Swivel recoiler

a recoiler and swivel technology, applied in the field of recoilers, can solve the problems of unbalanced forces on the recoiler, damage to the housing, and difficulty for customers to adequately review and manipulate merchandise,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

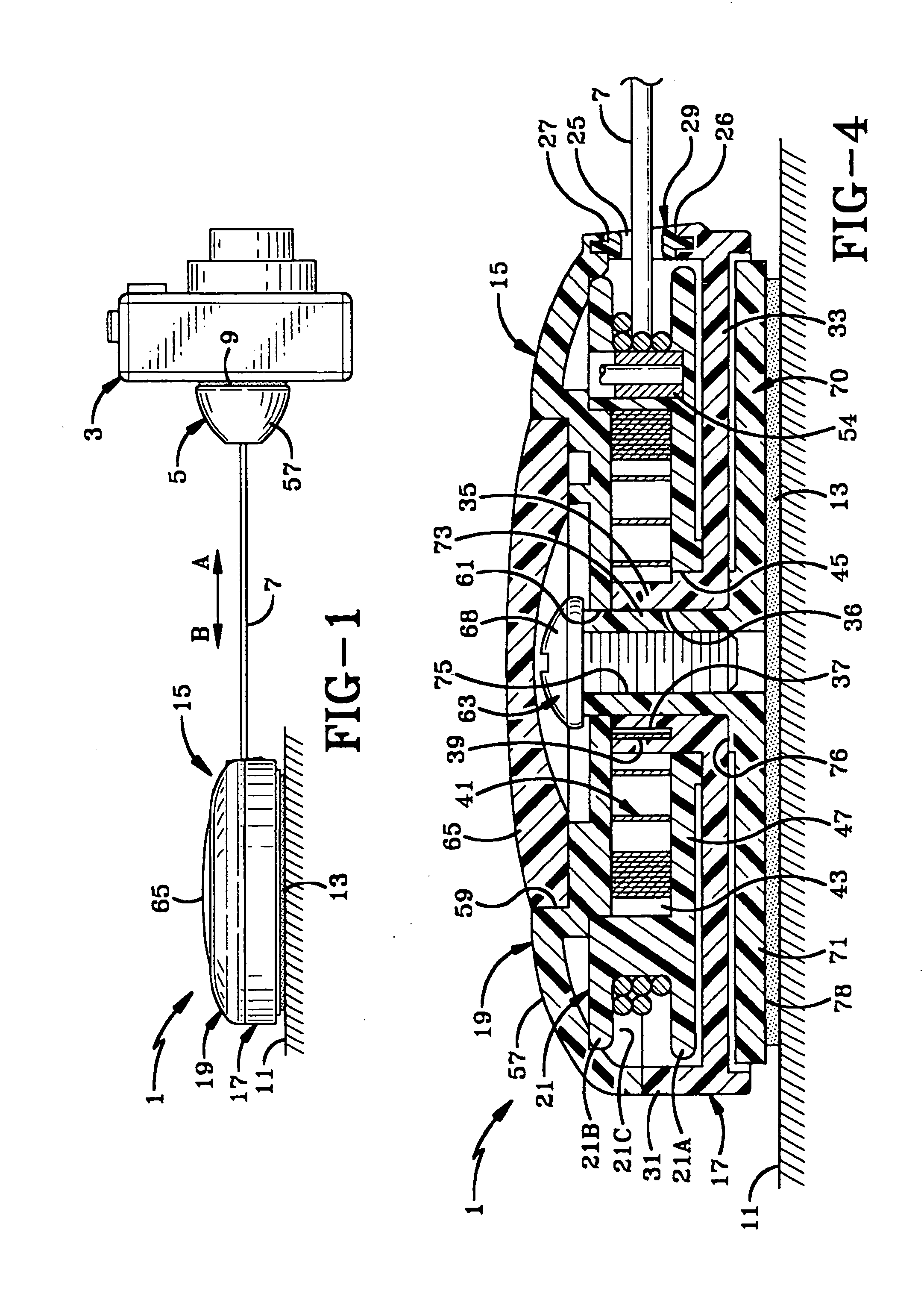

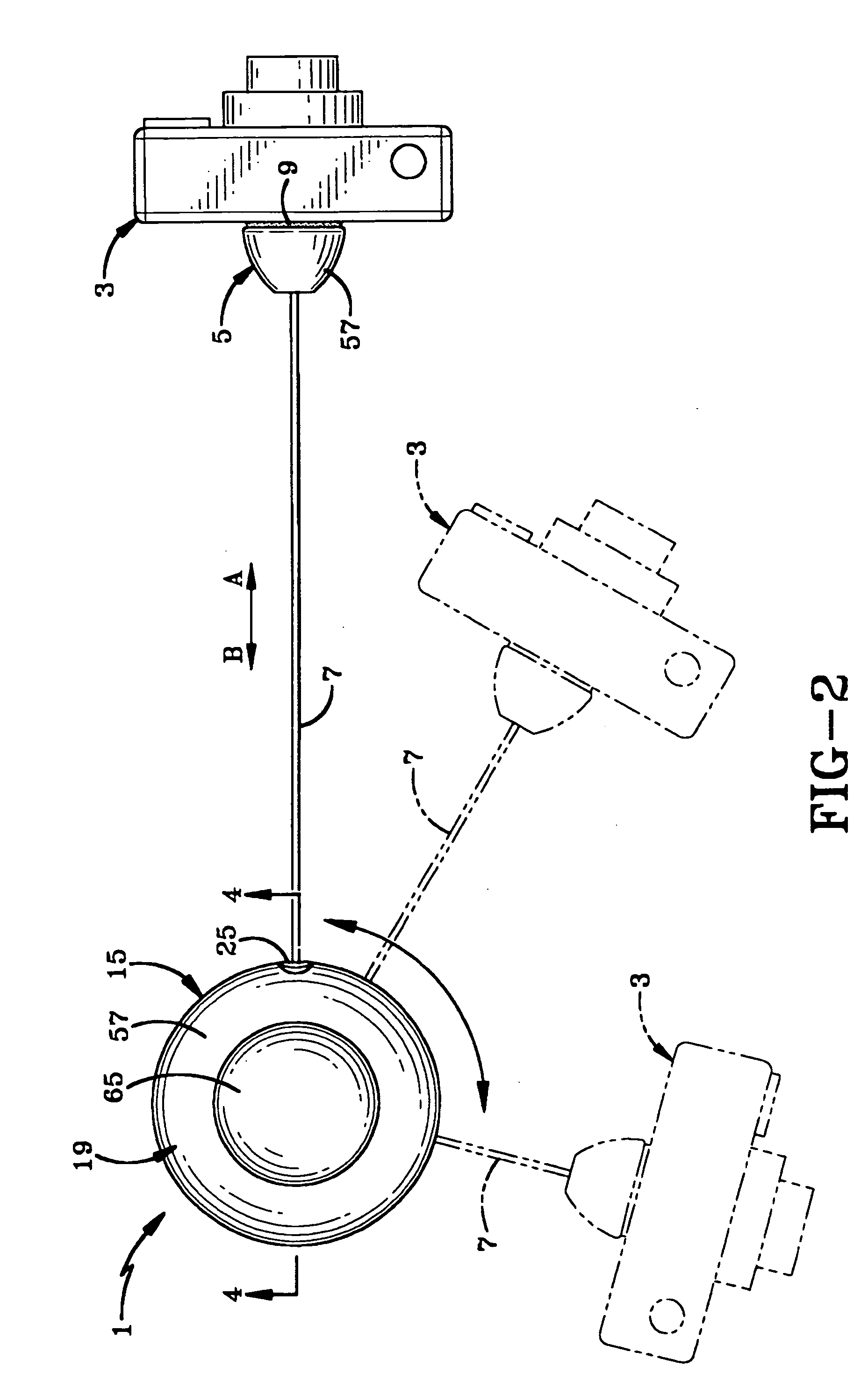

[0018]The recoiler of the present invention is indicated generally at 1, and is shown in FIGS. 1 and 2 being connected to an item of merchandise 3. Merchandise 3 is depicted as being a camera. However any item of merchandise and other types of objects can be connected to the recoiler by an attachment pad 5, which is connected to the distal end of a cable 7. Attachment pad 5 can be connected easily to merchandise 3 by a disc-shaped pressure sensitive adhesive pad 9 or other type of attachment device. Recoiler 1 preferably is mounted on a support structure 11 by a second pressure sensitive adhesive pad 13 or other type of mechanism.

