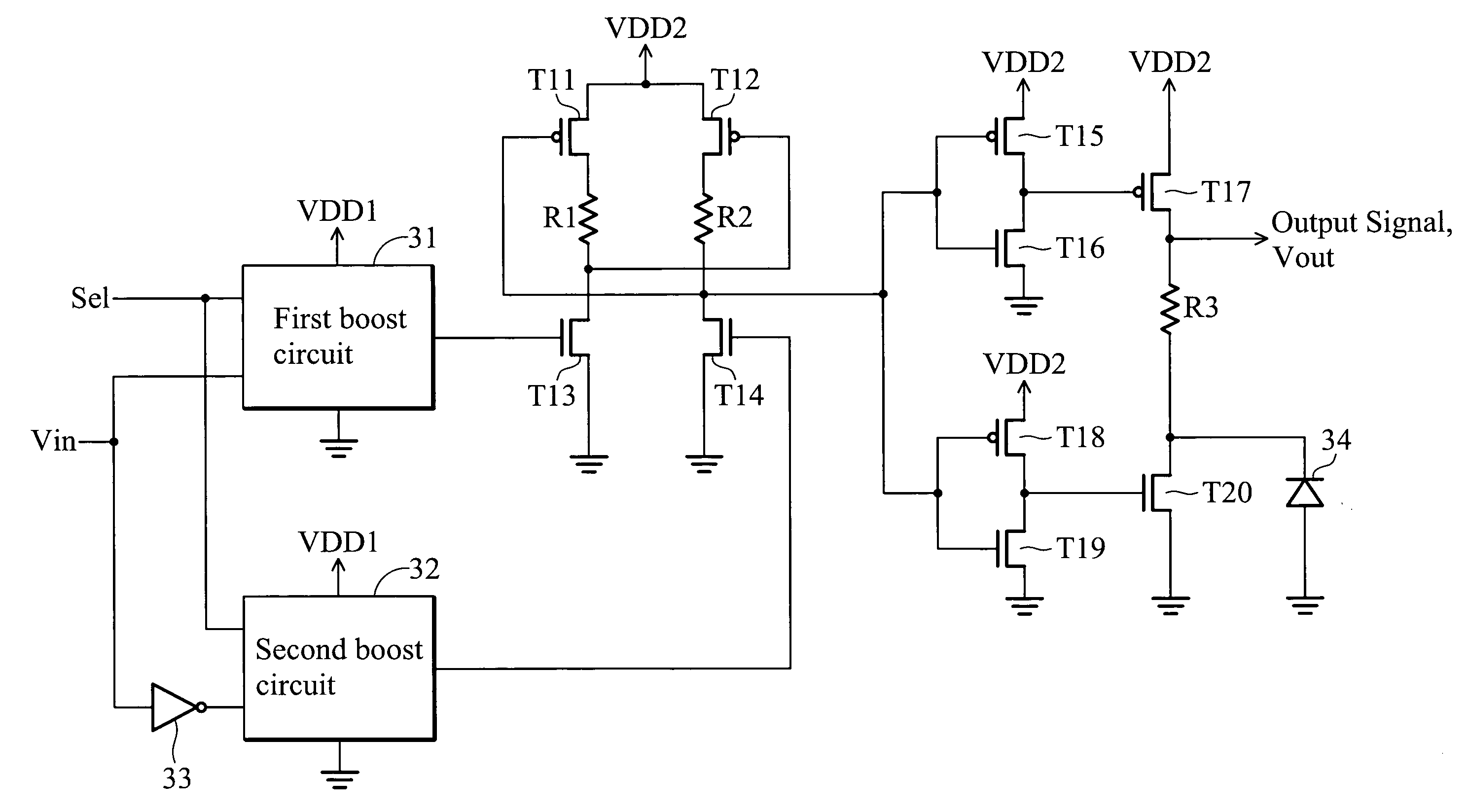

Boost circuit and level shifter

a level shifter and boost circuit technology, applied in logic circuits, pulse automatic control, instruments, etc., can solve problems such as the level shifter may not be properly driven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]The following description is of the best-contemplated mode of carrying out the invention. This description is made for the purpose of illustrating the general principles of the invention and should not be taken in a limiting sense. The scope of the invention is best determined by reference to the appended claims.

