Scroll type compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The following description is of the best-contemplated mode of carrying out the invention. This description is made for the purpose of illustrating the general principles of the invention and should not be taken in a limiting sense. The scope of the invention is best determined by reference to the appended claims.

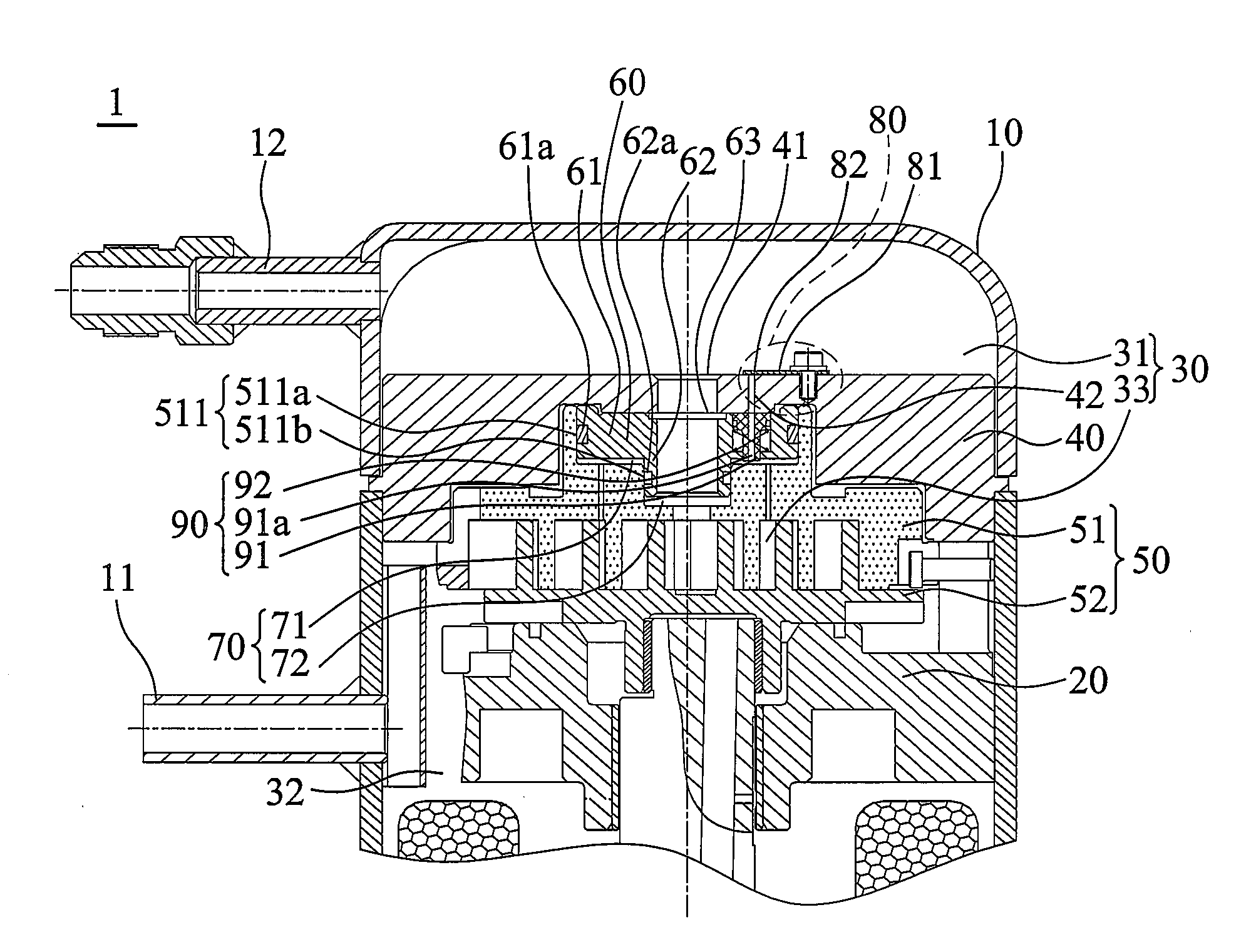

