Trick Dam

a circuitous motion and load technology, applied in water-power plants, mechanical equipment, machines/engines, etc., can solve the problems of limited scalability, limited efficiency, overly complicated and limited efficiency, etc., and achieve the effect of reducing the cost of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

: TRICK DAM

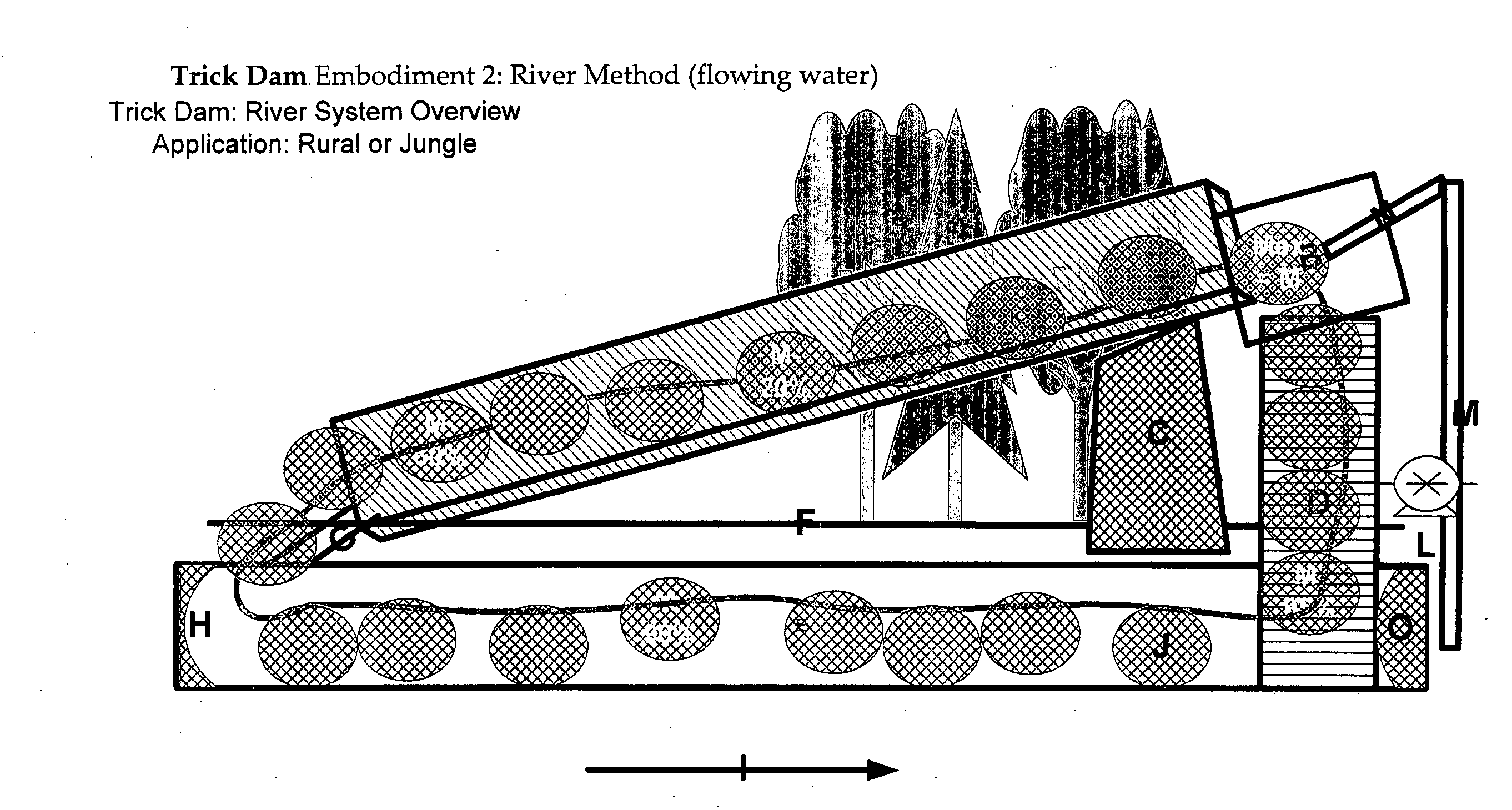

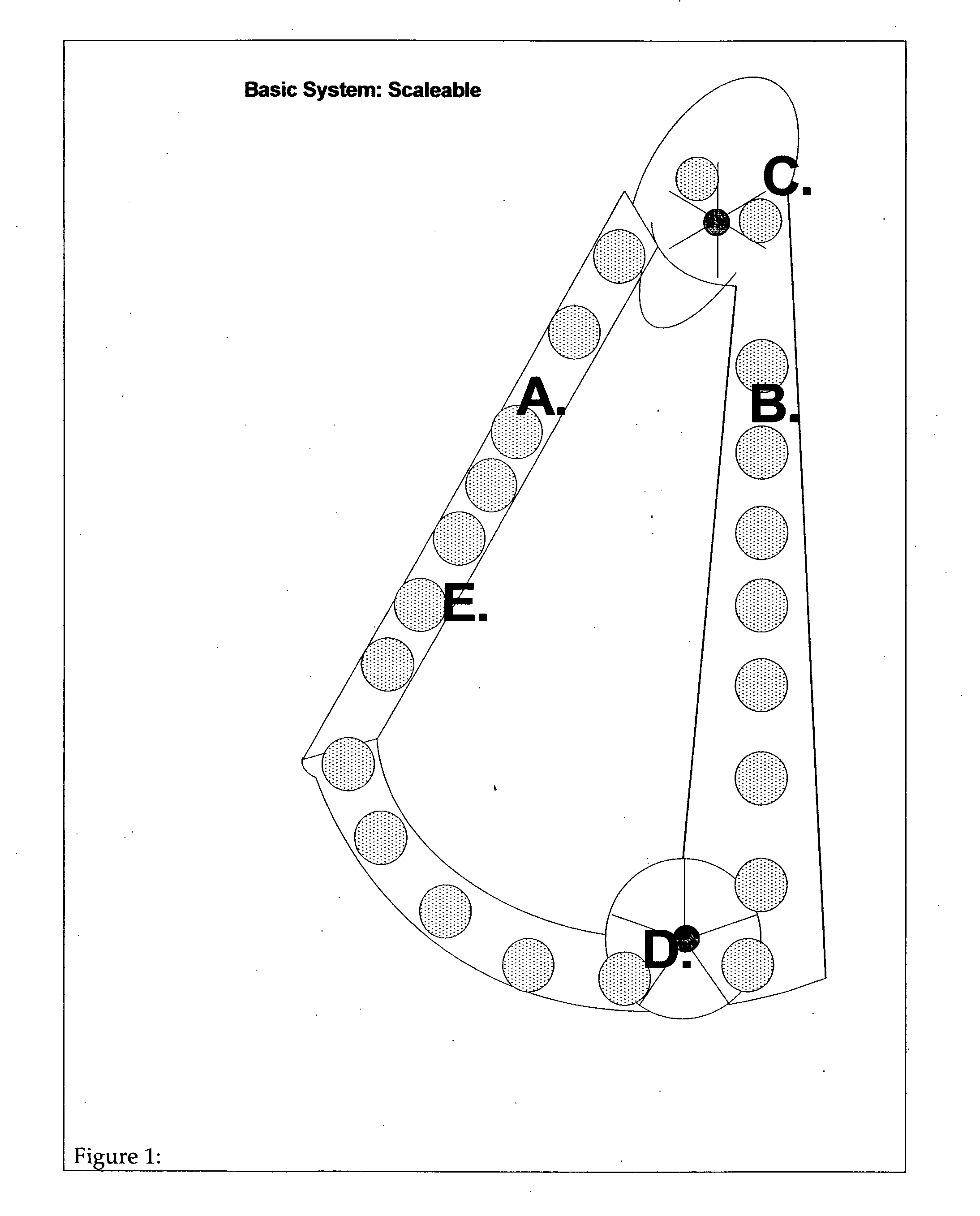

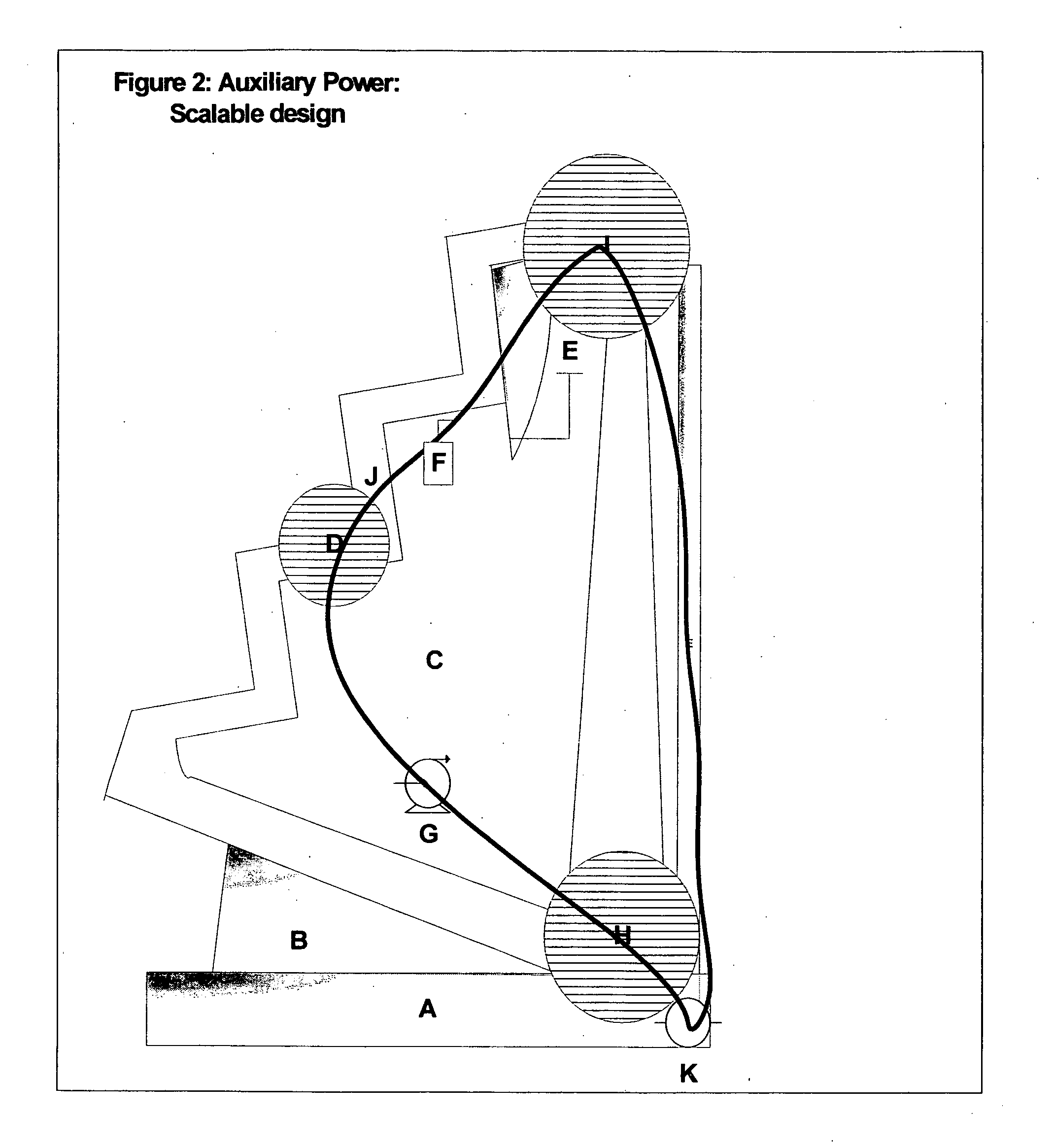

[0033]The Trick Dam is a simple yet powerfully elegant method of generating a continuous load generating cycle, with the least possible moving parts. The Trick Dam is comprised of three elements (FIG. 1: Basic System: Scaleable). These elements are ascent and descent channels, gateways that connect the channels, and a rotor system. I will describe the design steps, and considerations of a basic Trick Dam. It must be noted that the Trick Dam is independent of magnetic induction, although magnetic induction will be discussed here as a pedagogic device.

[0034]The Trick Dam can be primarily constructed from materials suited to a particular application. Plastics, metals, wood, and even paper are useful for channel construction. The channel construction materials must withstand the movement, and impacts of the rotors, while accomplishing the primary goals of the structure. The primary goals in all cases are to present an optimal path for the flow of the rotors through the system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com