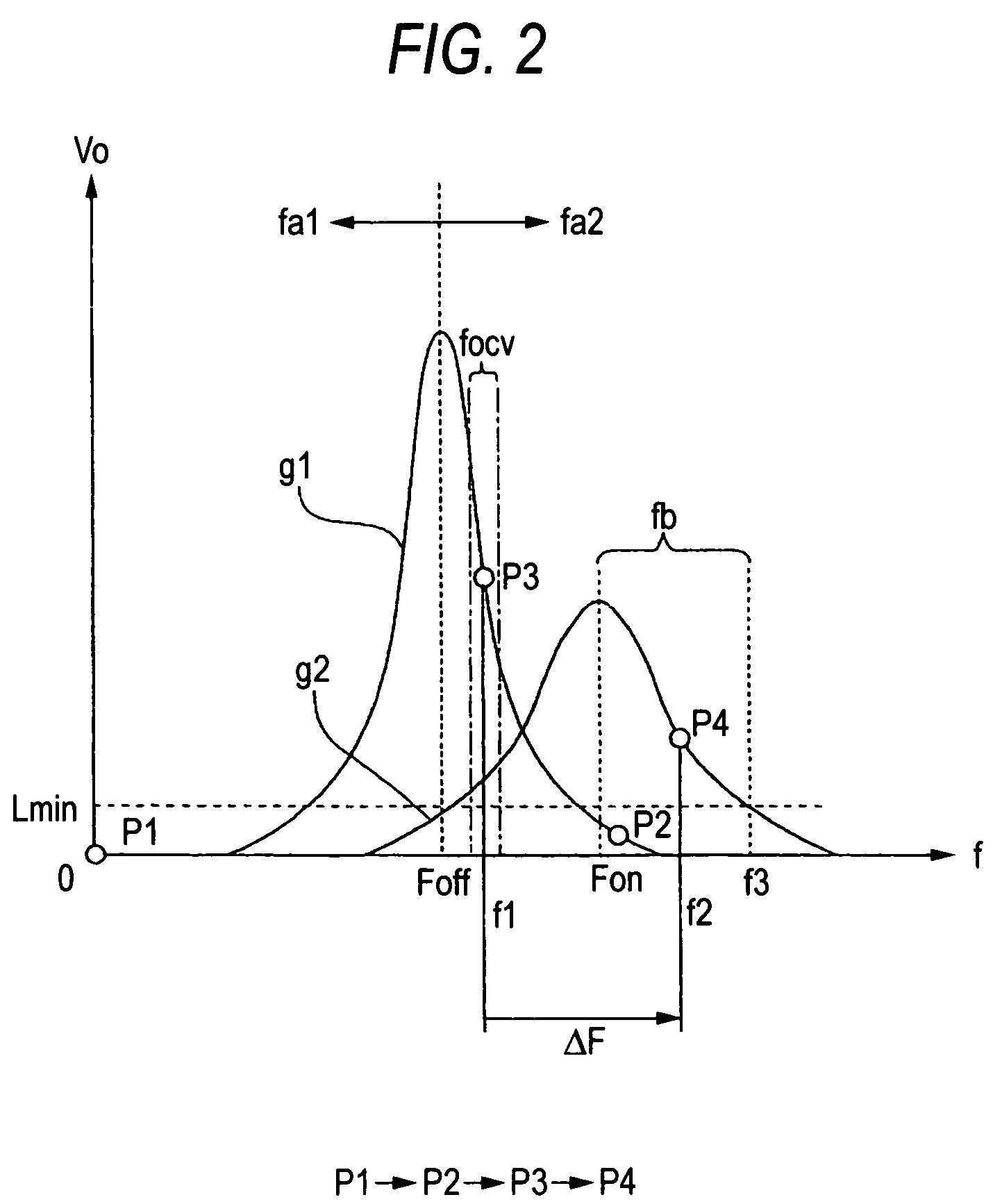

Discharge lamp lighting circuit

A control section is used to control a DC-to-AC converter circuit to perform lighting control of a discharge lamp. A transformer, switching elements, and a capacitor for resonance are included. The switching elements are driven and serial resonance of the capacitor and the inductance component of the transformer or an inductance element is produced. Before the discharge lamp is turned on, control is performed to cause the driving frequency of the switching elements to gradually approach Foff and to supply a start signal to the discharge lamp. Once the discharge lamp is turned on, control is performed to continuously change the driving frequency from f1 assumed before the discharge lamp is turned on to f2. A residence time in a frequency range lower than Fon is secured then the frequency is shifted to a frequency range fb higher than Fon, or an inductive range fb.

