Skid support for portable structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

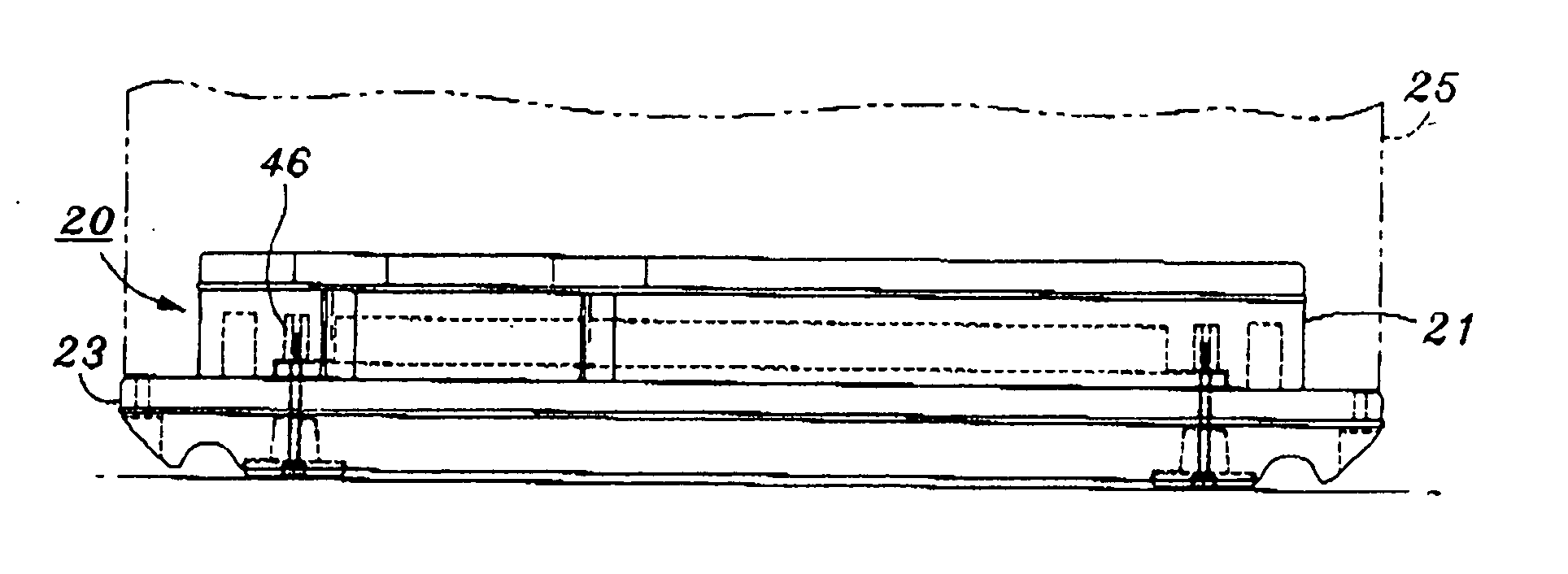

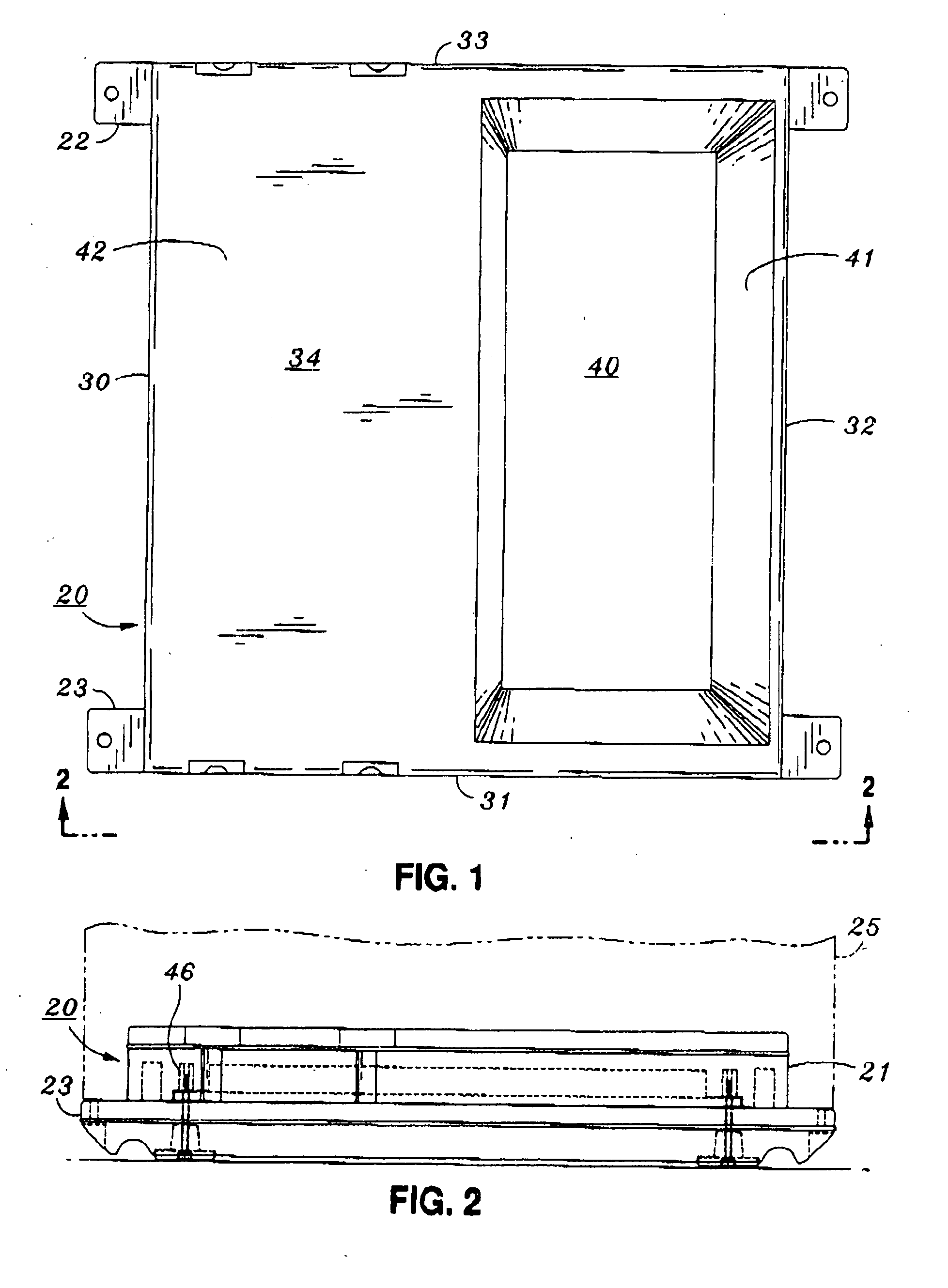

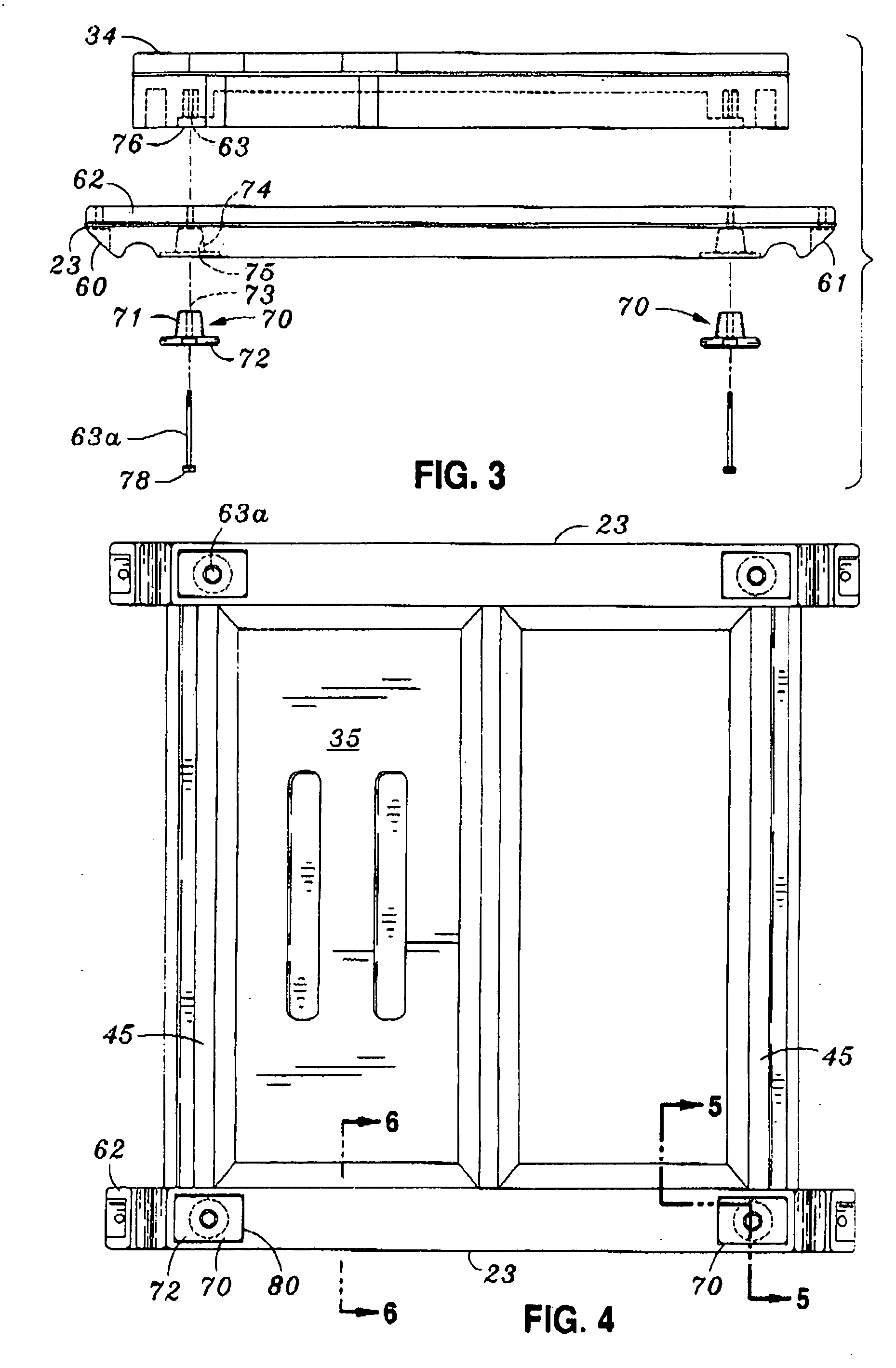

[0018] Support 20 includes a platform 21 and a pair of runners 22,23. Its function is to provide support for a structure 25 such as a portable toilet or washstand. These structures are well-recognized, they generally include a surrounding wall with a door. Customarily they enclose a commode or urinal and often a washstand. The functional details of the structure are arbitrary and form no necessary part of this invention. It simply rests on this support.

[0019] The platform has four sides 30, 31, 32, 33, a floor 34 (FIG. 1) and a base 35 (FIG. 4). The periphery is usually formed as a rectangle with two pairs of parallel sides.

[0020] The floor and the base are vertically spaced apart from one another over most of their areas, by outside side walls 30 (FIG. 5), and inside side walls 31. Together they form an internal chamber 36. The chamber can be filled with in-place molded structural foam 37 to provide additional structural strength to the support. Otherwise the wall thickness and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com