Gas bag finished with a flame retardant

a technology of flame retardant and gas bag, which is applied in the direction of pedestrian/occupant safety arrangement, thin material handling, vehicle safety arrangment, etc., can solve the problems of increased layer thickness and also a greater mass of gas bag fabric, and the use of special high-temperature resistant plastics is not justifiable economically, so as to achieve the effect of increasing heat resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

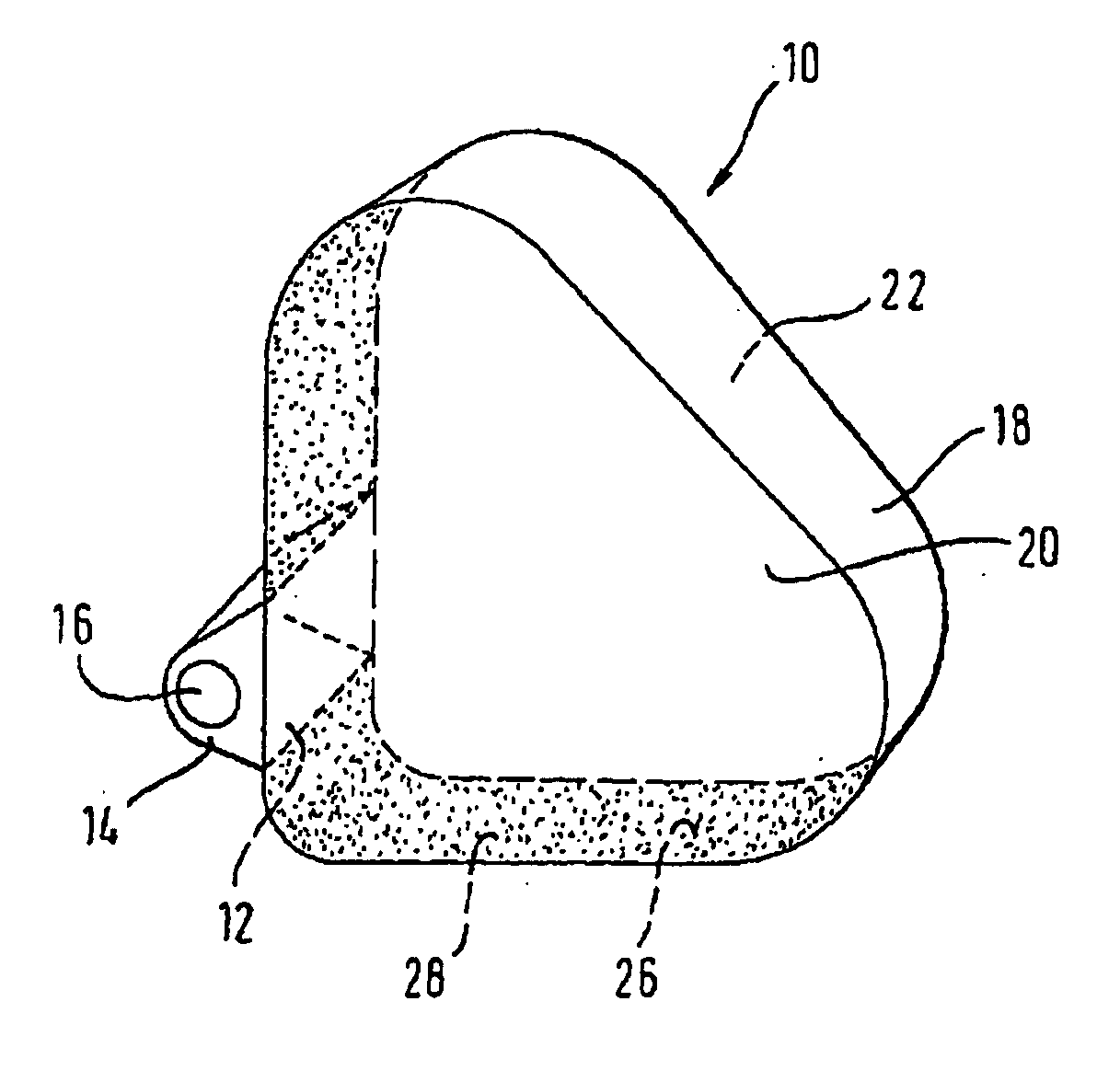

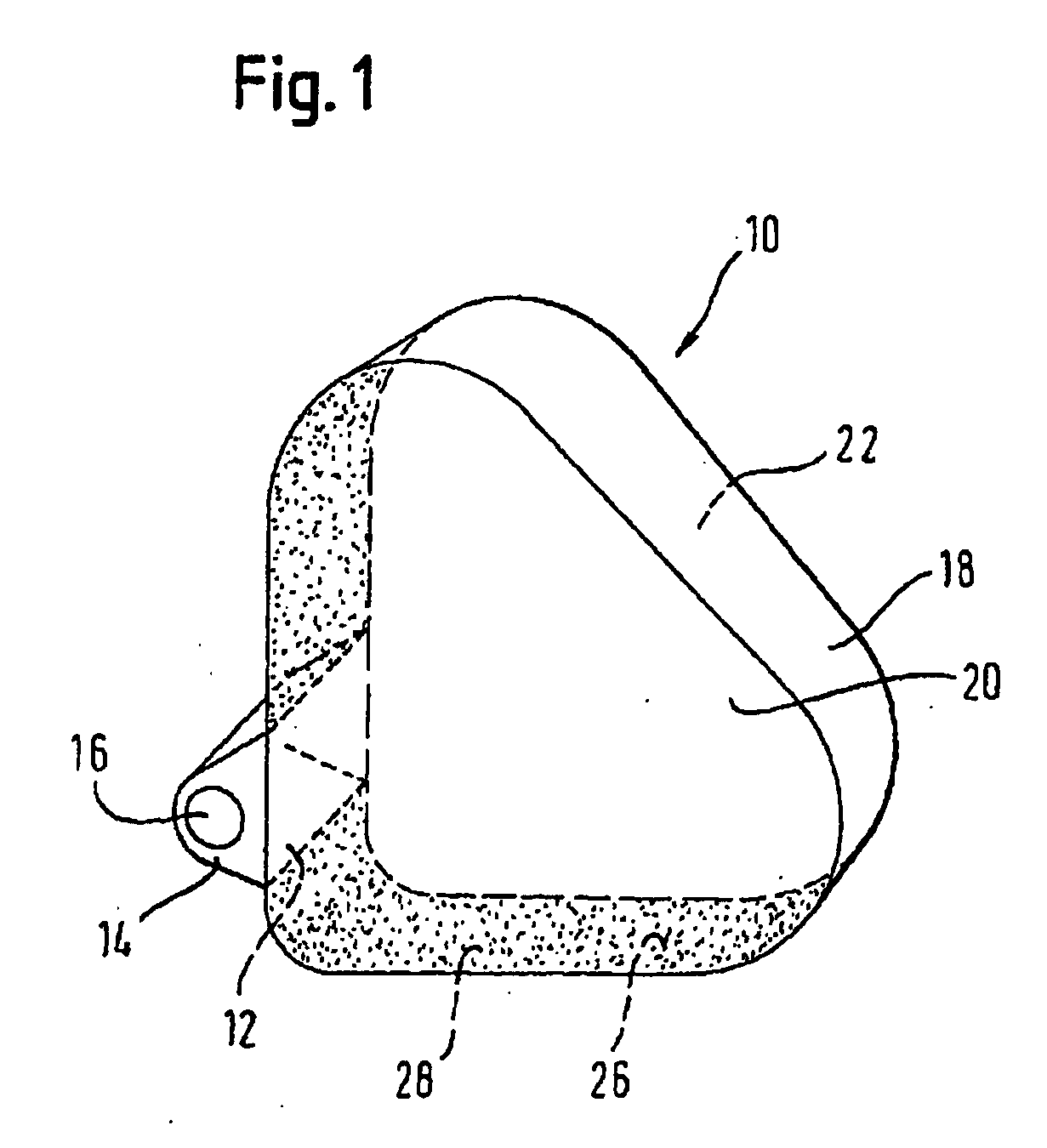

[0021] The gas bag 10, shown in FIG. 1 in the inflated condition, of a vehicle occupant restraint system is connected by its orifice 12 to the housing 14 of a gas generator 16. The gas bag 10 shown here consists of a middle wall part 18 and two lateral wall parts 20, 22, which are each constituted by a fabric. Other cuts may be used as well.

[0022] The wall parts 18, 20, 22 each have two opposite surfaces, one on the outside of the gas bag and one on the inside of the gas bag, which faces the gas volume flowing out from the gas generator 16 and into the gas bag 10. For a simplified representation, only the surface 26 of the wall part 18 facing the inflowing gas volume is shown in FIG. 1. In the embodiment shown here, the surface 26 on the inside of the gas bag is finished with a coating 28 to increase the heat resistance. The coating 28 is preferably a silicone rubber which contains the intumescent material in a proportion of approximately 10 percent by weight. The intumescent mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com