Owner:KOITO MFG CO LTD

Clamping plate

InactiveUS20060260903A1Reduce manufacturing costPrevent insertionMechanical actuated clutchesRecord information storageEngineeringMechanical engineering

Owner:TDK CORPARATION

Pod cramping unit, load port equipped with pod cramping unit and mini-environment system including pod and load port

ActiveUS20070231112A1Kept very reliableAvoid supportSemiconductor/solid-state device manufacturingArticle unpackingMechanical engineering

The invention is directed to a pod cramping unit for fixing a pod to a support table in a load port, the pod including a pod body capable of storing a wafer in the interior thereof and having an opening through which the wafer is to be taken out of / brought into the interior and a lid attached to the pod body to close / open the opening, the load port having a pod opener that opens / closes the lid to allow to bring the wafer out of / into the interior of the pod. The pod cramping unit includes a cramp portion that is provided on the support table and adapted to engage with a first engagement portion provided on a lower surface of the pod body to restrict upward movement of the pod relative to the support table, a restriction pin that is movable upwardly and downwardly relative to the support table and adapted to engage with a second engagement portion provided on the lower surface of the pod body to restrict movement of the pod in a disengaging direction that causes disengagement between the first engagement portion and the cramp portion, and a vertically driving portion that moves the restriction pin up to / down from the second engagement portion.

Owner:TDK CORPARATION

Circular saw bench

InactiveUS7261025B2Effective and simple meanKept very reliableGuide fencesShearing machinesCircular sawEngineering

