Heat sink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

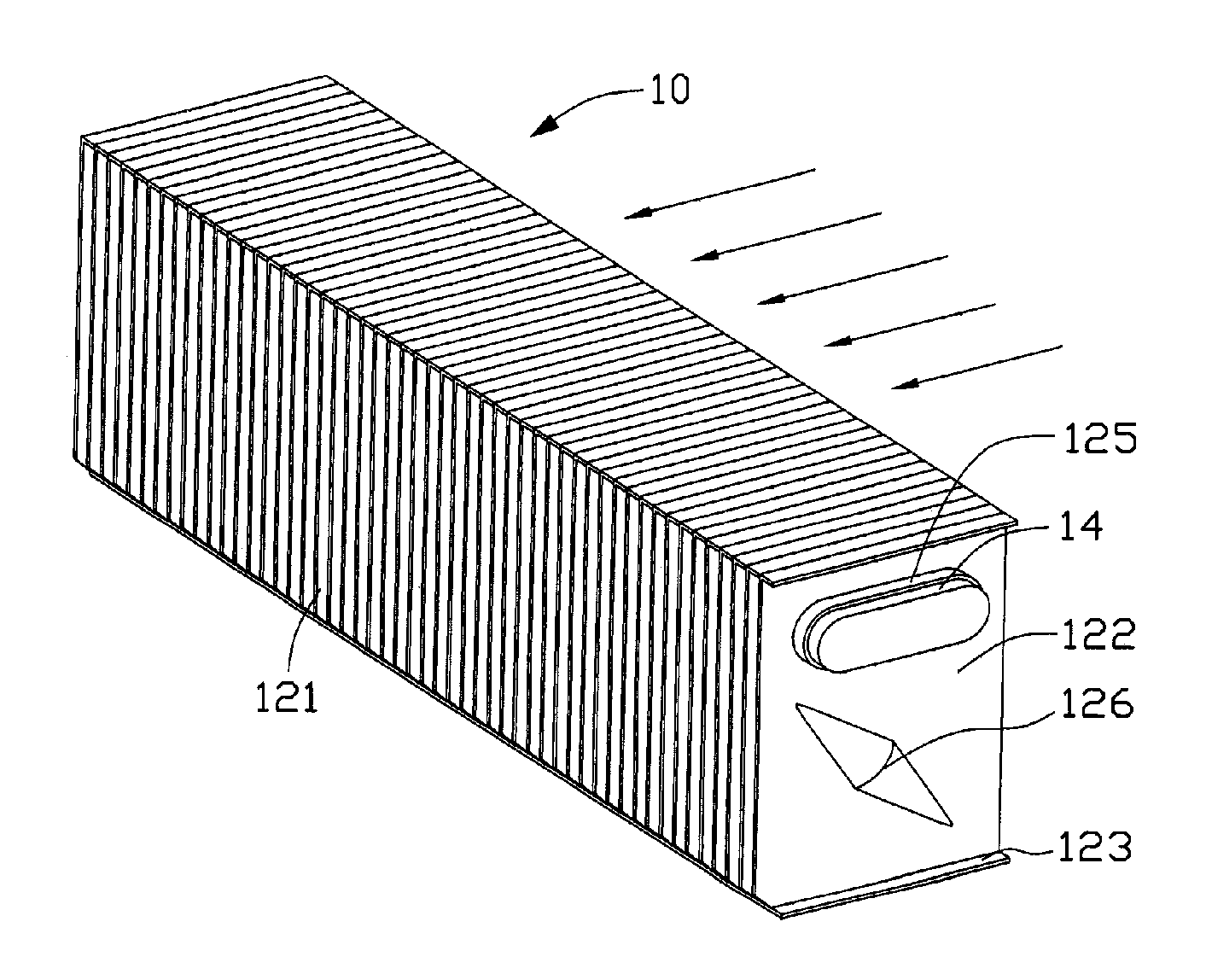

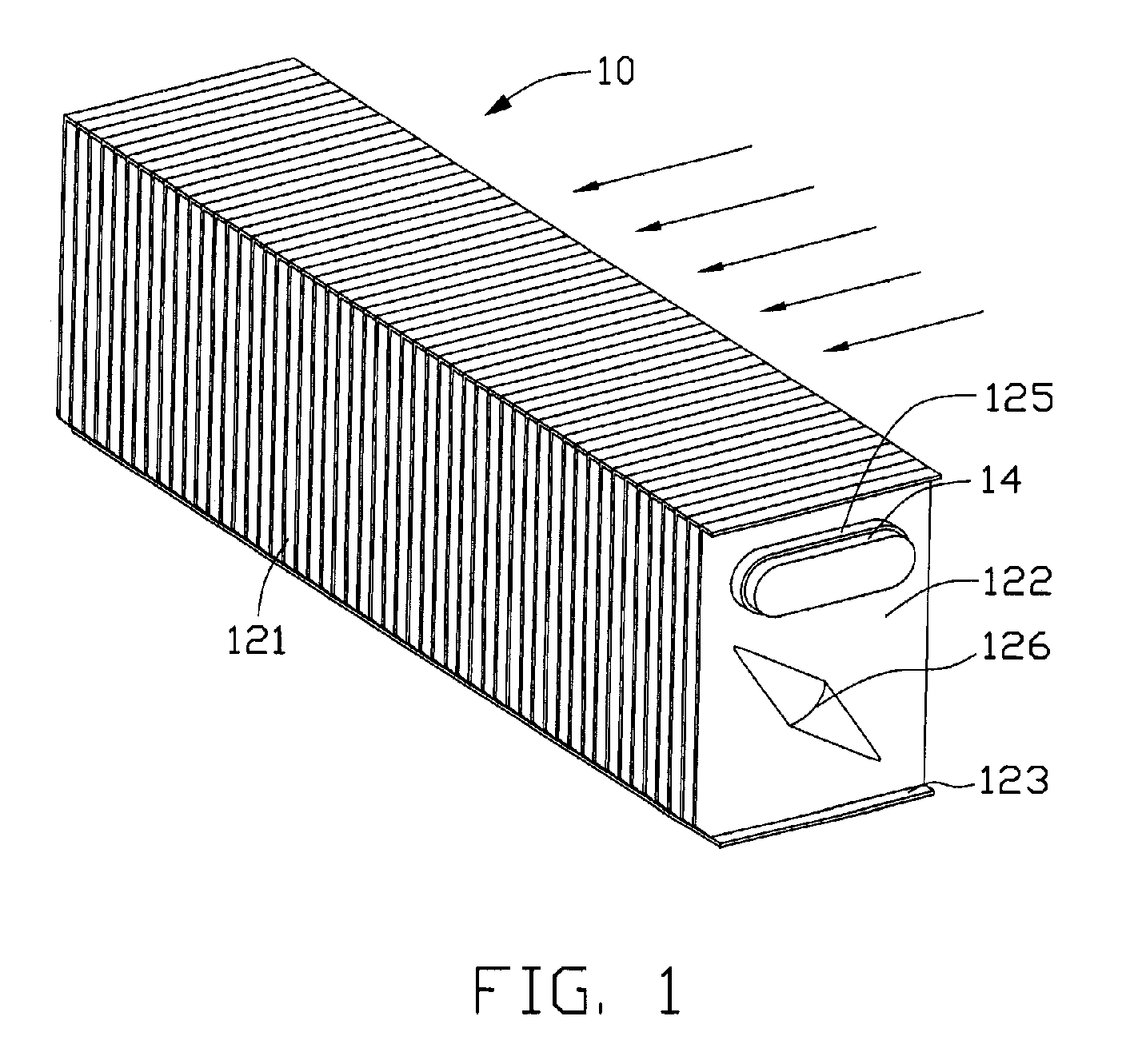

[0010] Referring to FIGS. 1 and 2, a heat sink 10 according to a preferred embodiment of the present invention is shown. A heat dissipating fan (not shown) is disposed at one side of the heat sink 10, for providing an airflow passing through the heat sink 10 to take away heat therefrom as indicated by arrows of FIG. 1. The heat sink 10 includes a plurality of parallel fins 12 and a heat pipe 14 extending through the fins 12. The heat pipe 14 has two opposite ends respectively connecting with a heat-generating electronic component (not shown) and the fins 12, for transferring heat therebetween.

