Natural gas processing method

a processing method and natural gas technology, applied in the direction of liquefaction, lighting and heating equipment, solidification, etc., can solve the problems of high equipment cost of a liquefying plant for producing lng, no known instance in which all three types of products are produced from the same plant, and complex equipment configuration, etc., to achieve the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(1) FIRST EMBODIMENT

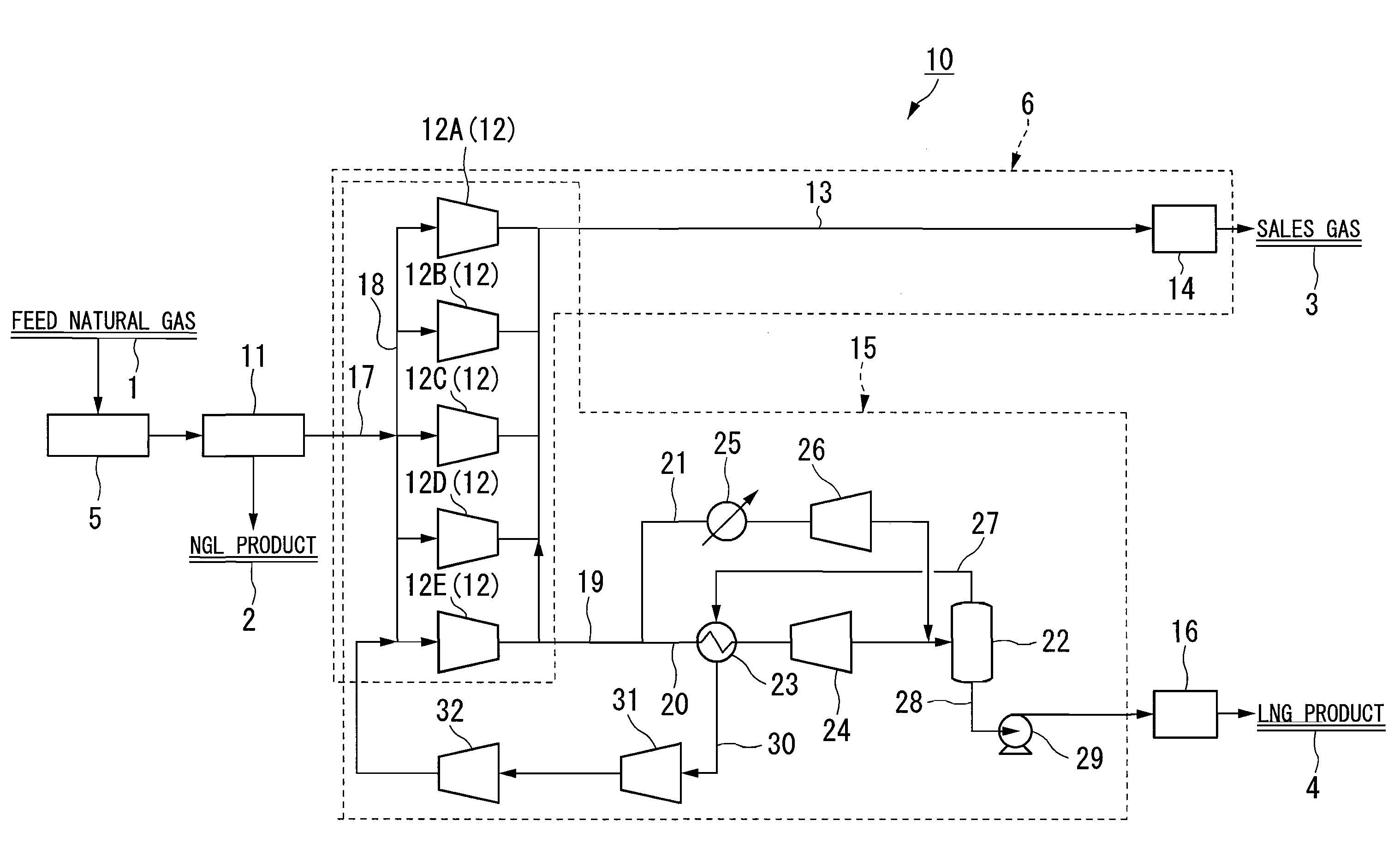

[0038]FIG. 1 is a schematic diagram illustrating a configuration of a natural gas processing plant for performing a natural gas processing method according to a first embodiment of the invention.

