Heat regenerative mini-turbine generator

a technology of mini-turbine generator and heat-regeneration, which is applied in the direction of steam engine plants, machines/engines, mechanical equipment, etc., can solve the problems of poor efficiency of small-sized turbines, and achieve the effect of poor efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

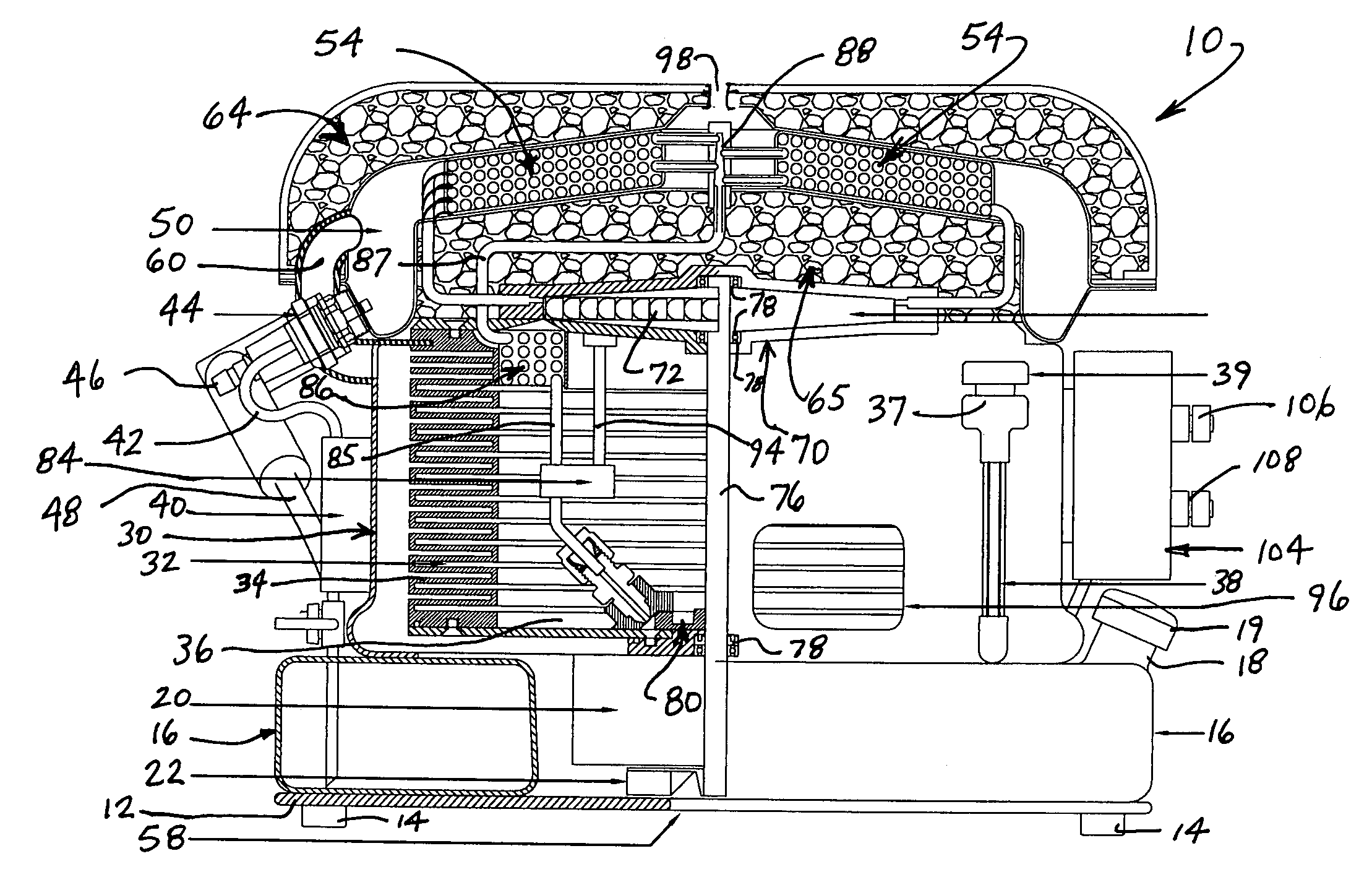

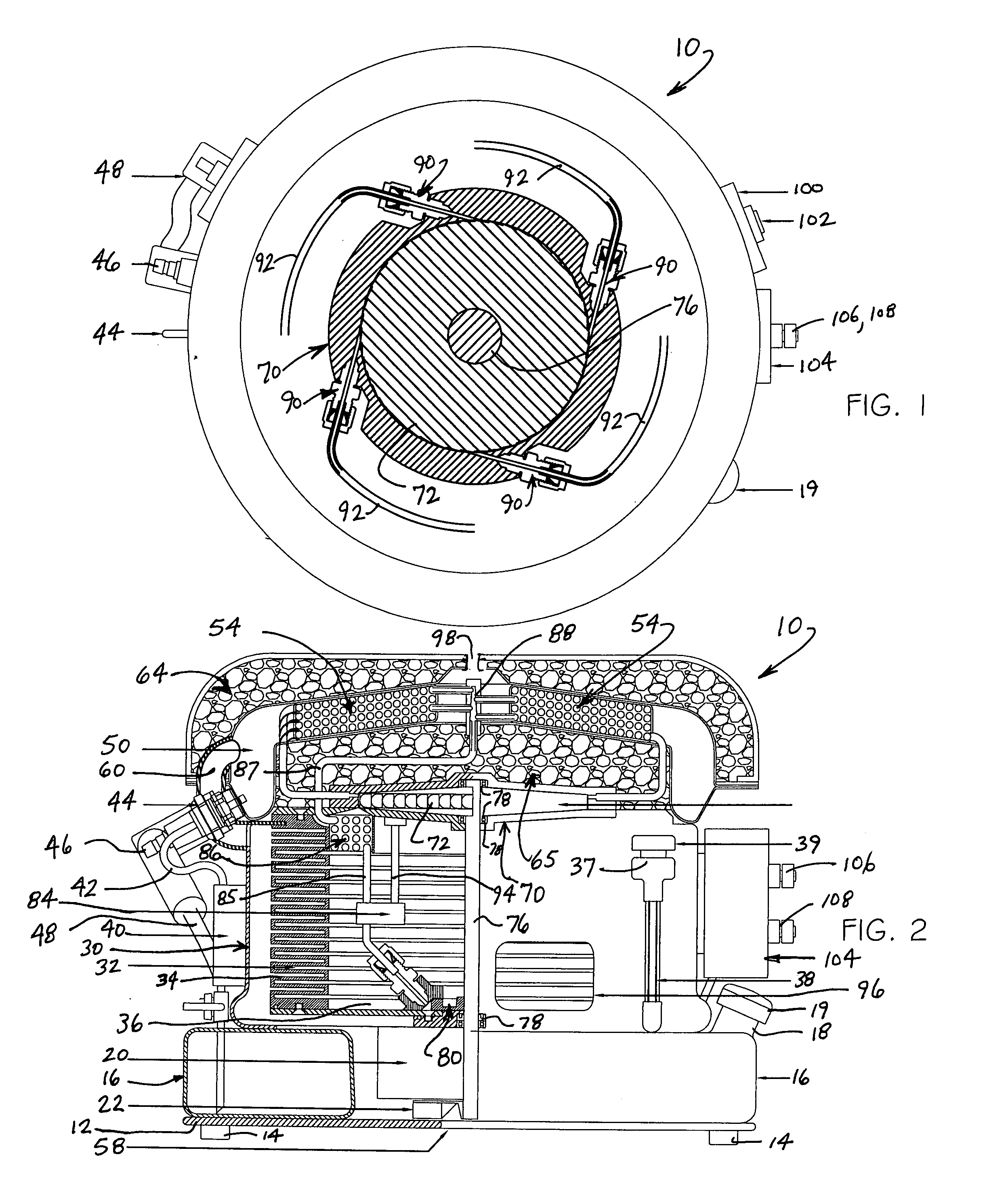

[0010]Referring to the several views of the drawings, and initially FIG. 2, the heat regenerative mini-turbine generator is shown and is generally indicated a 10.

[0011]The generator 10 is supported on a base 12 that may include feet 14 on the bottom for supported engagement on a floor, ground or counter surface. A fuel tank 16 rests on the top of the base. In a preferred embodiment, the fuel tank 16 is circular (i.e. donut shaped) to provide an open central area above the base that accommodates a centrifugal blower 22 and an alternator 20. A fill spout 18 with a cap 19 extends upwardly from the fuel tank to facilitate refilling of fuel.

