Method of Using a Bullet Proof Vest

a technology of bulletproof vest and bulletproof shell, which is applied in the field of bulletproof vest, can solve the problems of increasing the risk of injury to the wearer of the bulletproof vest, heavy weight and uncomfortable use of such vests, and increasing the risk of bulletproof vest wear, so as to increase the volume of the enclosure, increase the pressure inside the airtight enclosure, and ensure the safe reception of bullets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

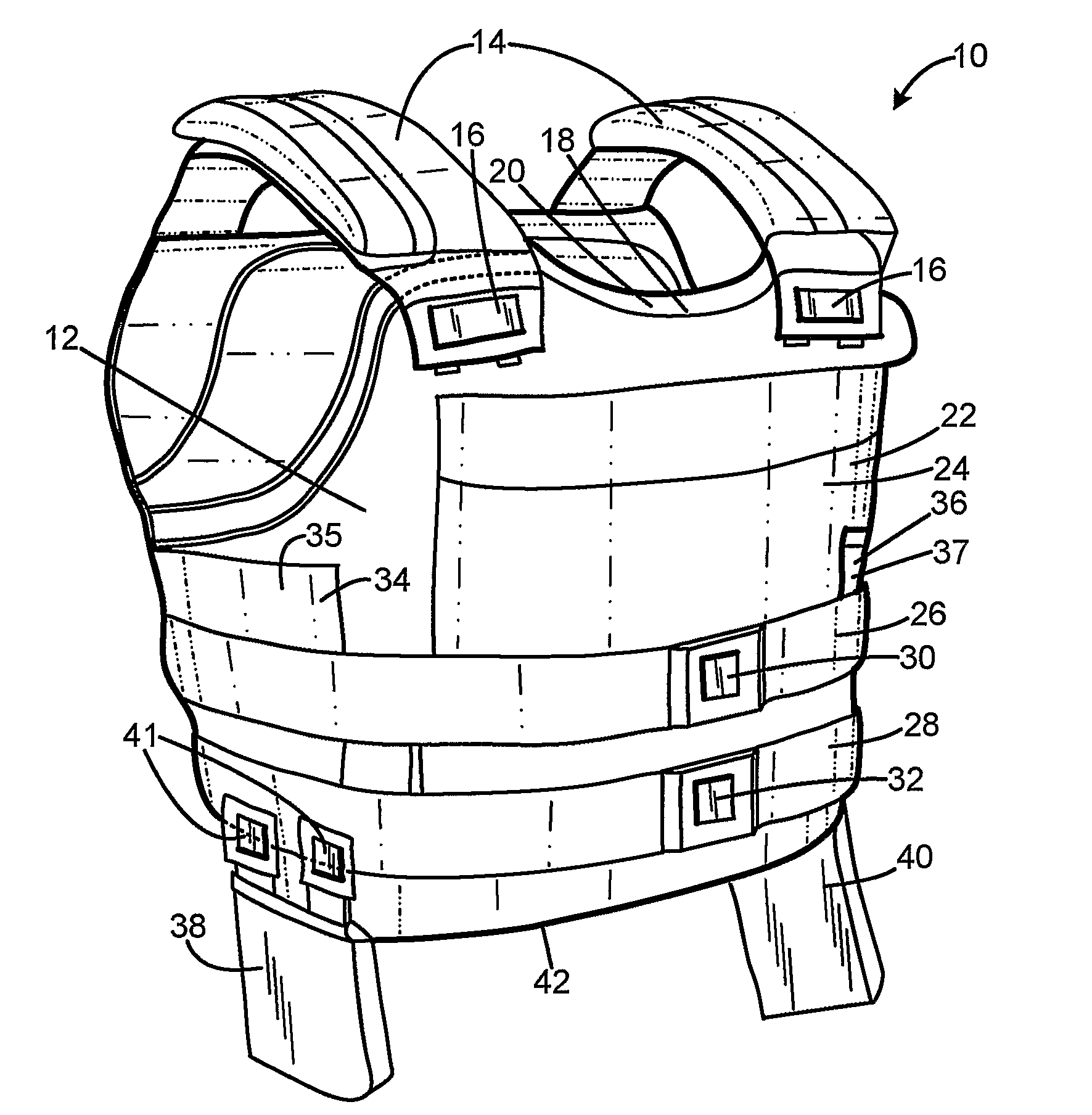

