Cold roll forming method for reducing a diameter of a metal pipe, and a metal pipe product having its diameter reduced by such method

a technology of metal pipe and cold roll forming, which is applied in the direction of drawing dies, manufacturing tools, mechanical equipment, etc., to achieve the effect of convenient and reliabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

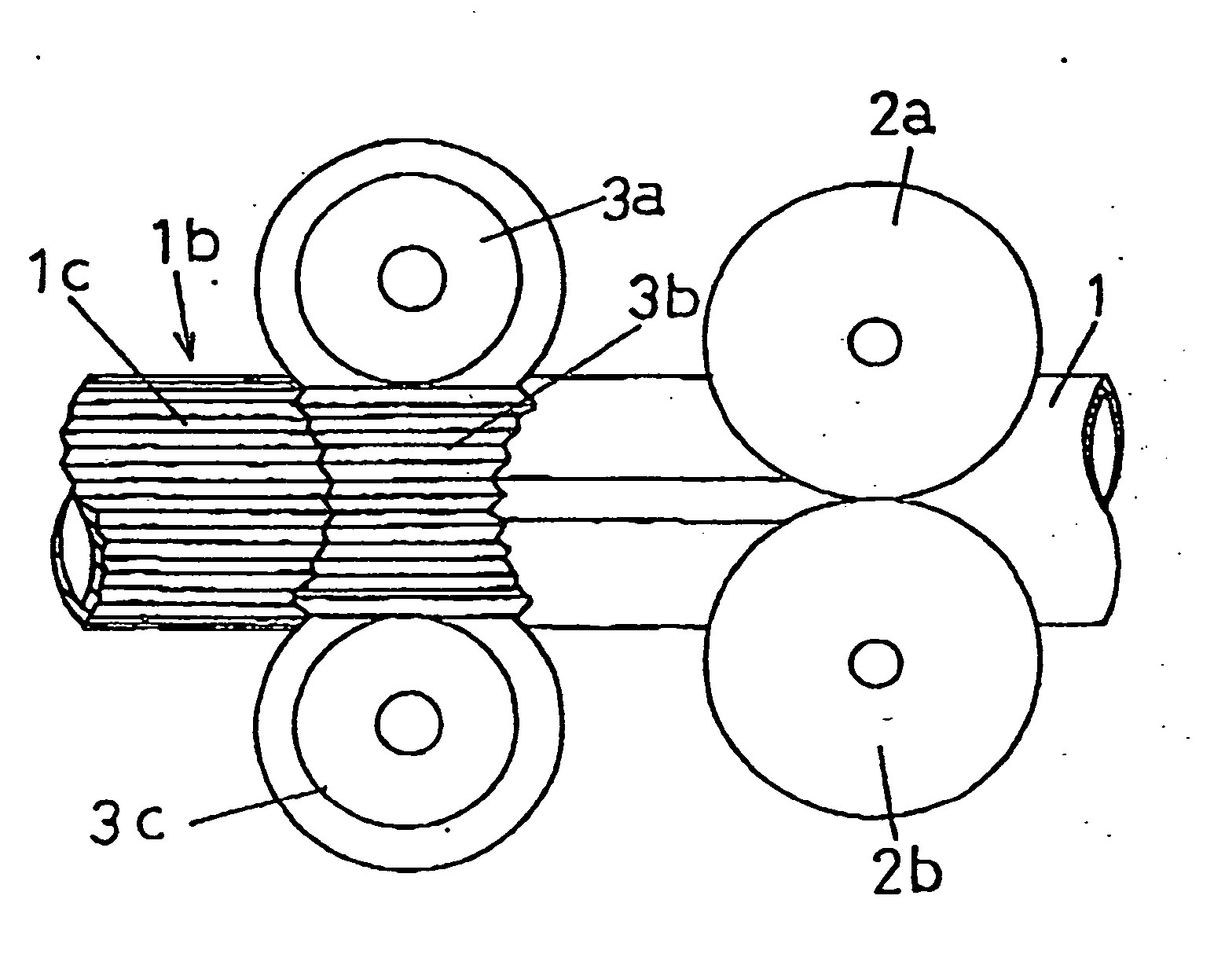

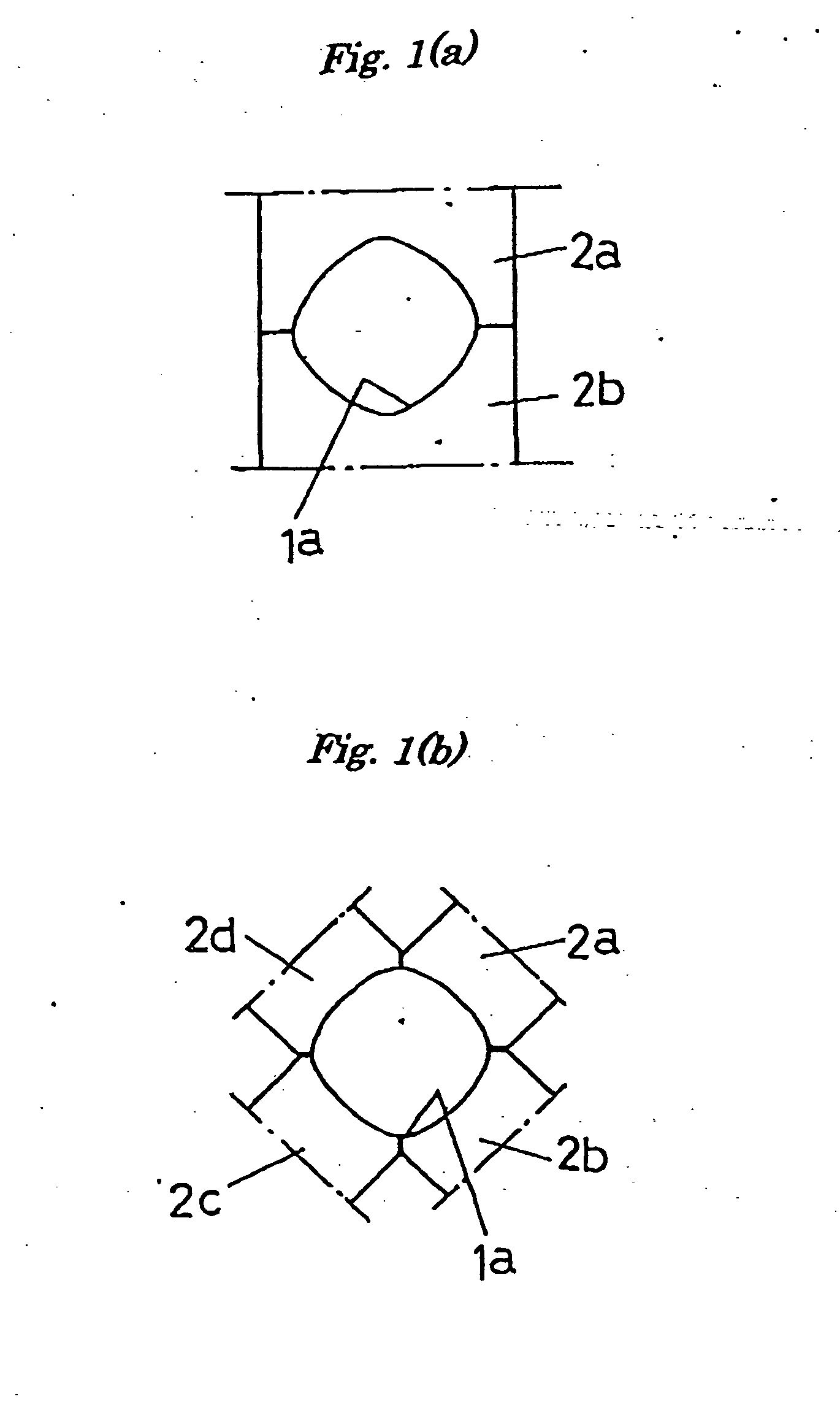

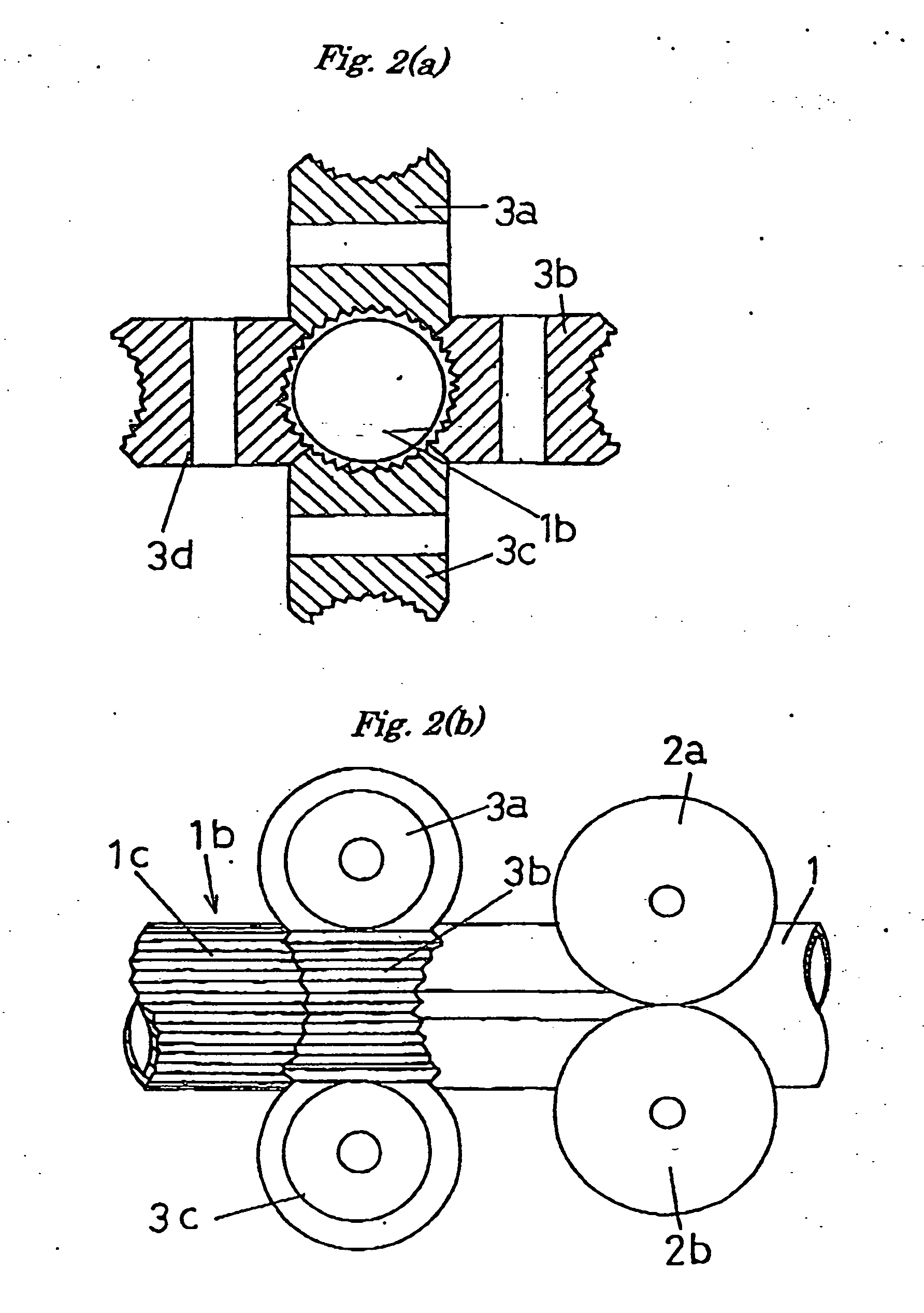

[0081] A raw pipe 1 that is subject to a diameter-reducing process is made of steel, and is originally formed into a round shape having an outer diameter of 216.3 mm. As an initial step, round steel pipe 1 may be passed through a set of pre-forming rolls 2a and 2b so that it can be formed into an intermediate steel pipe 1a having a rectangular cross section (FIG. 1(a)).

[0082] Then, the intermediate steel pipe 1a may be passed through a set of diameter-reducing rolls 3a, 3b, 3c and 3d so that it can be formed into a round steel pipe 1b having a reduced diameter (FIGS. 2(a) and (b)).

