Compositions for Golf Equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

[0337] The following non-limiting examples are included herein merely for illustration, and are not to be construed as limiting the scope of the present disclosure.

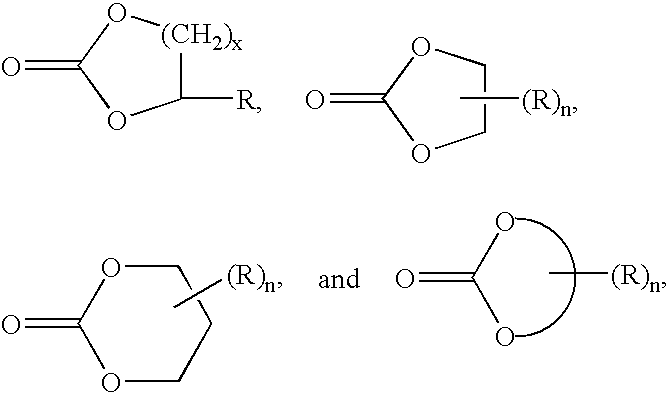

[0338] Conventional polyurea golf ball cover compositions were prepared by reacting a polyurea prepolymer (H12MDI / Jeffamine® D2000 with 7% post added triisocyanate) with 4,4′-bis(sec-butylamino)-dicyclohexylmethane (Clearlink® 1000). Fast reactivity caused the material to drool at the nozzles, requiring constant cleaning / replacing of the nozzles and cleaning of the molds.

[0339] Polyurea golf ball cover compositions of the present invention were similarly prepared, with the exception that propylene carbonate was added to the reaction mixture in varying amounts from 0.5 wt % to 6 wt %, based on the total weight of the polymer. There was no drool at the nozzle and the material was dispensed for an hour without any accumulation at the tip of the nozzle.

[0340] When numerical lower limits and numerical upper limits are set f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap