Ribbed post

a post and rib technology, applied in the field of ribbed posts, can solve the problems of affecting so as to prevent unintended dislodging of the wire and maintain the stability of the pos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

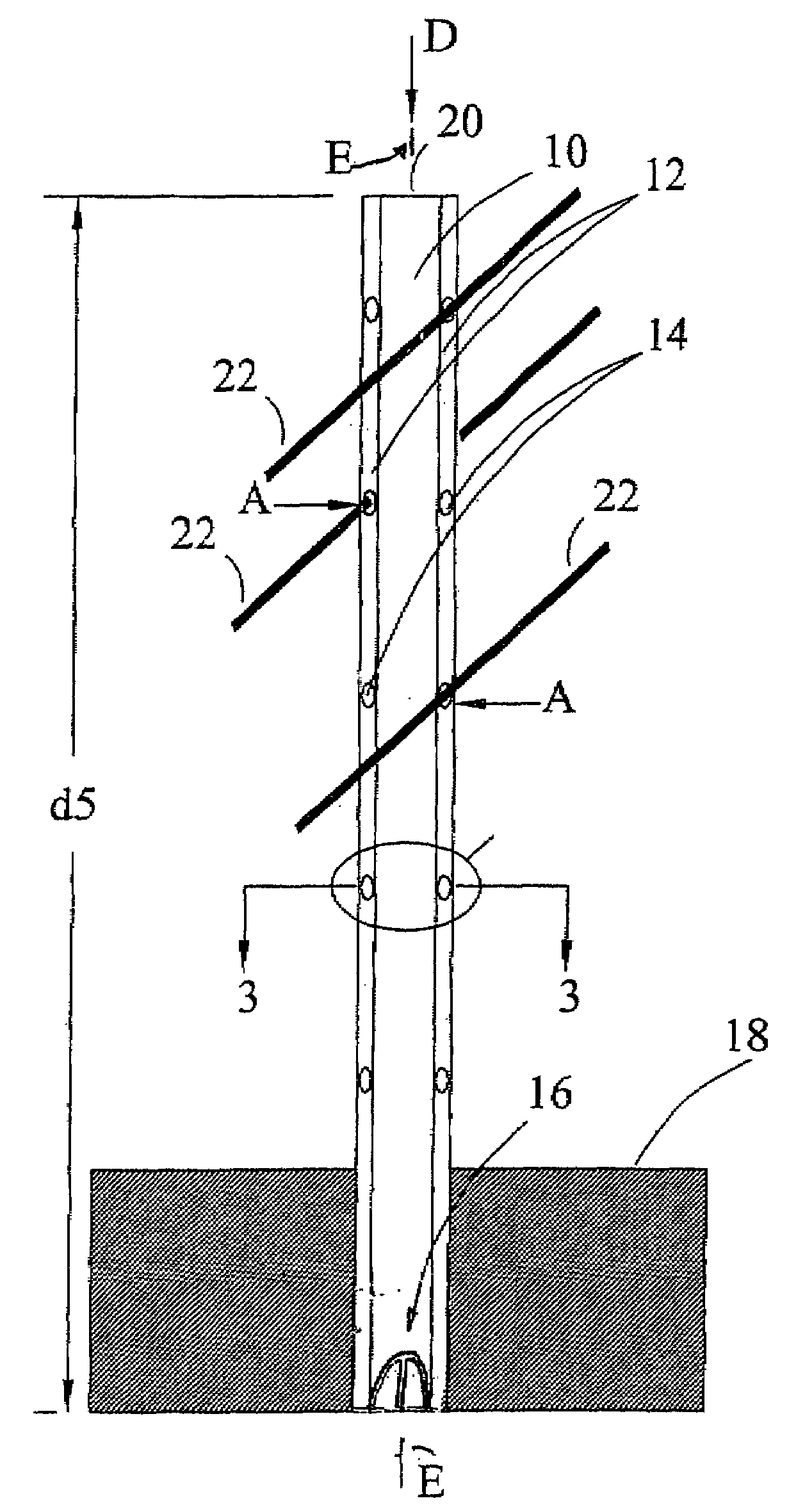

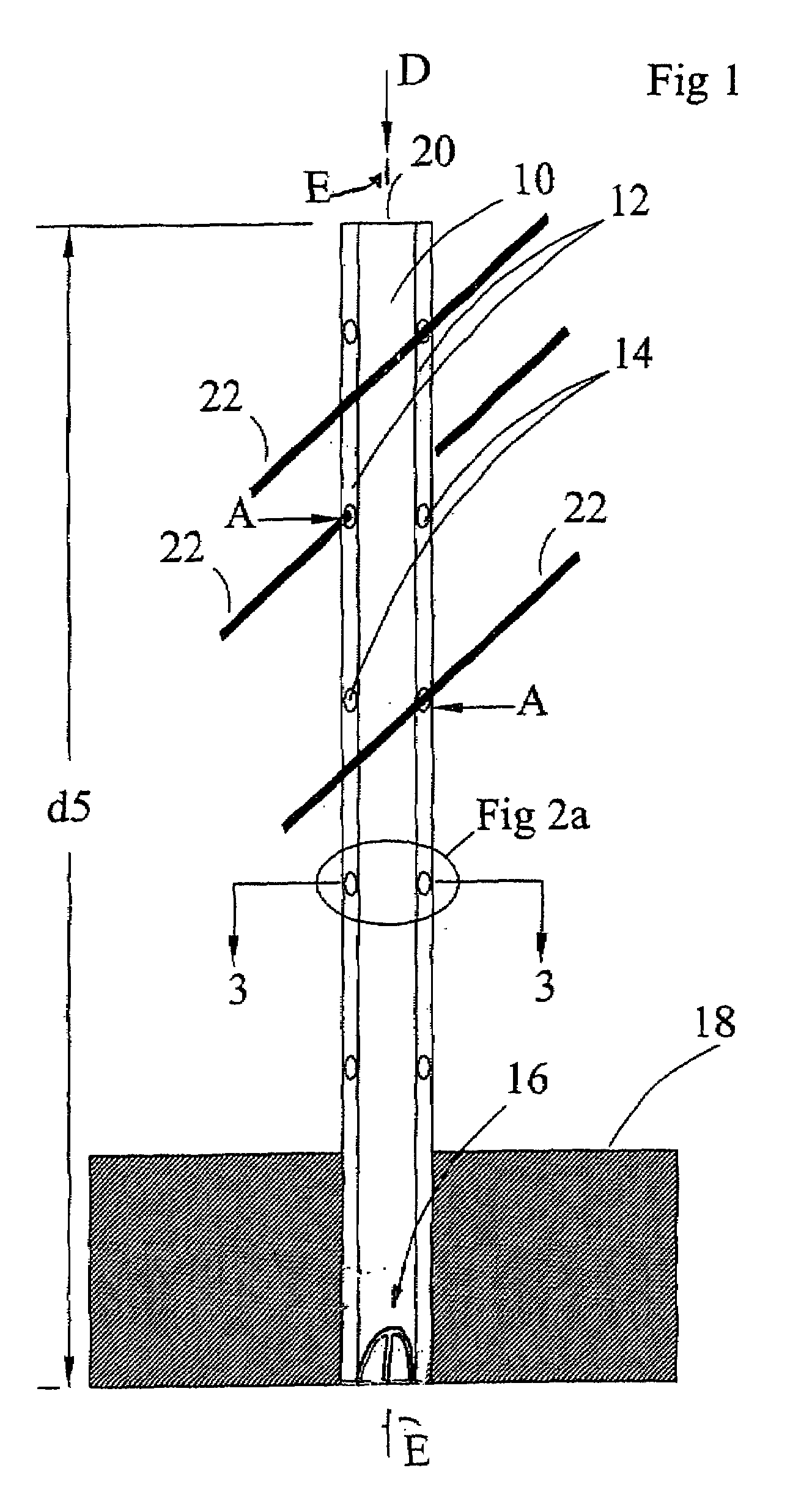

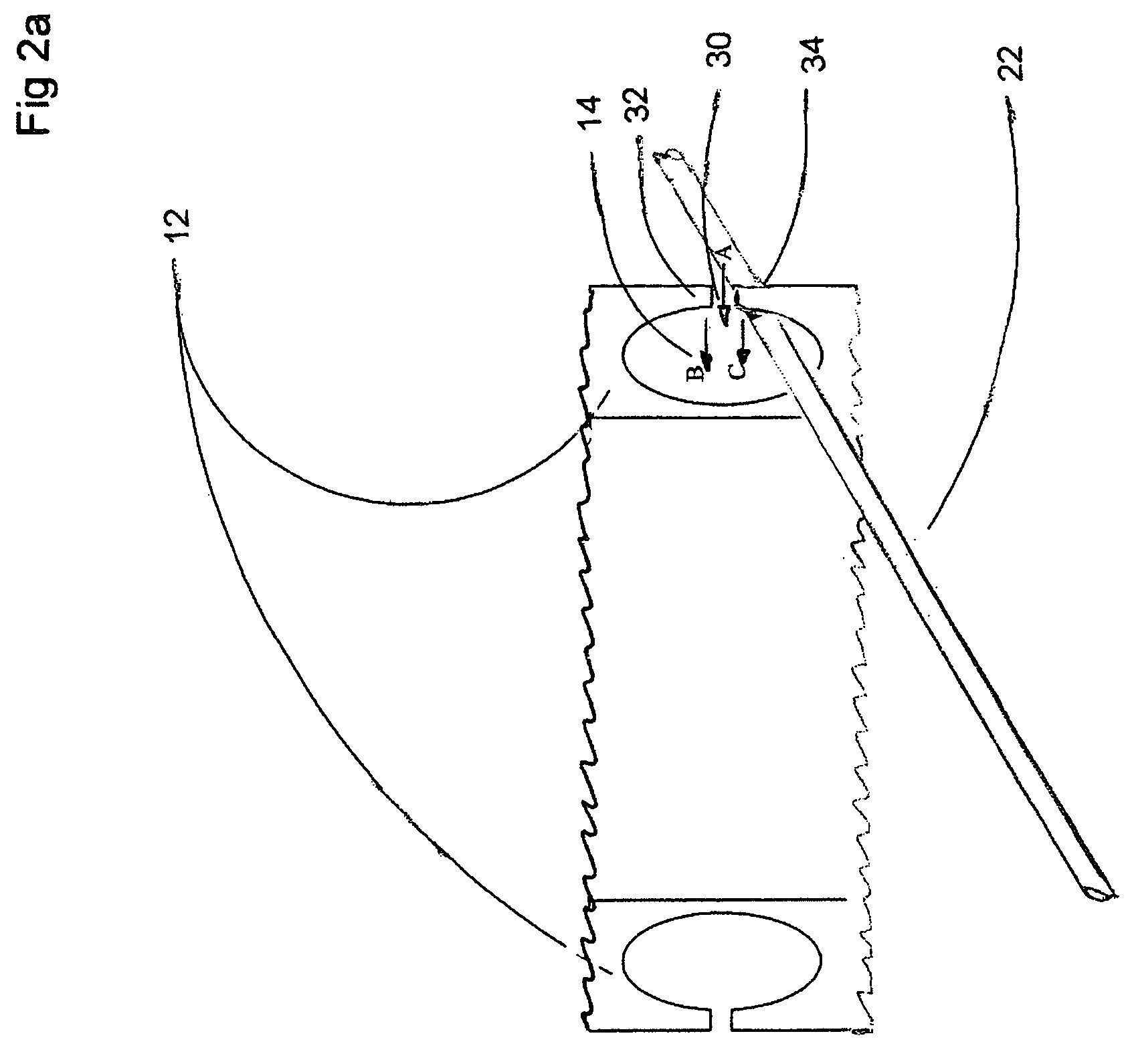

[0016]In the accompanying Figures, wherein like reference numerals denote corresponding parts in each view, FIG. 1 illustrates basal end 16 of post 10 driven into ground 18. It is understood that post 10 would be mounted sufficiently deeply into ground 18 so as to be free-standing when un-loaded. Post 10 is in one embodiment a hollow, cylindrical post. The post may be flat and sealed on apical end 20, and is preferably chisel shaped on basal end 16. The chiseled shape of basal end 16 of post 10 is such that post 10 may be inserted into an augered hole or into ground 18 with a post-pounder or other suitable post driving means thereby securing post 10 in ground 18 without twisting the direction of the flanges, keeping them parallel to adjoining post flanges in the trellis line. A pair of oppositely disposed ridges 12 are substantially co-planar, each ridge 12 containing a series such as linear spaced-apart arrays of notches or apertures 14 (collectively herein “apertures”). Apertures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com