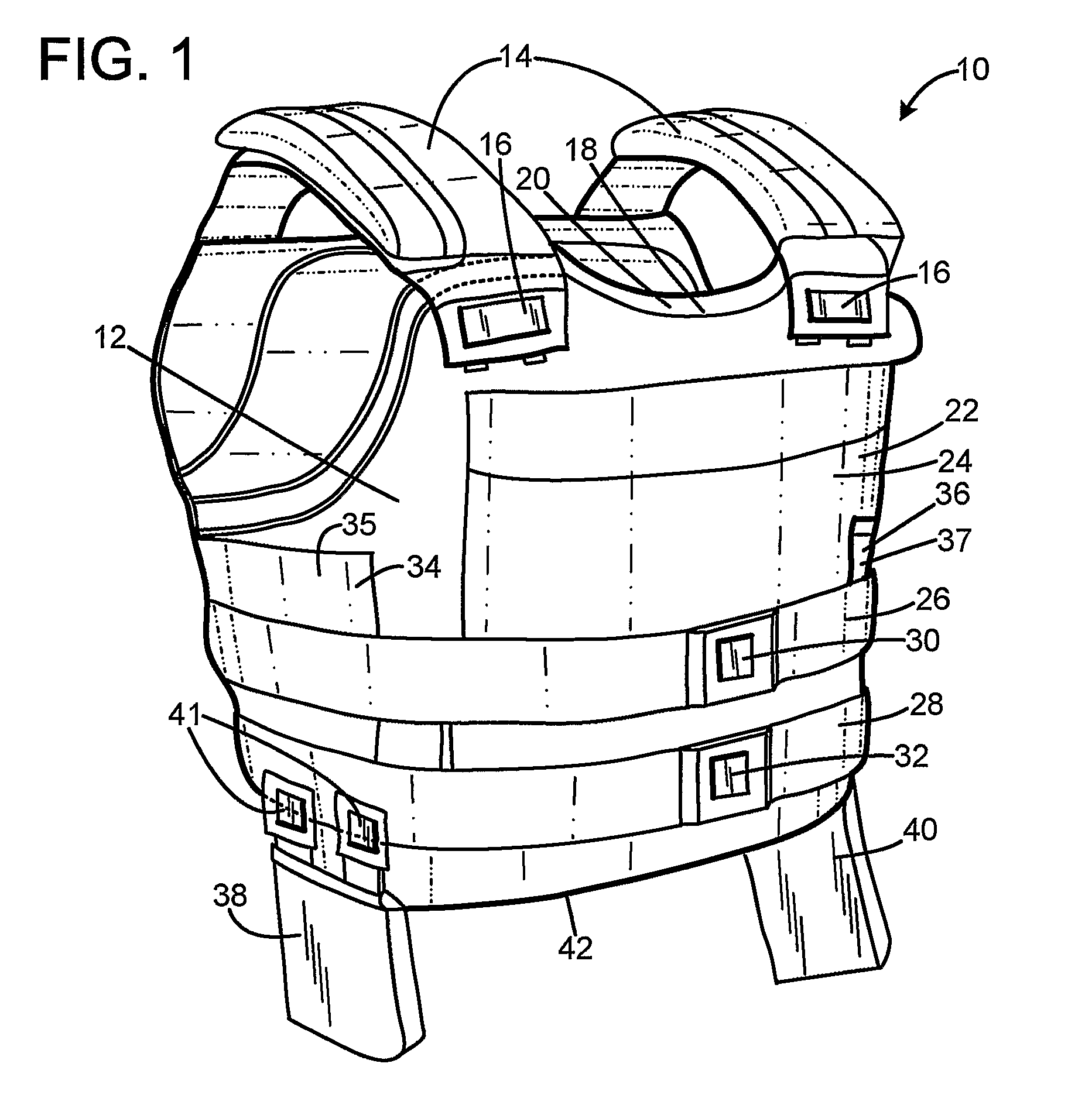

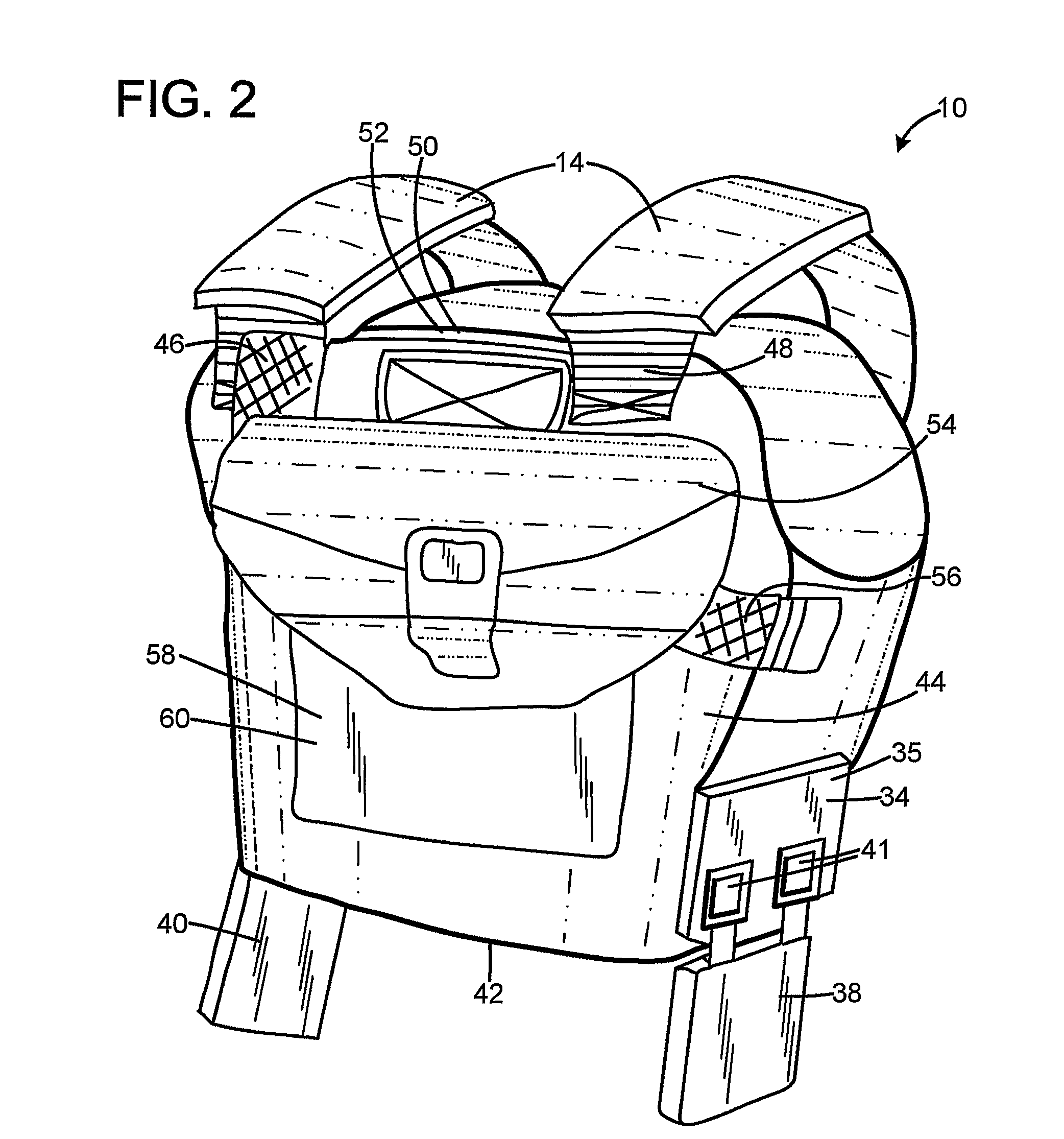

[0008]FIGS. 1-2 show a bullet proof vest 10 of the present invention that has a front body armor section 12 with shoulder straps 14 that have snap fasteners 16 for easy take off and fastening of the vest 10. The front section 12 has an openable inside pocket 18 defined therein that extends across the entire front section 12. The pocket 18 has an armor plate 20 disposed therein to provide bullet protection for the entire front page of the body of the wearer. The section 12 has an openable outside pocket 22 defined therein for holding an additional armor plate 24.

[0009]Straps 26, 28 enclose the vest 10. The straps 26, 28 have snap fasteners 30, 32 for easy take-on and take-off of the vest. Extra side plates 34, 36 may be disposed at the lower end of the vest in pockets 35, 37 to provide extra protection for the kidney and other vital organs of the wearer. Snap-on double side plates 38, 40 may extend downwardly or hang from a lower edge 42 of the vest to protect the hip area. The plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com