Image forming system and clear coating apparatus

a technology of forming system and clear coating, which is applied in the field of image forming system, can solve the problems of poor appearance, reduced quality of binding, and toner falling off at the folding position of the sheet, and achieve the effect of reducing the amount of consumption of clear toner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

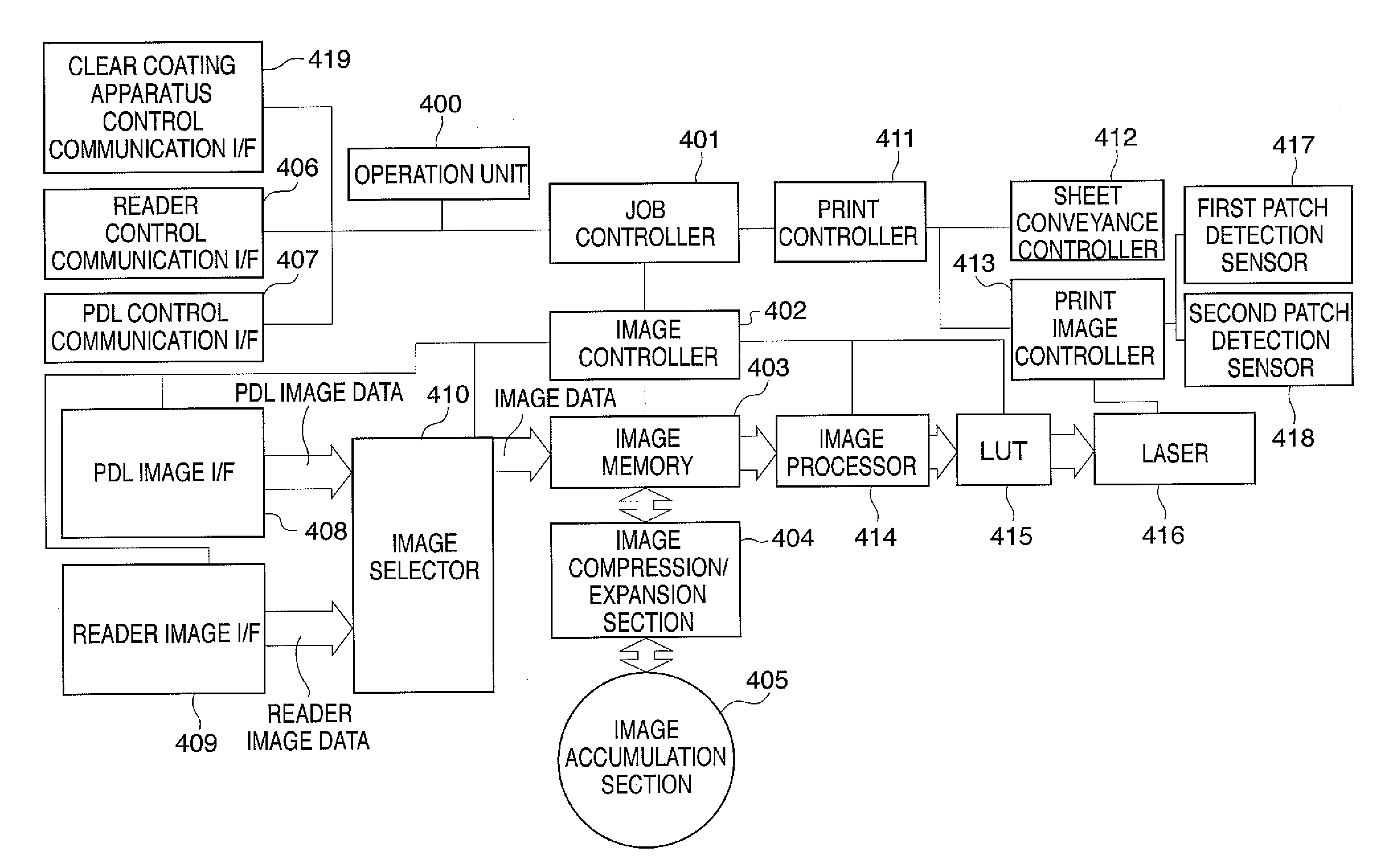

Image

Examples

Embodiment Construction

[0027]The present invention will now be described in detail below with reference to the drawings showing preferred embodiments thereof.