Owner:ROBERT BOSCH GMBH

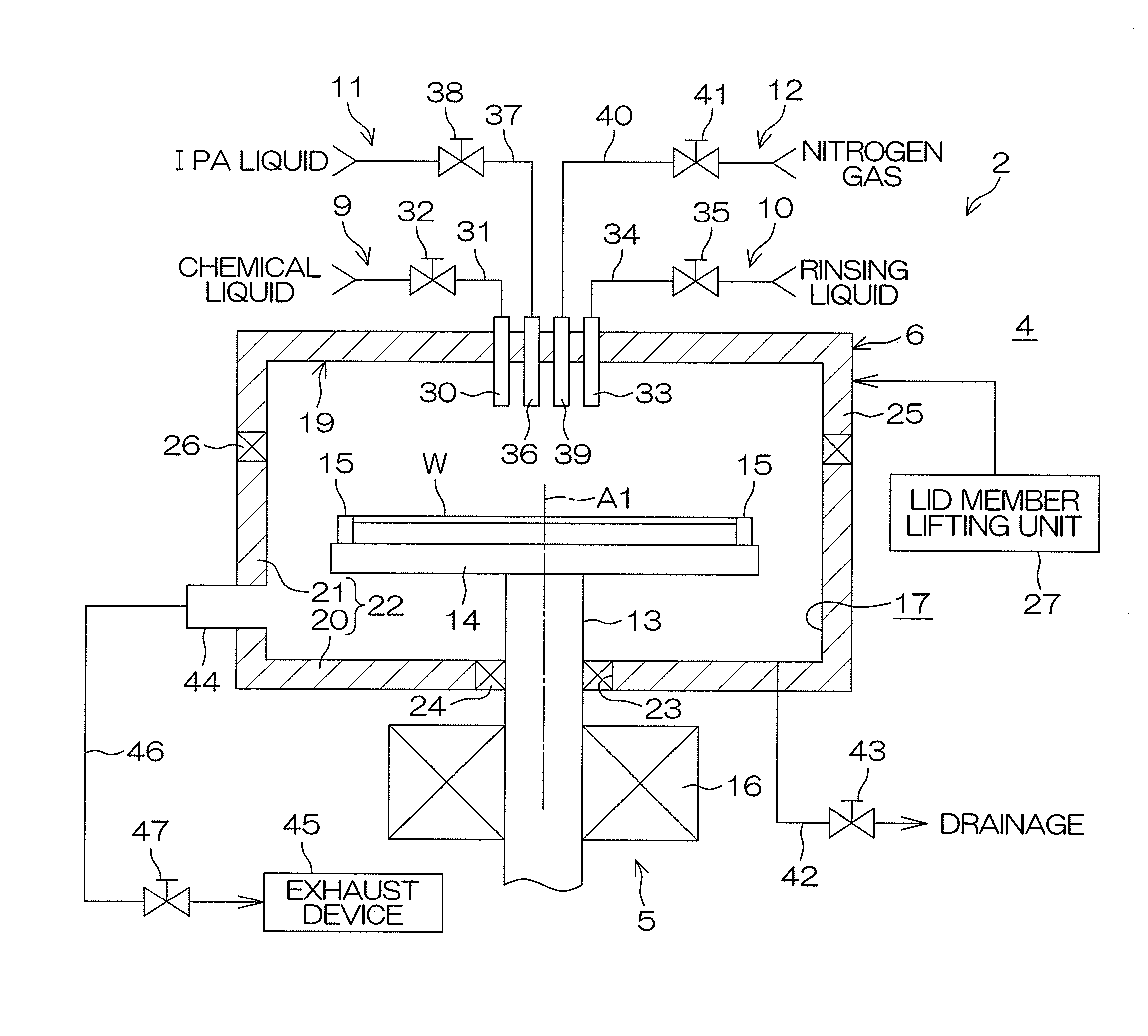

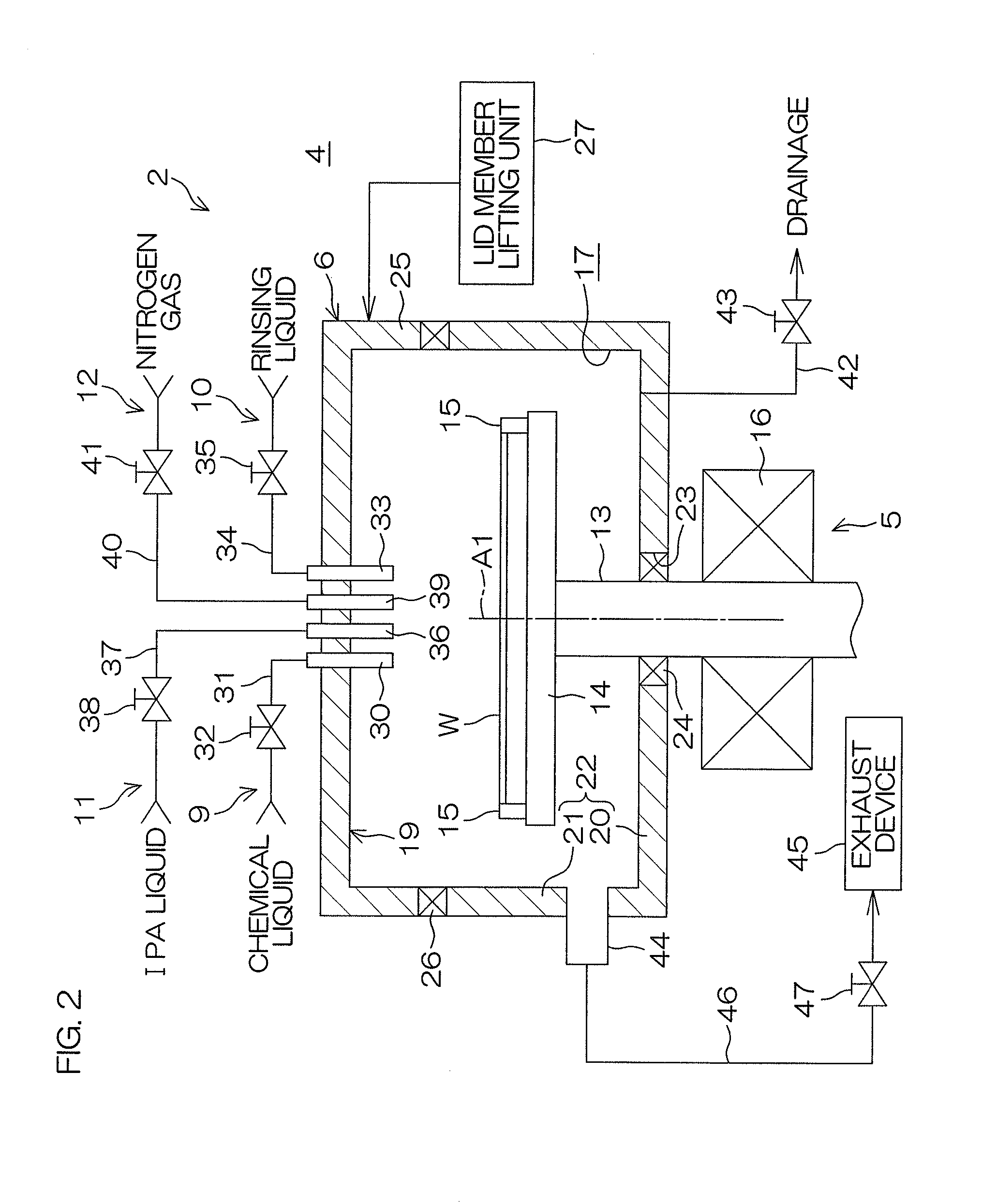

Substrate processing method and substrate processing apparatus

ActiveUS20160365238A1Uniform thicknessSmall thicknessSemiconductor/solid-state device manufacturingMicrostructural device manufactureOrganic solventAtmosphere

A substrate processing method includes a liquid film forming step of forming a liquid film of an organic solvent with which a whole area of an upper surface of a substrate is covered in order to replace a processing liquid existing on the upper surface with an organic solvent liquid, a thin film holding step of thinning the liquid film of the organic solvent by rotating the substrate at a first high rotational speed while keeping surroundings of the whole area of the upper surface in an atmosphere of an organic solvent vapor and holding a resulting thin film of the organic solvent on the upper surface, and a thin-film removing step of removing the thin film from the upper surface after the thin film holding step, and the thin-film removing step includes a high-speed rotation step of rotating the substrate at a second high rotational speed.

Owner:DAINIPPON SCREEN MTG CO LTD

Trip mechanism for fishing reel

The invention involves a holding mechanism located between and pivoting at two points, the first point at the rotor, and the second point at a location found on the primary bracket. In addition, the invention allows for the holding mechanism and the trip mechanism to be efficiently positioned on the primary bracket side of the rotor such that there are only a limited number of components remaining on the other side of the rotor, thus allowing for the rotor to be designed into a more complex shape, with a lighter weight and with a better balancing. The seizing or binding force during release of the bail wire mechanism is also reduced, since the bail wire, or other extended feature does not separate the holding and release mechanisms. In addition, the holding mechanism being pivotable between the two pivot points provides a smoother and more trip responsive fishing mechanism.

Owner:HELIGEAR ENG HK

Burn-in socket having pick-up arrangement for quickly pick-up IC package after IC package is tested

InactiveUS20080299793A1Kept very reliableEngagement/disengagement of coupling partsElectrical measurement instrument detailsEngineeringBurn-in

A burn-in socket for receiving an IC package (2) is provided. The burn-in socket includes a socket body with a plurality of contacts (7) disposed therein and a cover (6) rotatablely coupled to the socket body. The socket body defines a receiving space (500) for receiving the IC package (2) to be tested therein. The cover (6) has a pushing portion (611) capable of pressing on the IC package (2) toward the socket body when the cover (6) is turned to a closed position. At least one pair of pick-up arrangements (8) are provided around the pushing portion (611) for automatic pick-up of the IC package (2).

