Wood-type golf club

a golf club and wood-type technology, applied in the field of golf clubs, can solve the problems and achieve the effect of reducing the tendency of the shaft to twist or turn in the player's hand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

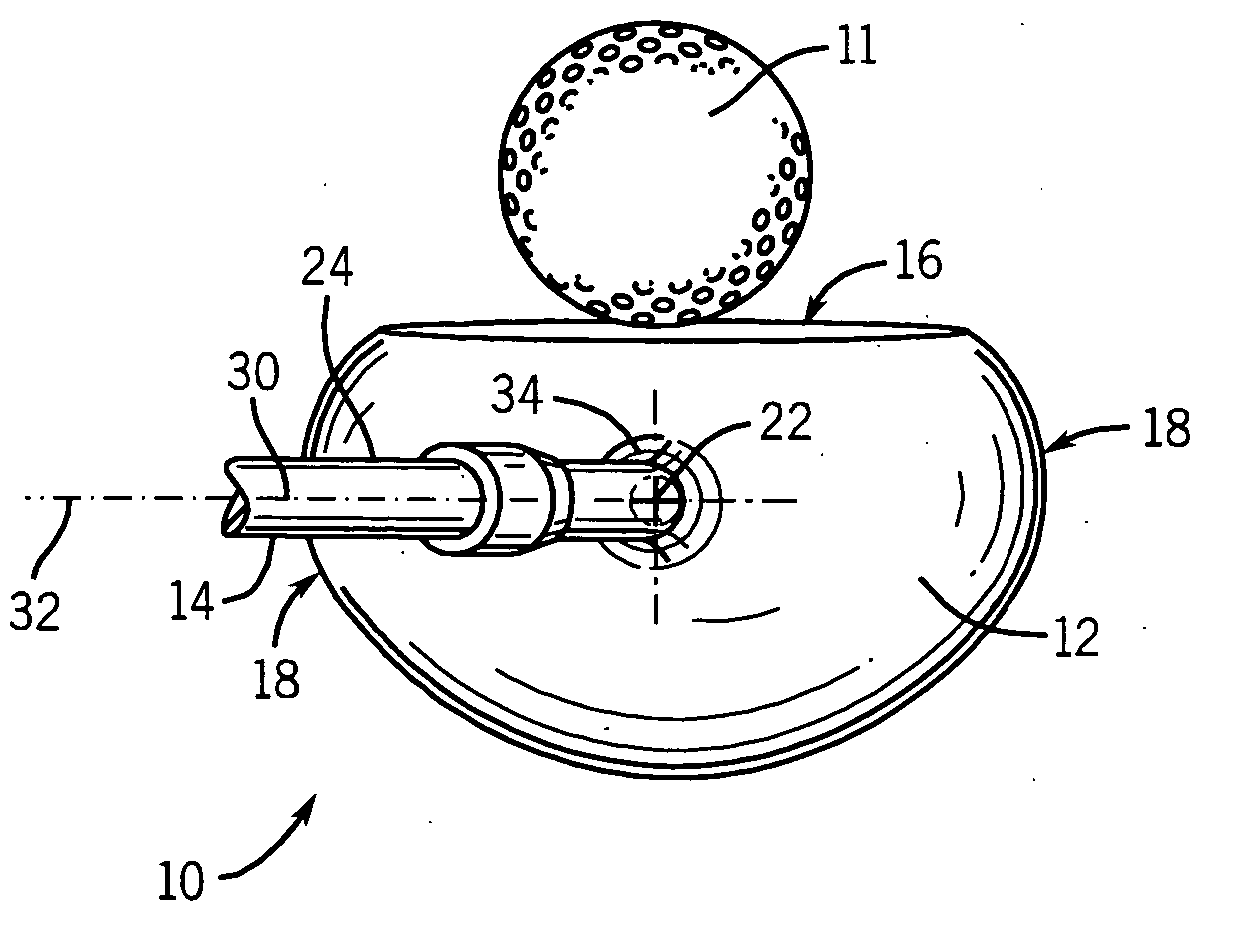

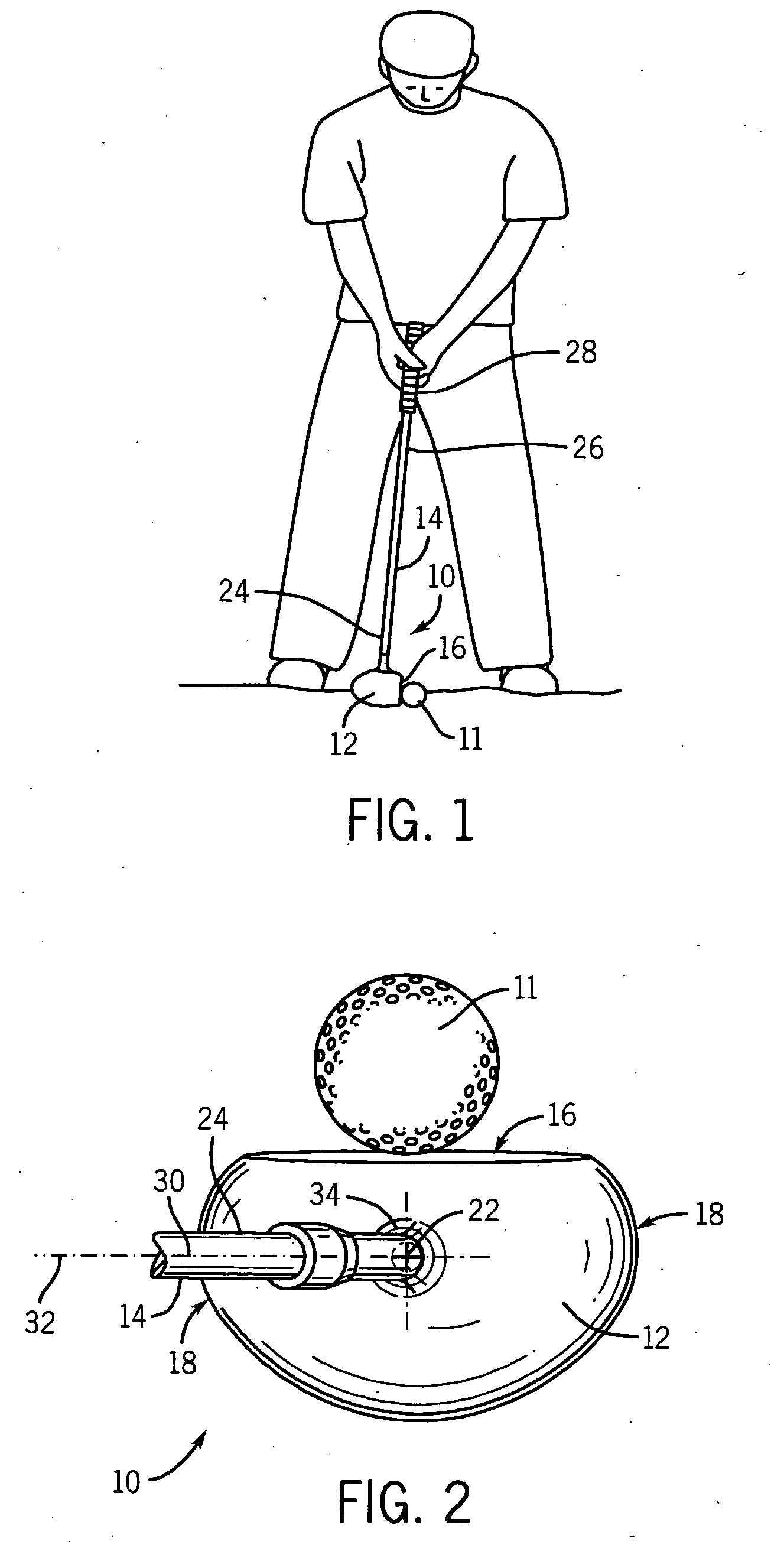

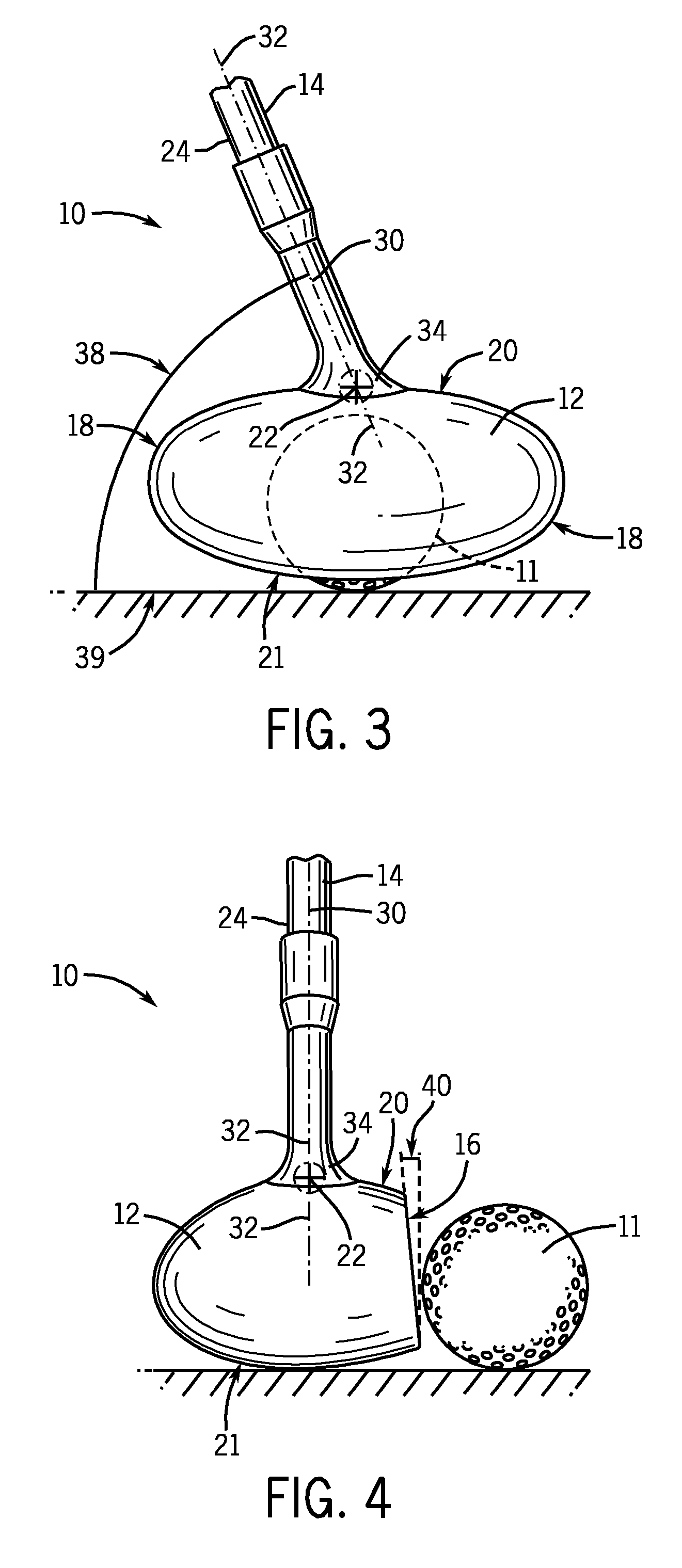

[0017] Referring to the drawings, FIGS. 1-4 illustrate a preferred embodiment of the wood-type golf club 10 of the present invention. Golf club 10 has an oval-shaped club head 12 connected to an elongated shaft 14. The club head 12 can be at least partially formed from wood, metal or composite material. The preferred material is wood, but the term “wood” and “wood-type” when used in connection with golf clubs is commonly used, and is used herein, to describe clubs formed of wood, graphite, metal, composite material, or any combination thereof. The club head could even be formed of other materials, including plastic. The club head 12 has a flattened striking face 16 for striking a golf ball 11, two spaced-apart side surfaces 18, a top surface 20, a bottom surface 21, and a top midpoint 22. The top midpoint 22 is located behind the striking face 16 on the top surface 20 at a point substantially equidistant between the spaced apart side surfaces 18. Most specifically, the top midpoint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com