Core structure of housingless-type oil cooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

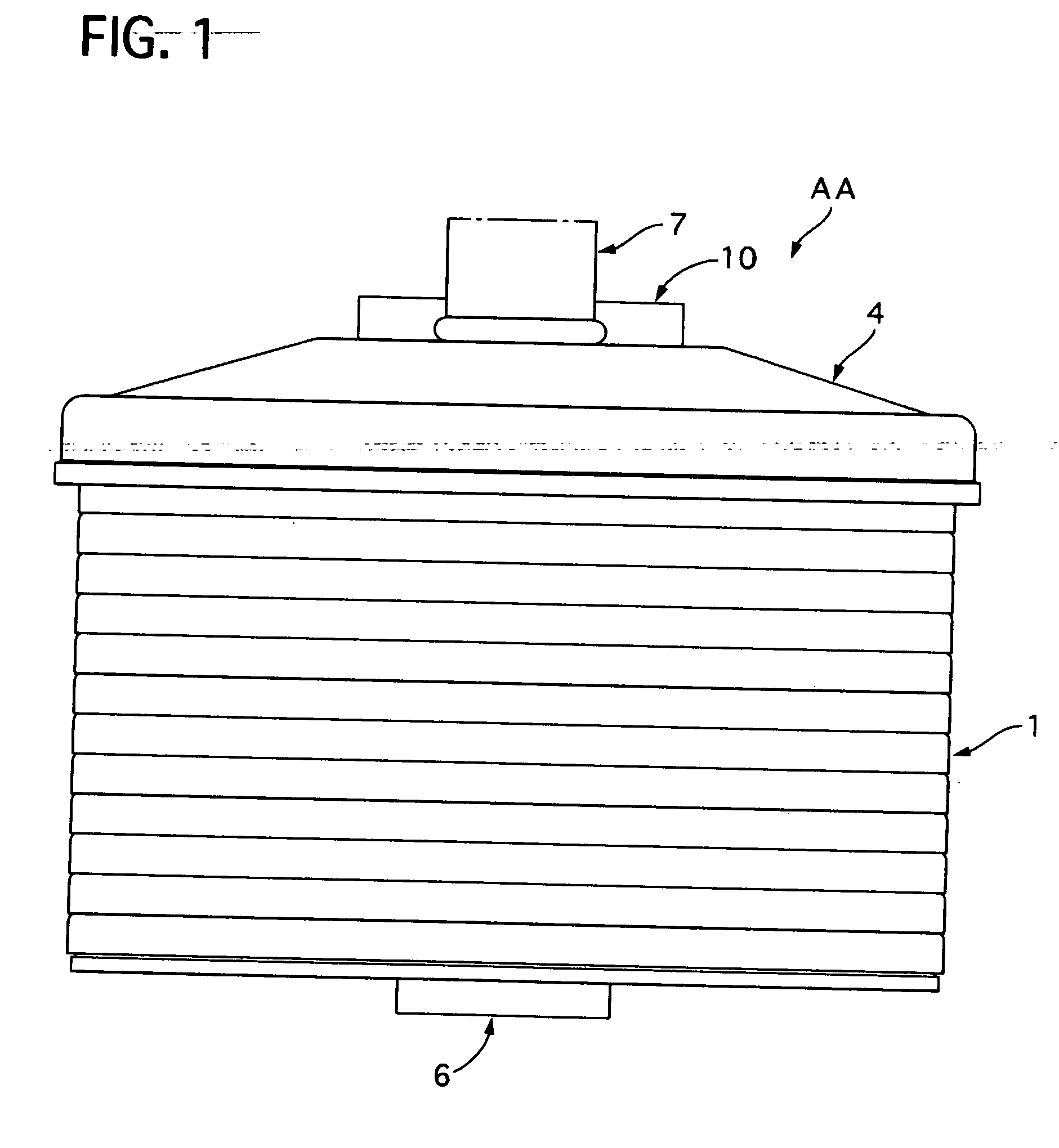

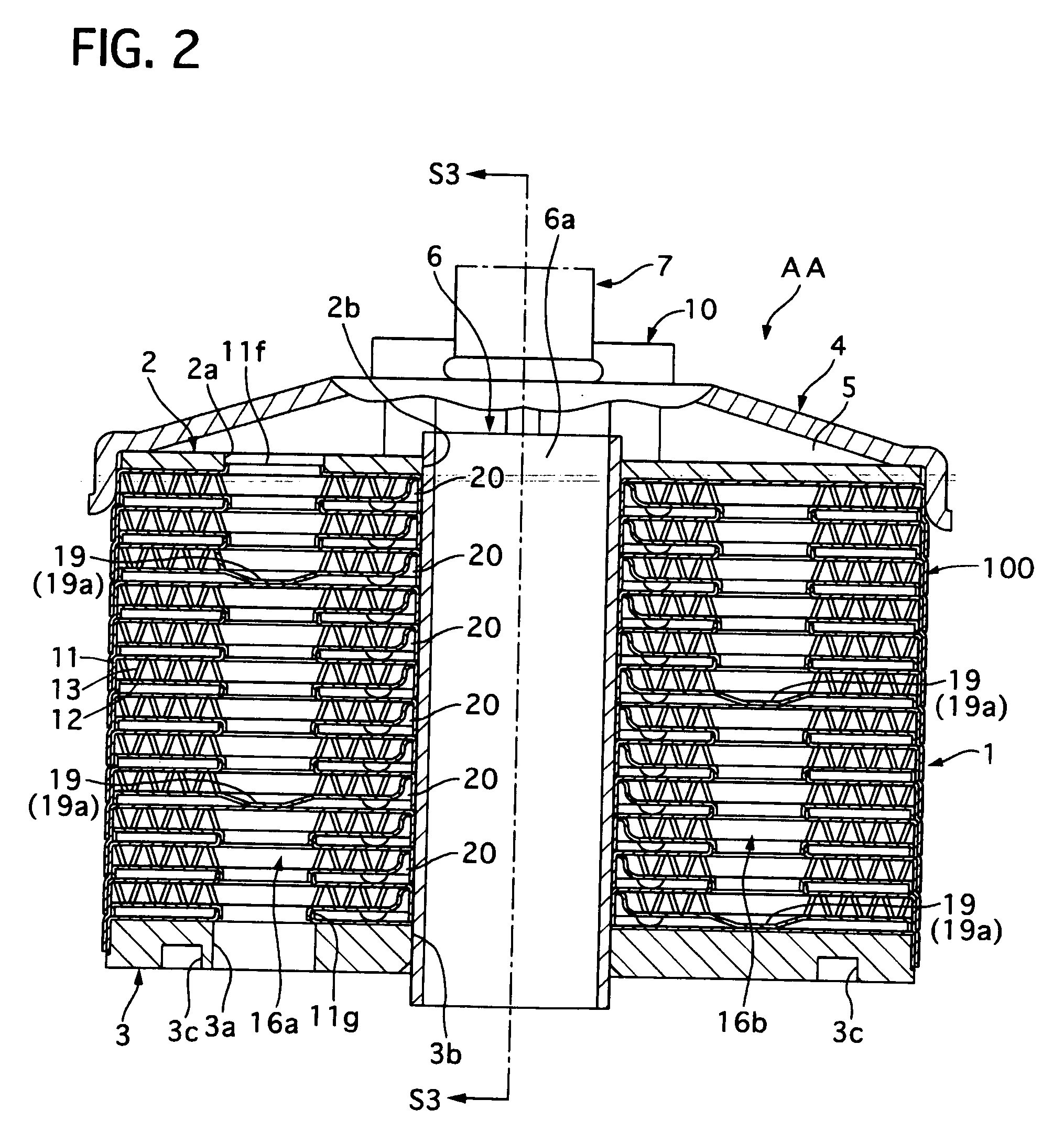

first embodiment

[0044] The inner fin 13 is an offset fin in the first embodiment, but may be used another type one. The inner fin 13 is formed with first to fifth through-holes 13a to 13e corresponding to the first to fifth cylindrical portions 11a to 11e of the first plate 11 and to the first to fifth cylindrical portions 12a to 12e of the second plate 12.

[0045] The first plate 11 and the second plate 12 are coupled with each other, containing the inner fin 13 therein, to form an inner space therebetween for containing the inner fin 13, thereby forming the cooling element. The inner space forms an oil chamber 15 as shown in FIGS. 4B and 5B.

[0046] The second and third cylindrical portions 11b and 11c of the first plate 11 and the second and third cylindrical portions of the next second plate 12 are fitted with each other, as shown in FIG. 4B, to form a pair of oil passages 16a and 16b for fluidically connecting with the adjacent oil chambers 15.

[0047] On the other hand, the second plate 12 and it...

second embodiment

[0062] Next, a core structure of a housingless-type oil cooler of a second embodiment according to the present invention will be described with reference to the accompanying drawings.

[0063] As shown in FIG. 9A, in the core structure of the housingless-type oil cooler BB of the second embodiment, a first plate 11 has a first cylindrical portion 11a projecting downward and shaped in a large circular cylinder at it center position. The first cylindrical portion 11a has a bending portion 21, at an upper end portion thereof, narrowing its opening as a position of the first cylindrical portion 11a becomes lower.

[0064] On the other hand, a second plate 12 has a first cylindrical portion 12a projecting downward, not having a bending portion like the first embodiment.

[0065] The first plate 11 and the second plate 12 are coupled with each other, containing an inner fin 13 therebetween, to form a cooling element. A plurality of the cooling elements are piled up in a vertical direction to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com