Integral sensor and control for dry run and flow fault protection of a pump

a sensor and control technology, applied in the field of pumps, can solve the problems of increasing the work required for installation, increasing the risk of leakage in the plumbing, and adding to the physical component coun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

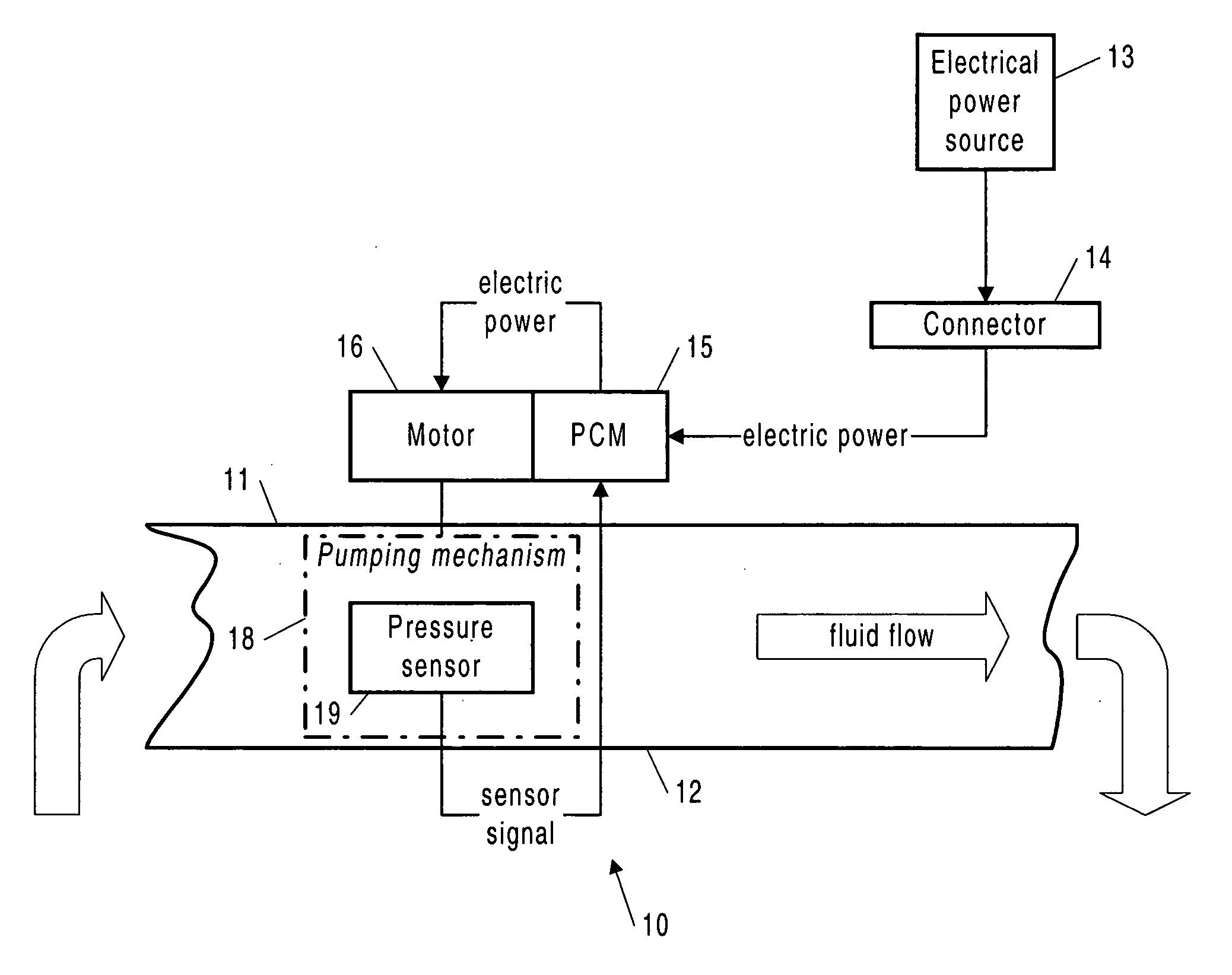

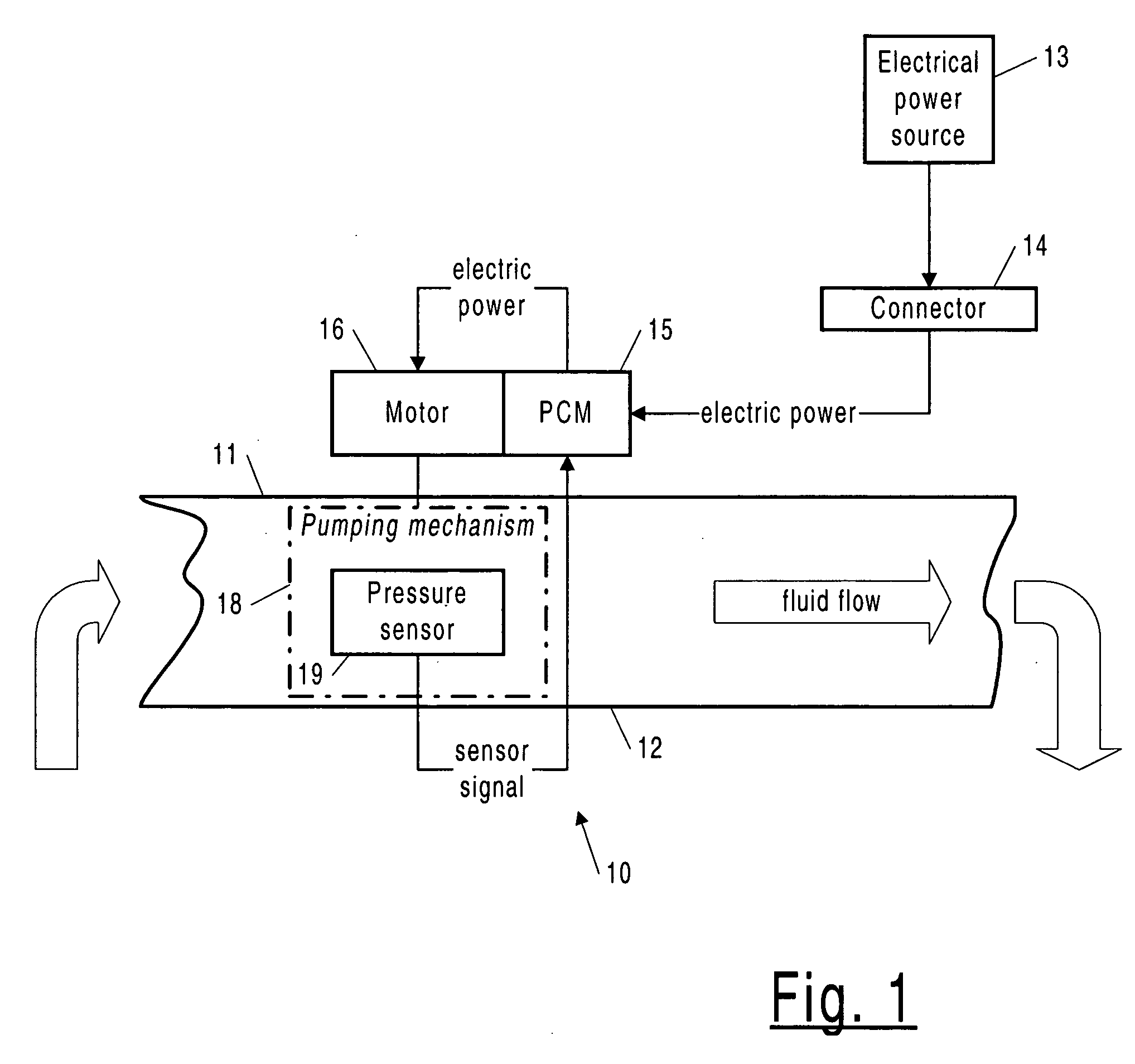

FIG. 1

[0017]FIG. 1 shows a pump system 10 according to the invention, for pumping a fluid. It includes a pump control module (PCM) 15 serving as a controller for a pump electric motor 16, built into or attached to the pump. An electrical power source 13 (AC or DC), is connected to the PCM 15 by an electrical connection 14.

[0018] The pump system includes a pumping mechanism 18 driven by the pump motor 16 and installed in a plumbing line, so as to have inlet plumbing 11 and outlet plumbing 12. The pumping mechanism includes an inlet cavity and an outlet cavity, and a structure (not shown) such as valve chambers in a positive displacement diaphragm pump, located between the two cavities and driven by the electric motor in a cyclical pattern so as to give rise to a pumping action. A pressure sensor 19 is built into the inlet and / or outlet cavity, and communicatively coupled to the PCM so as to provide to the PCM signals indicative of the fluid pressure in the (inlet or outlet) cavity. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com