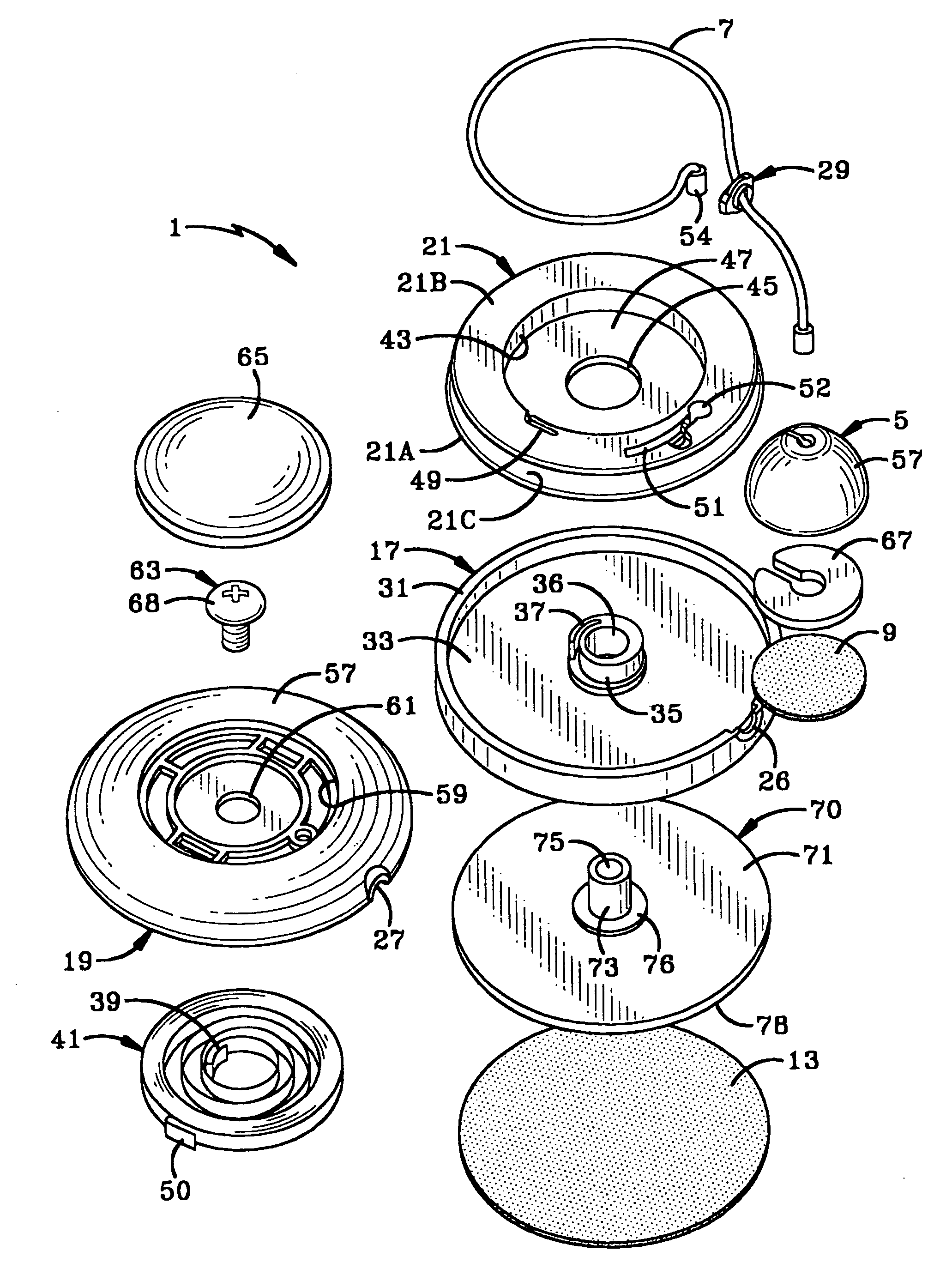

[0019]The components of recoiler 1 are best shown in FIGS. 3 and 4. Recoiler 1 includes a housing indicated generally at 15, which includes a bottom housing member 17 and a top housing member 19, each of which preferably is formed as a one piece member of plastic material enabling them to be mass produced at a relatively low cost. A spool 21 stores a predet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com