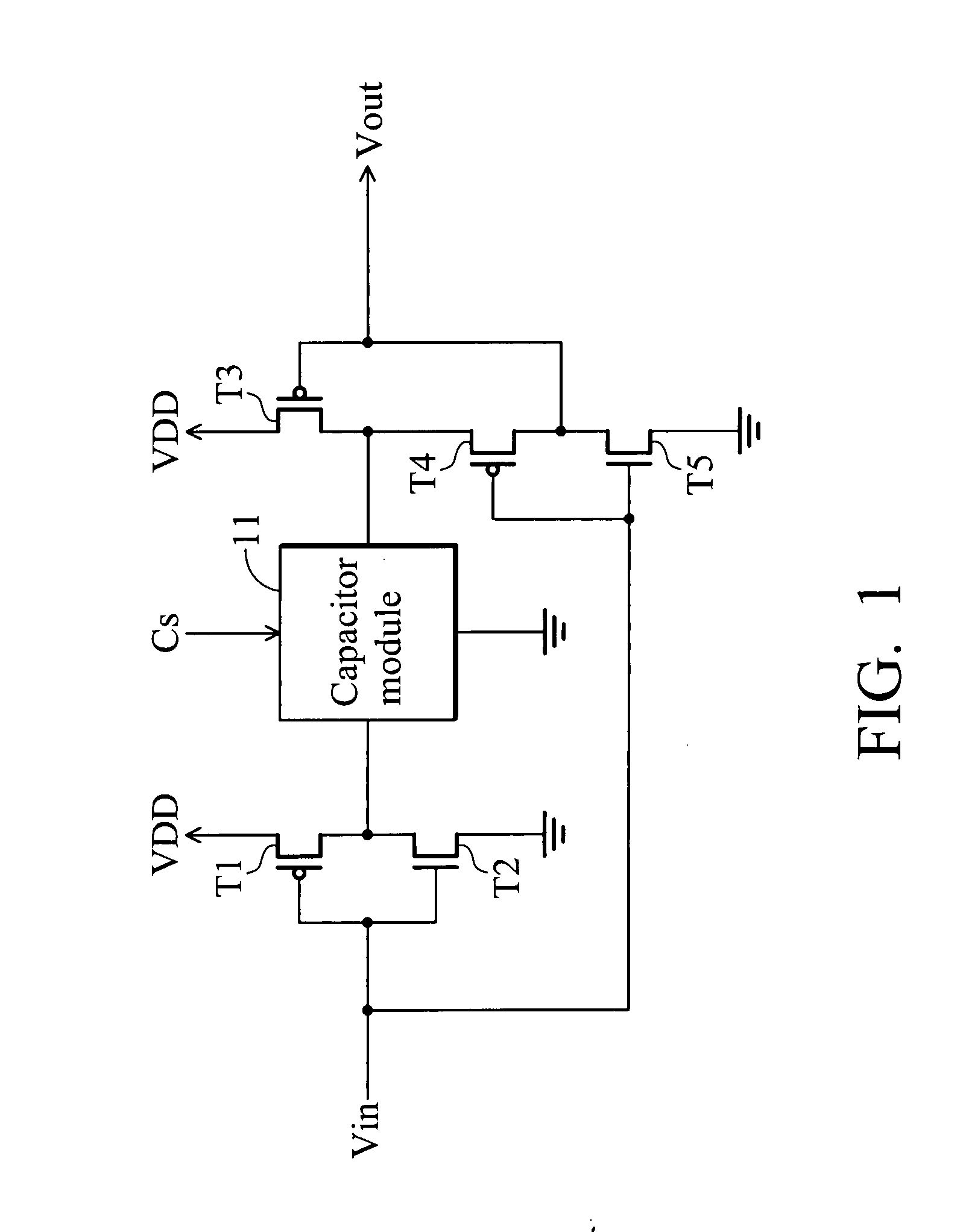

[0013]FIG. 1 is a circuit diagram of an embodiment of a boost circuit of the invention. The transistor T1 has a first source, a first gate and a first drain, wherein the first source is coupled to a voltage source VDD. The second transistor T2 has a second source, a second gate and a second drain, wherein the second drain is coupled to the first drain, the second source is grounded, and the second gate is coupled to the first gate to receive an input signal Vin. The capacitor module 11 has a first terminal and a second terminal, and is controlled by a control signal Cs to change a capacitance of the capacitor module for changing the discharge time of the capacitor modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com