Nine-position resistor ladder switch assembly

a resistor and ladder technology, applied in transmission systems, analogue/digital conversion, instruments, etc., can solve problems such as complex problems, fluctuations in battery voltage and voltages appearing at the output of ladder networks, and limited number of resistor ladder switch assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following detailed description of the invention is merely exemplary in nature and is not intended to limit the scope, applicability, or configuration of the invention in any way. Rather, the following description provides a convenient illustration for implementing exemplary embodiments of the invention. Various changes to the described embodiments may be made in the function and arrangement of the elements described herein without departing from the scope of the invention.

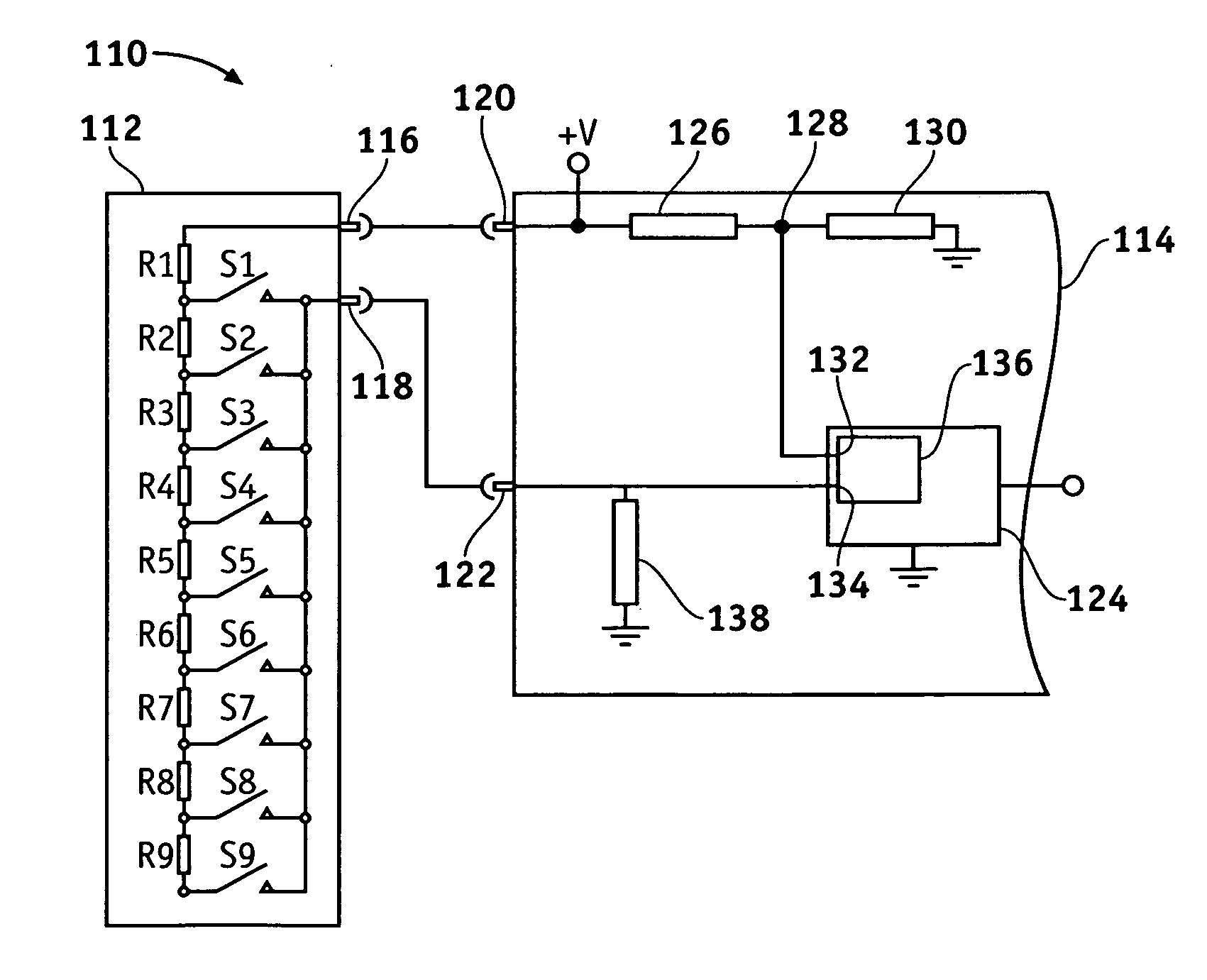

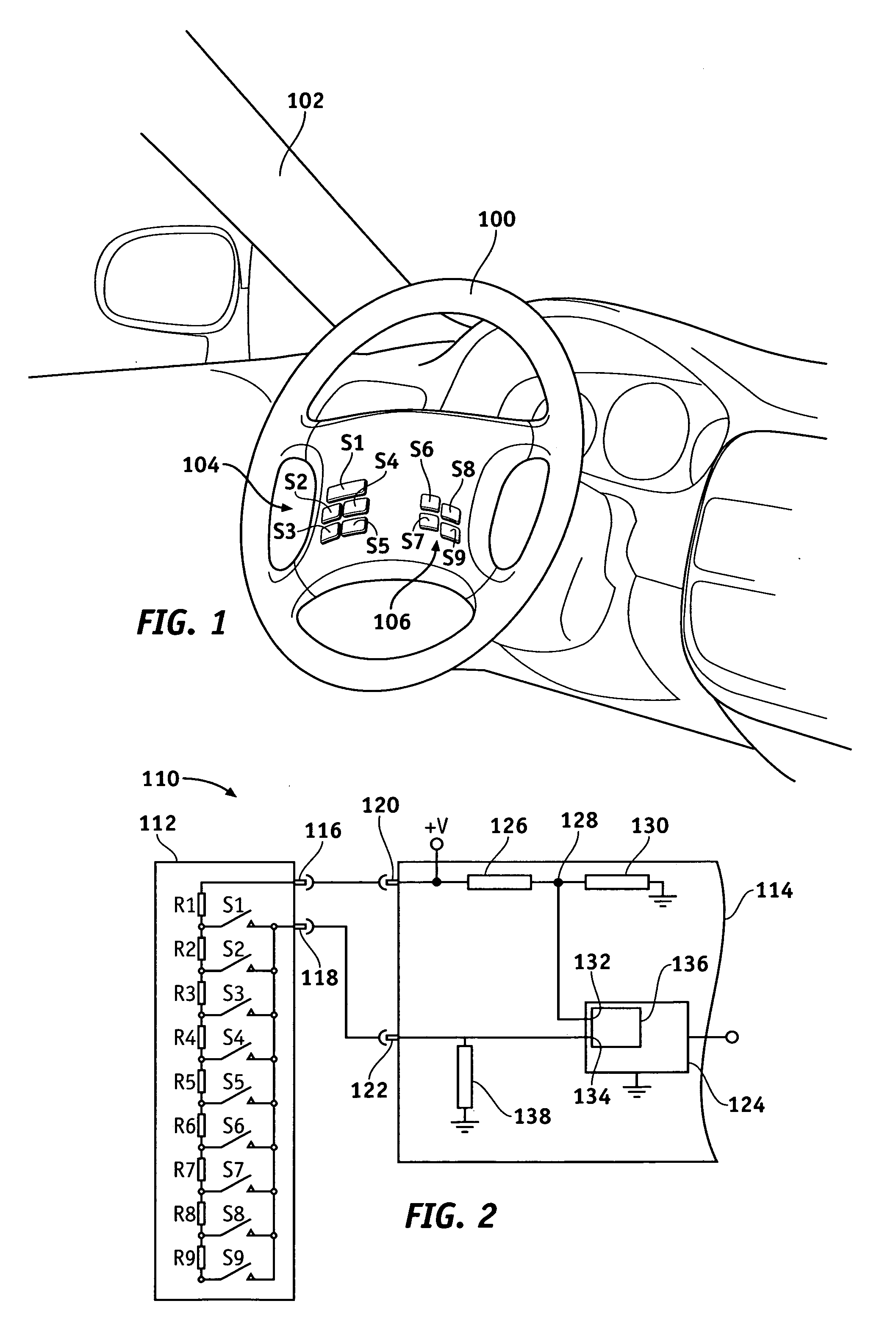

[0013]FIG. 1 is an isometric view of a steering wheel assembly 100 deployed on a vehicle 102. A user interface comprising nine switches S1-S9 is deployed on a portion of steering wheel assembly 100. Switches S1-S9 may be separated into various switch clusters, and each switch cluster may control a different vehicular feature or different aspects of the same vehicular feature. As shown in FIG. 1, for example, switches S1-S5 may be employed in a left hand switch cluster 104 and configured to control the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com