Well production by fluid lifting

a technology of fluid lifting and wells, which is applied in the direction of fluid removal, earth-moving drilling, borehole/well accessories, etc., can solve the problem of limited tubing down-flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

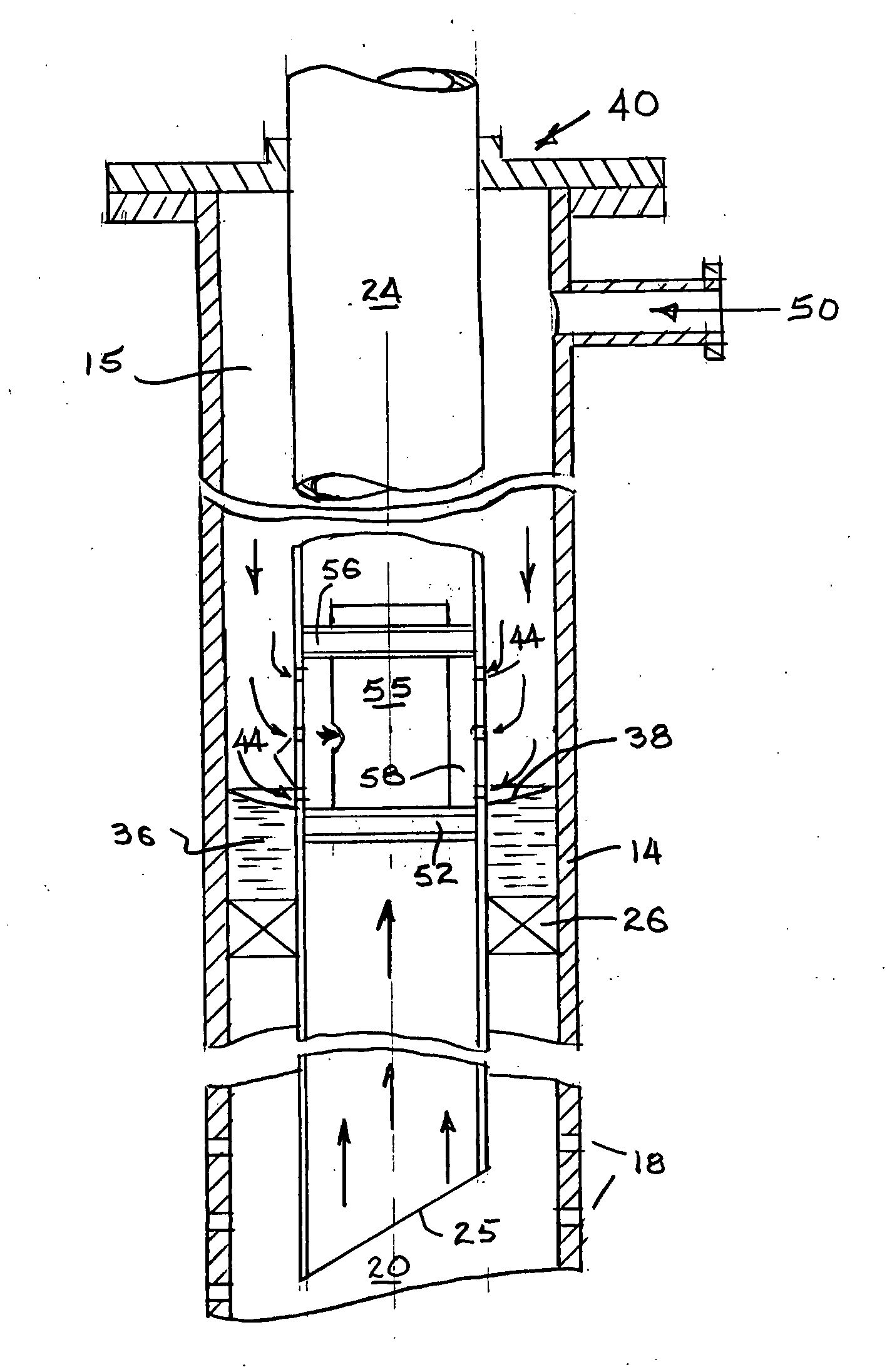

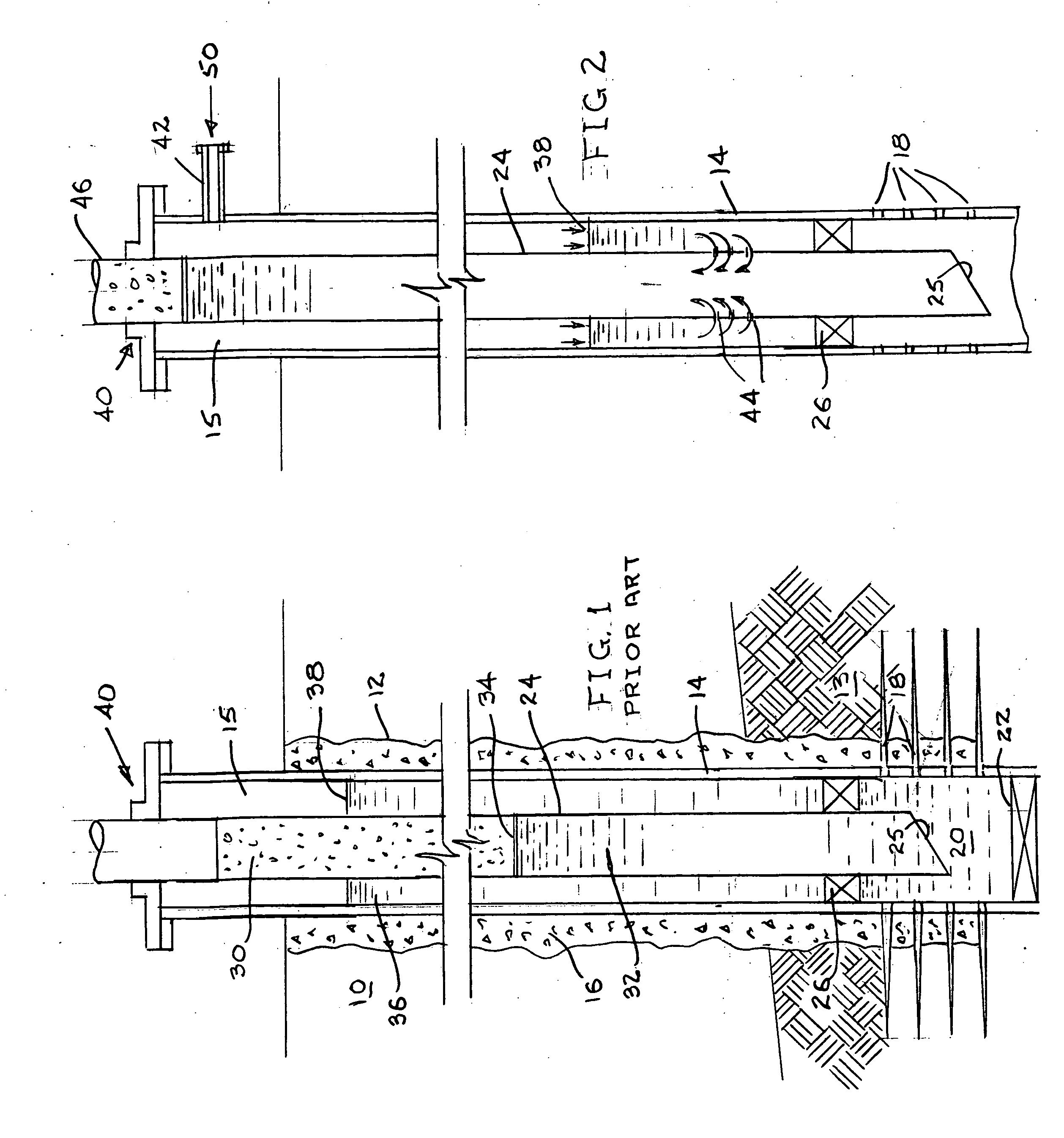

[0036] In the invention, represented by FIG. 2, for example, restoration of productive flow from a “depleted” well includes the preparatory step of securing an injection flow connection 42 proximate of the wellhead 40 for injecting pressurized charging fluid into the casing annulus 15. The charging fluid is preferably oxygen depleted air such as non-cryogenic nitrogen. However, other non oxidizing fluids such as natural gas, methane, carbon dioxide may also be suitable depending on the well site economics.

[0037] Further to the charging fluid connection, 42, the preexisting production tube 24 is in situ perforated at a strategic point 44 above the packer 26. Usually, in situ production tube perforations are executed by a “slick line” or wire-line operation that includes a small diameter perforating gun suspended from the surface at the end of a wire-line. The depth of tubing perforation is selected to sufficiently reduce the tubing column overburden pressure sufficient to restore pro...

