Intermittent and continuous motion high speed pouch form-fill-seal apparatus and method of manufacture

a form-fill-seal and pouch technology, applied in the direction of packaging, transportation and packaging, successive articles, etc., can solve the problems of limited line speed and resultant rate of finished pouch production, and achieve the effect of high-speed form-fill-seal pouch production and more cost-effective manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

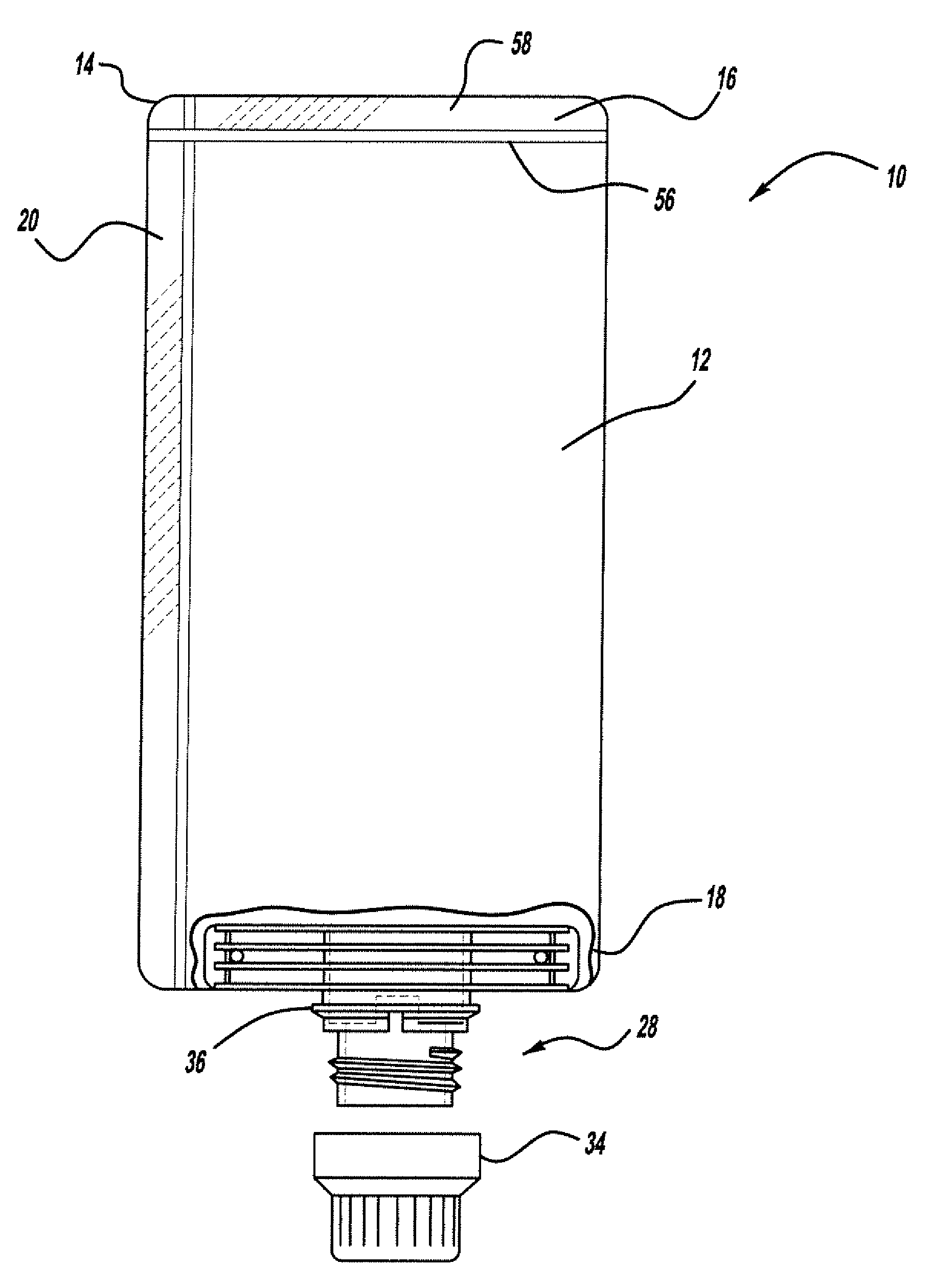

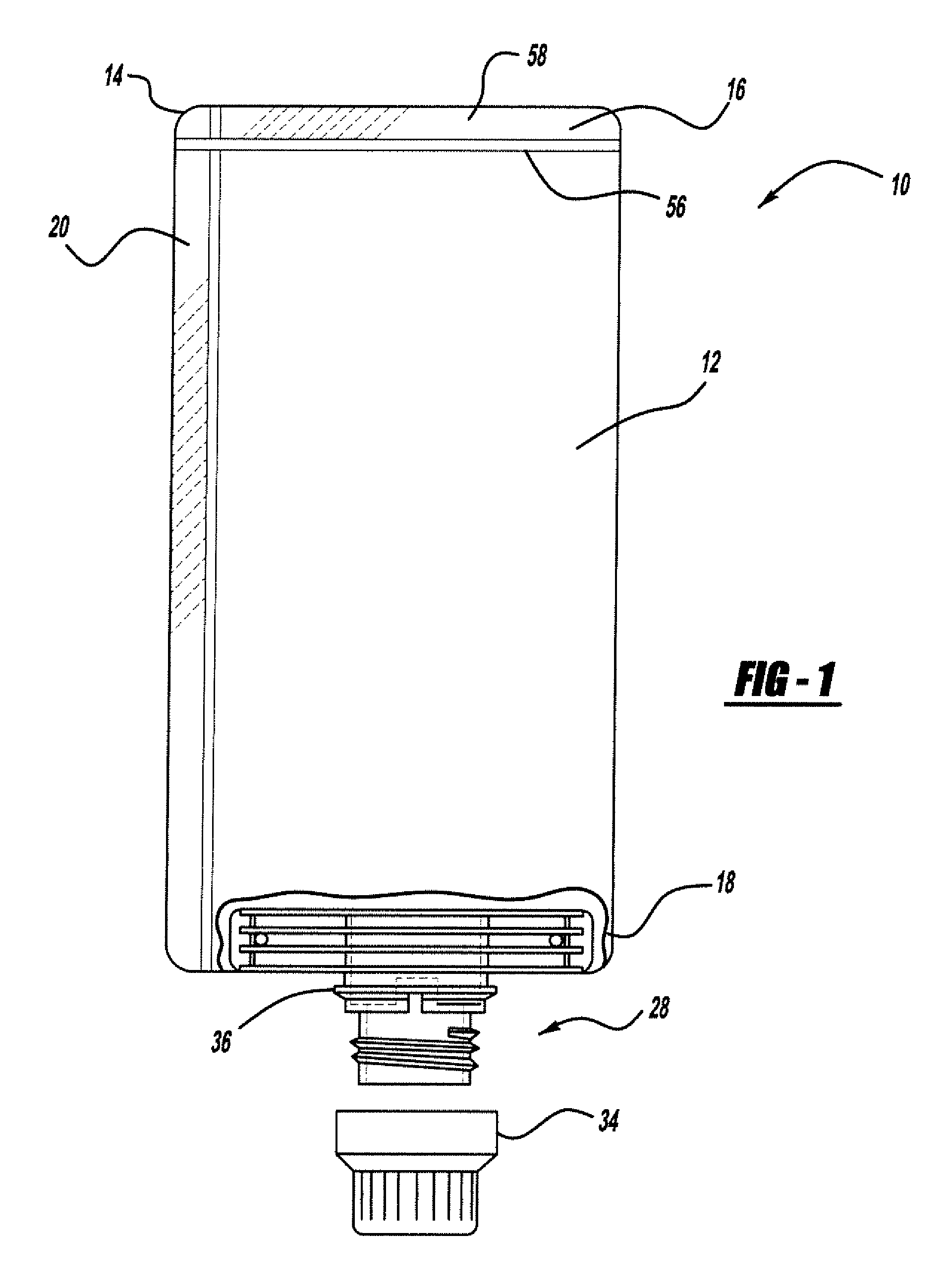