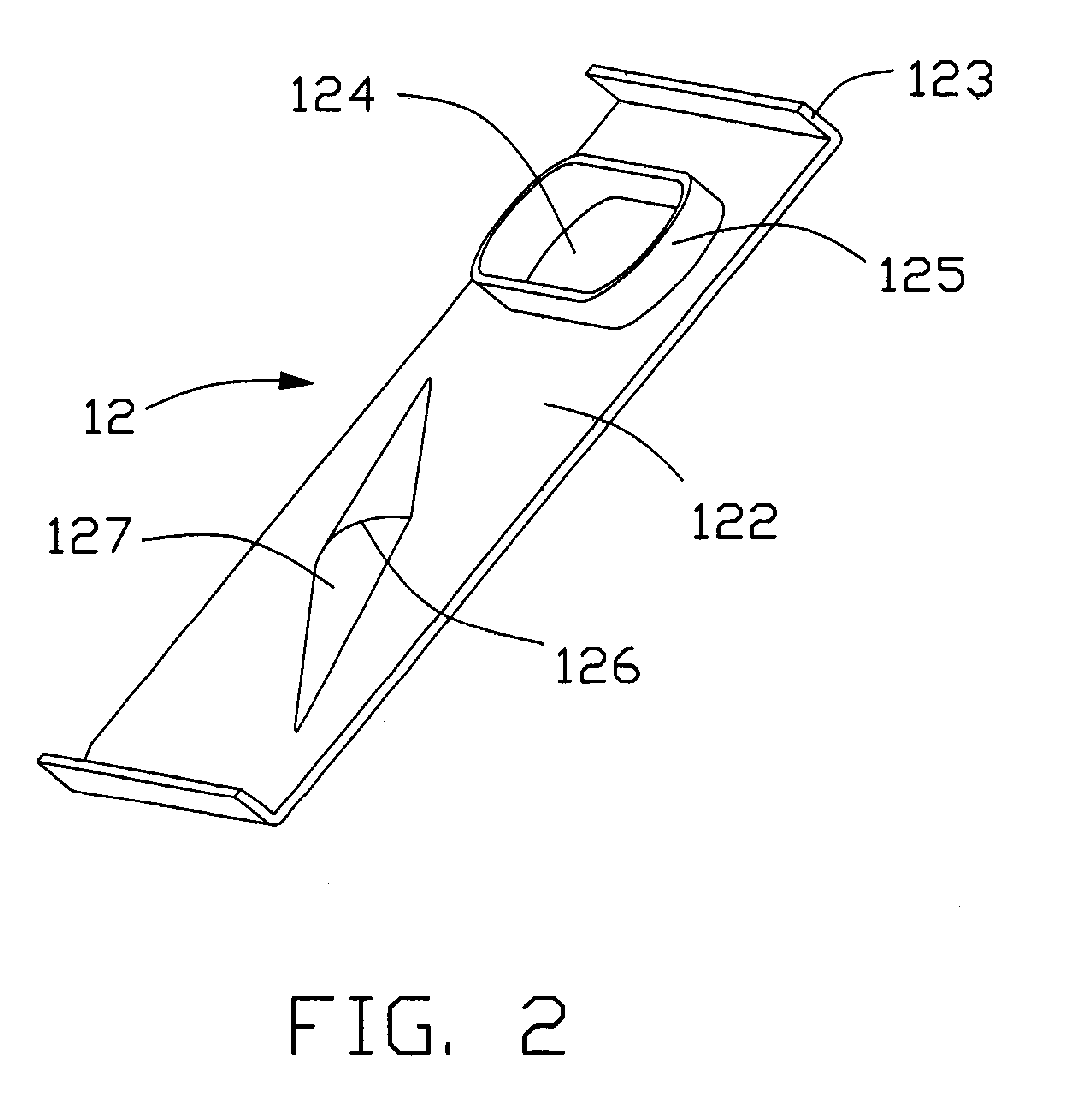

[0011] Each of the fins 12 includes a rectangular shaped main body 122, and two flanges 123 extending from two opposite ends of the main body 122. The fins 12 are stacked together with the flanges 123 of a rear fin 12 abutting against the main body 122 of a front fin 12. A plurality of air passages 121 are formed between two adjacent fins 12 to allow the airflow pass through. The main body 122...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com