[0039]In FIG. 1, Reference Numeral 1 denotes a feed natural gas. Reference Numeral 2 denotes a natural gas liquid (NGL). Reference Numeral 3 denotes a sales gas. Reference Numeral 4 denotes liquefied natural gas (LNG). Reference Numeral 5 denotes a pretreatment plant. Reference Numeral 6 denotes a sales gas production plant. Reference Numeral 10 denotes an entire natural gas processing plant. Reference Numeral 11 denotes an NGL recovery plant. Reference Numeral 12 denotes sales gas compressors. Reference Numeral 13 denotes a line. Reference Numeral 14 denotes a sales gas pipeline. Reference Numeral 15 denotes a natural gas liquefying plant. Reference Numeral 16 denotes an LNG storing tank. Reference Numerals 17, 18, 19, 20, and 21 denote lines. Reference Numeral 22 denote...

second embodiment

(2) SECOND EMBODIMENT

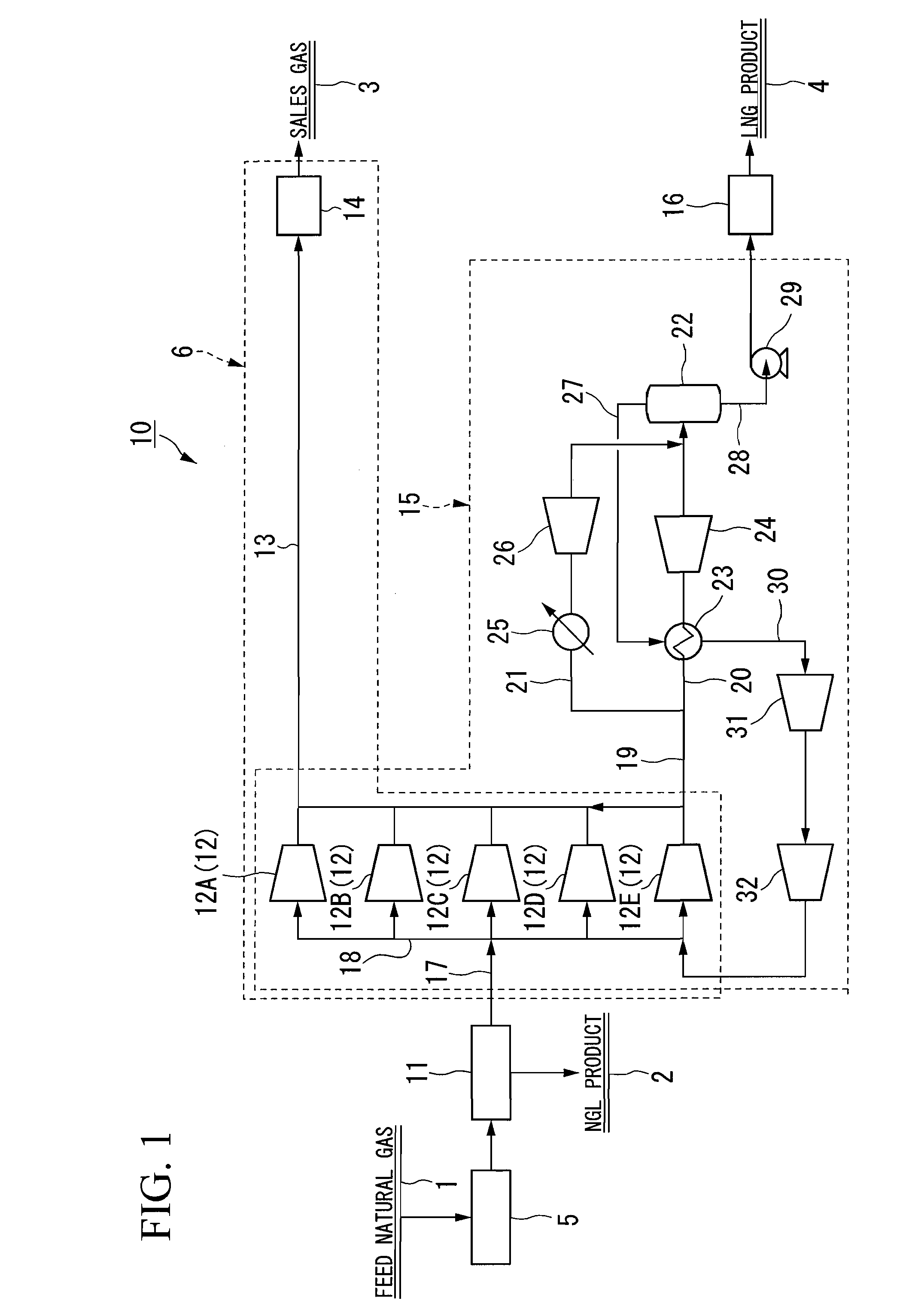

[0078]FIG. 2 is a schematic diagram illustrating a configuration of a natural gas processing plant for performing a natural gas processing method according to a second embodiment of the invention.

[0079]In FIG. 2, the same reference numerals are used for the same components as those of the natural gas processing plant 10 shown in FIG. 1 and explanations thereof are omitted.

[0080]A natural gas processing plant 40 is different from the above-described natural gas processing plant 10 in that a second gas compressor 41 compressing only an LNG feed gas is provided between a line 19 and a line 19′ and before a diverging point of lines 20 and 21. Other configurations are the same as those according to the above-described first embodiment.

