Reflection-type liquid crystal display device

a liquid crystal display and reflection-type technology, applied in the field of reflection-type liquid crystal display devices, can solve the problems of air bubbles infiltration, poor display quality, and difficulty in using this constitution except the small devices, and achieve the effect of suppressing the blurring of images and suppressing the decrease of contras

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

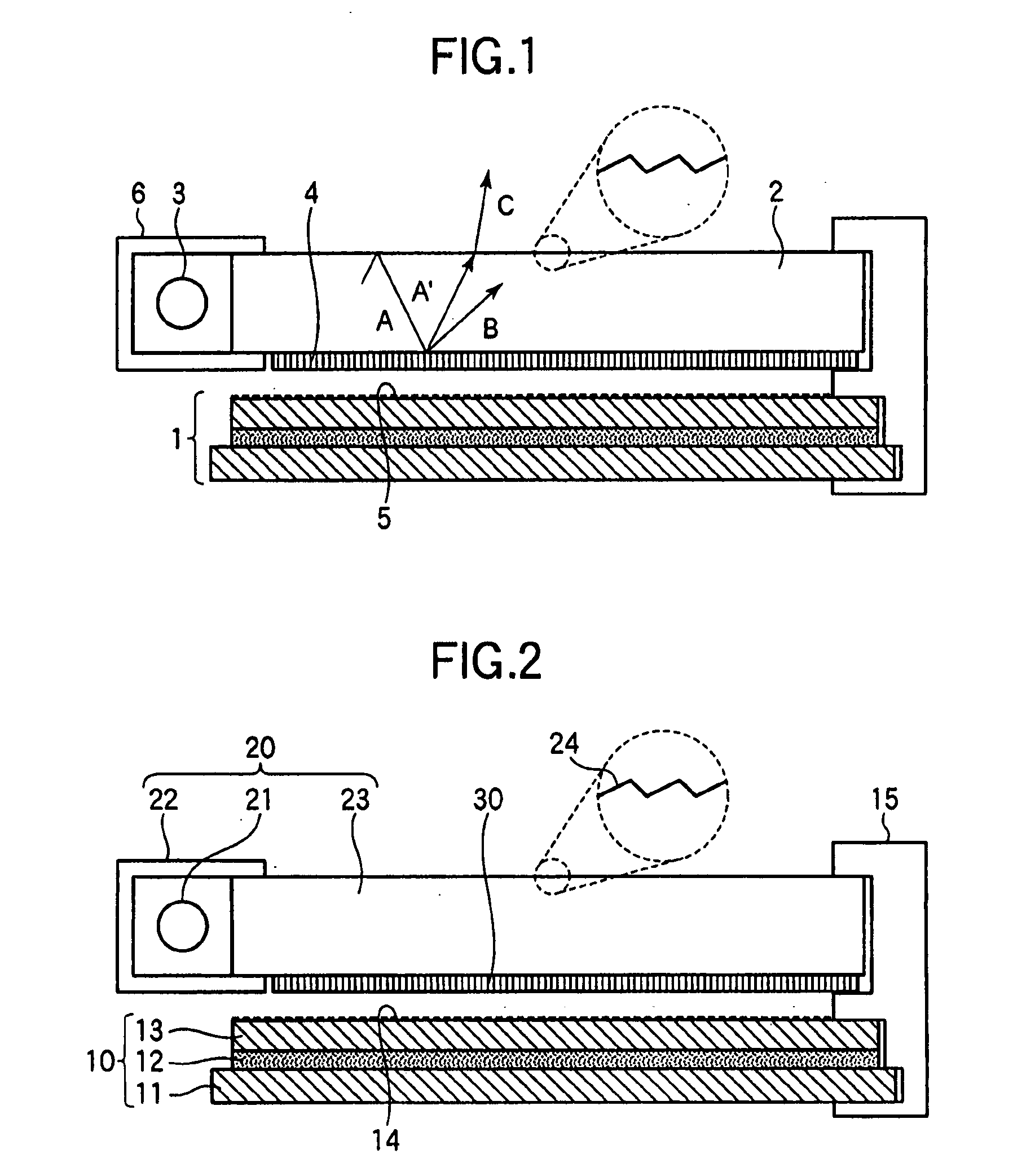

[0129] A reflection-type liquid crystal display device according to the invention will now be described with reference to FIG. 2.

[0130]FIG. 2 is a sectional view schematically illustrating the reflection-type liquid crystal display device according to the first embodiment of the present invention, which comprises a front light unit 20, and a liquid crystal display panel 10 constituted by a liquid crystal layer 12 held between a TFT substrate 11 having an alignment film provided on a glass substrate via a reflection electrode and a CF substrate 13 having an alignment film provided on a glass substrate via a transparent electrode. The front light unit 20 and the liquid crystal display panel 10 are firmly held by a frame 15 being opposed to each other maintaining a small gap of not larger than, for example, 1 mm.

[0131] The front light unit 20 includes a source 21 of light constituted by a cold cathode tube containing Ar or Ne gas and a trace amount of Hg, a reflector 22 for reflecting...

second embodiment

[0138] Next, the reflection-type liquid crystal display device according to the present invention will be described with reference to FIG. 3.

