Anisotropic conductive connector and circuit-device electrical inspection device

a technology of anisotropic conductive connectors and electrical inspection devices, which is applied in the direction of coupling device connections, semiconductor/solid-state device details, instruments, etc., can solve the problem of difficulty in sufficiently controlling the noise of high-frequency signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

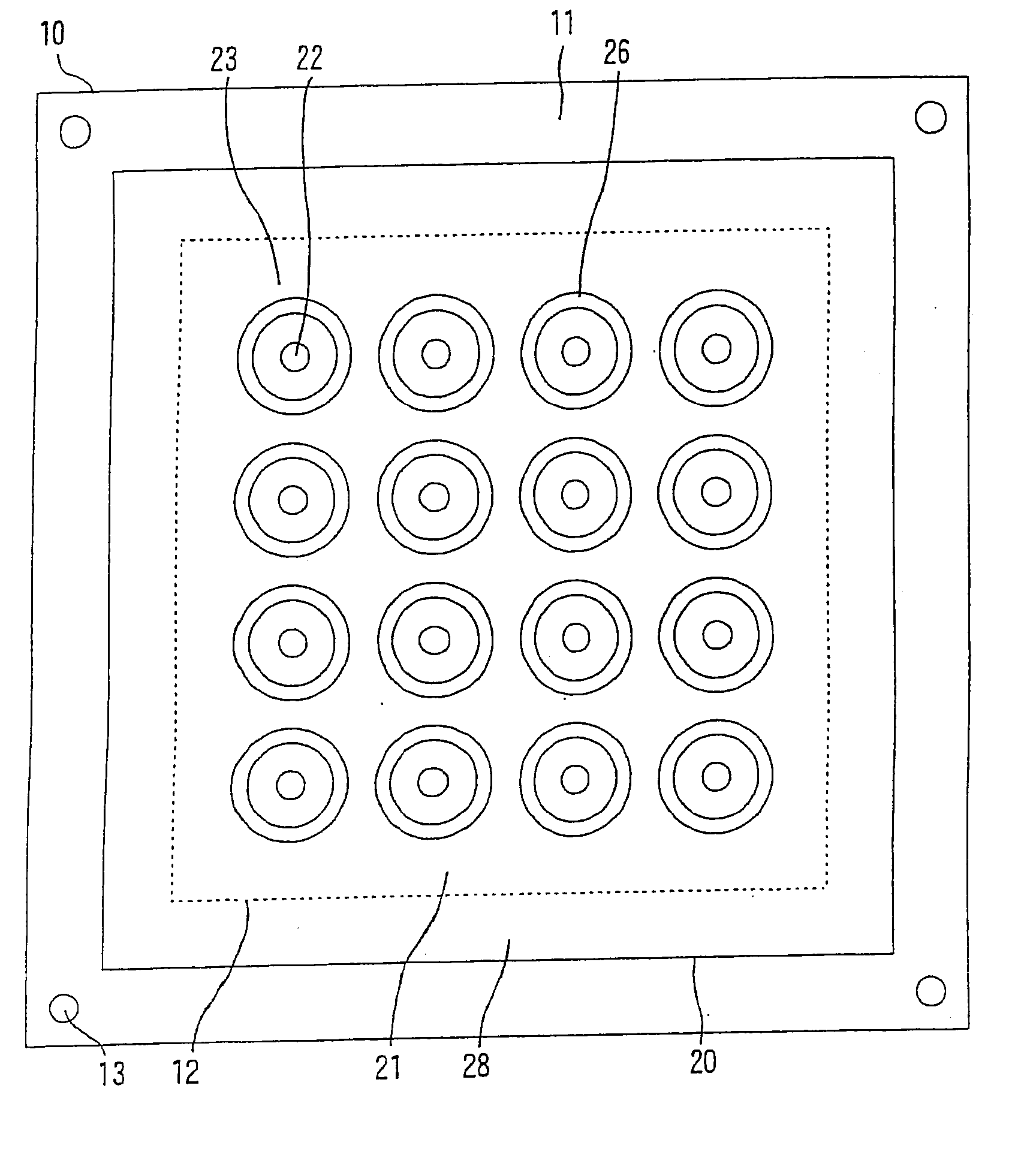

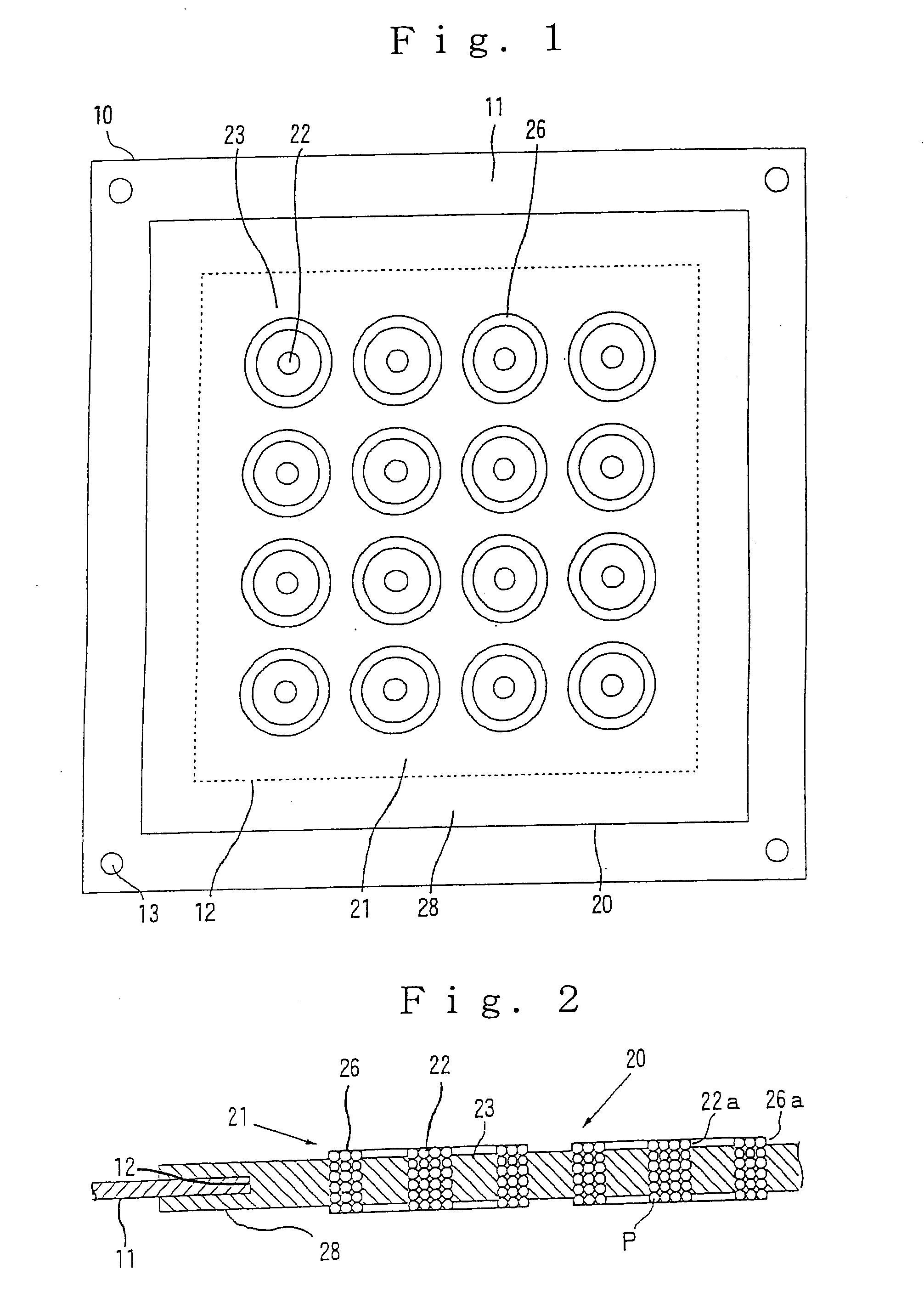

[0313] An anisotropically conductive connector (10) according to the present invention was produced under the following conditions in accordance with the construction illustrated in FIG. 14 and FIG. 15.

[0314] [Frame Plate (11)]

[0315] A frame plate of the following specification was produced.

