Fuel cap

a technology of fuel cap and seal ring, which is applied in the field of fuel cap, can solve the problems of reducing affecting the service life so as to facilitate the mounting work of the seal ring, correct positioning, and not to deteriorate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are described in the following with reference to the accompanying drawings.

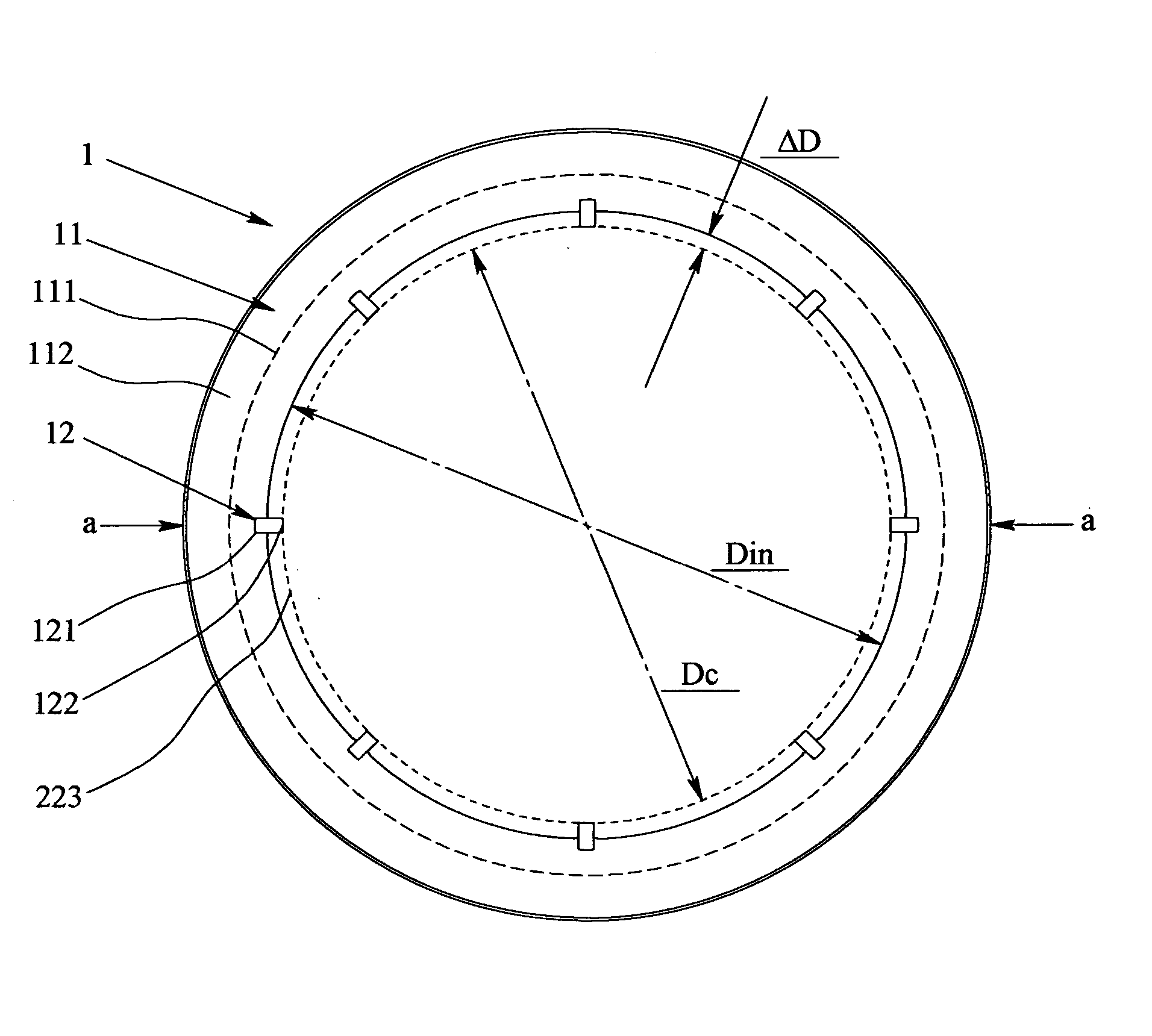

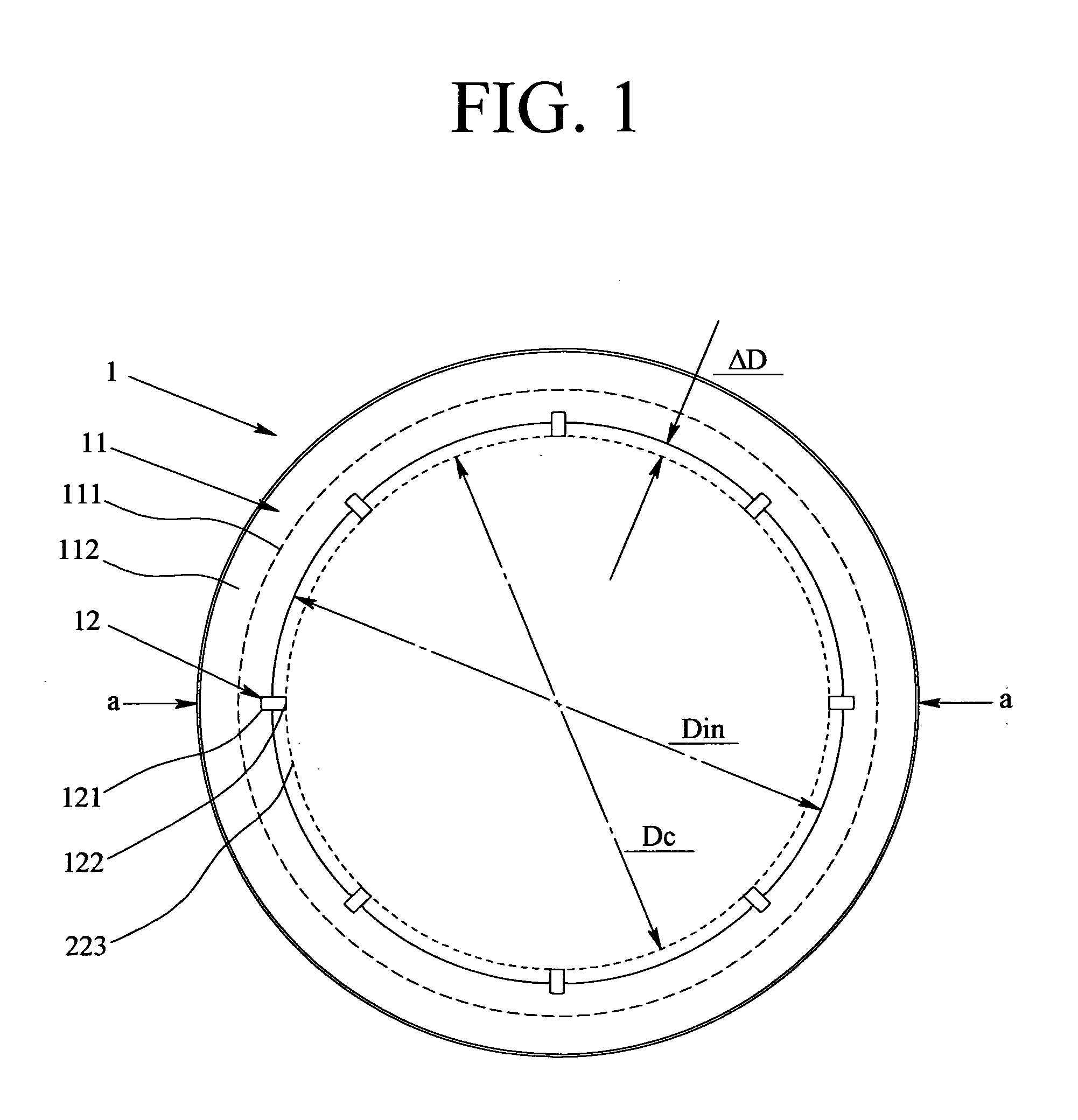

