Coiled tubing well tool and method of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

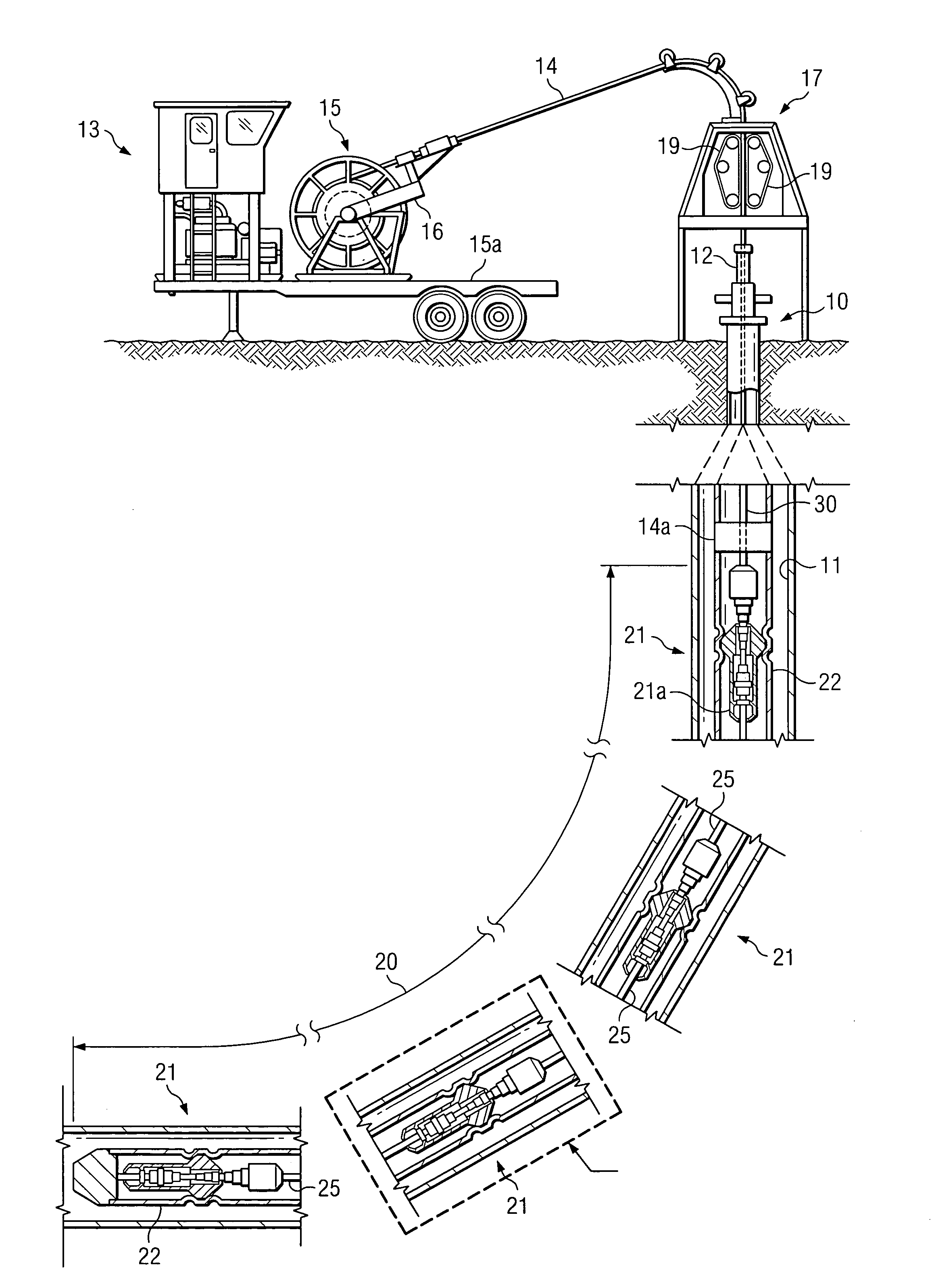

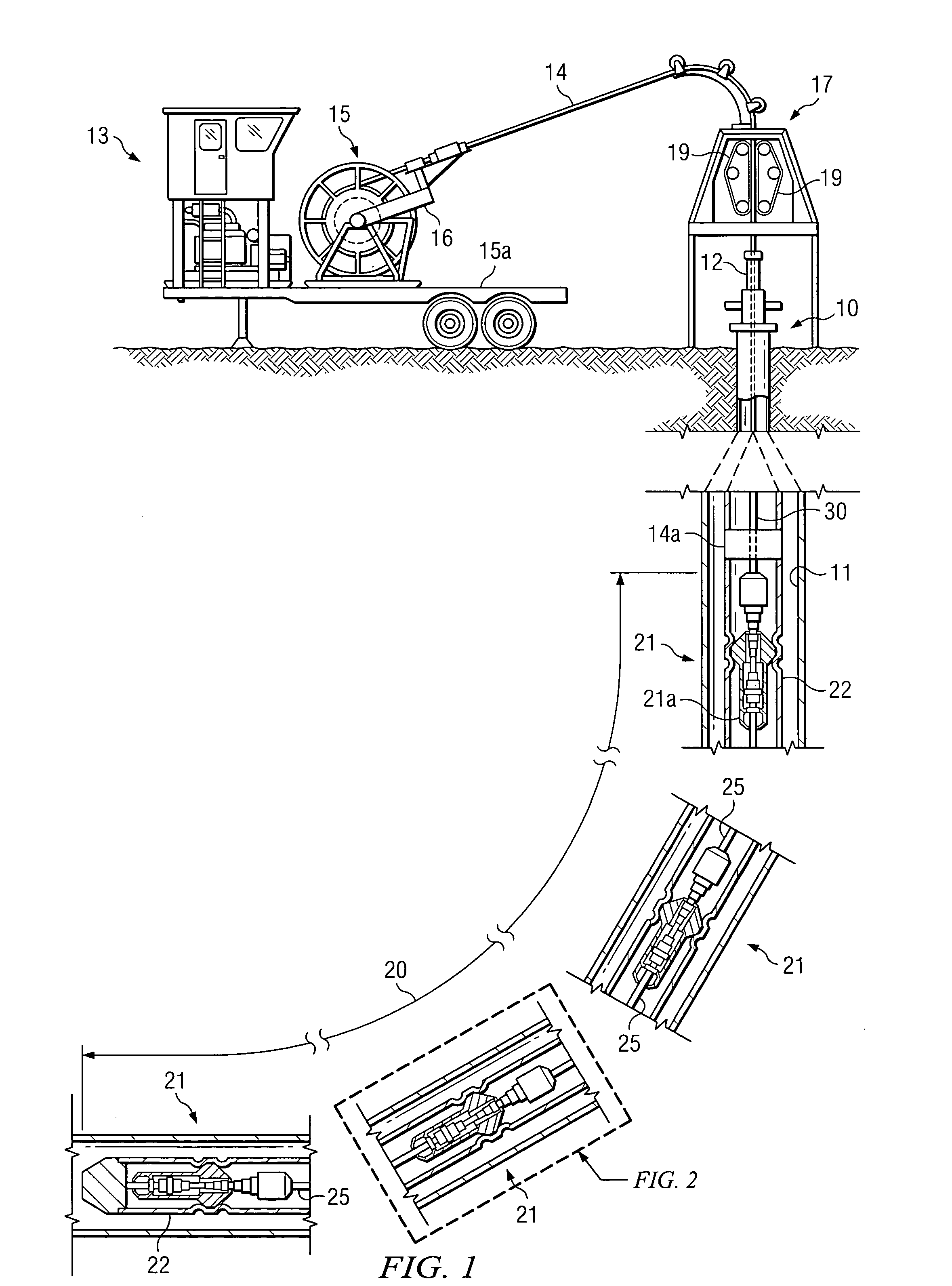

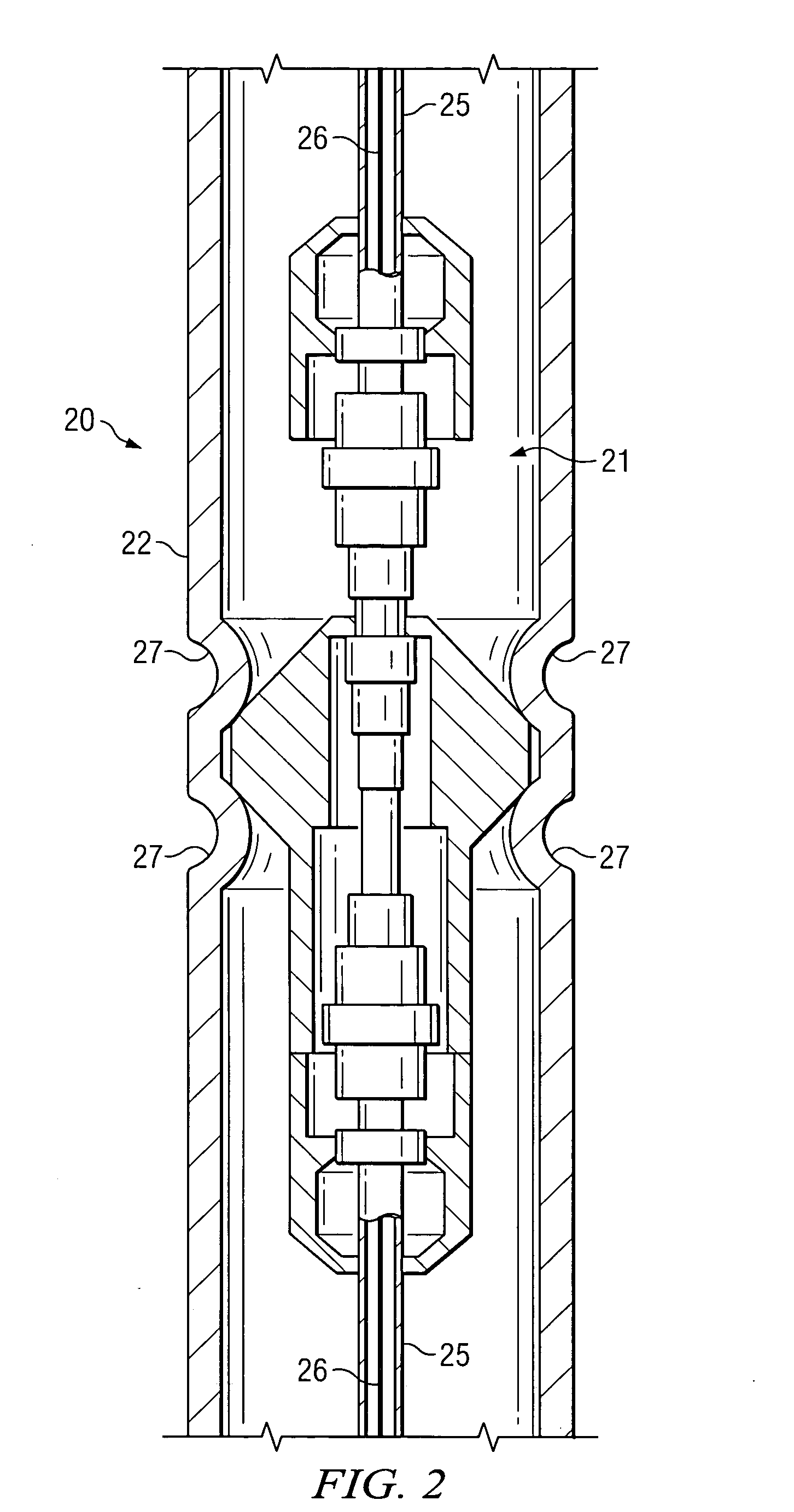

[0018]Referring now to the drawings, FIG. 1 illustrates a well 10 having a wellbore 11 and a wellhead 12. As will be understood, wellbore 11 can be cased (as shown), lined, open, or otherwise completed and can be vertical, slanted, and / or horizontal. A typical, coiled tubing system 13 is positioned on the surface for running a coiled tubing string 14 into and out of the wellbore 11 through wellhead 12. As will be understood in the art, the term “coiled tubing”, as used herein is a continuous length of a relatively small diameter (up to 6 inches), thin-walled relatively flexible metal tubing (e.g. steel or other high-strength alloy tubing such as titanium alloy, chrome alloy, or composite material) 14 which can be wound or coiled onto reel or spool 15 which, in turn, can be mounted on a mobile trailer 15a or the like.

[0019]Reel 15 may include a “level wind” mechanism 16 or the like to align the continuous length of tubing in relatively uniform layers as the tubing is reeled onto / off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com