Electronic control transformer using DC link voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

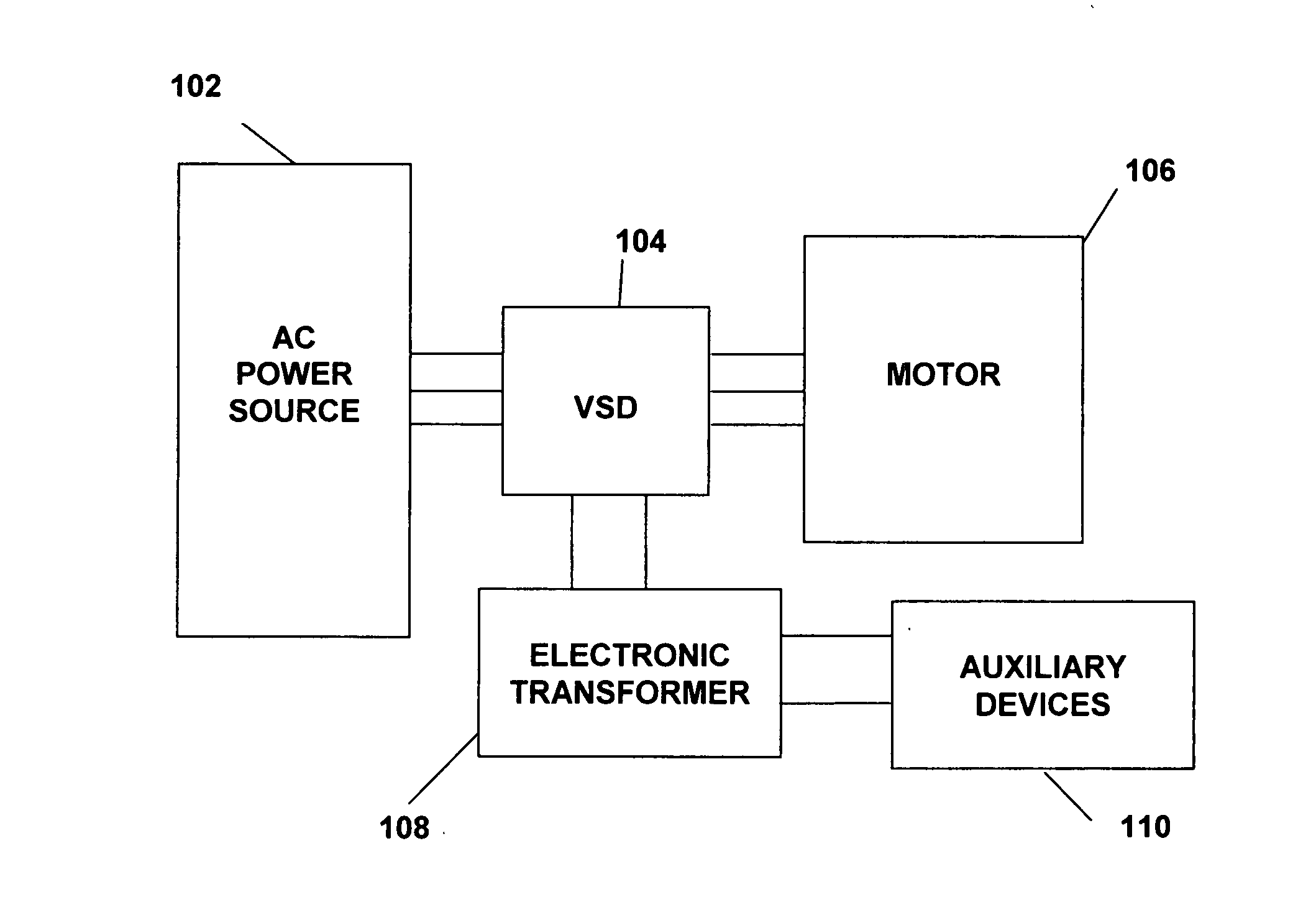

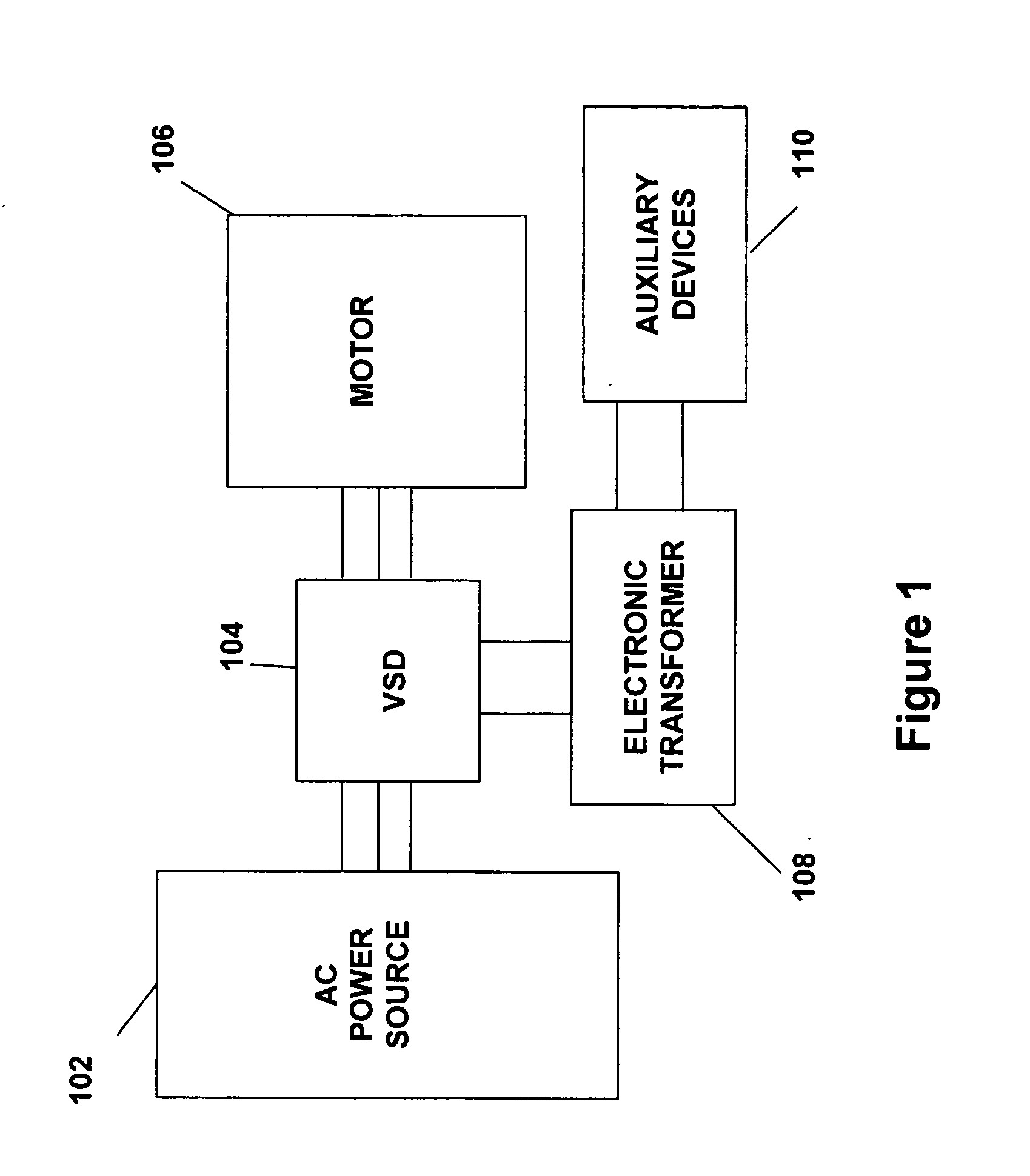

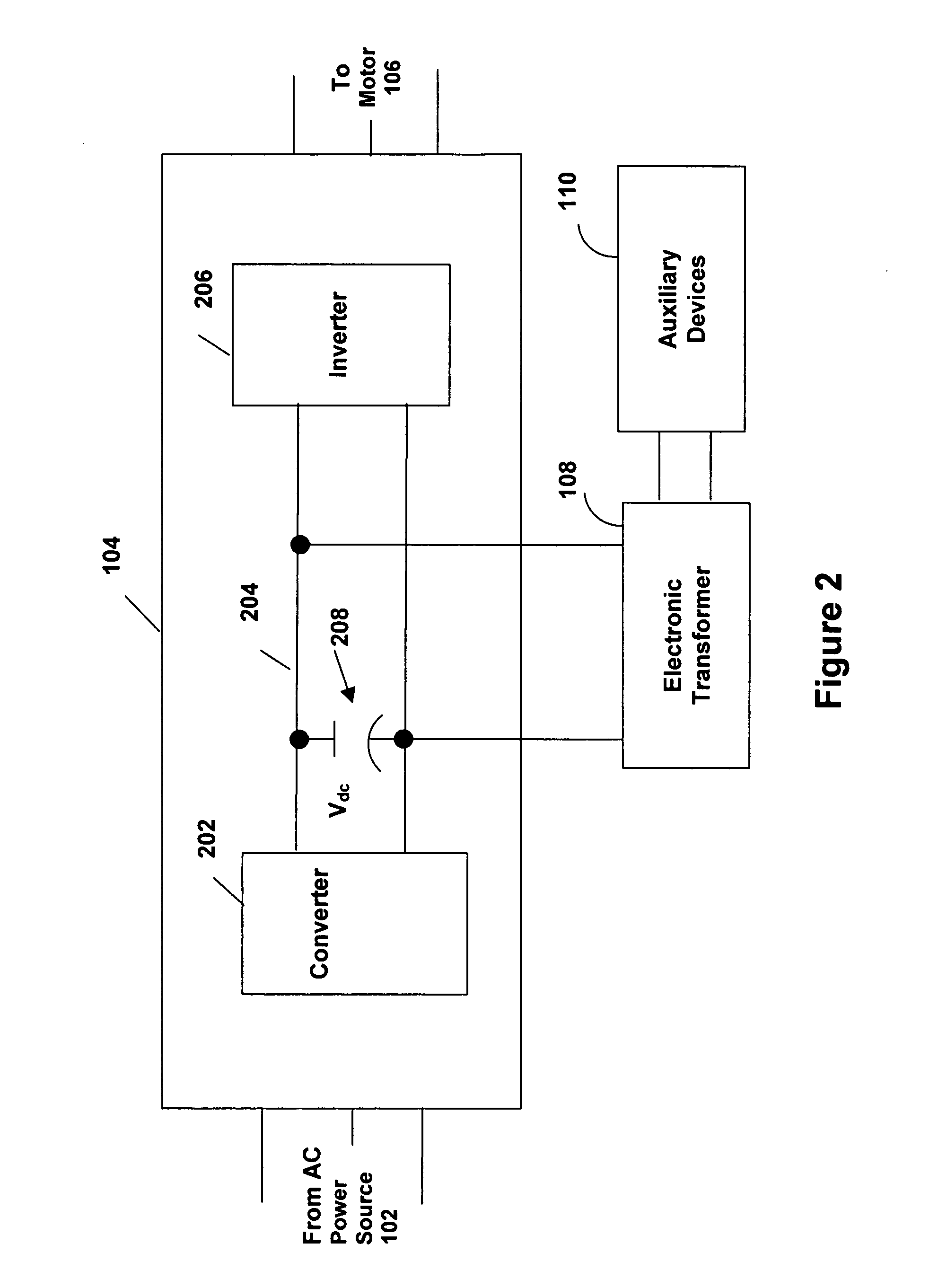

[0026]FIGS. 1 and 2 illustrate generally the system configuration of the present invention. An electronic transformer 108 is configured to provide AC power from the DC link 204 of a variable speed drive (VSD) 104. The electronic transformer 108 has at least four semiconductor switches and converts the DC link voltage to a fixed voltage, fixed frequency AC output. An AC power source 102 supplies AC power to the VSD 104, which in turn, supplies AC power to a motor 106. In another embodiment of the present invention, the VSD 104 can power more than one motor 106. The motor 106 is preferably used to drive a corresponding compressor of a refrigeration or chiller system. The VSD 104 also supplies power to an electronic transformer 108 from the DC link 204. The electronic transformer 108 converts the DC power from the DC link 204 to a fixed voltage and frequency AC control power source for various auxiliary devices 110, e.g. a control panel, contactors, relays, pumps and fans, that are com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com