Air supply system

a technology of air supply system and air supply, which is applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of difficult to reduce increase in installation space and weight of silencers, and difficulty in reducing noise in a wide frequency band, so as to reduce the noise of compressors, reduce the noise of gas discharge, and suppress the rapid change of gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

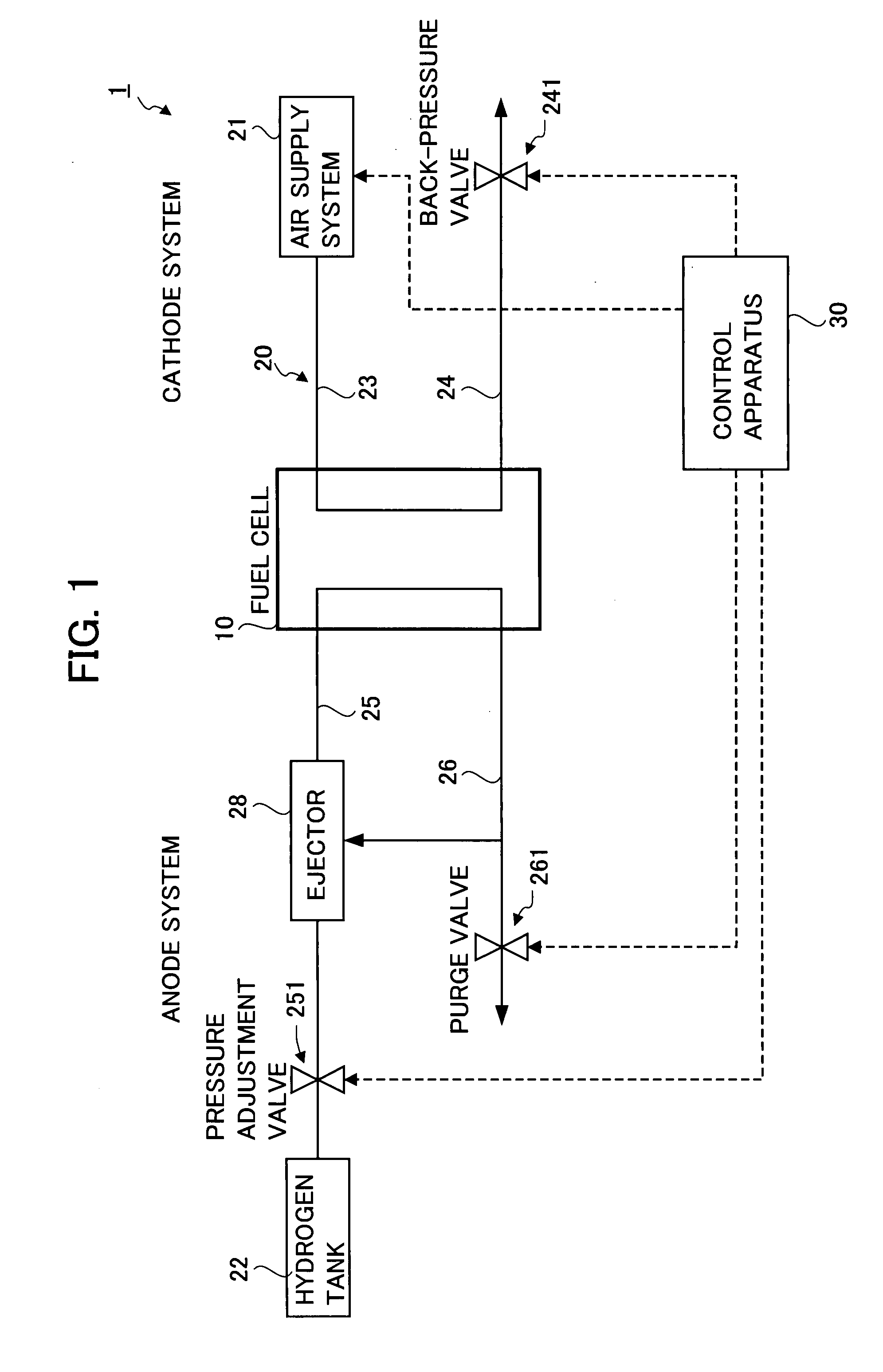

[0029]FIG. 1 illustrates a block diagram of a fuel cell system 1 using an air supply system 21.