third embodiment

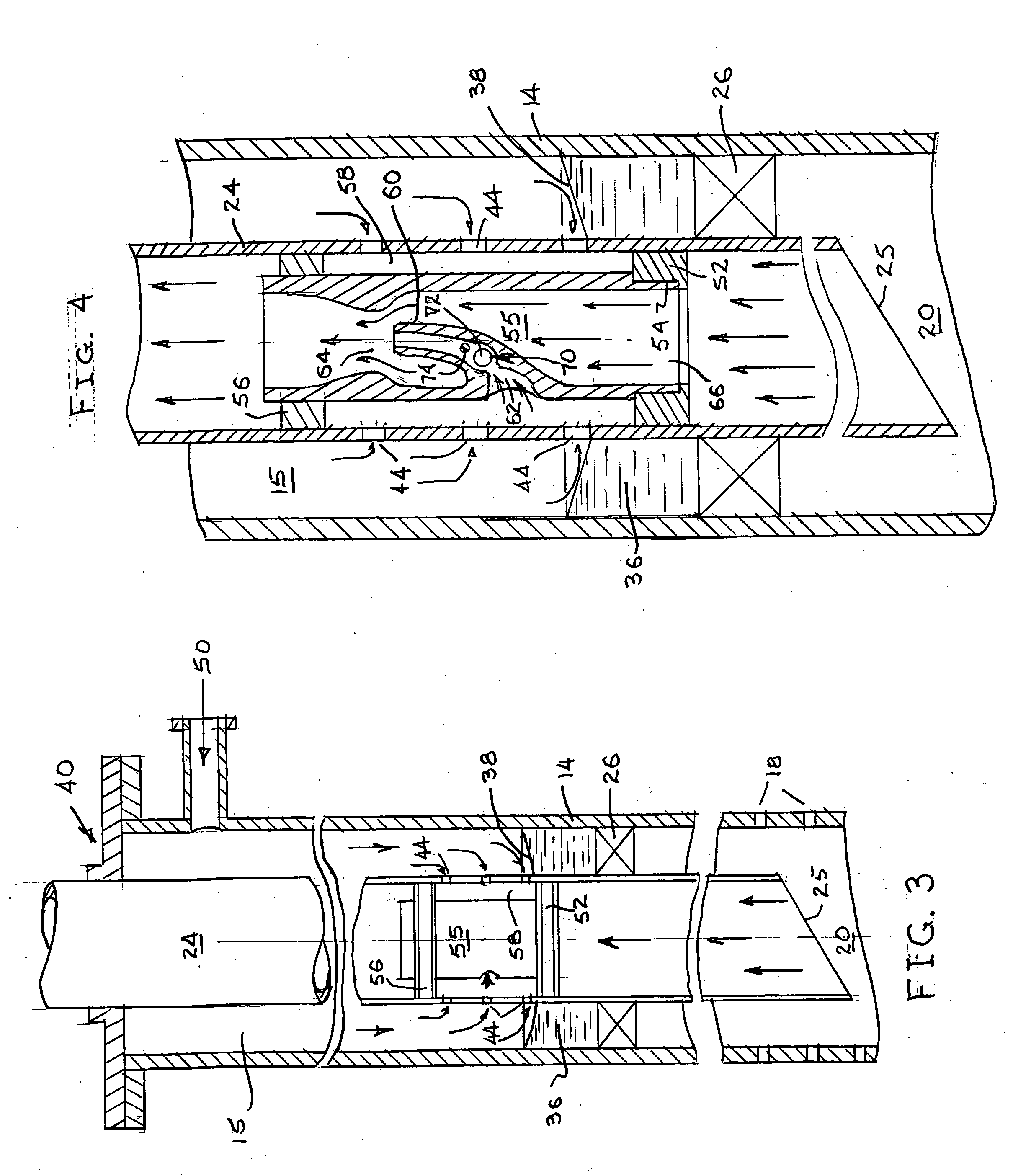

[0048]FIGS. 5 and 6 illustrate the invention that comprises a jet pump sub 80 that is line coupled in a straight tubing string 24 or below a side pocket mandrel tube 82.

[0049] The jet pump sub 80 essentially conforms to the jet pump body 55 illustrated by FIG. 4 with the exception that the nozzle inlet 62 is protected by a slotted screen 84, for example.

[0050] Unless the original production tube is installed with the jet pump sub 80 in-line, which it may be, it will be necessary to withdraw the tubing 24 to insert the pump sub 80. However, no wire-line or perforating procedures are necessary. The entire casing annulus becomes the charging fluid plenum for the pump sub 80.

[0051] In the case of the FIG. 6 embodiment, a gas-lift valve string 28 comprises several lift valves 90, 92 and 94, for example. The valve orifices and mechanisms are disposed in side-pocket mandrel joints 82 above the jet pump 80.

[0052] Operatively, the casing annulus 15 is charged with an opening pressure that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com