Top drive interlock

a top drive and interlocking technology, applied in the direction of electric controllers, surveyors, borehole/well accessories, etc., can solve the problems of increasing the possibility of downtime, increasing the likelihood of thread damage, and consuming the process of connecting and disconnecting the casing using a thread connection, so as to improve the operation of the top drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

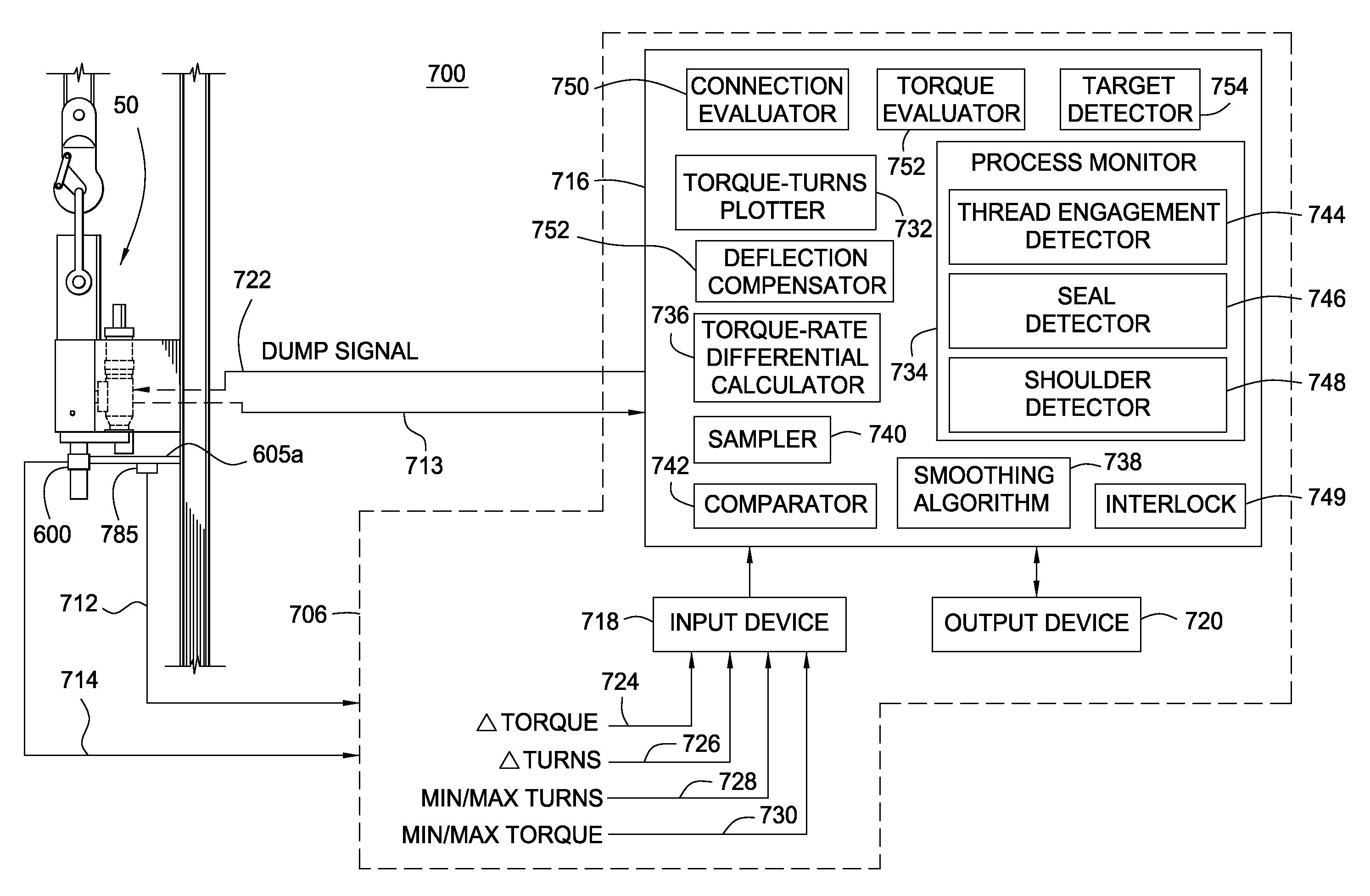

Embodiment Construction

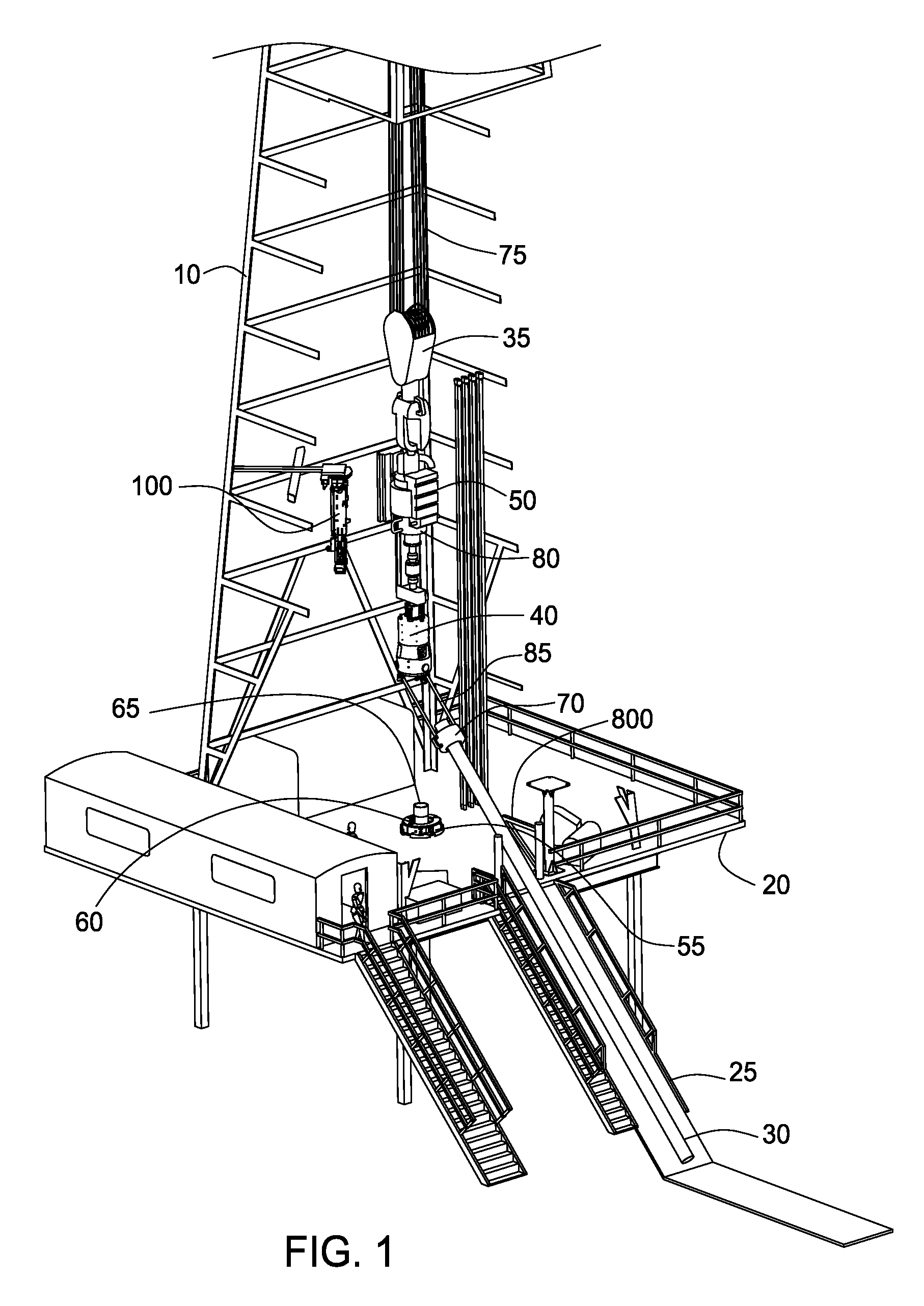

[0021]FIG. 1 shows a drilling rig 10 applicable to drilling with casing operations or a wellbore operation that involves picking up / laying down tubulars. The drilling rig 10 is located above a formation at a surface of a well. The drilling rig 10 includes a rig floor 20 and a v-door 800. The rig floor 20 has a hole 55 therethrough, the center of which is termed the well center. A spider 60 is disposed around or within the hole 55 to grippingly engage the casings 30, 65 at various stages of the drilling operation. As used herein, each casing 30, 65 may include a single casing or a casing string having more than one casing. Furthermore, aspects of the present invention are equally applicable to other types of wellbore tubulars, such as drill pipe.

[0022]The drilling rig 10 includes a traveling block 35 suspended by cables 75 above the rig floor 20. The traveling block 35 holds the top drive 50 above the rig floor 20 and may be caused to move the top drive 50 longitudinally. The top dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com