[0081]Hereinafter, an operation of the natural gas processing plant 40 will be described and a method of processing a natural gas according to the second embodiment will be described.

[0082]First, a feed natural gas 1 obtained from a wel...

third embodiment

(3) THIRD EMBODIMENT

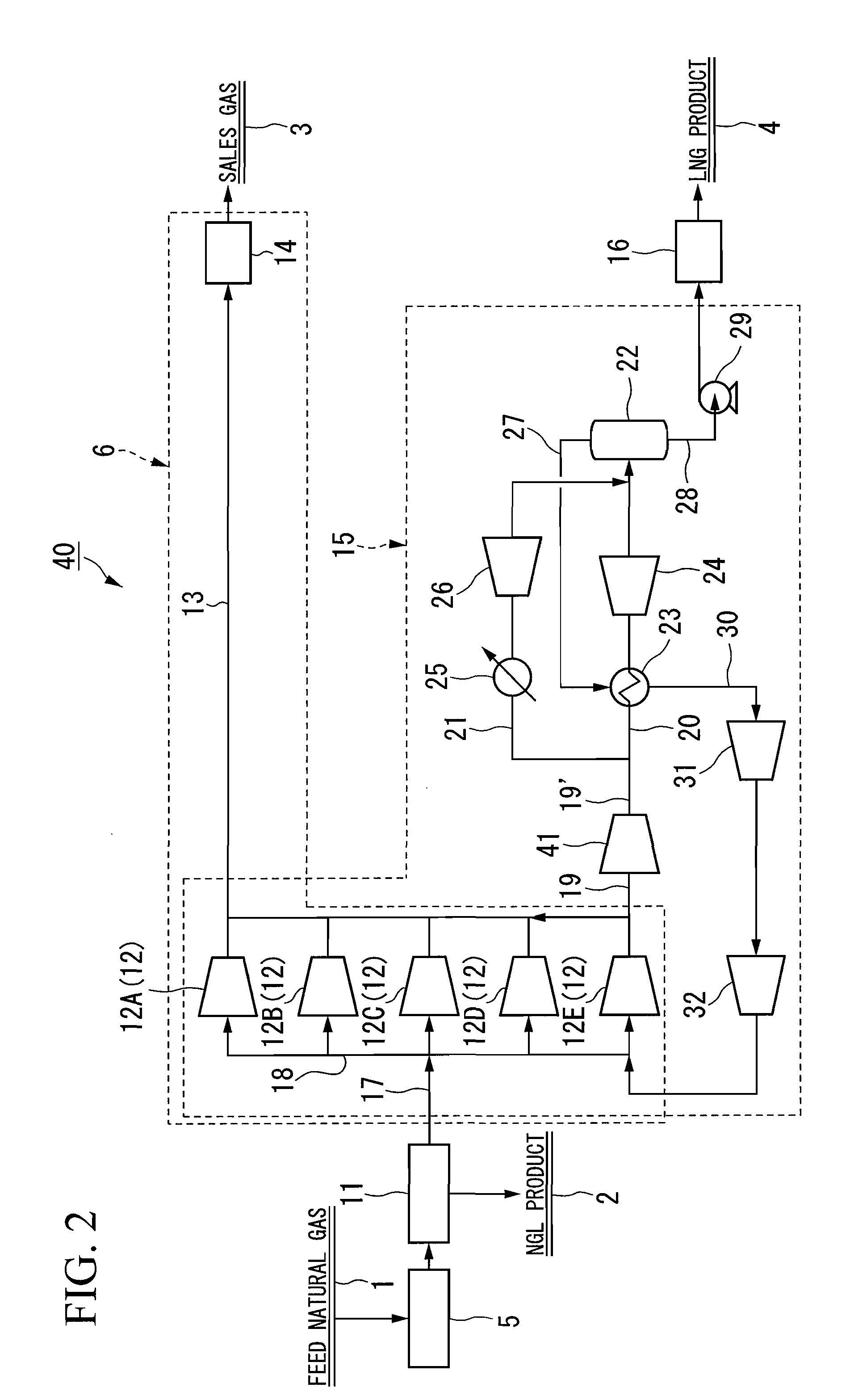

[0090]FIG. 3 is a schematic diagram illustrating a configuration of a natural gas processing plant 50 for performing a natural gas processing method according to a third embodiment of the invention.

[0091]In FIG. 3, the same reference numerals are used for the same components as those of the natural gas processing plant 10 shown in FIG. 1 and the explanations thereof are omitted.

[0092]A natural gas processing plant 50 according to the third embodiment is different from the above-described natural gas processing plant 10 in that the line 21 diverging from the line 20 in the midway of a line 19 in a natural gas liquefying plant 55 has different connected portions. Specifically, the line 21 is further diverged to provide a line for liquefying the LNG feed gas to obtain a product, and a line for transferring the LNG feed gas as a cooling medium. Other configurations are basically the same as those according to the above-described first embodiment.

[0093]In FIG. 3, Refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com