[0030] The fuel cell system 1 has a fuel cell 10, a supply apparatus 20 which supplies hydrogen gas and air to the fuel cell 10, and a control apparatus 30 which controls the fuel cell 10 and the supply apparatus 20.

[0031] In the fuel cell 10 as described above, when the anode (positive electrode) is supplied with hydrogen gas and the cathode (negative electrode) is supplied with air containing oxygen, power is generated by way of the electrochemical reaction.

[0032] The supply apparatus 20 is configured to include an air supply system 21 which supplies air to the cathode of the fuel cell 10, and a hydrogen tank 22 and an ejector 28 which supply hydrogen gas to the anode.

[0033] The air supply system 21 is connected to the cathode of the fuel cell 10 via an air supply path 23.

[0034] The cathode of the fuel cell 10 is connected with an air exhaust path 24. The end of this air exhaust pat...

embodiment 1

Illustrative Embodiment 1

[0054]FIG. 4 shows the first illustrative embodiment and a comparative example of the air supply system. More specifically, FIG. 4 shows a relation between noise level and a compressor revolution speed when the discharge outlet of a compressor includes the rectification apparatus.

[0055] As can be seen from FIG. 4, an air supply system including the rectification apparatus can reduce noise in a wide range of revolution speeds more than in a case of the air supply system not including the rectification apparatus.

[0056] Especially, noise is greatly reduced at medium and high revolution speeds.

[0057] This embodiment provides the following advantages.

[0058] 1. The rectification apparatus 45 for rectifying air is disposed at the intake flow path 43 and the discharge flow path 44. Therefore, the turbulence associated with a shock wave caused by air intake and discharge is rectified and the sudden change of the air flow is suppressed so as to reduce the noise le...