[0083] During the diameter-reducing process, a hydraulically-operated cylinder 4 may be operated so that its piston rod 5 can be moved forward in a direction of arrow 6 in FIG. 4, thereby moving the round steel pipe 1 in that direction. There are cases in which a size, particularly a length, of the hydraulically-operated cylinder 4 should be reduced into a particular size or length for some reasons. In t...

embodiment 2

[0088] A raw pipe 7 is also made of steel, and has a round shape. Different from the preceding embodiment, the raw pipe 7 is a double pipe including an additional pipe 8 made of synthetic resin that is inserted into the raw steel pipe 7. A diameter reducing process includes a pre-forming step, followed by a diameter reducing step, like in the preceding embodiment, but differs in that each of rolls 3a, 3b, 3c, 3d in a set of diameter-reducing rolls has no pattern of ridges and grooves on its circumferential surface.

[0089] By passing the raw steel pipe 7 through the pre-forming step and then through the diameter reducing step, a double pipe 10 may be obtained, including the outer steel pipe 7 and the inner synthetic resin pipe 8 as shown in FIG. 3(b).

[0090] Specifically, when the raw steel pipe 7 is passed through the diameter reducing step, it may have a reduction in terms of its diameter. In the double pipe 10 thus obtained, the outer steel pipe 7 and the inner synthetic resin pip...

embodiment 3

[0091] A steel pipe “STKM13A” (carbon steel pipe for machine structural purposes) as specified in relevant JIS specifications is used as a raw steel pipe. The raw steel pipe has an outer diameter of 60.5 mm and a wall thickness of 2.9 mm.

[0092] This embodiment uses a process shown in FIG. 5(b). A diameter reducing process may be performed by passing the raw steel pipe through a set of two pre-forming rolls so that it can be formed into an intermediate steel pipe having an elliptical cross-sectional shape, and then by passing the intermediate steel pipe through a set of two diameter-reducing rolls so that it can be formed into a final steel pipe having a reduction in terms of its diameter. The final steel pipe has an outer diameter of 58.2 mm, which corresponds to a diameter reduction rate of 3.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com