Liftable cover

a technology of lifting cover and pivotal hole, which is applied in the field of covers, can solve the problems of plastic members being damaged by metallic springs, the clearance between the pivotal shaft and the pivotal hole may become larger, and the pivotal shaft cannot always penetrate into the pivotal hole very smoothly, so as to achieve the effect of easy replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]In order to make the Examiner to better understand the characteristics and technical contents of the present invention, a detailed description will be made with reference to the accompanying drawings. However, it should be understood that the drawings are illustrative only but not to limit the scope of the present invention.

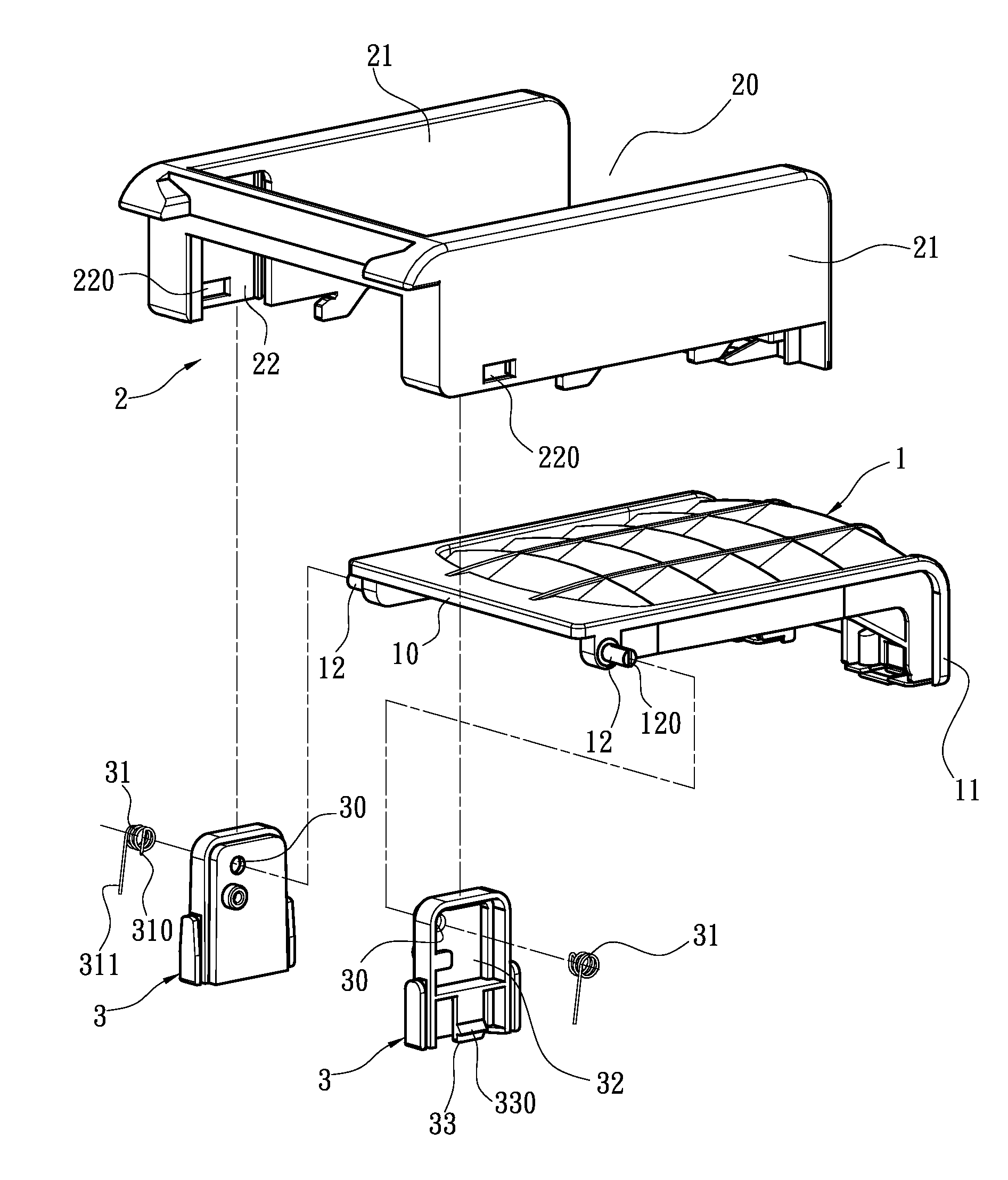

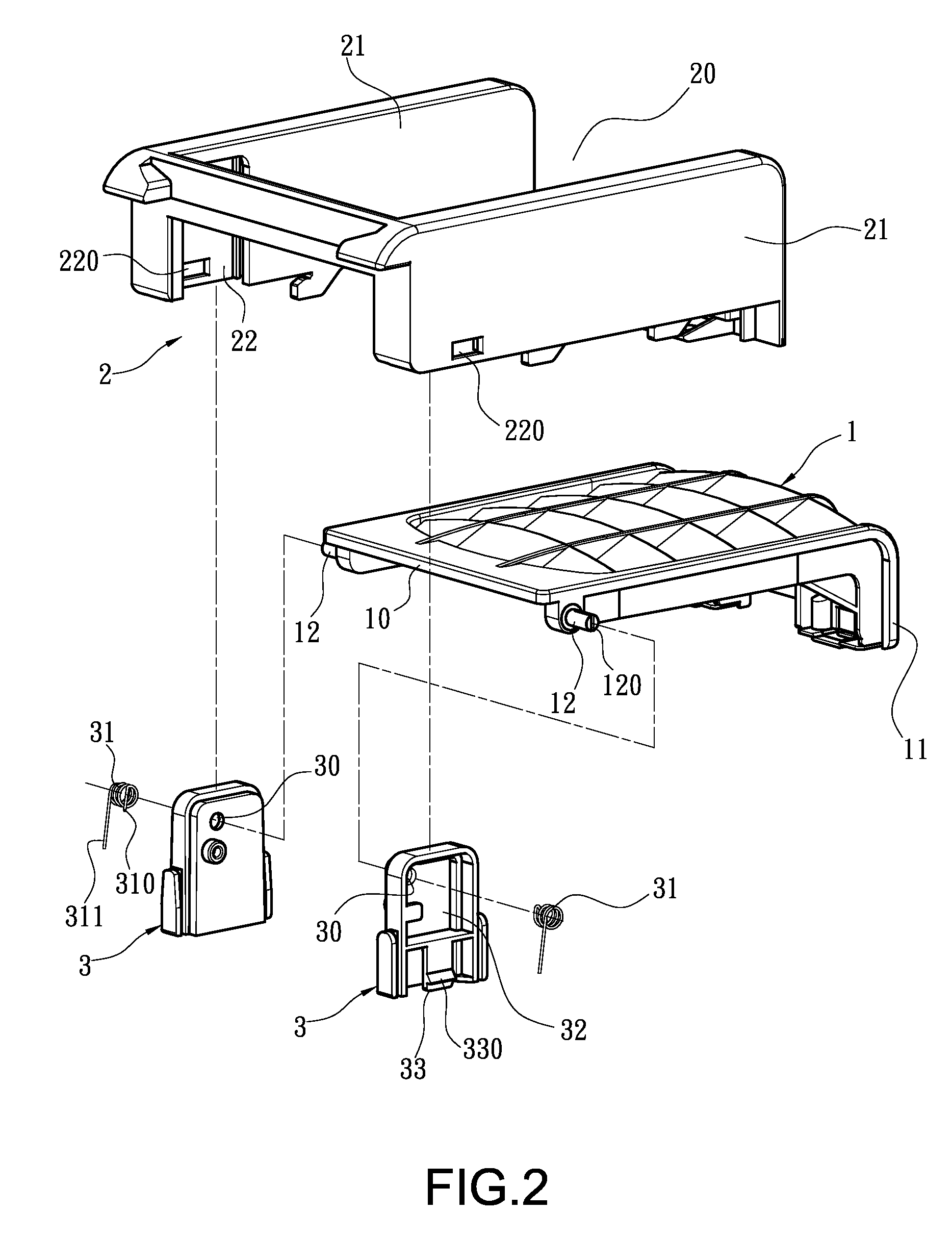

[0023]FIG. 2 is an exploded perspective view of the present invention. FIG. 3 is an assembled perspective view showing that the present invention is lifted, and FIG. 4 is an assembled perspective view showing that the present invention is covered. The present invention provides a structure of a liftable cover, which includes a cover 1 and a covering seat 2.

[0024]The cover 1 has a pivoting end 10. The pivoting end 10 is usually located at one end of the cover 1, and can be also located in the middle section of the cover 1. The other end of the cover 1 has a cover-lifting end 11. With the pivoting end 10 of the cover 1 being pivotally connected on the coverin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com