Thermosetting resin composition and method of producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0112] Examples according to the invention and comparative examples are described below. Note that the invention is not limited to the following examples. (Examples 1 to 7 and Comparative Examples 1 to 3)

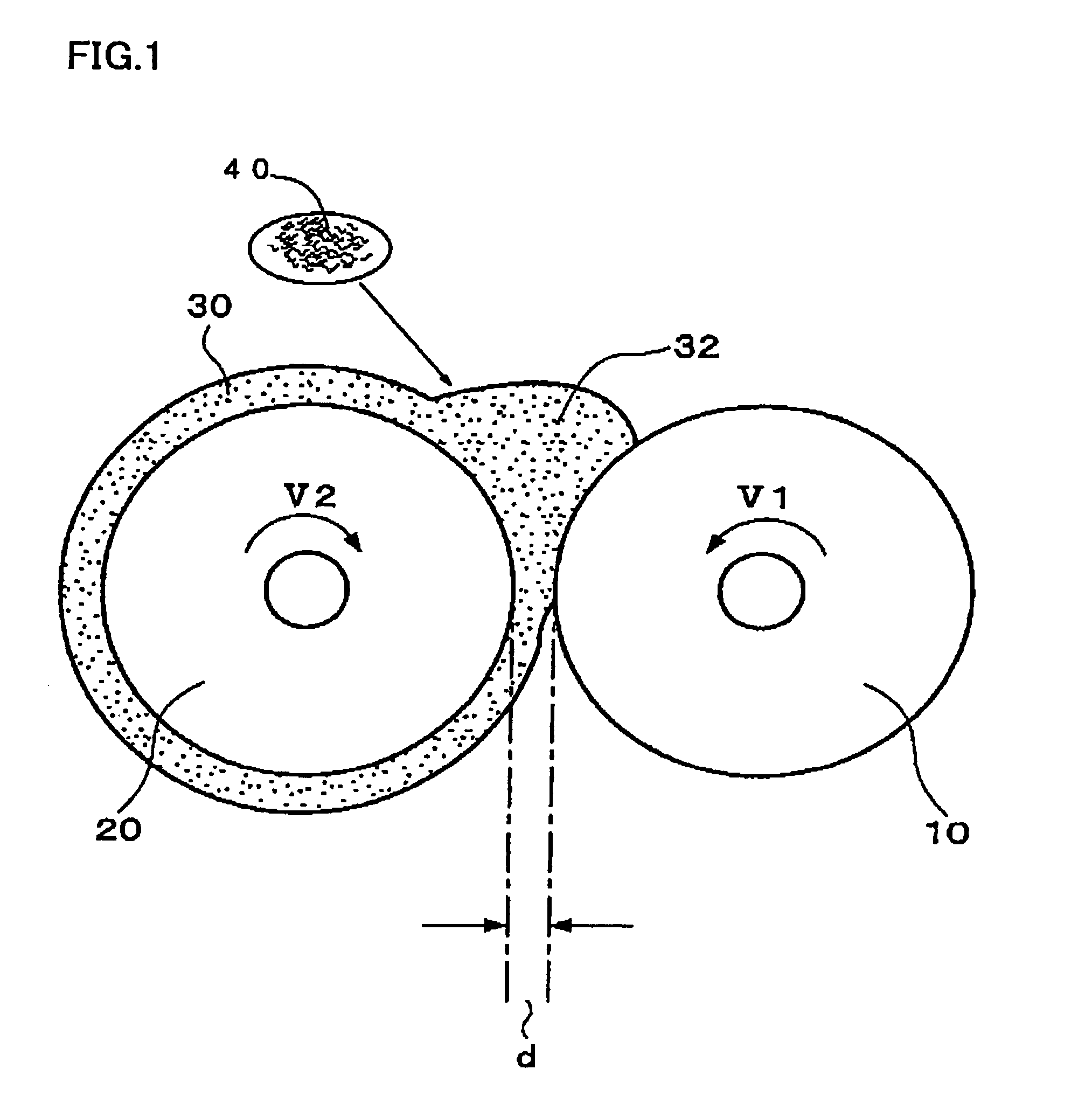

(1) Preparation of Sample

[0113] Step (c)

