Refrigerant circuit system

a circuit system and refrigeration technology, applied in refrigeration components, transportation and packaging, light and heating apparatus, etc., can solve the problems of increased labor and material costs, and achieve the effect of maximizing efficiency and minimizing costs and difficulties in manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The following detailed description and appended drawings describe and illustrate various exemplary embodiments of the invention. The description and drawings serve to enable one skilled in the art to make and use the invention, and are not intended to limit the scope of the invention in any manner.

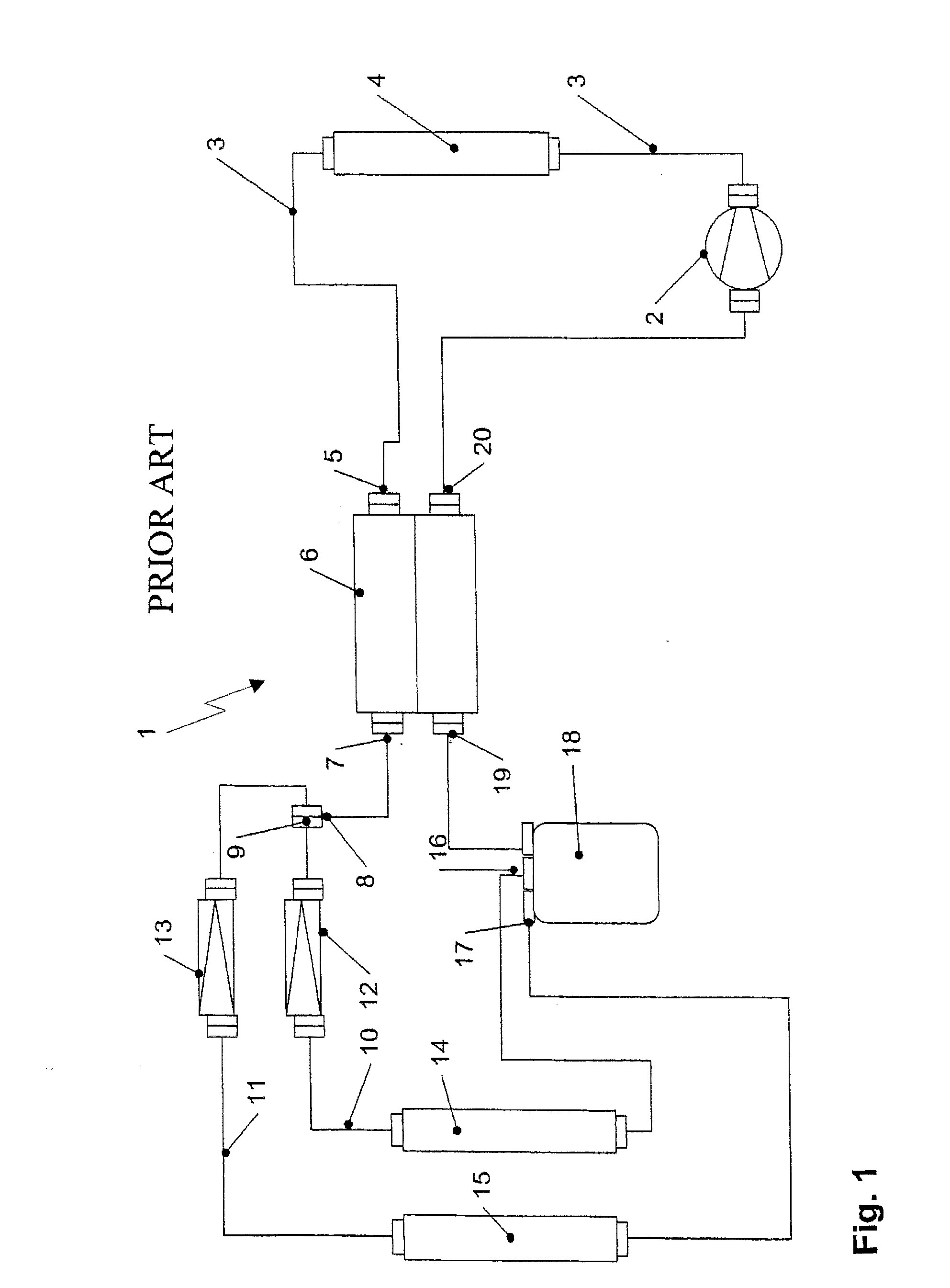

[0030]The block diagram of FIG. 1 shows a prior art HVAC usable to condition air in a vehicle. Such an HVAC has a refrigerant circuit system 1 employing a suitable refrigerant. From a compressor 2 the refrigerant flows through the refrigerant line 3 on the high-pressure side to a gas cooler 4, where the refrigerant is cooled by an environmental air flow. Then the refrigerant flows over the high-pressure entrance 5 into the internal heat exchanger 6 and after having passed the internal heat exchanger 6, over a high-pressure exit 7 to a manifold connection 8. The manifold connection 8 is placed on the refrigerant line 3, whereby the manifold 9 established as three-way screwing point di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com