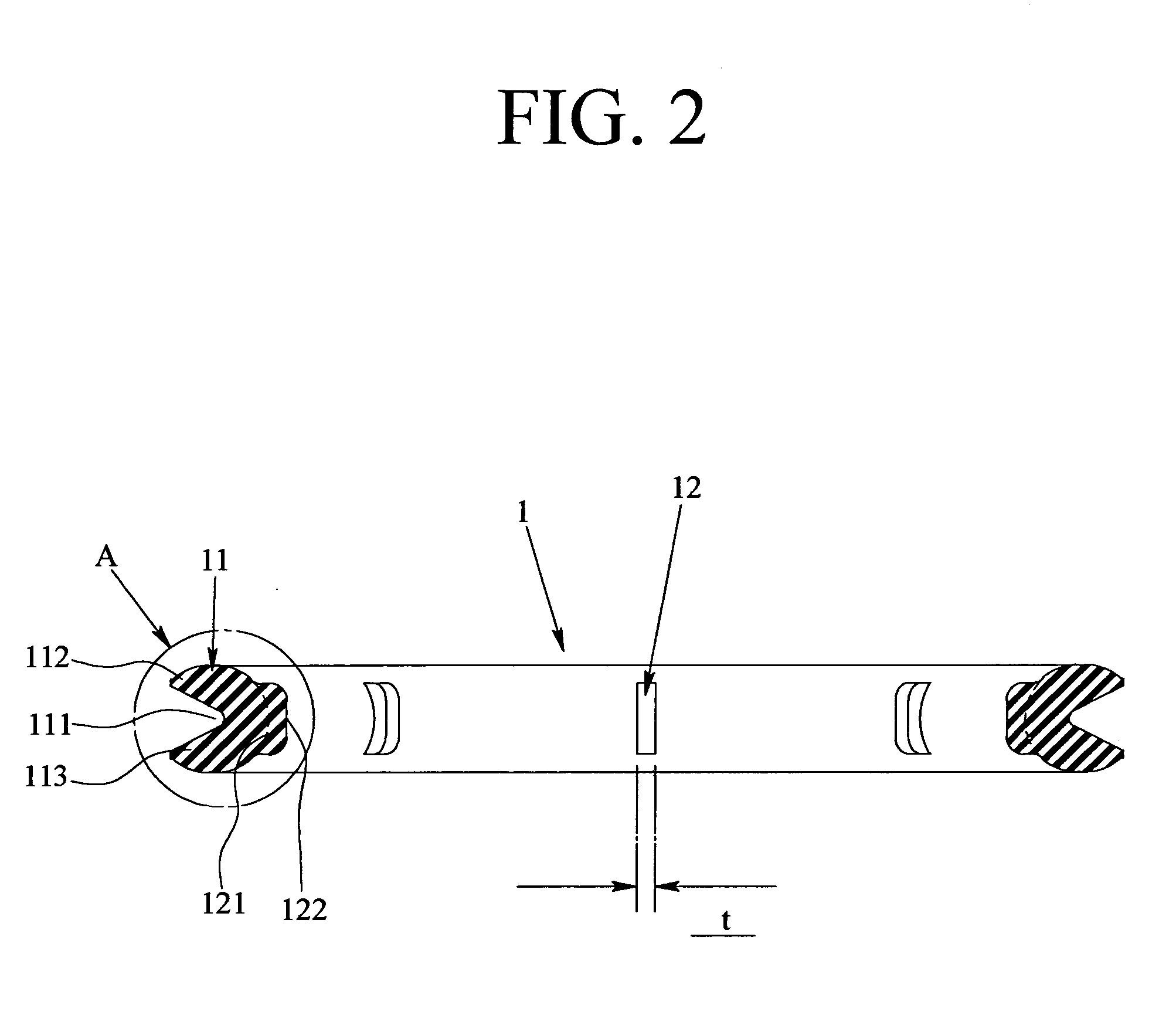

[0034] A fuel cap 2 of an embodiment has a general structure including an outer cap 21 and an inner cap 22, as shown in FIG. 4. A seal ring 1 is mounted on a cap trunk portion 223 locating between an upper flange 221 for mounting the outer cap 21 thereon and a lower flange 222 pairing up with the upper flange 221. The fuel cap 2 clamps and crushes the seal ring 1 between the lower face of the upper flange 221, a cap sealing face 23 and a filler neck sealing face 31 so that the liquid tightness and the gas tightness are worked effectively.

[0035] As shown in FIGS. 1 to 3, the seal ring 1 is molded of synthetic rubber integrally with: a ring body 11 of a C-shaped section having an upper and a lower lip portions 112,113 across a wedged circumference groove 111 on the outer circumference side thereof; and a plurality of vertical members 12 as the elastic ridge disposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com