second embodiment

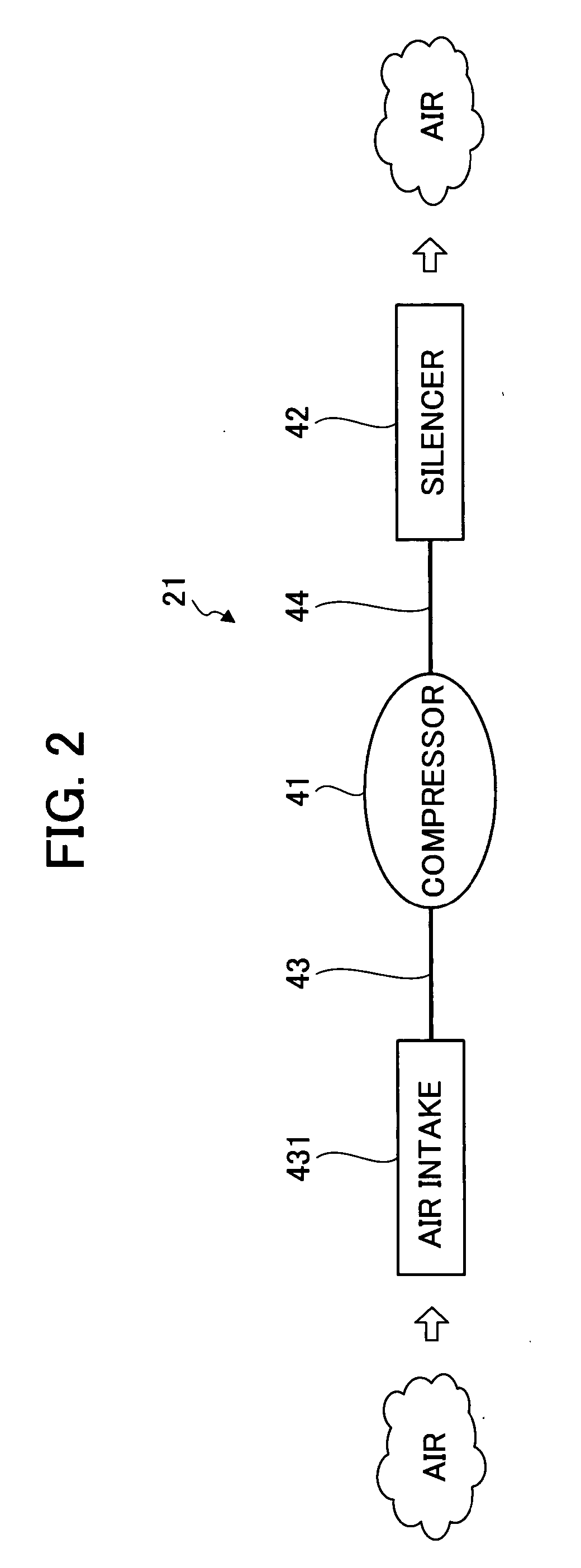

[0060] The second embodiment differs from the first embodiment in the position and shape of the rectification apparatuses 45A and 45B.

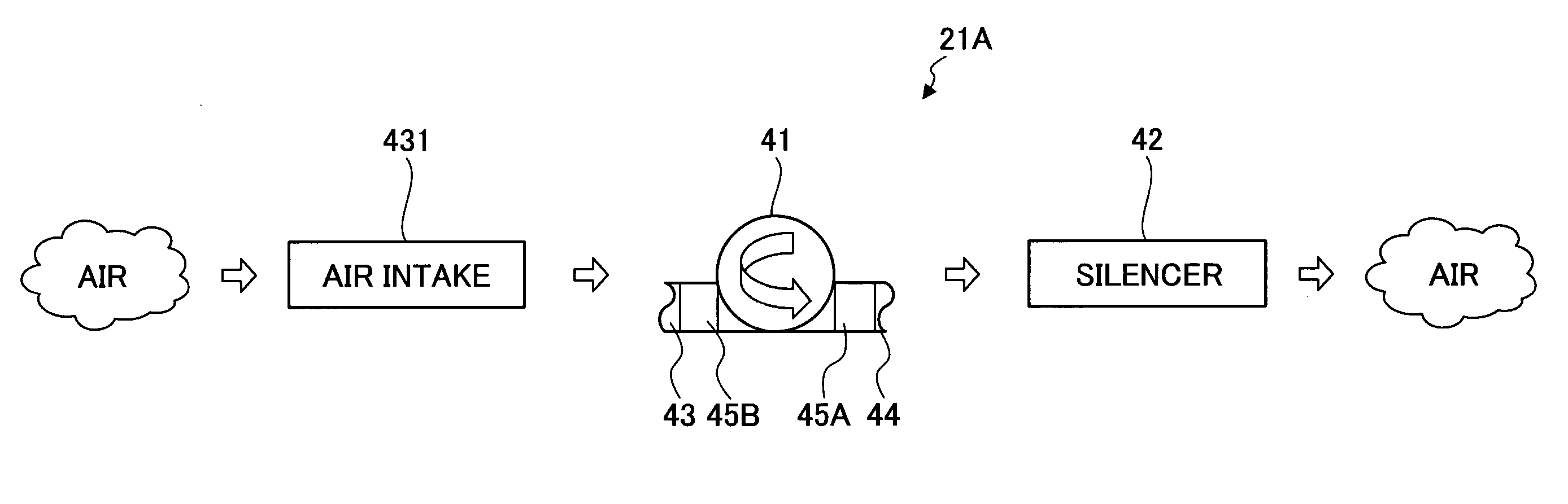

[0061] More specifically, as shown in FIG. 5, a rectification apparatus 45A in an air supply system 21A is abutted with the discharge outlet of the compressor 41 and a rectification apparatus 45B is abutted with the inlet of the compressor 41.

[0062] It is assumed that the number of rectification channels 451 of the rectification apparatuses 45A and 45B to the cross-sectional area of the discharge flow path 44 and the intake flow path 43 represent a density of the rectification apparatus. It is also assumed that the lengths of the rectification apparatuses 45A and 45B in the direction along which the discharge flow path 44 and the intake flow path 43 extend represent a length of the rectification apparatus.

[0063]FIG. 6 shows a relation between the volume of air discharged from the compressor and the pressure drop by the rectification apparatus. In F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com