Self-gripping rack for cantilevered tanks

a self-gripping, cantilever technology, applied in the direction of loading/unloading vehicle arrangment, transportation items, load accommodation, etc., can solve the problems of increased fuel consumption, increased costs, and difficulty in transporting a large number of tanks, and achieves easy installation and assembly. , the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

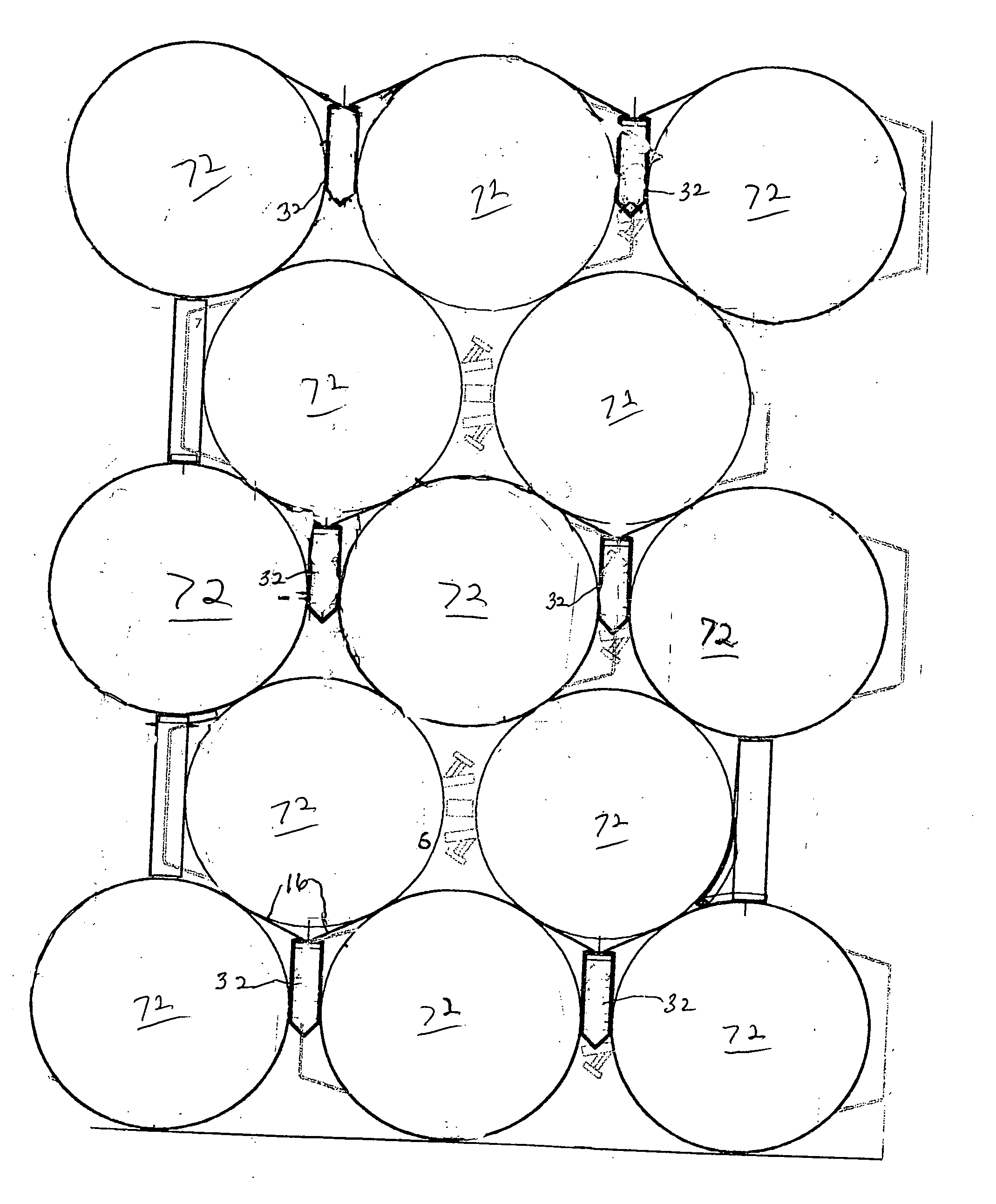

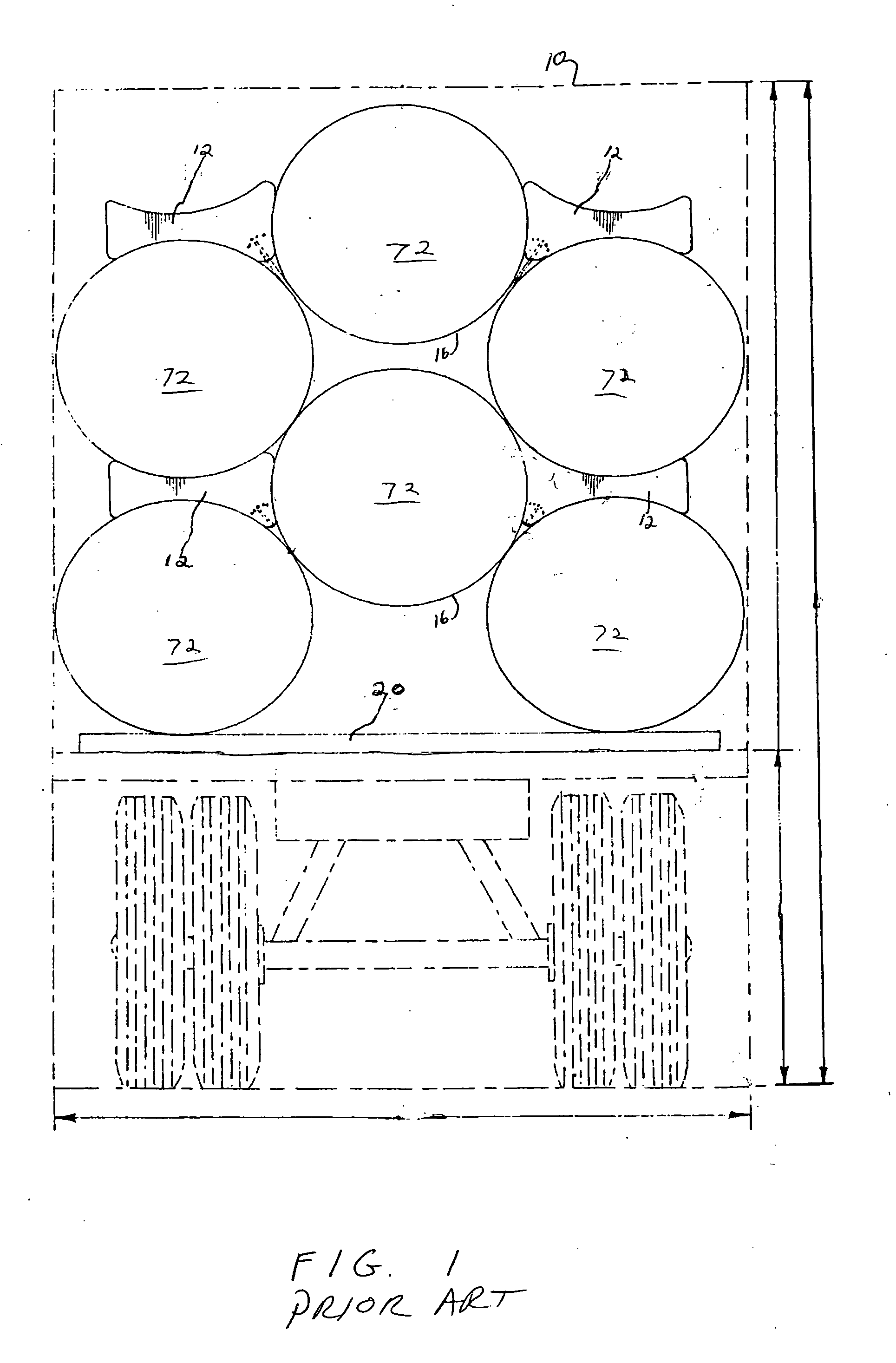

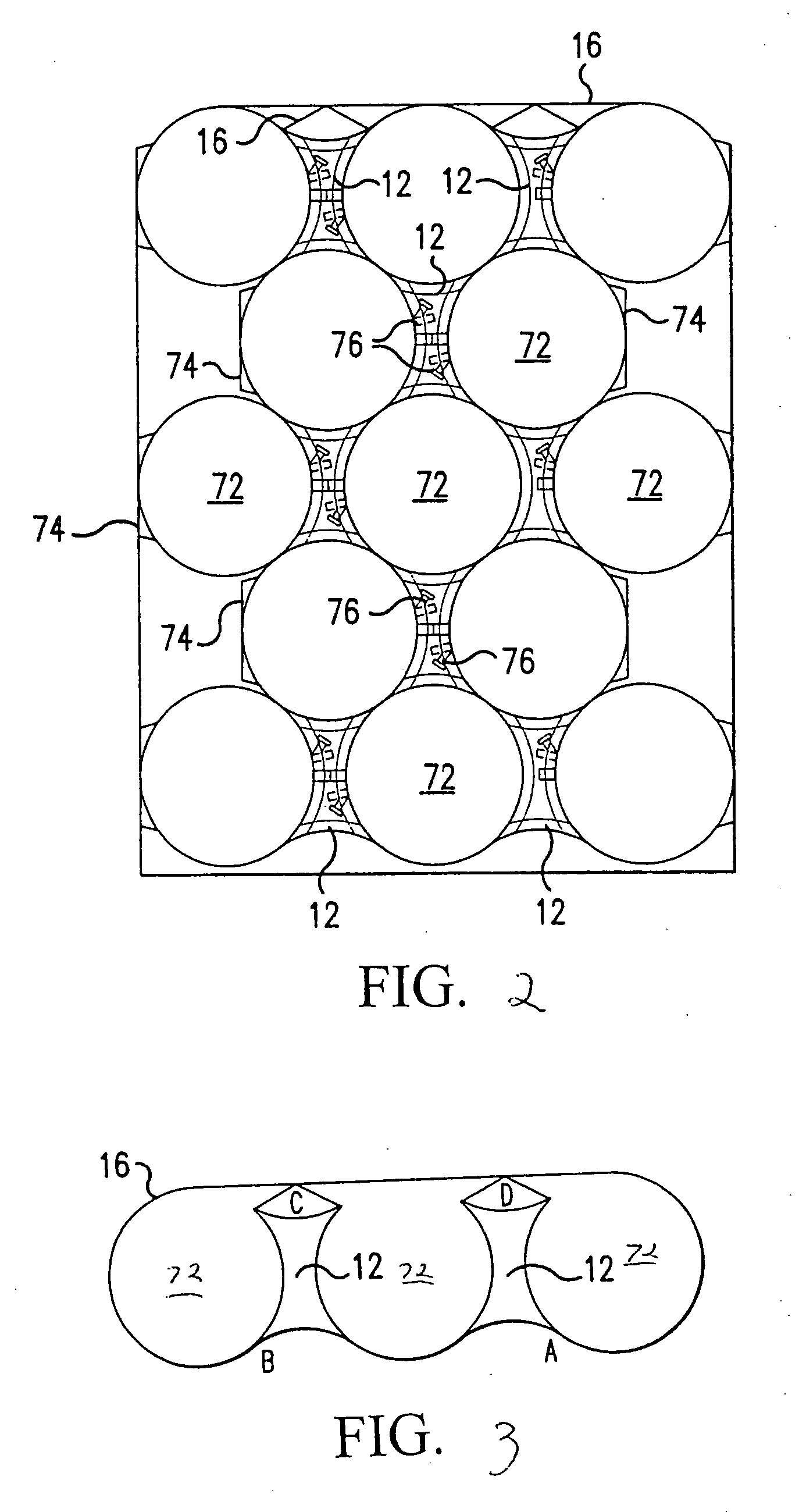

[0033]Referring to the drawings, wherein like reference numerals designate identical or corresponding parts throughout the several views, and more particularly to FIG. 2 thereof, wherein an arrangement of articles such as propane tanks 72 are shown being held by holders 12. The holders 12 are connected using straps 16 which support the intervening tanks 72 and are also used for connecting together the top row of tanks in a different configuration. As shown in FIG. 3, three tanks are connected together through strapping 16 with holders 12 space there between.

[0034]The strap starts at point A and extends along the bottom side of the right hand rack through two cutouts. It then proceeds under the center tank and through cutouts on the bottom edge of the left hand rack. The strap then extends under and around the left hand tank and extends over the top of the center tank and right hand tank and then down and under the right hand tank to return to point A. At this point, the strap extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com