[0139]FIG. 3 is a sectional view schematically illustrating the reflection-type liquid crystal display device according to the second embodiment of the invention. The basic constitution is the same as that of the reflection-type liquid crystal display device of the above first embodiment. In the second embodiment, however, the surface of the liquid crystal display panel 10 is not roughened as designated at rough surface 14 but is, instead, provided with a light-diffusing film 31 which comprises a TAC film 32 and a sticking layer 33 containing a light-diffusing material.

[0140] The light-diffusing material, in this case, may be, for example, TiOx and its amount can be determined to maintain a balance in the effects for decreasing the blurring amount of image, moiré fringes and interference rainbow, and may be such that H≦50 [%].

[0141] In this c...

third embodiment

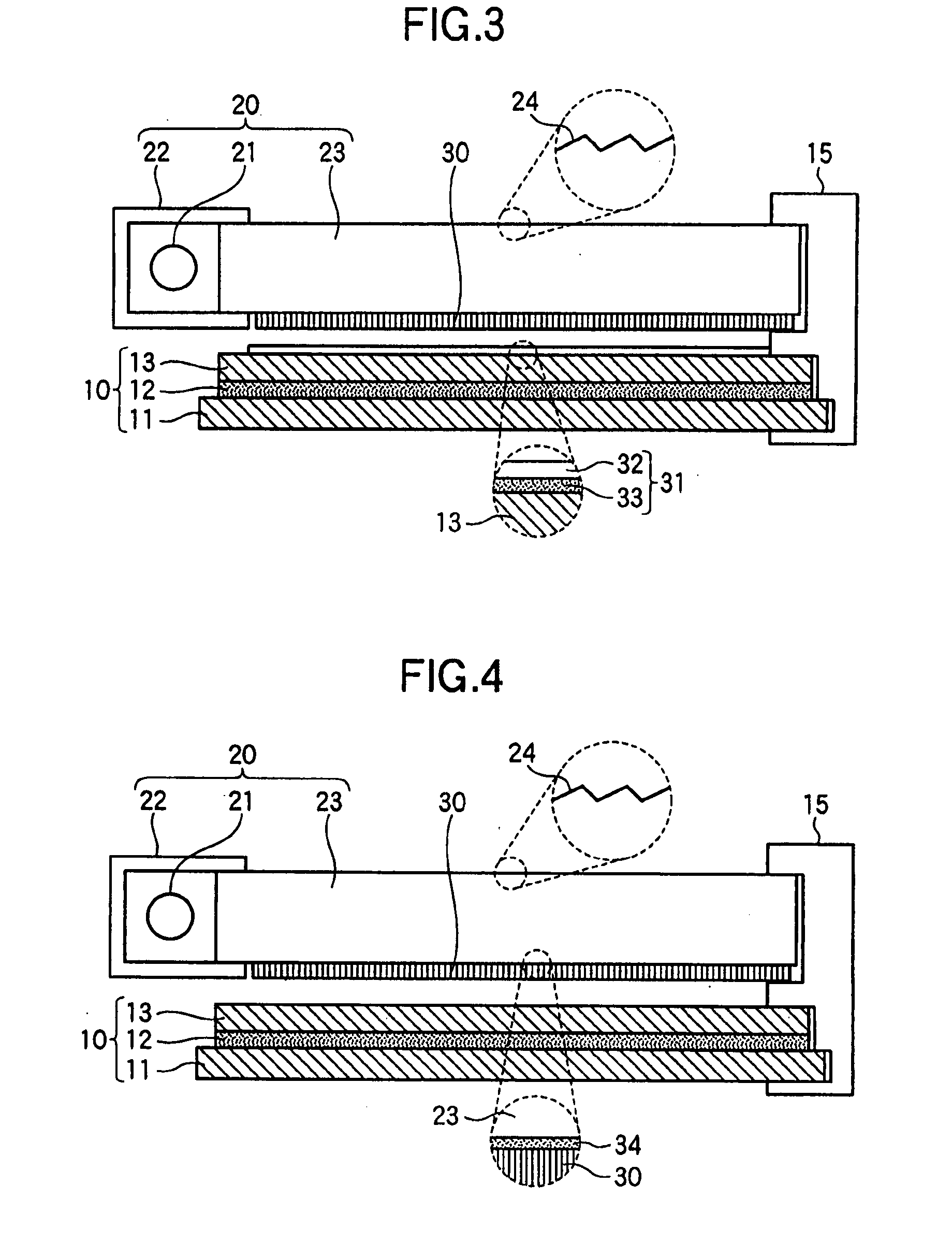

[0142] Next, the reflection-type liquid crystal display device according to the present invention will be described with reference to FIG. 4.

[0143]FIG. 4 is a sectional view schematically illustrating the reflection-type liquid crystal display device according to the third embodiment of the invention. The basic constitution is the same as that of the reflection-type liquid crystal display device of the above first embodiment. In the third embodiment, however, the surface of the liquid crystal display panel 10 is not roughened as designated at rough surface 14 and, besides, the polarizing element 30 is stuck to the light guide plate 23 by using a sticking layer 34 containing a light-diffusing material.

[0144] In the third embodiment, the light directed by the prism 24 toward the side of the liquid crystal display panel is diffused by the sticking layer 34 containing the light-diffusing material provided on the back surface of the light guide plate 23, and is converted in a direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com