Panel wiper

a wiper and panel technology, applied in the field of wipers, can solve the problems of difficult to fully clean off dust accumulation in corners, difficult to use such wipers to fully clean off dust and dirt, etc., and achieve the effect of effectively cleaning off dust and dir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

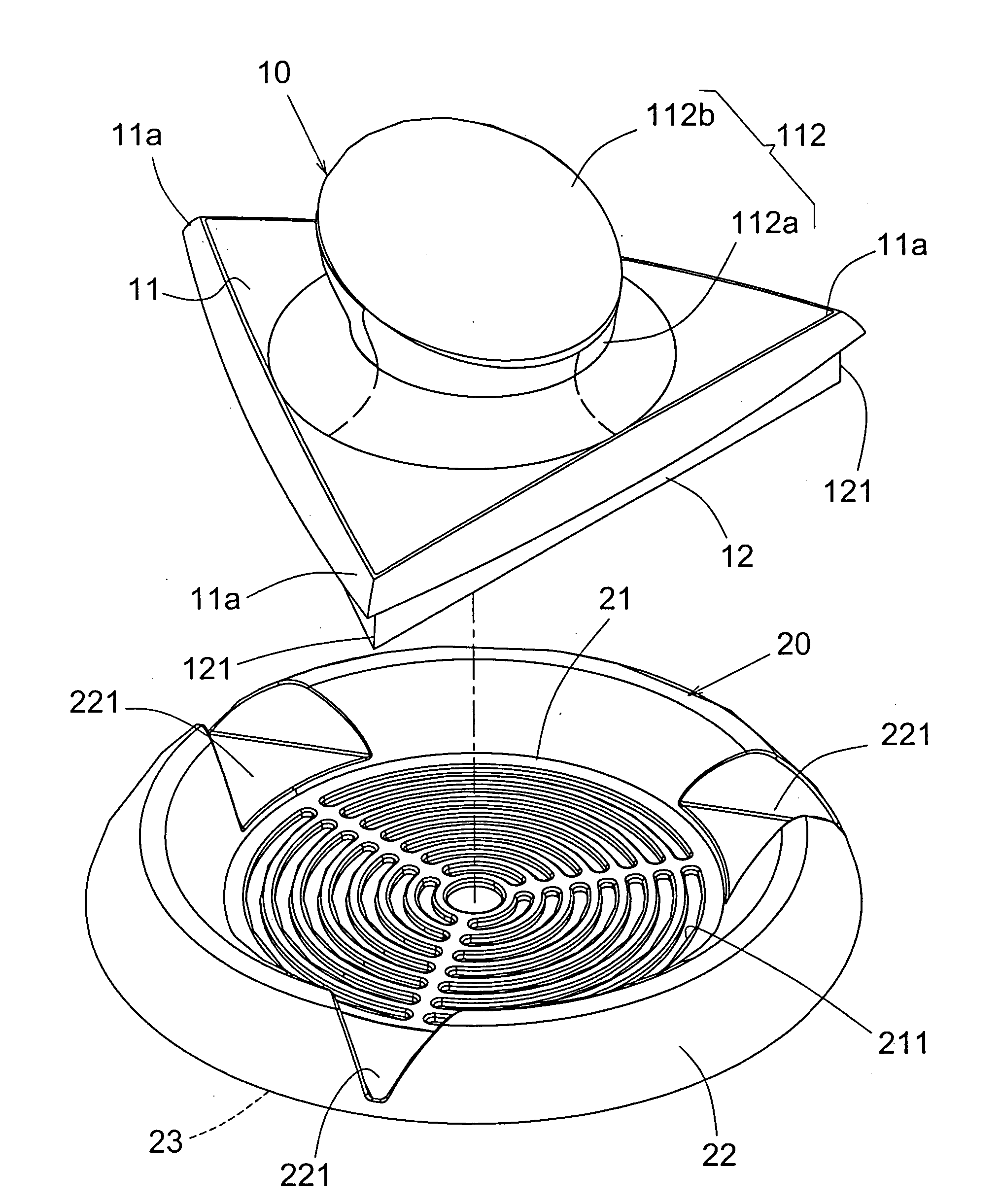

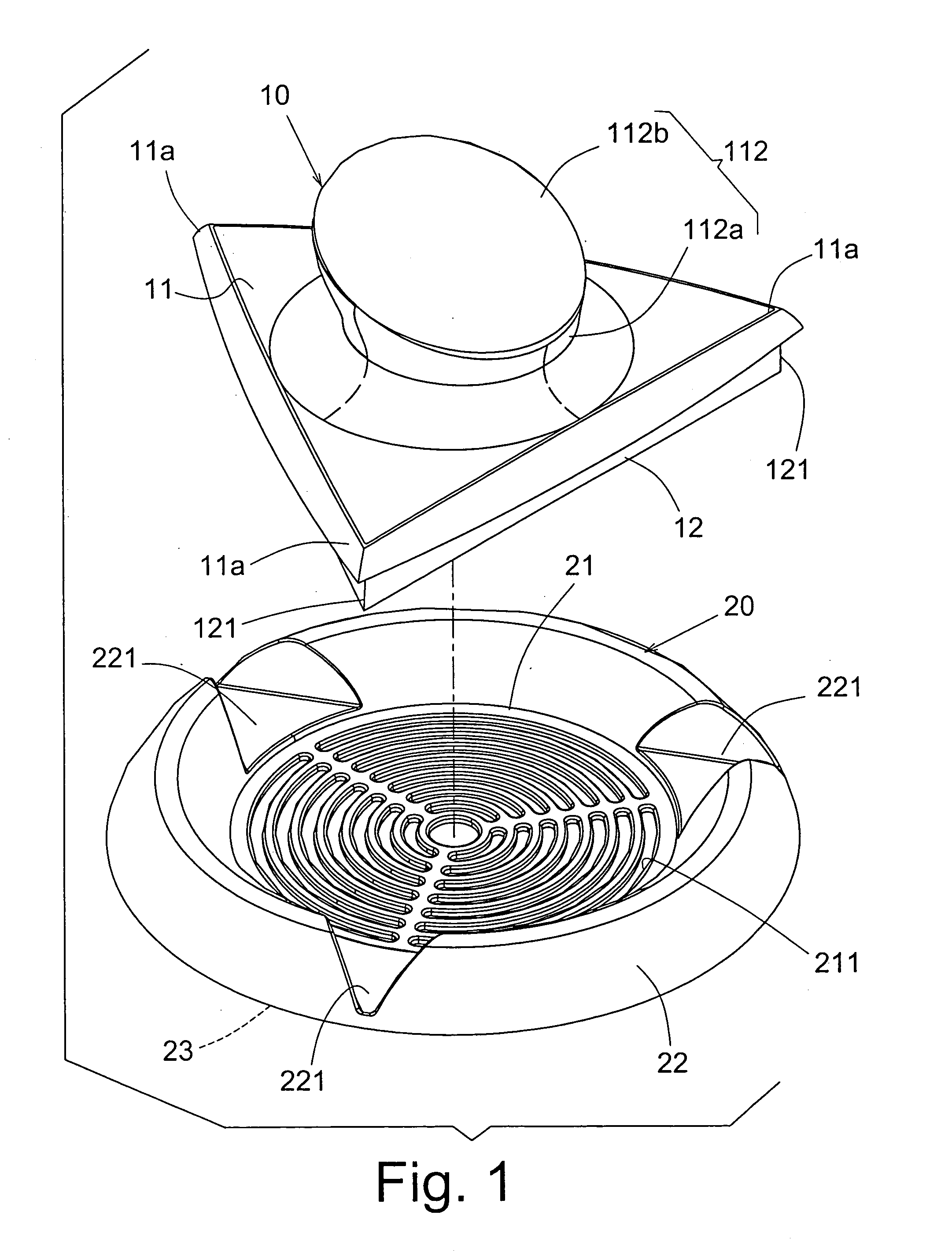

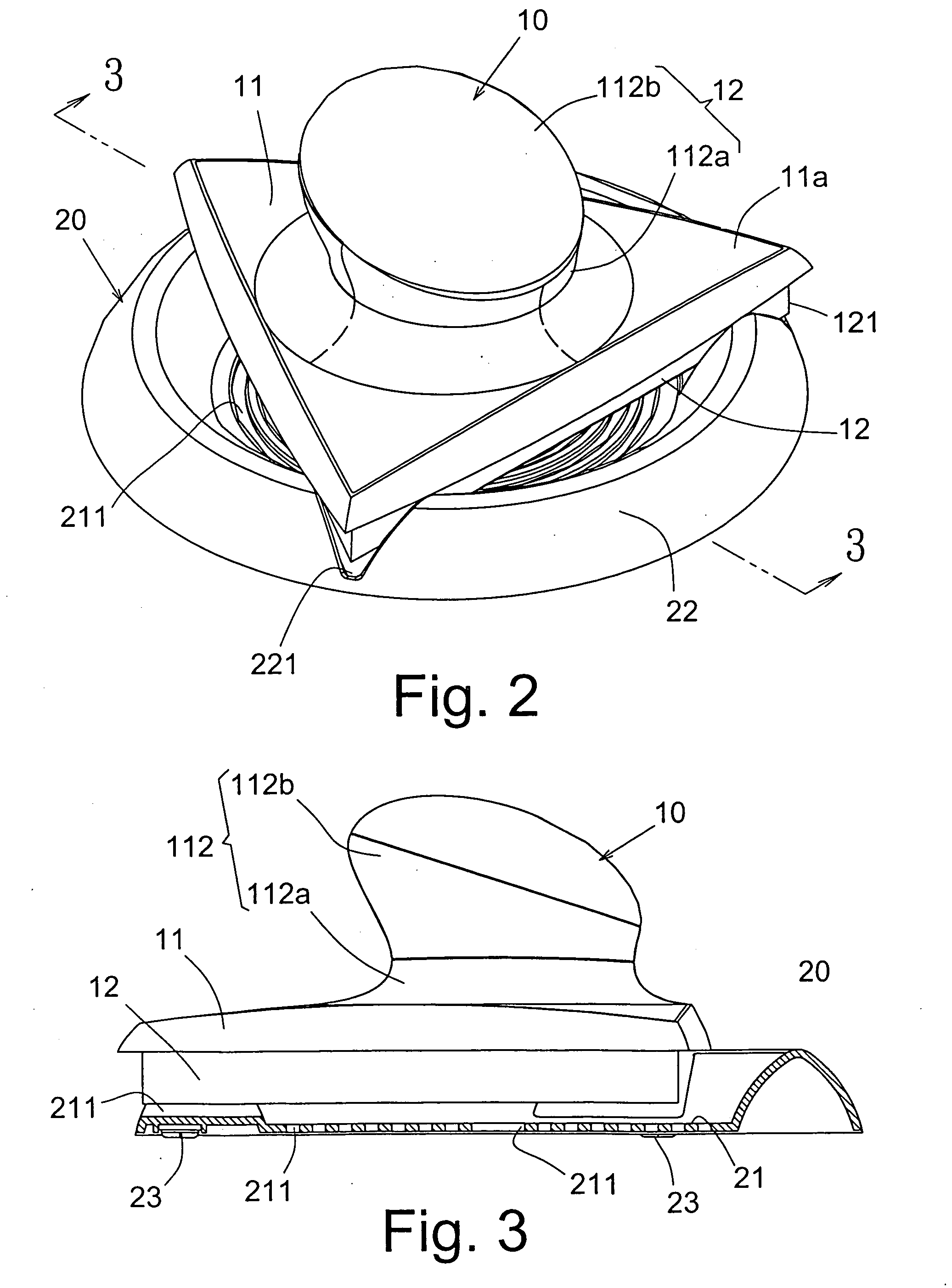

[0024]Please refer to FIGS. 1 to 4. The panel wiper of the present invention includes a wiping member 10 and a holder 20. The wiping member 10 includes a baseboard section 11 and a cleaning plate 12 connected under a bottom of the baseboard section 11. The cleaning plate 12 has at least one acute wiping corner 121 for extending into the respective corners 31 of the panel 30 to reciprocally fully wipe and clean off the dusts. The holder 20 has a bed section. 21 and an annular wall section 22 swelling from a circumference of the bed section 21. The annular wall section 22 is formed with several receptacles 221 adapted to the profile of the baseboard section 11 of the wiping member 10. Accordingly, the wiping member 10 can be seated in the receptacles 221 and stably rested on the bed section 21. Multiple supporting stands 23 are arranged under a bottom of the bed section 21. In addition, the bed section 21 is formed with multiple vents 211. Accordingly, the cleaning plate 12 of the wip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com