[0316] Material: Stainless steel (JIS Standard Code: SUS304), dimensions: 10 mm×10 mm×0.1 mm, diameter of opening (12): 500 μm, the number of openings (12): 16 (4×4), arrangement pitch of openings (12): 1 mm. [Mold for Molding Elastic Anisotropically Conductive Film]

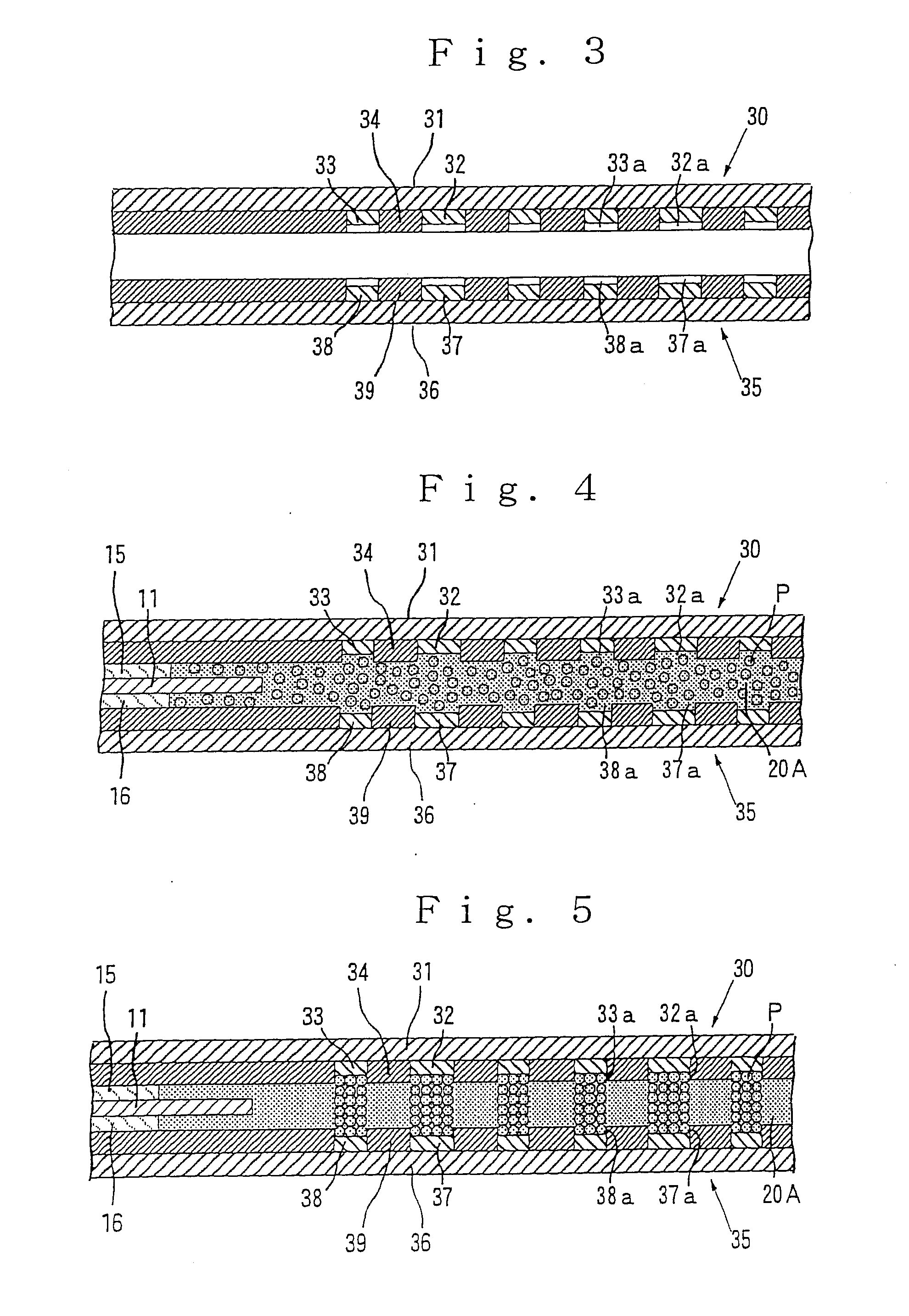

[0317] A mold for molding an elastic anisotropically conductive film composed of a top force (30) and a bottom force (35) of the following specification was produced in accordance with the construction illustrated in FIG. 3.

[0318] Ferromagnetic base plates (31, 36):

[0319] Material: steel material (JIS Standard Code: SS400),

[0320] Thickness: 6 mm.

[0321] Ferromagnetic substance layers (32, 37):

[0322] Material: nickel,

[0323] Diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com