Pressure balancing accumulator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

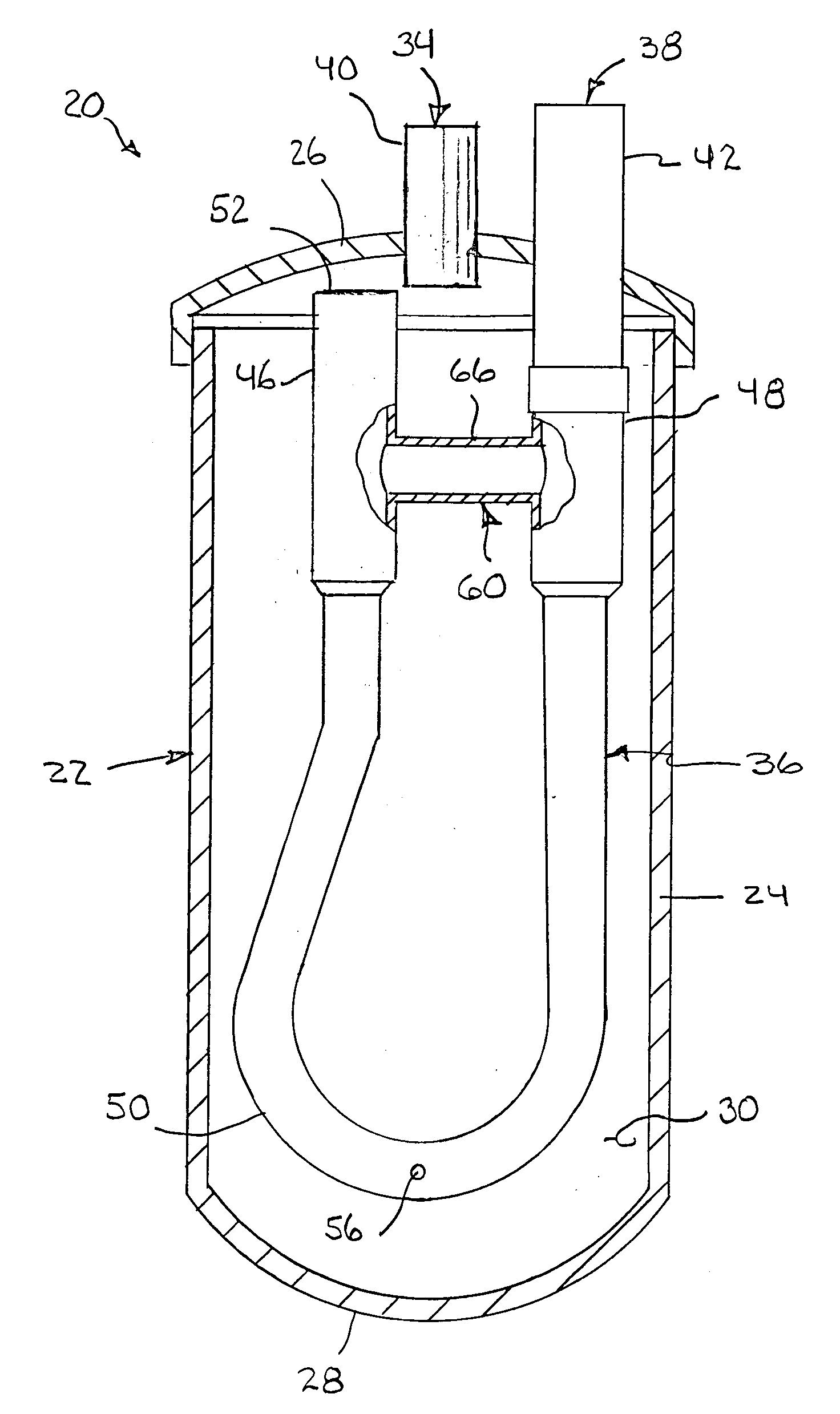

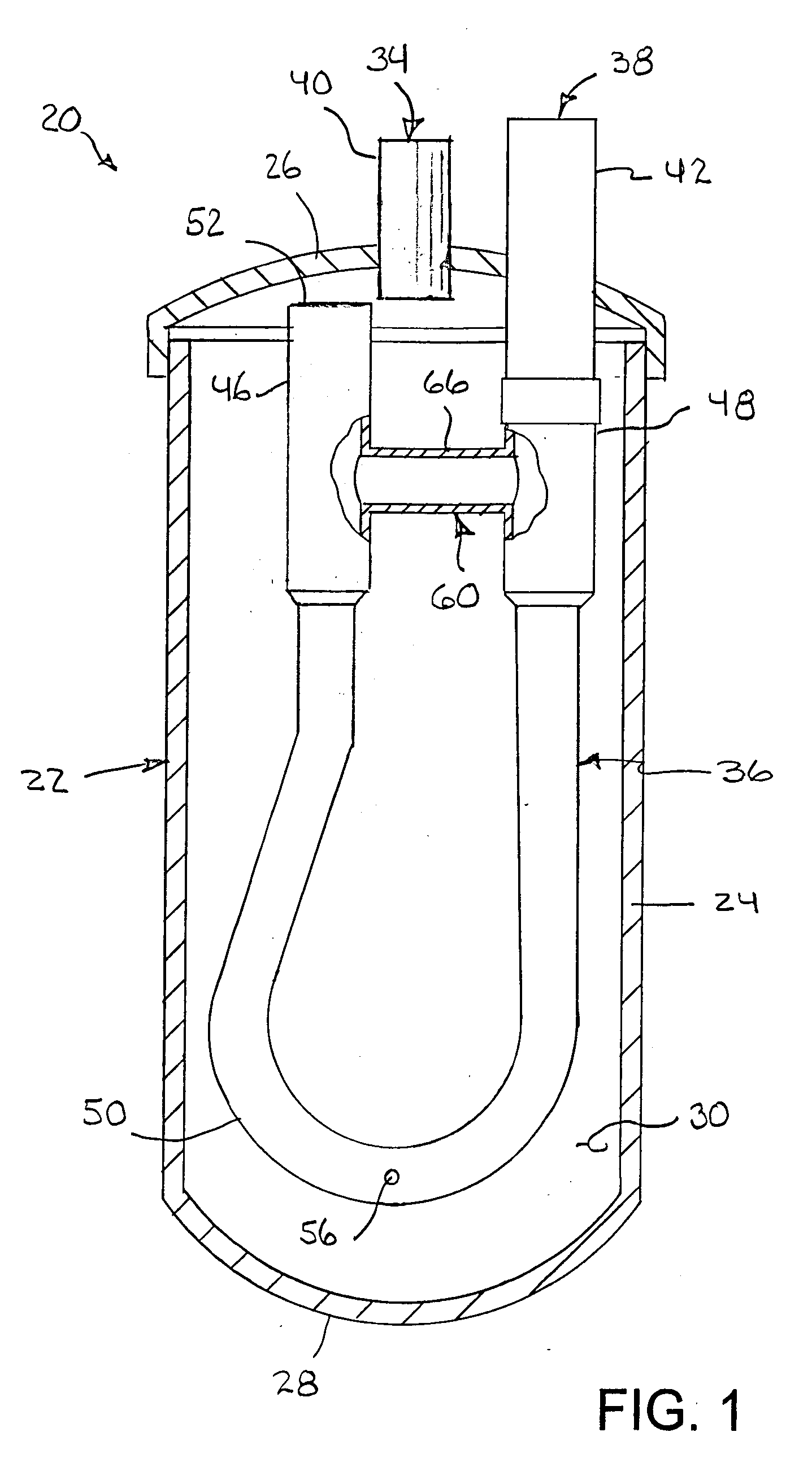

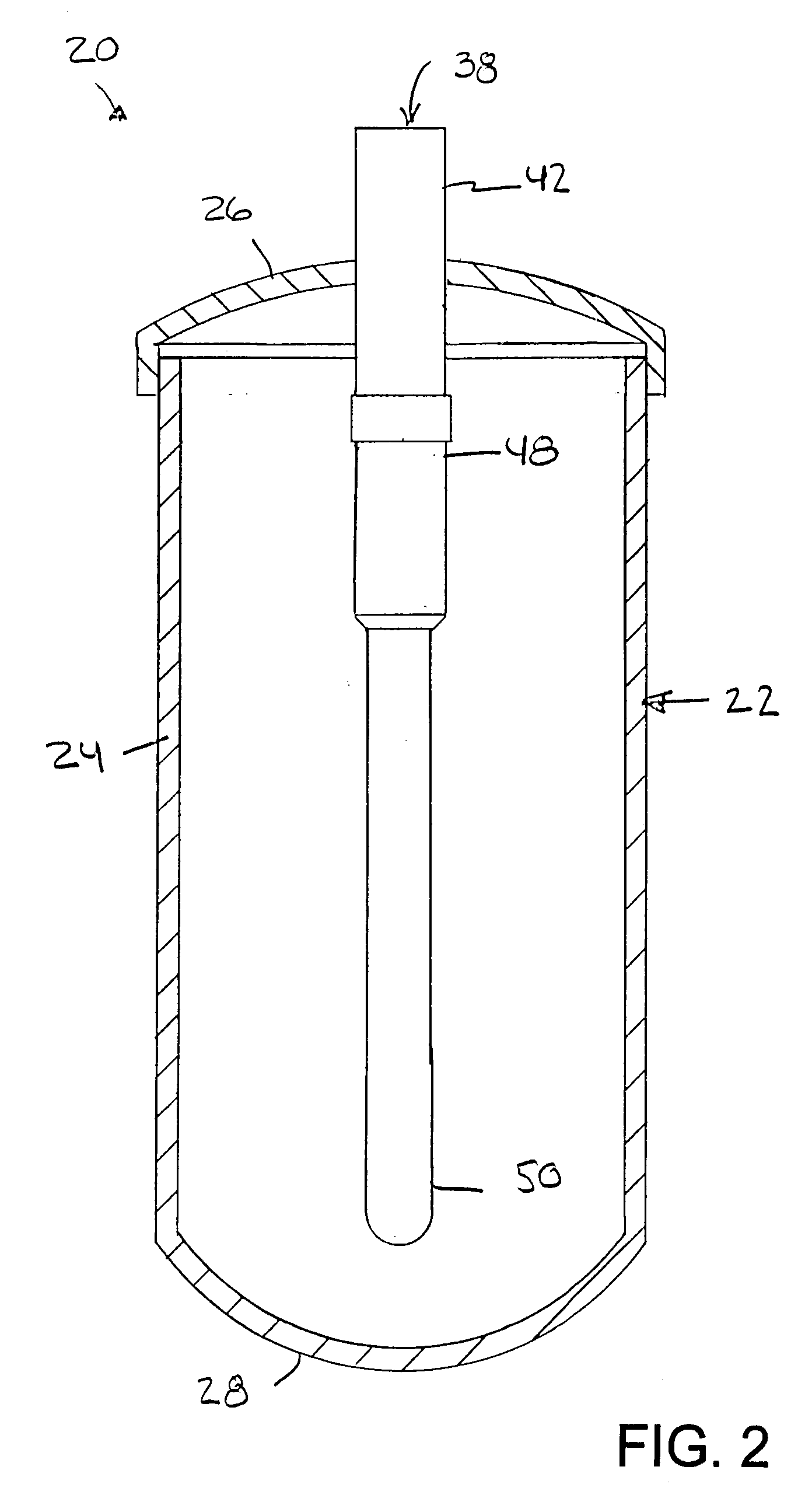

[0027] Referring now to the drawings in detail and initially to FIGS. 1 and 2, an exemplary accumulator according to the principles of the present invention is illustrated generally at 20. The accumulator includes an outer canister, housing or other container 22. The container 22 has a tubular sidewall or shell 24, an upper end wall 26 and a lower end wall 28. The shell may be cylindrical, and the sidewall and lower end wall may be formed together in one piece using common forming techniques such as impacting or extruding a sheet of metal or injection molding plastic. The upper end wall 26 may be formed separately as a cap or cover that is joined by any suitable means in a fluid-tight manner to the upper end of the shell 24. The upper end wall 26, lower end wall 28 and cylindrical sidewall 24 define an internal chamber indicated generally by reference number 30. As shown, the end walls may be convexly or dome shaped as is conventional.

[0028] The illustrated accumulator 20 is partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com