Pre-fillable and disposable sippy cup

a sippy cup and pre-filling technology, applied in the field of child and infant feeding cups, can solve the problems of bloating of the baby's stomach, baby ingesting a large amount of air, and the history of the liquid feeding system of the baby and toddler, and achieve the effect of convenient configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

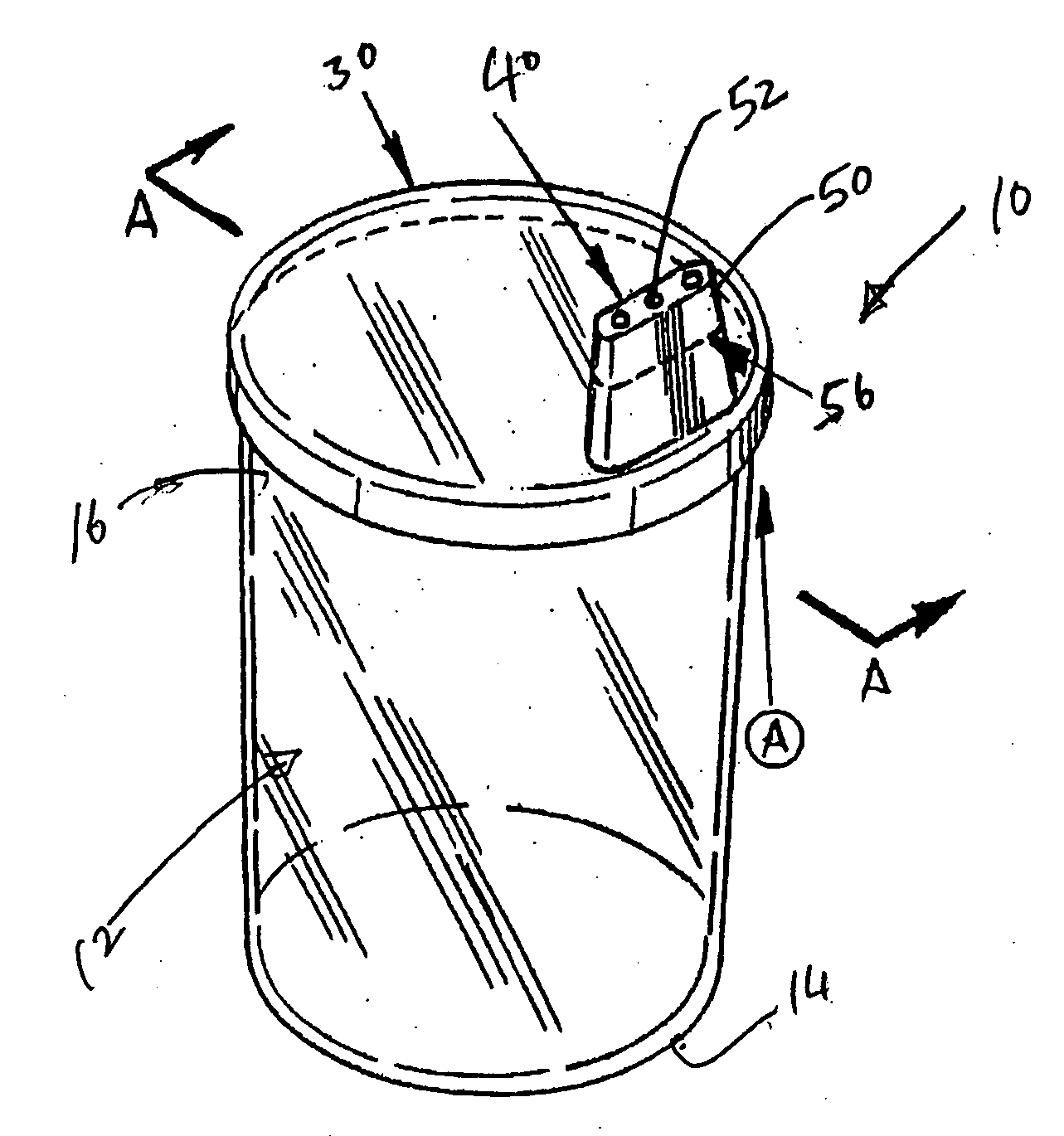

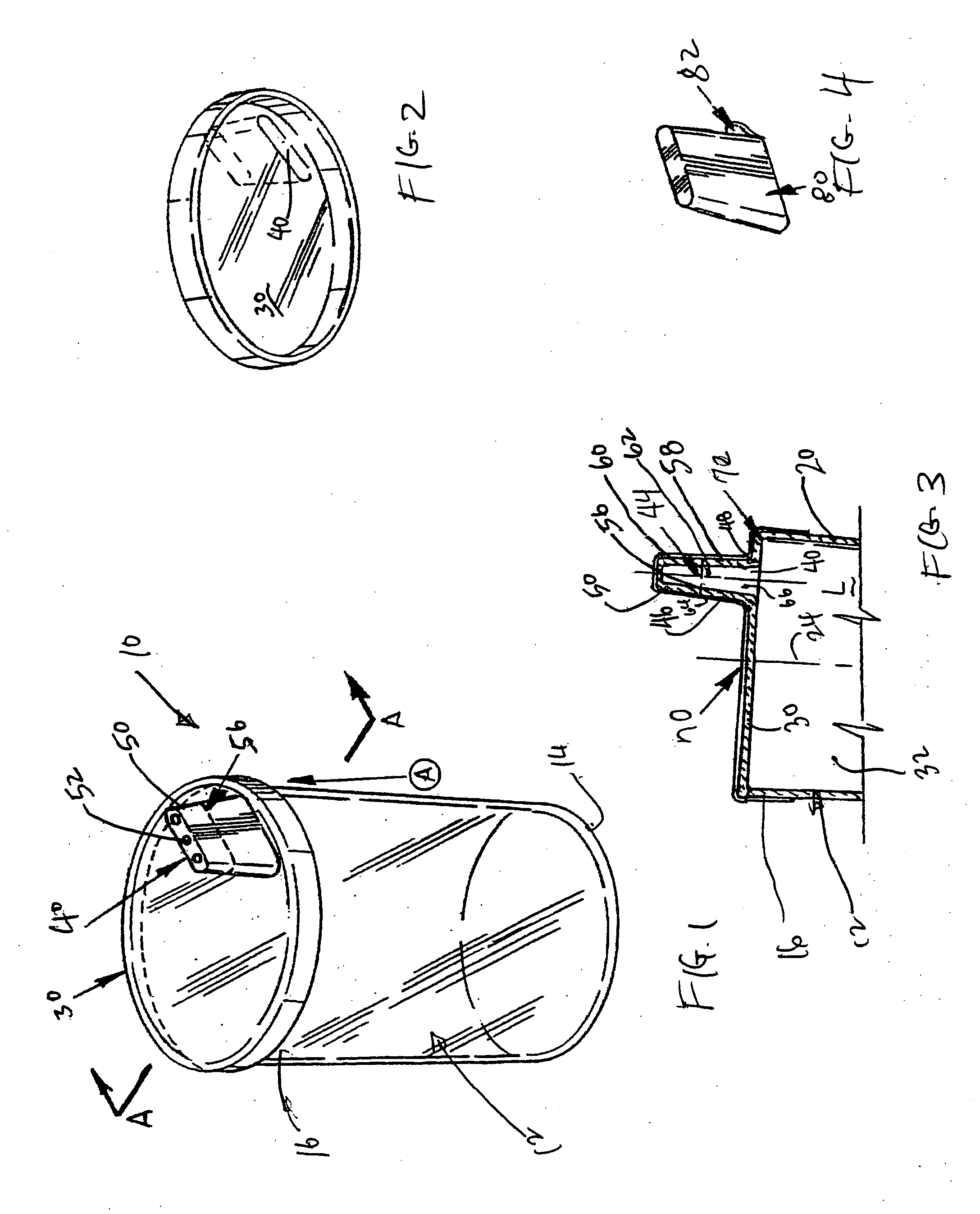

[0018]Referring to the figures, it can be understood that the present invention is embodied in a disposable sippy cup 10 which can be sold in stores and which will contain liquid, such as juice, milk, or the like and which is to be discarded after use. Sippy cup 10 comprises a one-piece main body 12. The one piece nature of the body makes is easy and convenient for a manufacturer to pre-load liquid into the cup and seal it for storage and shipping. The one piece nature of the cup will allow sealing in a manner that prevents bacteria or the like from entering the cup whereby the storage of the cup will be safe. Still further, the one piece nature of the cup will prevent, or at least minimize, leakage and spillage during use of the cup. In one form of the invention, body 12 is plastic.

[0019]One piece body 12 includes a first end 14 which is a bottom end when the body is in use, with the use orientation being shown in FIG. 1. Body 12 further includes a second end 16 which is a top end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com