Owner:HON HAI PRECISION IND CO LTD

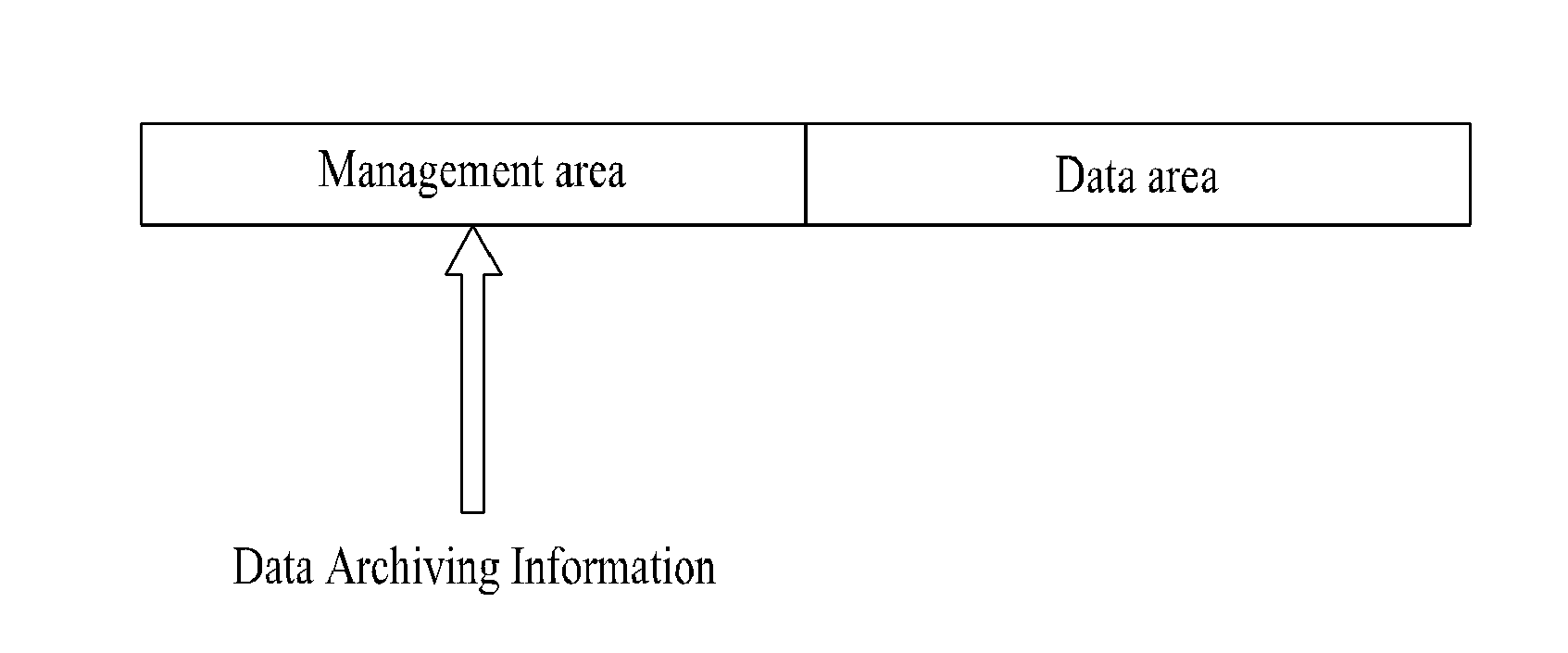

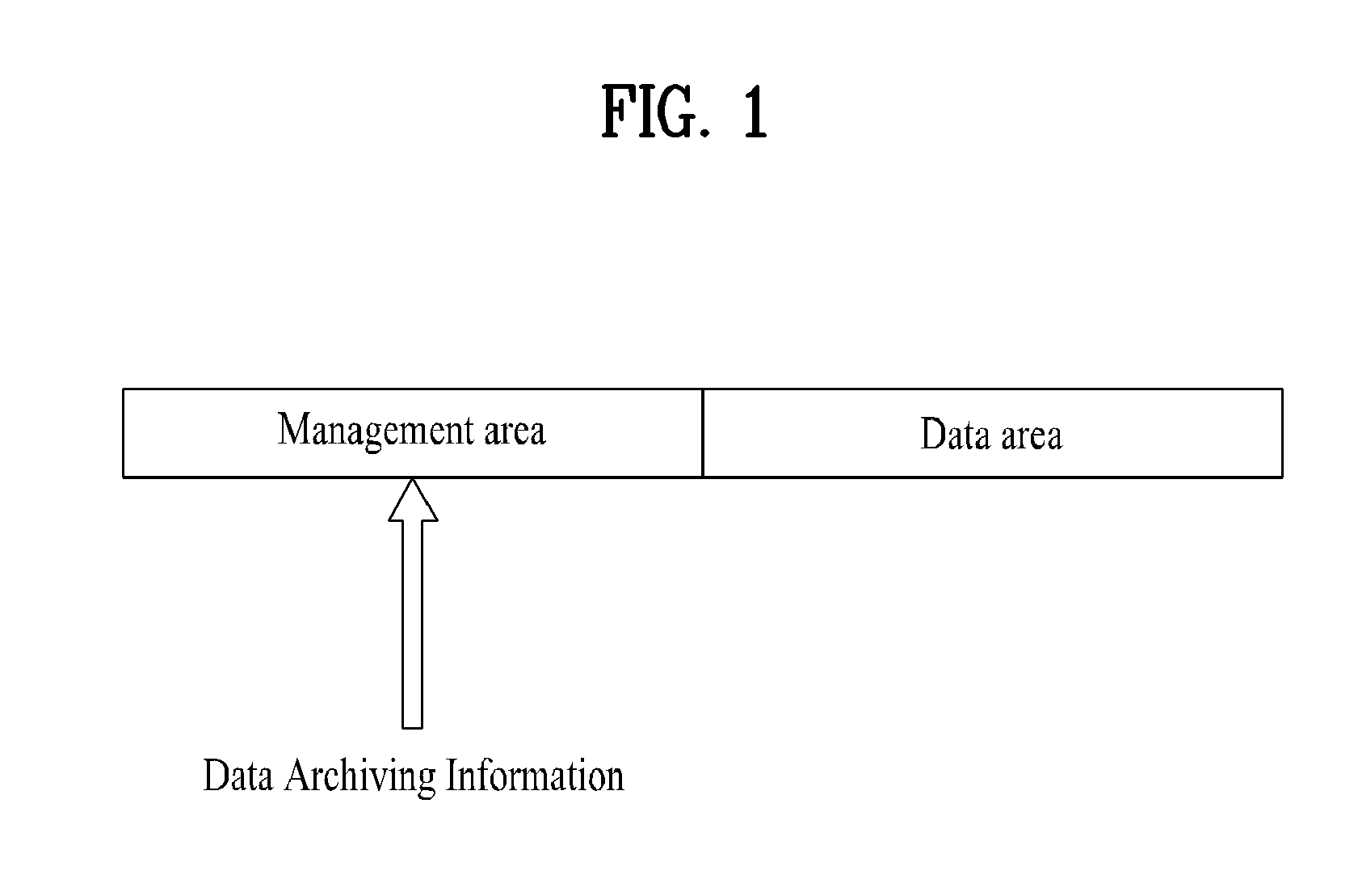

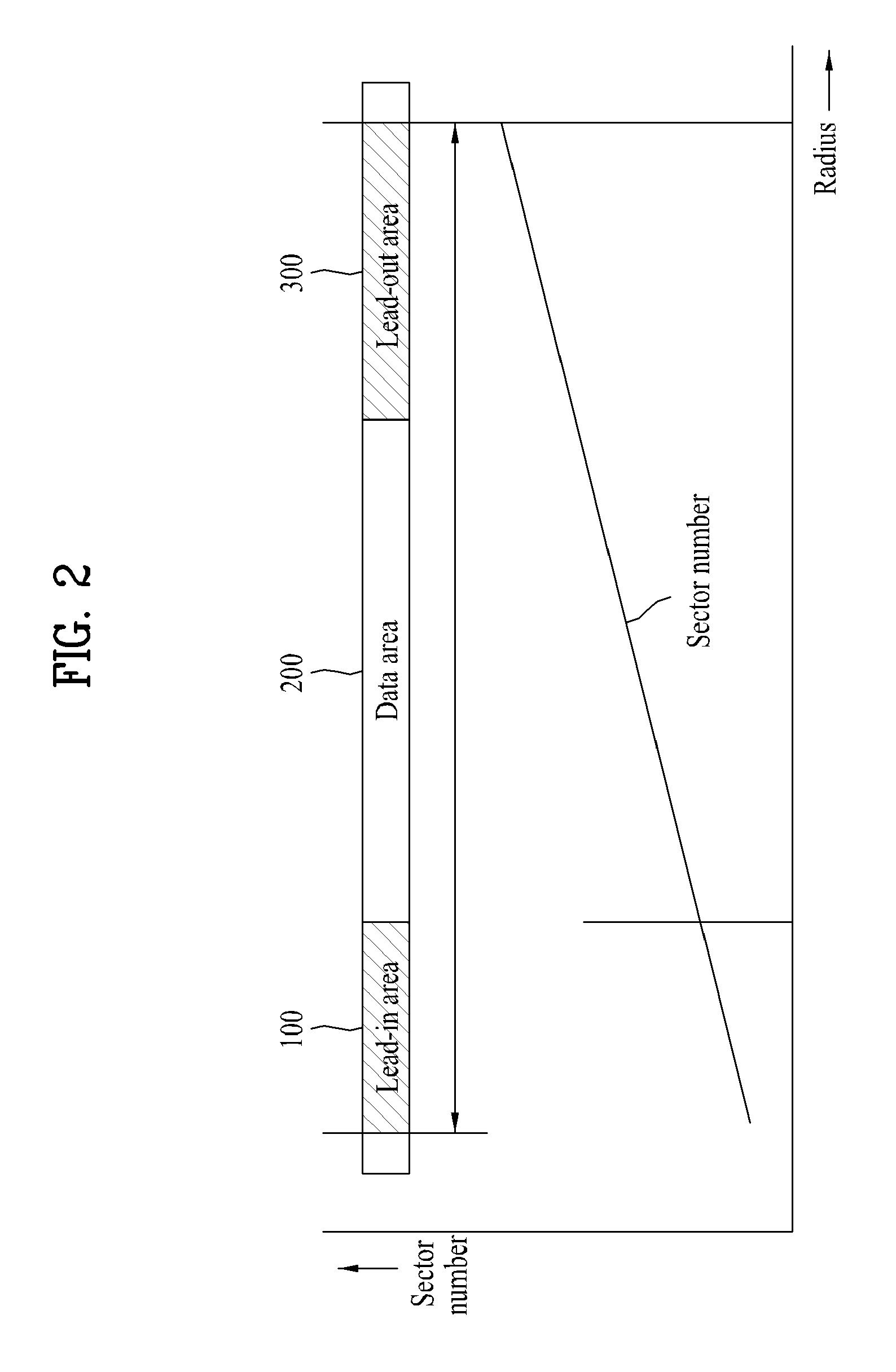

Recording medium for archiving data, recording method, recording apparatus, reproducing method, and reproducing apparatus

InactiveUS20110138137A1Stay efficientKept very reliableMemory loss protectionRecord information storageComputer hardwareManagement area

A recording medium for archiving data, a recording method, a recording apparatus, a reproducing method, and a reproducing apparatus are disclosed. The recording medium includes a data area for recording user data and a management area for managing information recorded on the recording medium. The management information includes data archiving information.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com