Electronic component, module, module assembling method, module identification method and module environment setting method

a technology of electronic components and modules, applied in the direction of electrical apparatus, semiconductor devices, semiconductor/solid-state device details, etc., can solve the problems of excessive time and effort, and achieve the effect of favorable modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] Now referring to the drawings, preferred embodiments of the invention are described below.

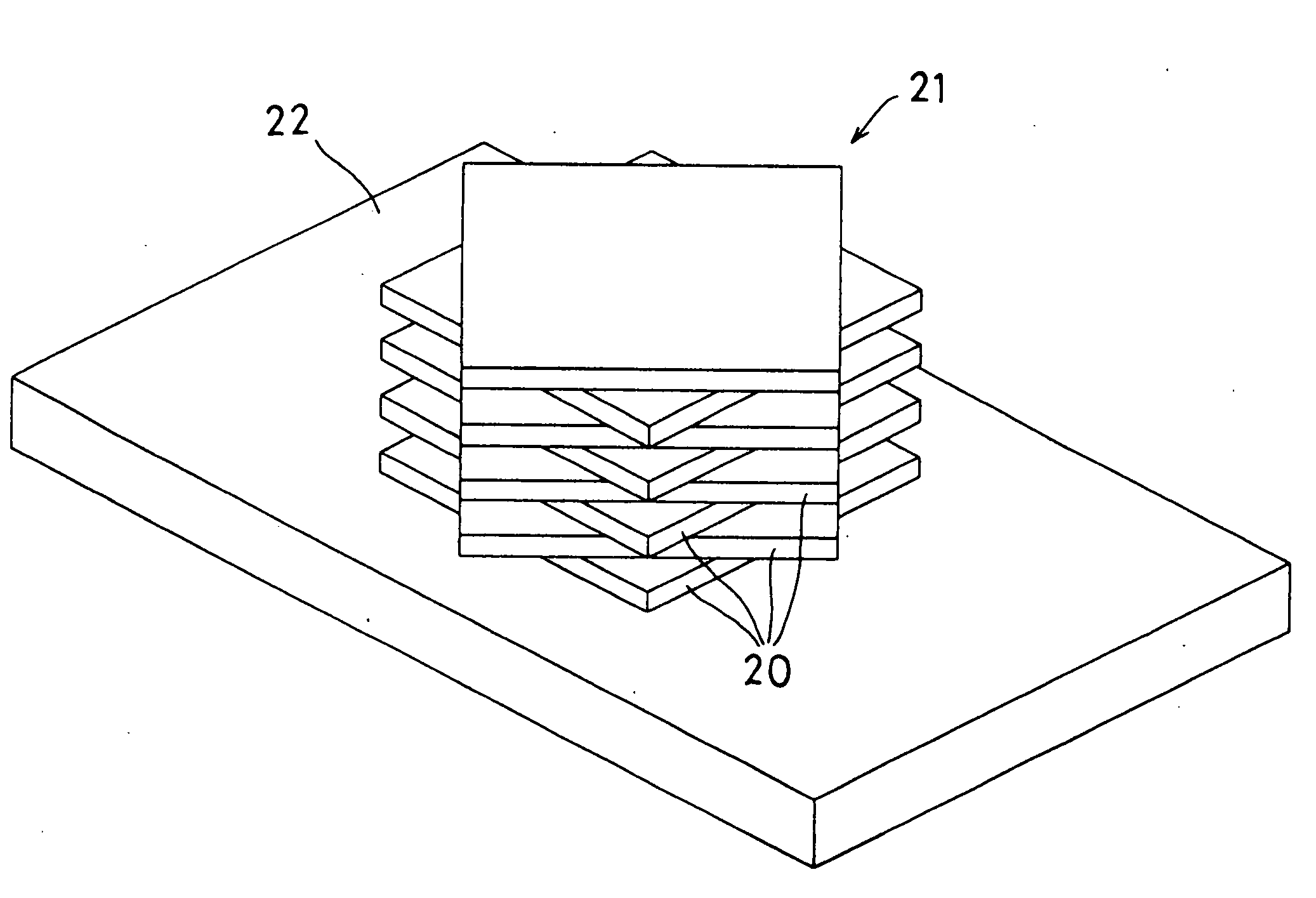

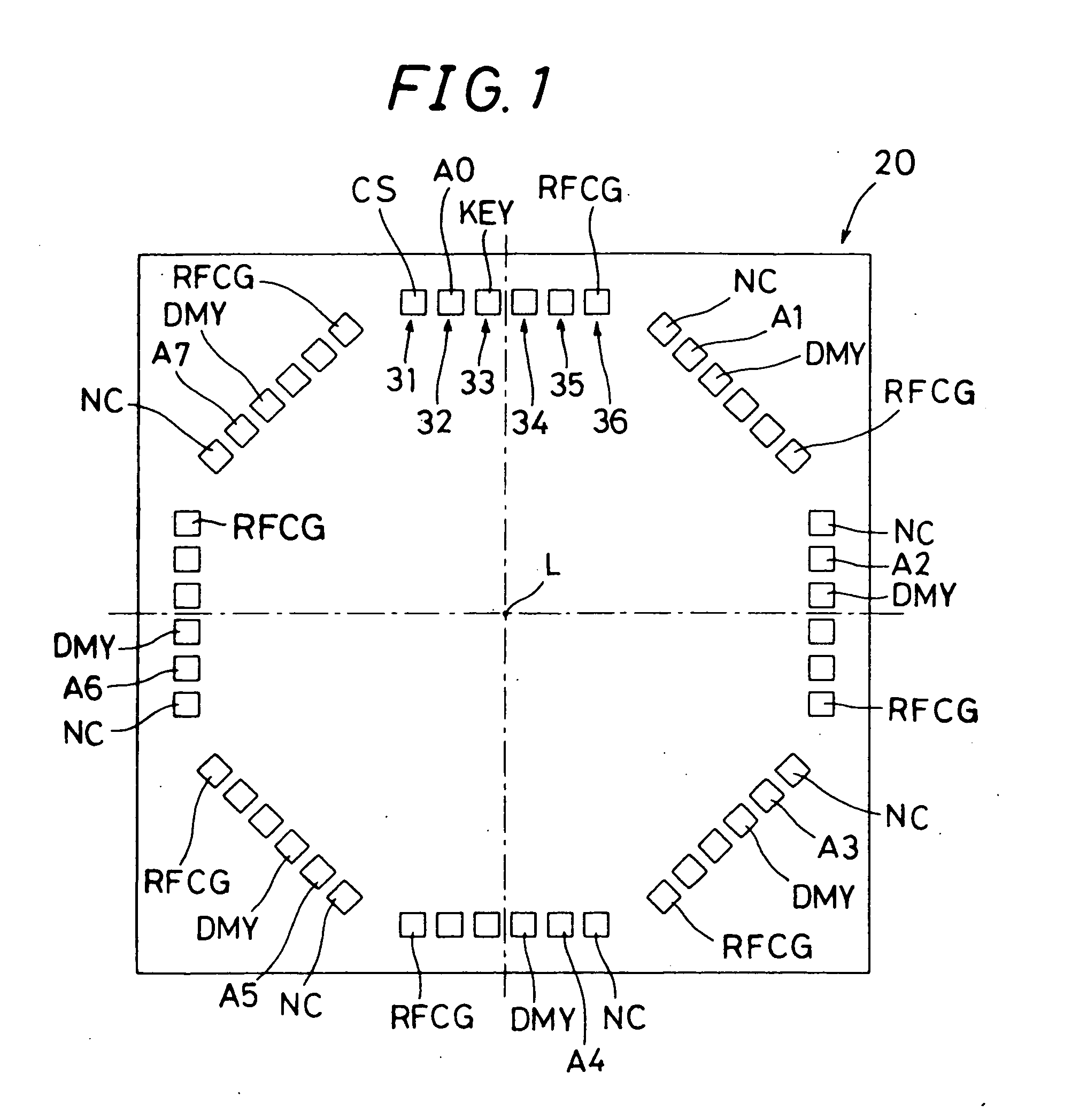

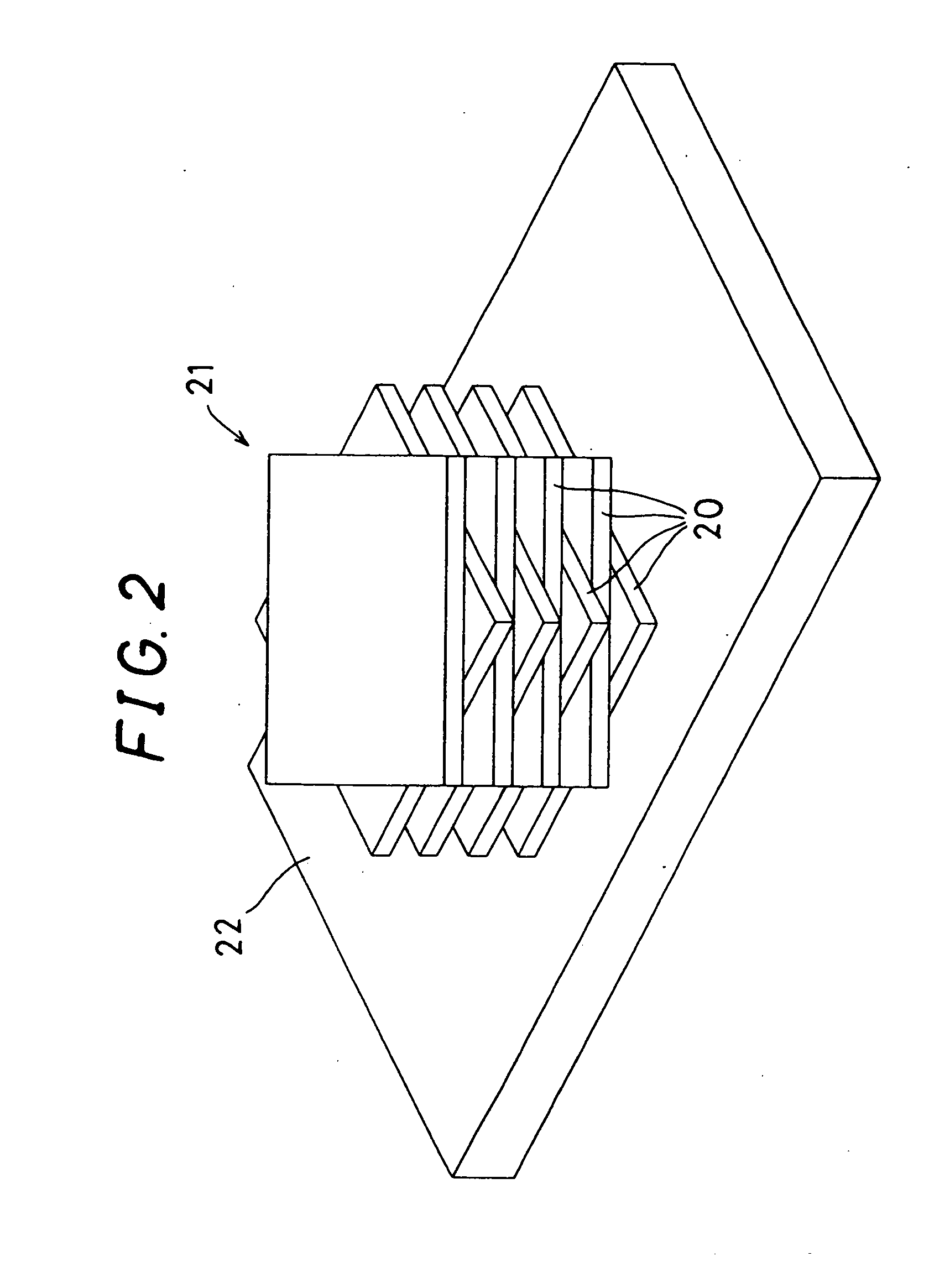

[0096]FIG. 1 is a front view showing a memory chip 20 according to an embodiment of the invention. FIG. 2 is a perspective view showing a memory module 21 assembled by using the memory chips 20 in a state mounted on a board 22. The memory chip (occasionally referred to as “chip” hereinafter) 20 is an electronic component, and used for assembling the memory module (occasionally referred to as “module” hereinafter) 21, which is high-capacitance and small-sized, by stacking a plurality of chips 20 in order to realize high-density packaging.

[0097] The chip 20 is formed into a plate shape, and the external shape thereof perpendicular to a thickness direction is a square shape. The chip 20 is a semiconductor device, and has a configuration that an internal circuit (not shown) is formed on at least a principal surface that is a one surface in a predetermined thickness direction of a semicondu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com