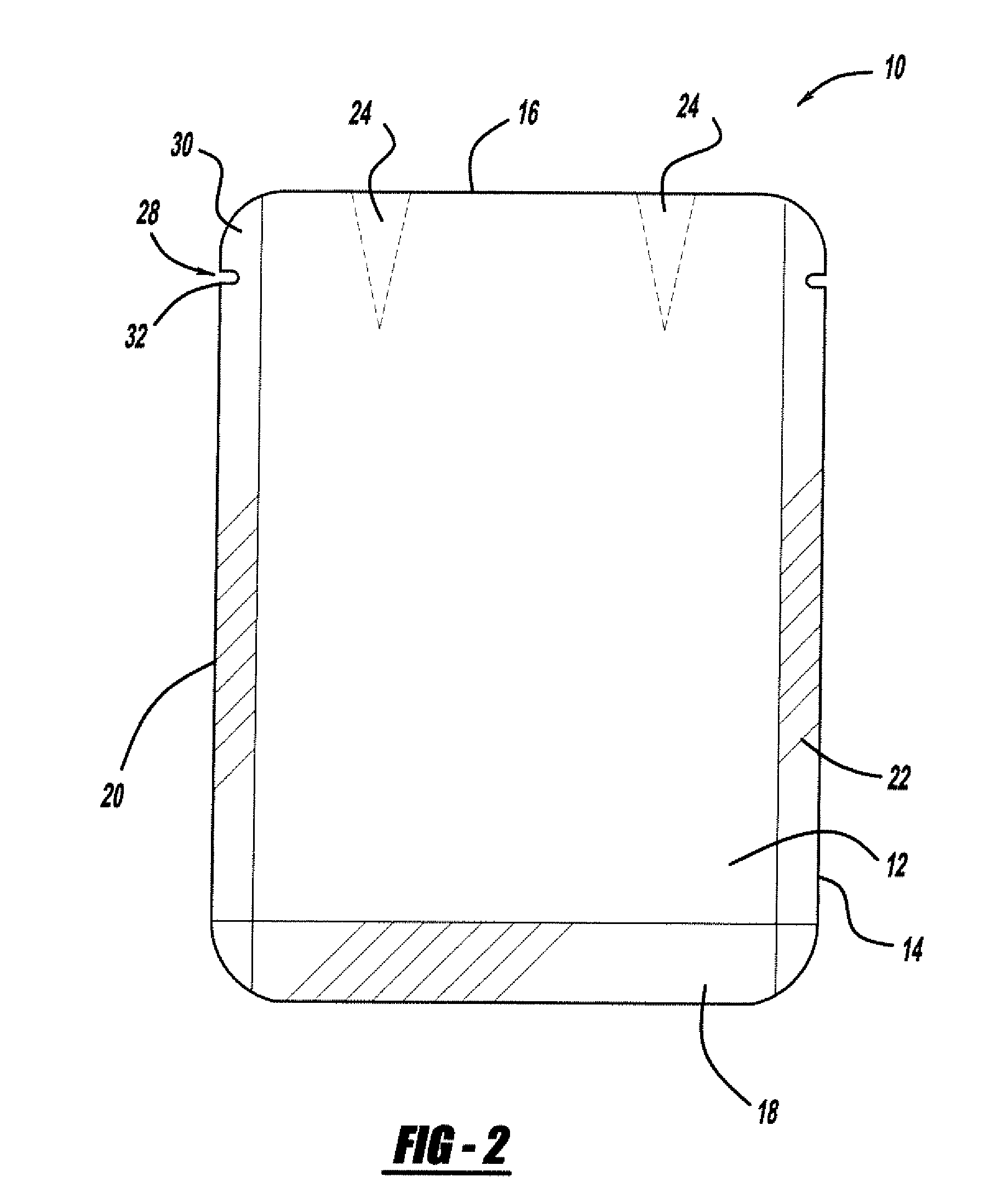

[0015]Referring to FIGS. 1-3, a flexible pouch 10 is illustrated. The pouch 10 is filled with a product 90 and scaled. The type of product is unlimited, and could have a solid or a liquid form. The product, may be a food item, or a non-food item. It is contemplated that the pouch may contain a single portion or multiple portions of the product. The filled pouch 10 may assume various shapes, such as cylindrical, cube, conical or the like. The type of product and usage of the pouch may influence the shape and features associated with the pouch. The pouch 10 may have one compartment for the product. Alternatively, the pouch 10 may include multiple discrete compartments. The compartments may be separated by a frangible seal to allow mixing of the contents of each compartment, or by a permanent seal to prevent mixing. An example of such a pouch is disclosed in commonly assigned U.S. patent application Ser. No. 11 / 367,613, which is incorporated herein by reference.

[0016]The flexible pouch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com