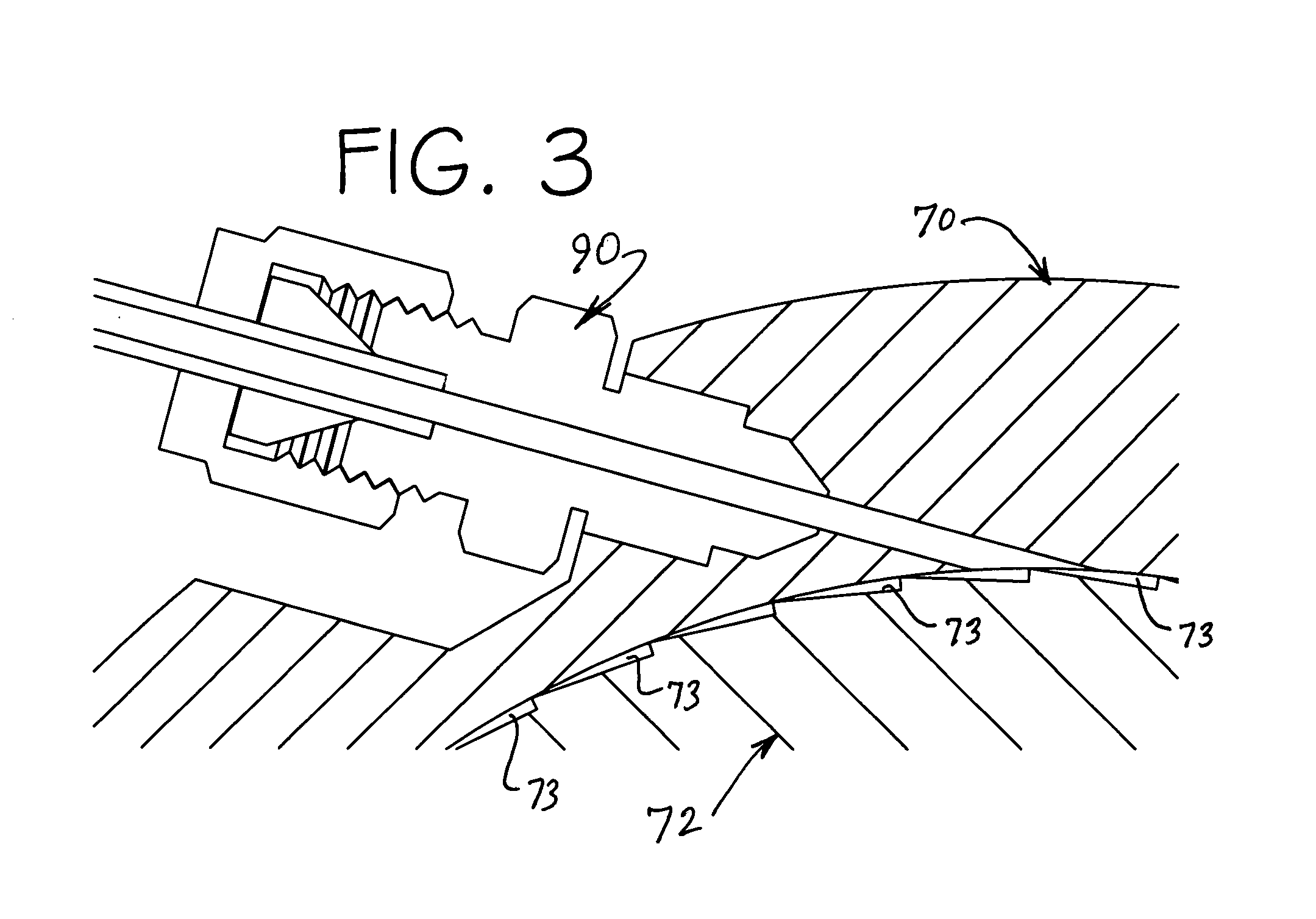

[0012]A condenser chamber 30 sits above the fuel tank 16 and alternator 20 and contains a centrifugal condenser 32 and a condensate collection pan 36 at the bottom of the condenser chamber. The centrifugal condenser has a spaced arrangement of condenser plates 34 that present a large surface area for maximizing heat transfer within a relatively compac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com