Method and apparatus for plugging perforations

a technology of perforation and method, applied in the direction of wellbore/well accessories, fluid removal, insulation, etc., can solve the problems of oil or gas flow reducing to a point where the well is no longer commercially viable, water flow becomes a problem, water is undesirable, etc., to achieve the effect of enhancing the efficiency of the plugging operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

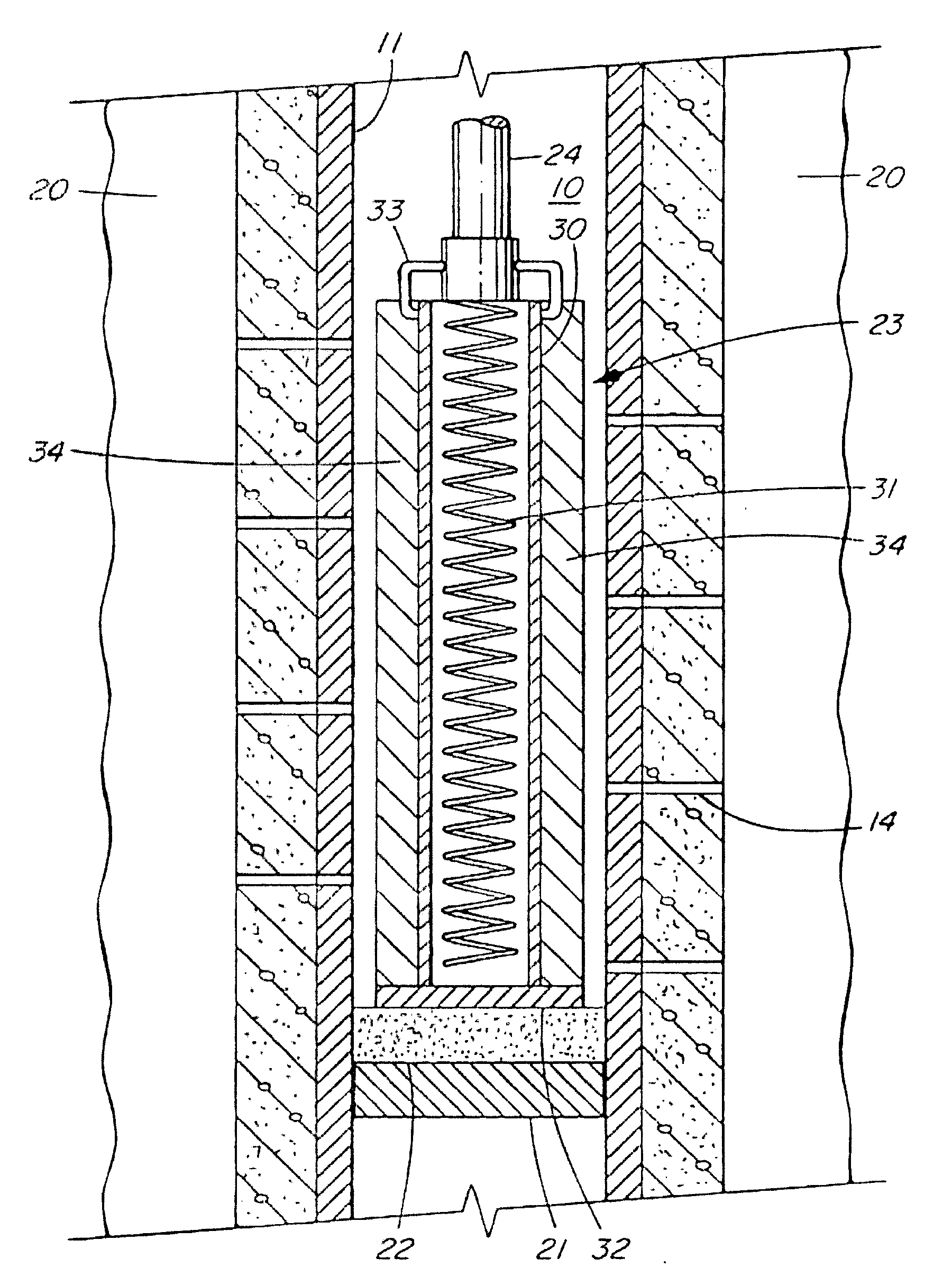

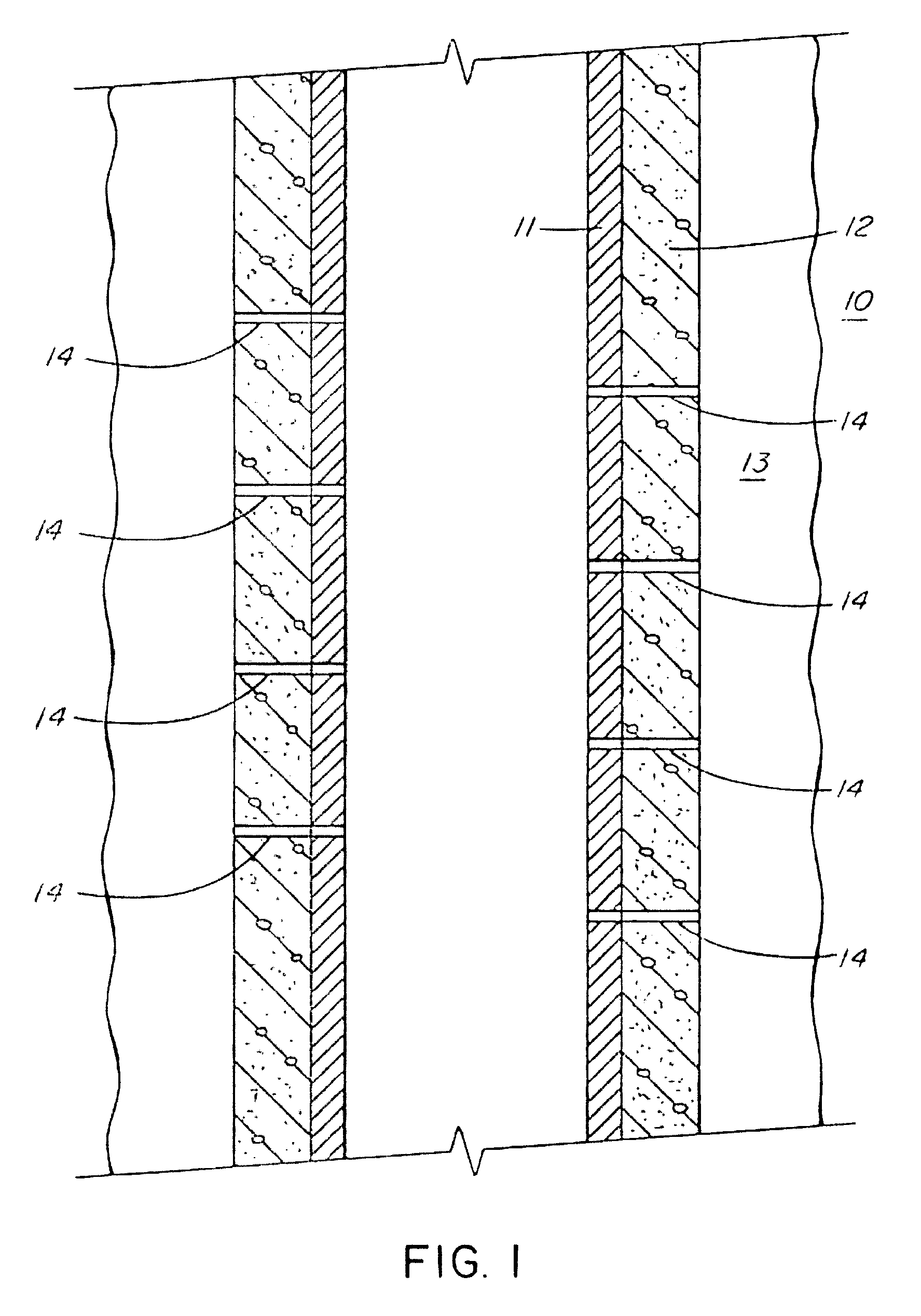

[0015] Referring now to the drawings, an oil or gas well is generally illustrated at 10 in FIG. 1 with the production casing 11 being cemented in by cement 12 which seals the production casing from the formation of interest which is an oil or gas bearing formation generally illustrated at 13.

[0016] Perforations 14 have been formed in the casing 11 and extend into the formation of interest 13.