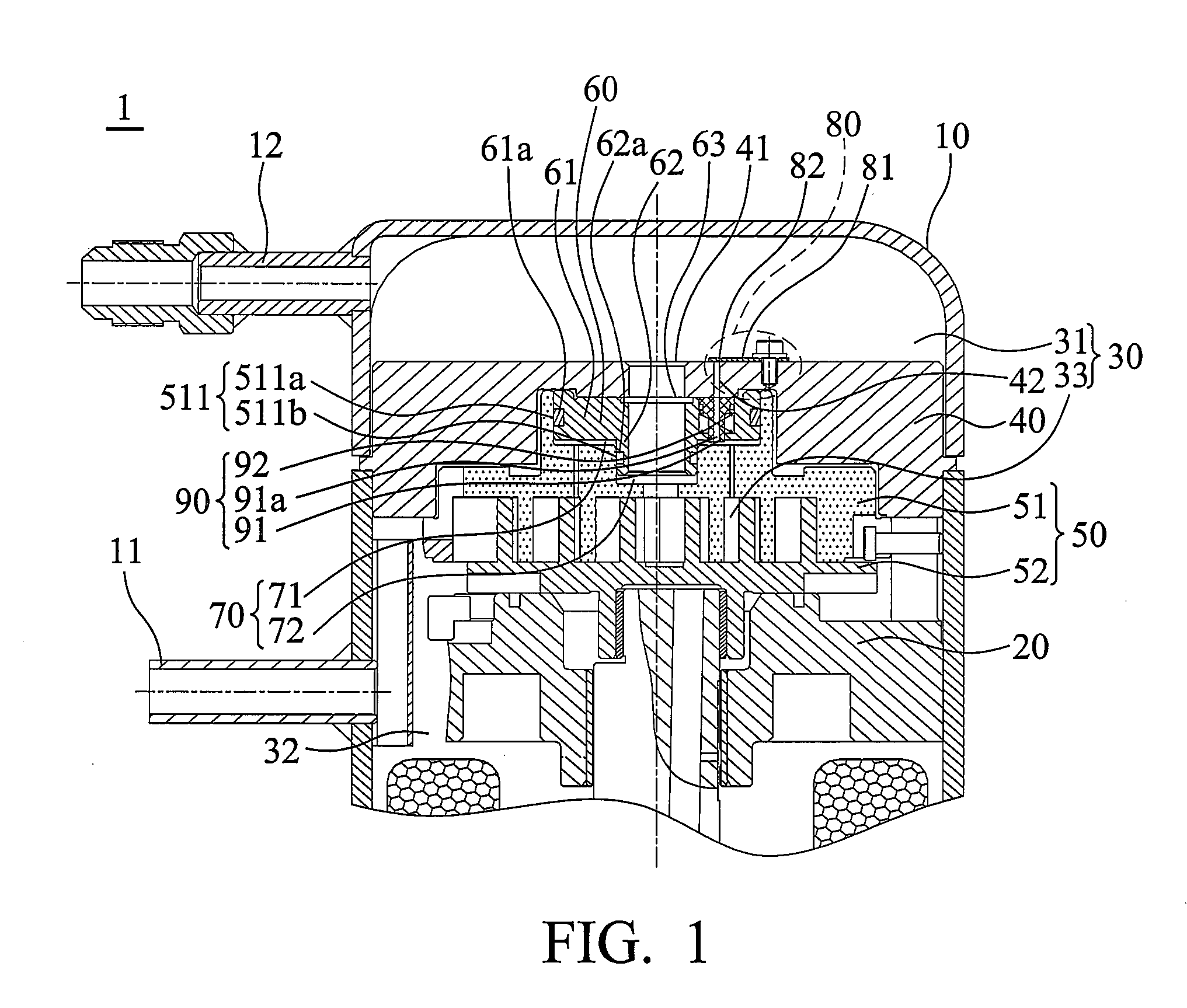

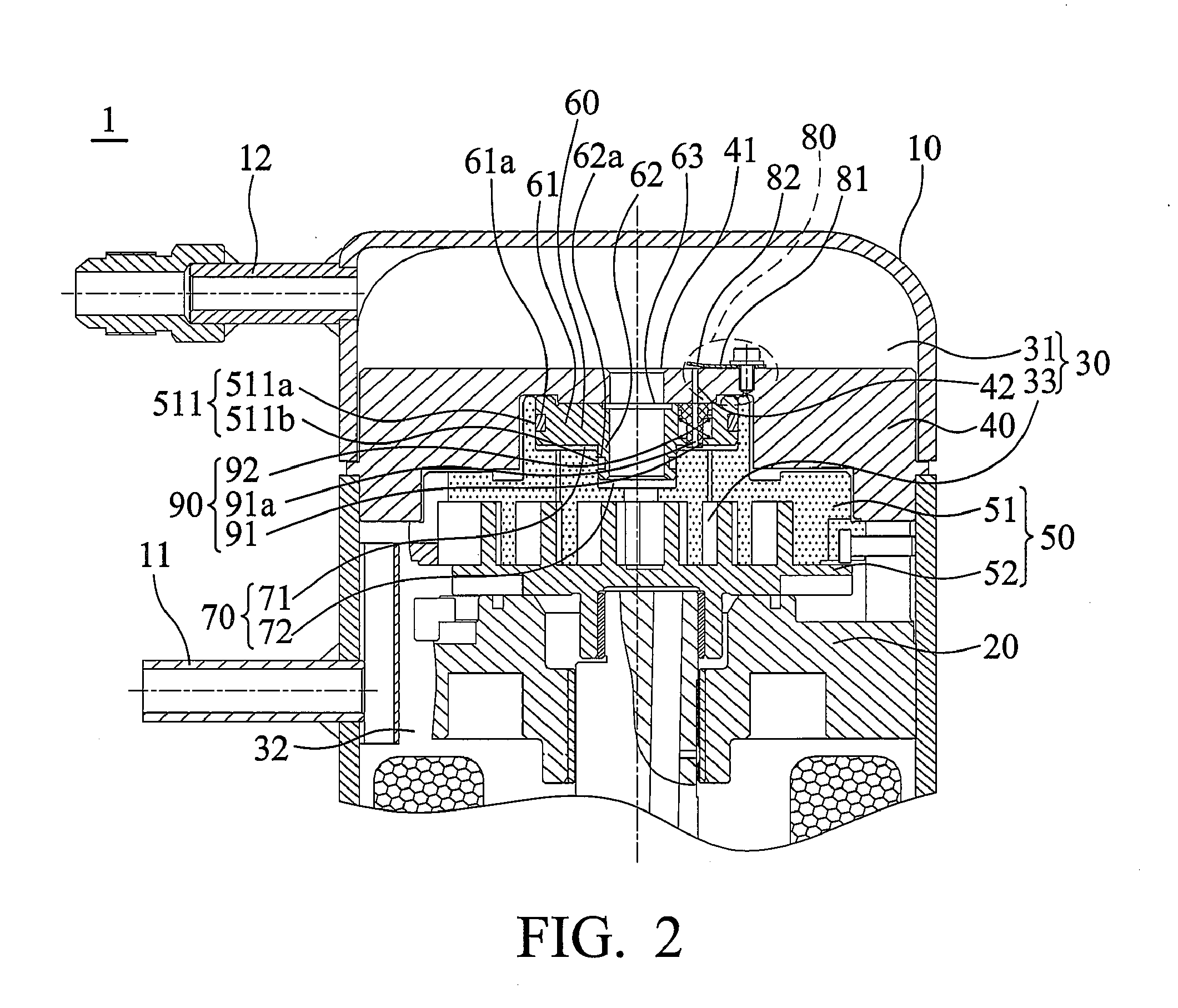

[0028]Referring to FIG. 1, the scroll type compressor 1 comprises a housing 10, a frame 20, a compartment 30, a separator 40, a scroll pairs 50, a slider 60, two compartments 70, at least a pressure-regulating mechanism 80 and a guiding element 90. The housing 10 comprises a flow inlet 11 and a flow outlet 12. The frame 20 is fixed in the housing 10. The compartment 30 is disposed in the housing 10 and separated into a high-pressure compartment 31, a low-pressure compartment 32 and a middle-pressure compartment 33 disposed therebetween. The separator 40 is disposed between the high-pressure compartment 31 and the low-pressure compartment 32, and above the scroll pairs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com