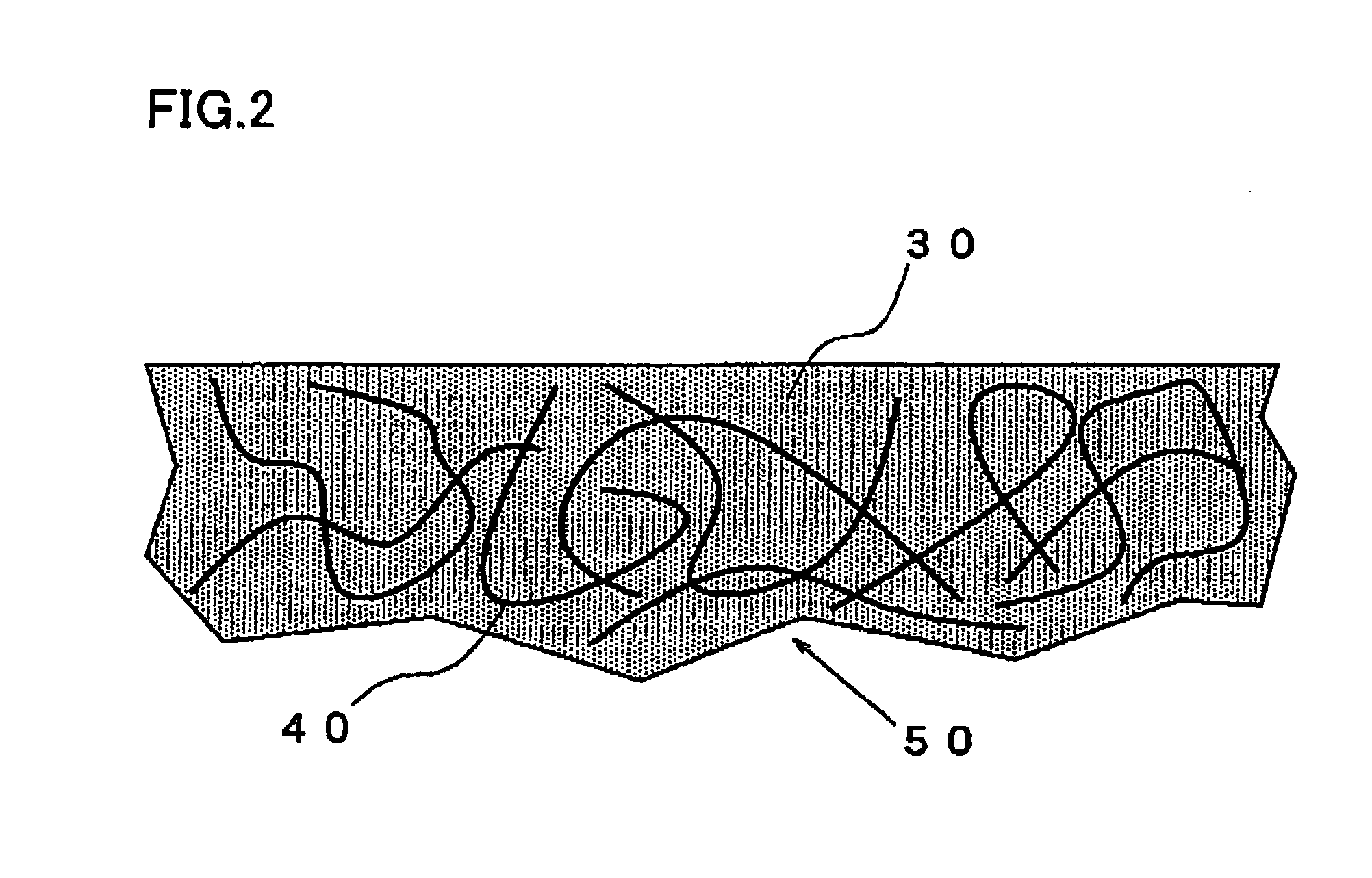

[0114] An epoxidized elastomer was supplied to a 6-inch open roll (roll temperature: 10 to 50° C.) and wound around the roll. An epoxy resin (base resin) was supplied to and mixed with the epoxidized elastomer to obtain a first mixture. The roll distance was set at 1 mm, and the roll rotational speed was set at 22 rpm / 20 rpm. The types and amounts (phr) of the epoxidized elastomer and the epoxy resin are shown in Tables 1 and 2.

[0115] Step (d)

[0116] A filler was supplied to and mixed with the first mixture. After reducing the roll distance to 0.1 mm, the mixture was tight-milled five times to obtain a second mixture. The roll rotational speed was set at 22 rpm / 20 rpm. After setting the roll distance at 1 mm and the roll rotational speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com