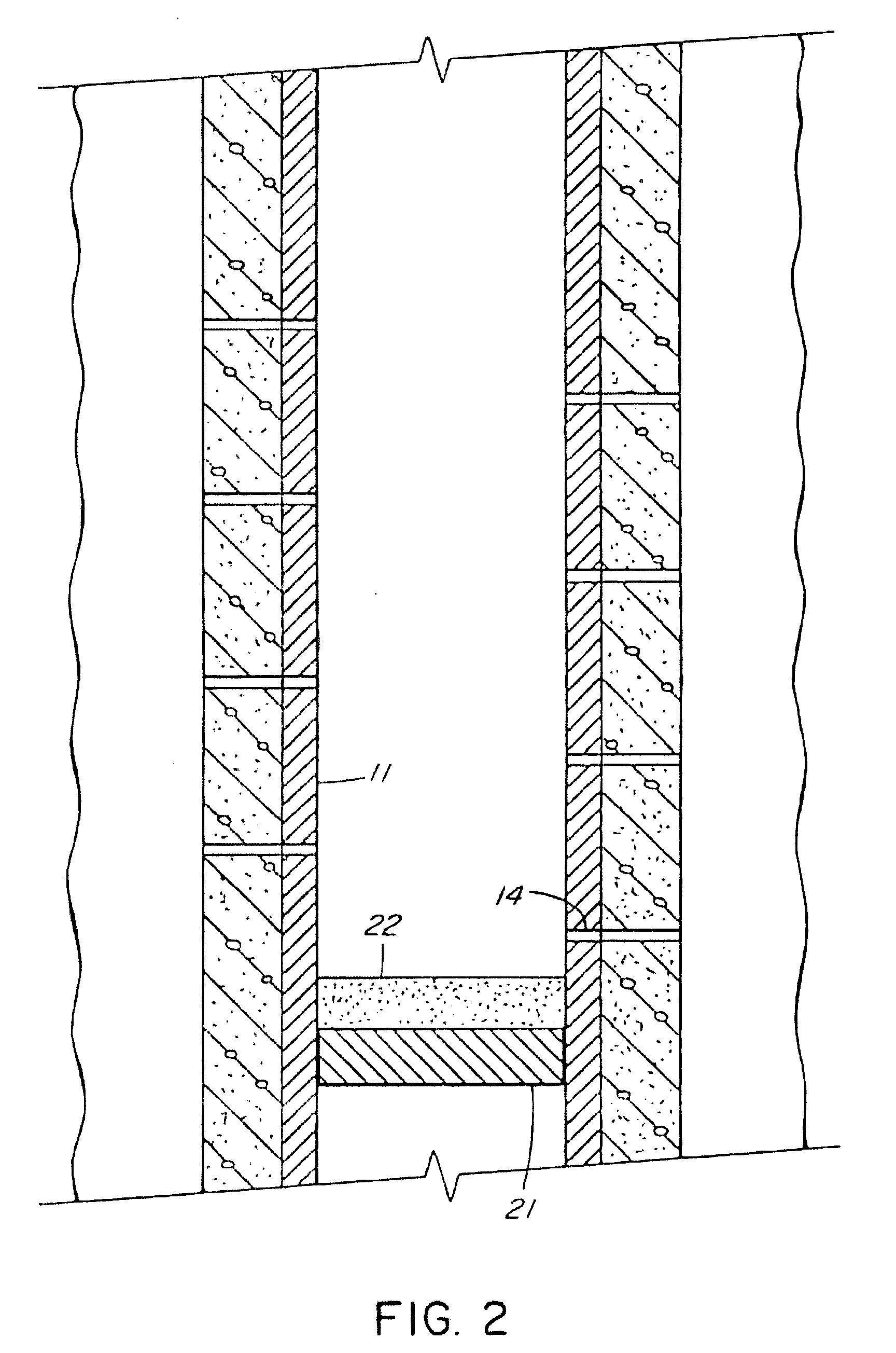

[0017] It is desired to plug the perforations 14 and to terminate flow from the formation 13 through the perforations 14 and into the casing 11. To do so, a retrievable bridge plug 21 is set in the casing 11 below the lowest one of the perforations 14 as illustrated in FIG. 2. The bridge plug 21 is formed within the casing 11 using wire line procedure which is known. A volume of sand 22 is then dumped into the casing 11 and on top of the bridge plug 21. The thickness of the sand layer 22 should extend upwardly to a position just below the lowermost one of the perforations of interest 14.

[0018...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermally conductive | aaaaa | aaaaa |

| fusible | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com