Semiconductive coating and application process for shielded elastomeric electrical cable accessories

a technology of elastomeric insulating dielectrics and semi-conductive coatings, which is applied in the manufacture of non-conductive materials with dispersed conductive materials, cable/conductor devices, woodworking apparatuses, etc., can solve the problem that the chemical bonding between an elastomeric semi-conductive coating and an elastomeric insulating dielectric cannot be satisfactorily achieved, and the application of secondary coatings to irregular interior surfaces is difficult to achieve effectively and cost. problem problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

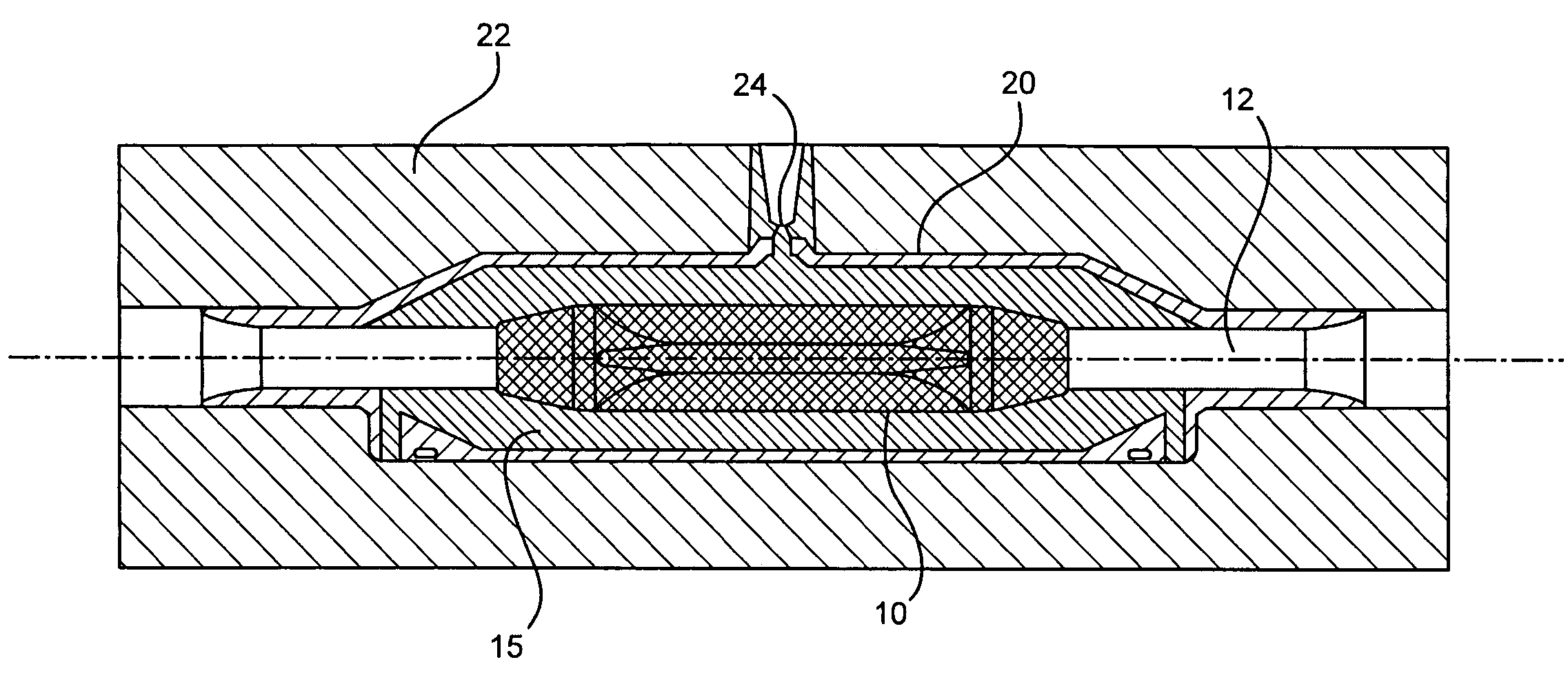

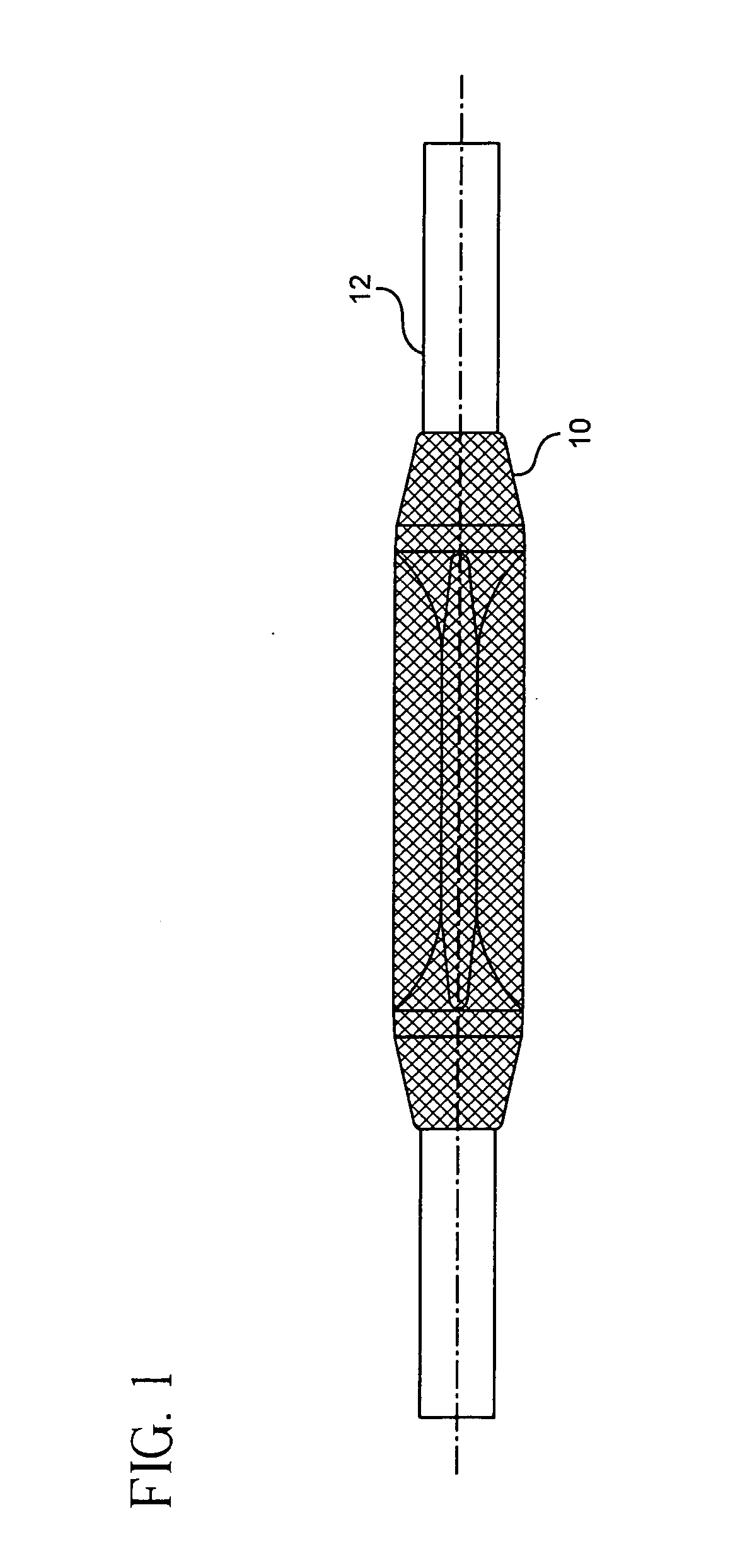

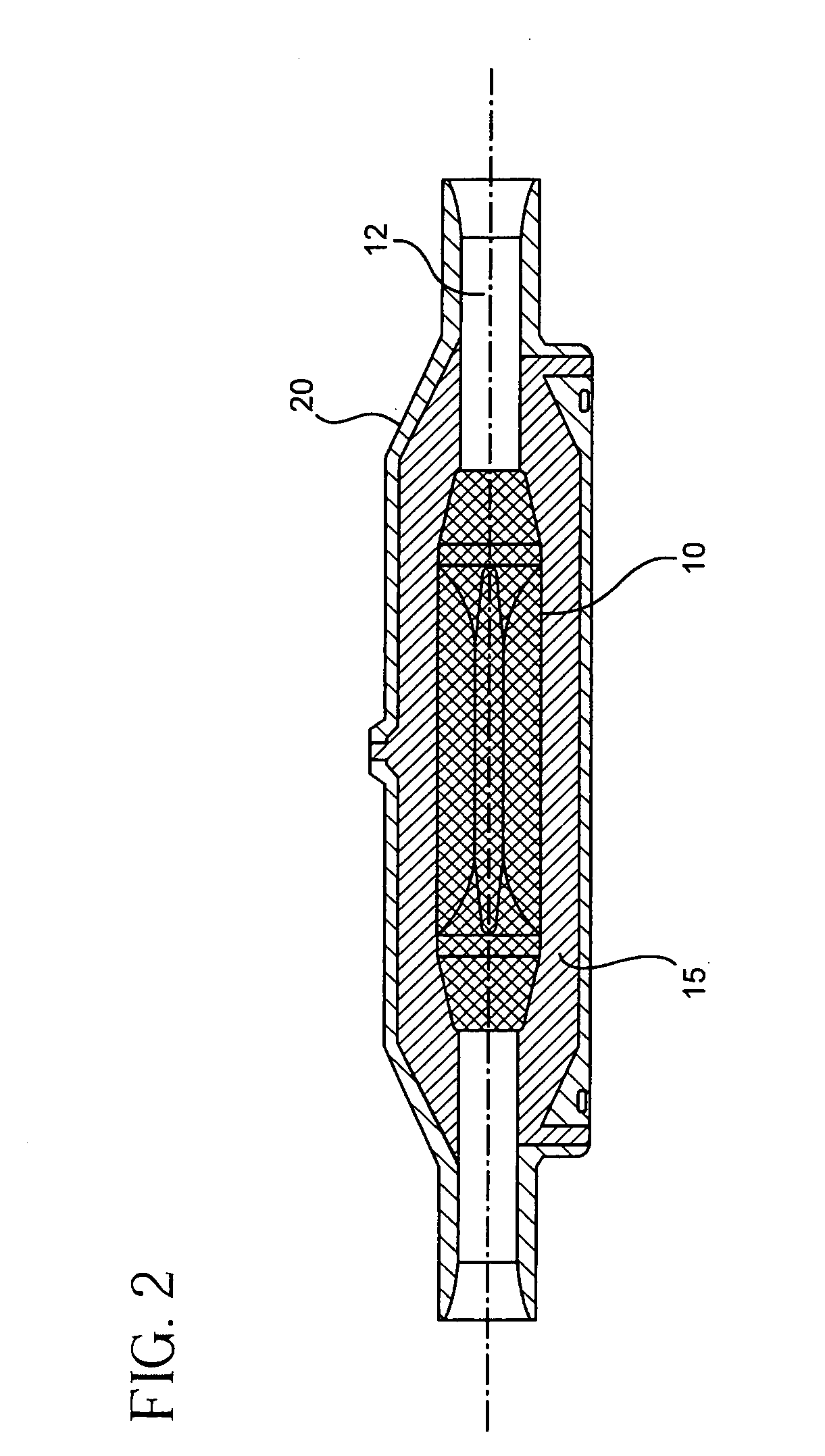

[0018] The present invention provides a method for manufacturing a semiconductive shield capable of providing geometric electrical stress control and / or shielding to medium to high voltage electrical cable accessories. The process of the present invention includes the transfer of a conventionally applied elastomeric semiconductive coating from an intermediate substrate to an elastomeric insulating dielectric during cure of the coating and insulating dielectric.

[0019] The present invention includes an elastomeric semiconductive coating process by which an elastomeric semiconductive coating is transferred from an intermediate substrate to an elastomeric insulating dielectric during the cure of the coating and elastomeric insulating dielectric. The formulated elastomeric semiconductive coating may include, for example, an EPDM elastomer. However, the formulated coatings may also be based on silicone (VMQ) and other elastomeric polymers.

[0020] The elastomeric semiconductive coating us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| semiconductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com