Method Of Moistening Paper Web And Paper Web Moistening Device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

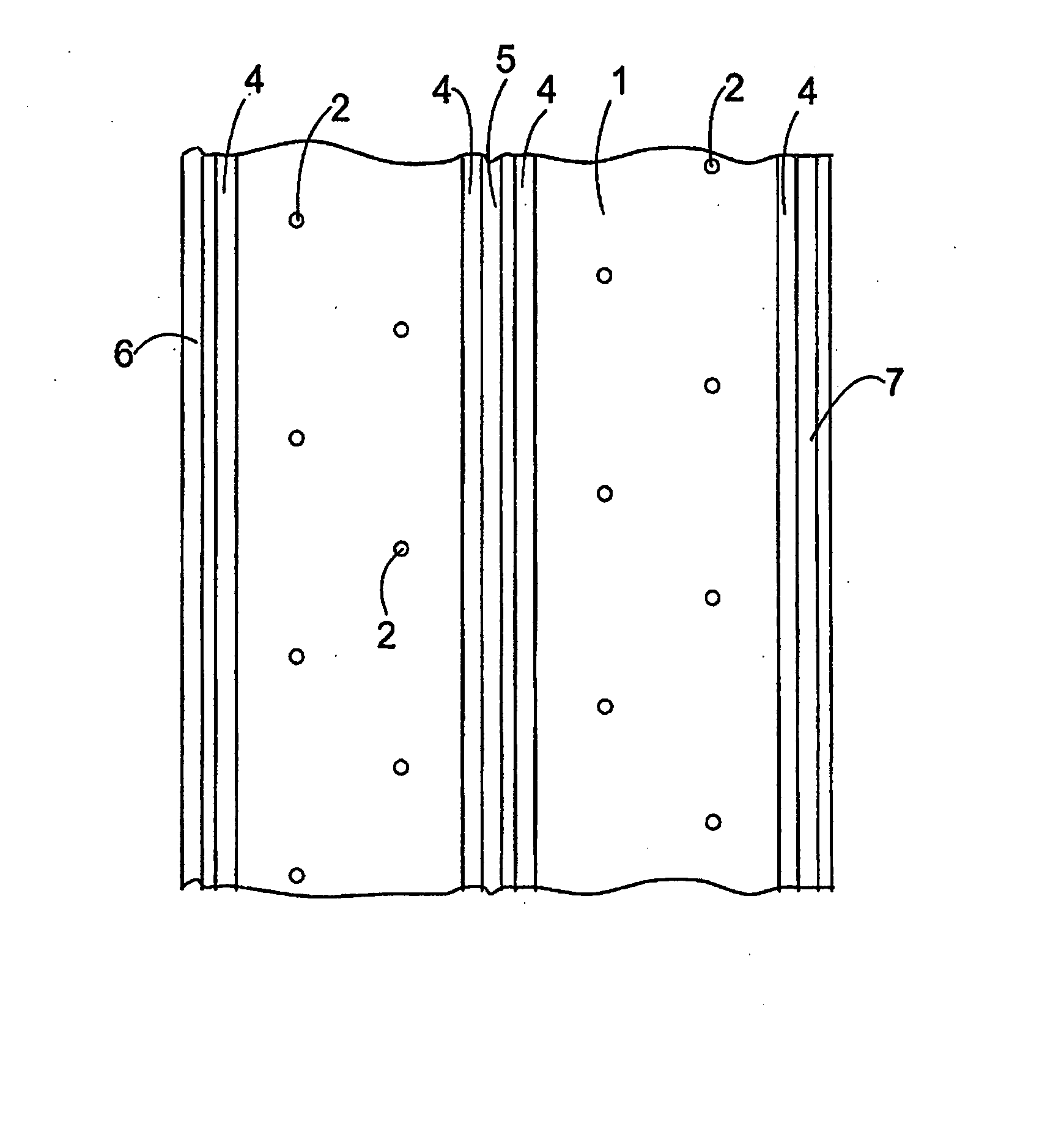

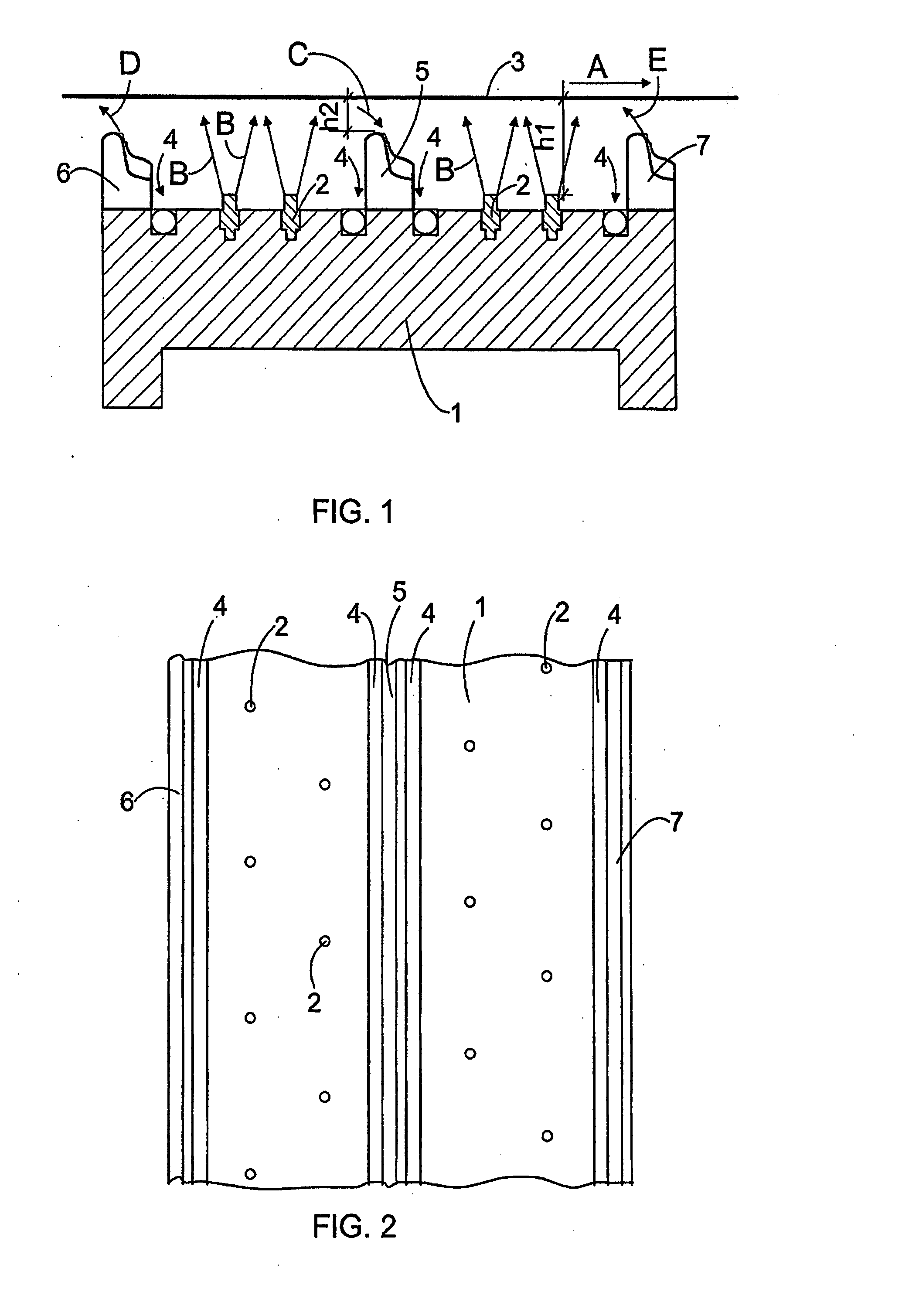

[0015]FIG. 1 illustrates a paper web moistening device where the body 1 is provided with moistening nozzles 2. The body 1 is a beam arranged in the cross direction of the paper web 3. The moistening device is arranged below the paper web 3. The paper web 3 moves in the direction of arrow A. The paper web 3 may be a paper or cardboard web already manufactured in a paper machine or a fibrous web in a paper machine or cardboard machine, still containing moisture that is to be removed in the paper machine. The moistening device is typically arranged below the paper web 3, but if desired, it may also be mounted above the paper web 3 or both above and below the paper web. The particular purpose of the moistening device is to increase the moisture content of the paper web 3.

[0016] Water mist is blown or sprayed by moistening nozzles 2 towards the paper web 3 surface, the water mist being typically a mixture of air and water. The cone-shaped water mist spray achieved by means of the moiste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distance | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com