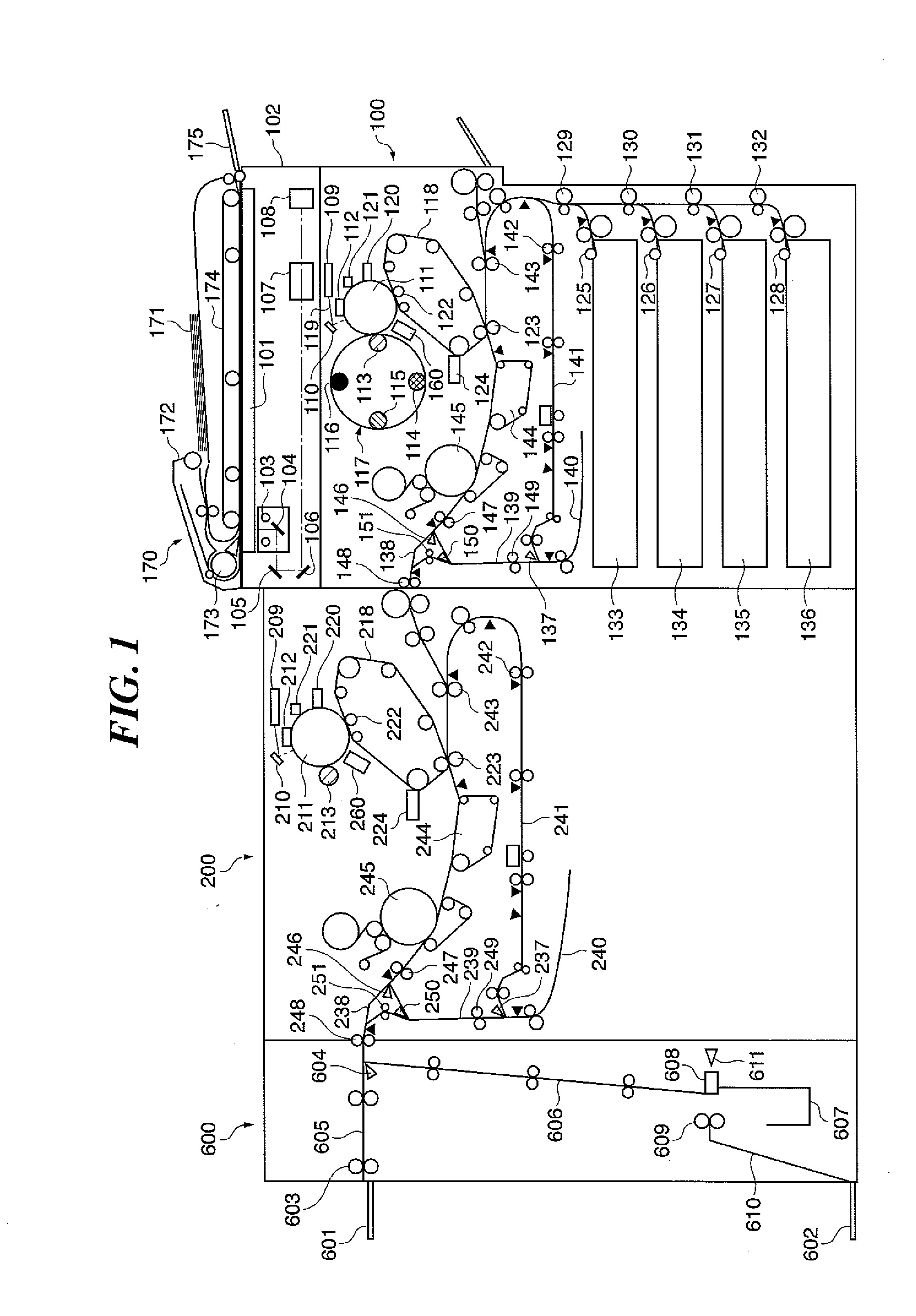

[0028]FIG. 1 is a view that schematically shows the configuration of an image forming system according to an embodiment of the present invention.

[0029]In FIG. 1, the image forming system comprises an image forming apparatus 100, a clear coating apparatus 200 connected at the stage subsequent thereto, and a bookbinding apparatus 600 connected at the stage following the clear coating apparatus 200. In the present embodiment, although a color image forming apparatus is described as an example of the image forming apparatus 100, the image forming apparatus 100 may be a monochrome image forming apparatus.

[0030]The image forming apparatus 100 is comprised of a platen glass 101 as an original placement stage and a scanner 102. The scanner 102 comprises an original illuminating lamp 103, scanning mirrors 104 to 106, a lens 107, and an image sensor section 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com