Air Bleeding Pipe Joint

a technology of air bleeding and pipe joints, which is applied in the direction of machines/engines, lighting and heating apparatus, heating types, etc., can solve the problem of hard to inject engine cooling water into the radiator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

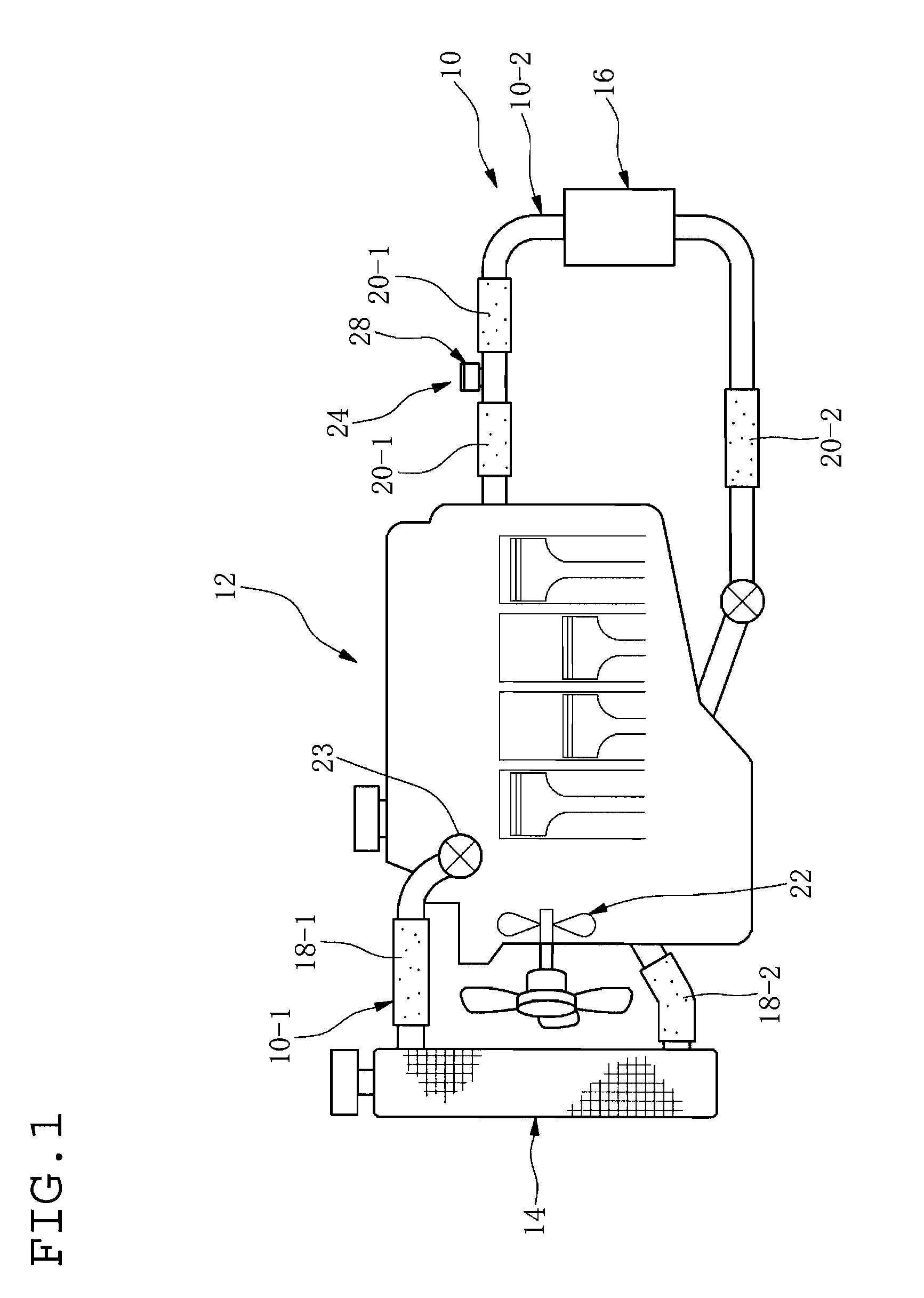

[0071]With reference to FIG. 1, reference numeral 10 indicates a circulation pipeline for an engine cooling water, reference numeral 10-1 indicates a radiator-end pipeline communicating between an engine 12 and a radiator 14, and reference numeral 10-2 indicates a heater-end pipeline communicating between the engine 12 and a heater core 16 for heating a vehicle compartment.

[0072]In the Figure, reference numeral 18-1 indicates a upper radiator hose made of rubber, constituting a part of the circulation pipeline 10, specifically a part of the radiator-end pipeline 10-1, and reference numeral 18-2 indicates a lower radiator hose.

[0073]Reference numeral 20-1 indicates an upper heater hose made of rubber, constituting similarly a part of the circulation pipeline 10, specifically a part of the heater-end pipeline 10-2, and reference numeral 20-2 indicates a lower heater hose.

[0074]Further, reference numeral 22 indicates a water pump, and reference numeral 23 indicates a thermo valve with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com