Steam Turbine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

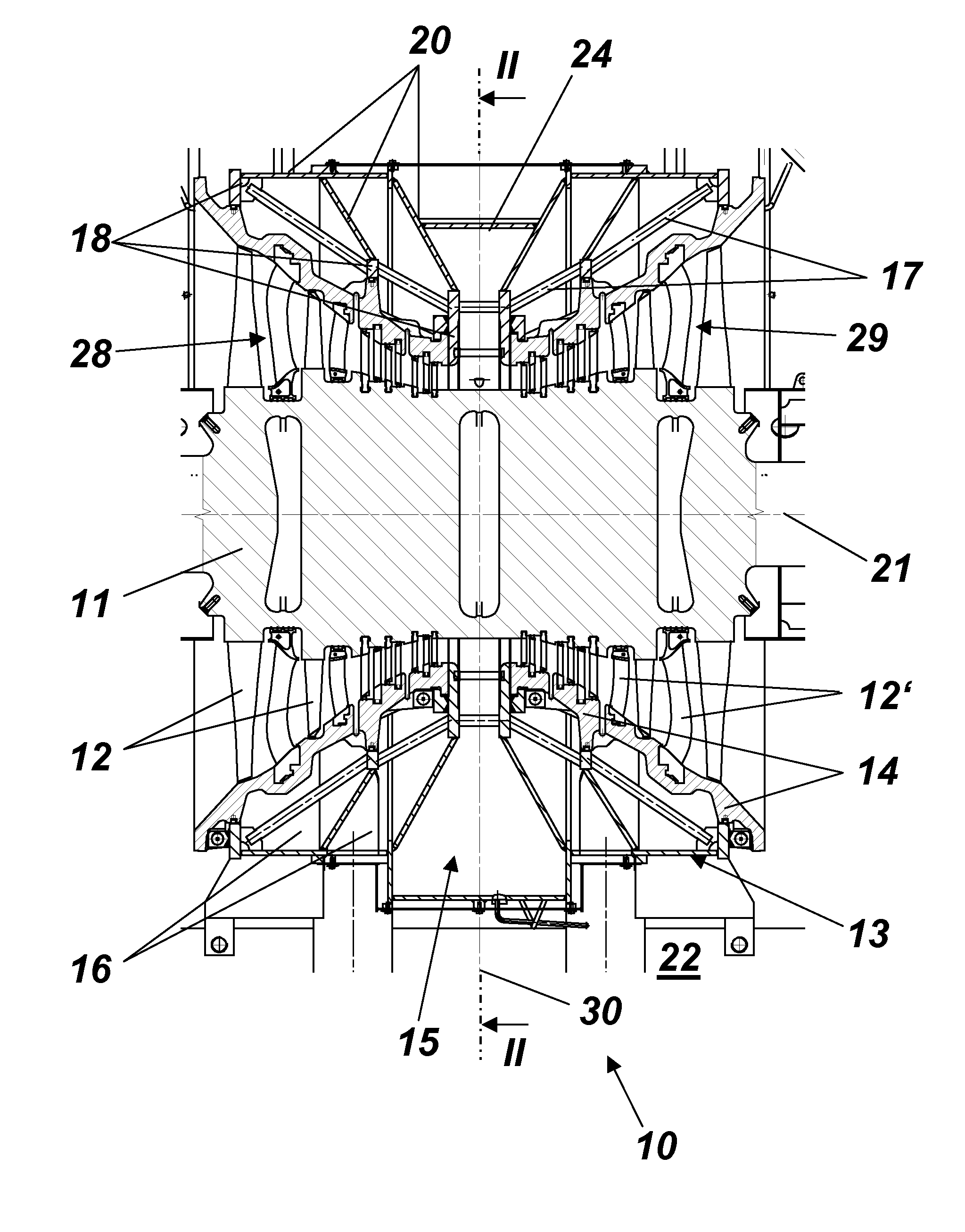

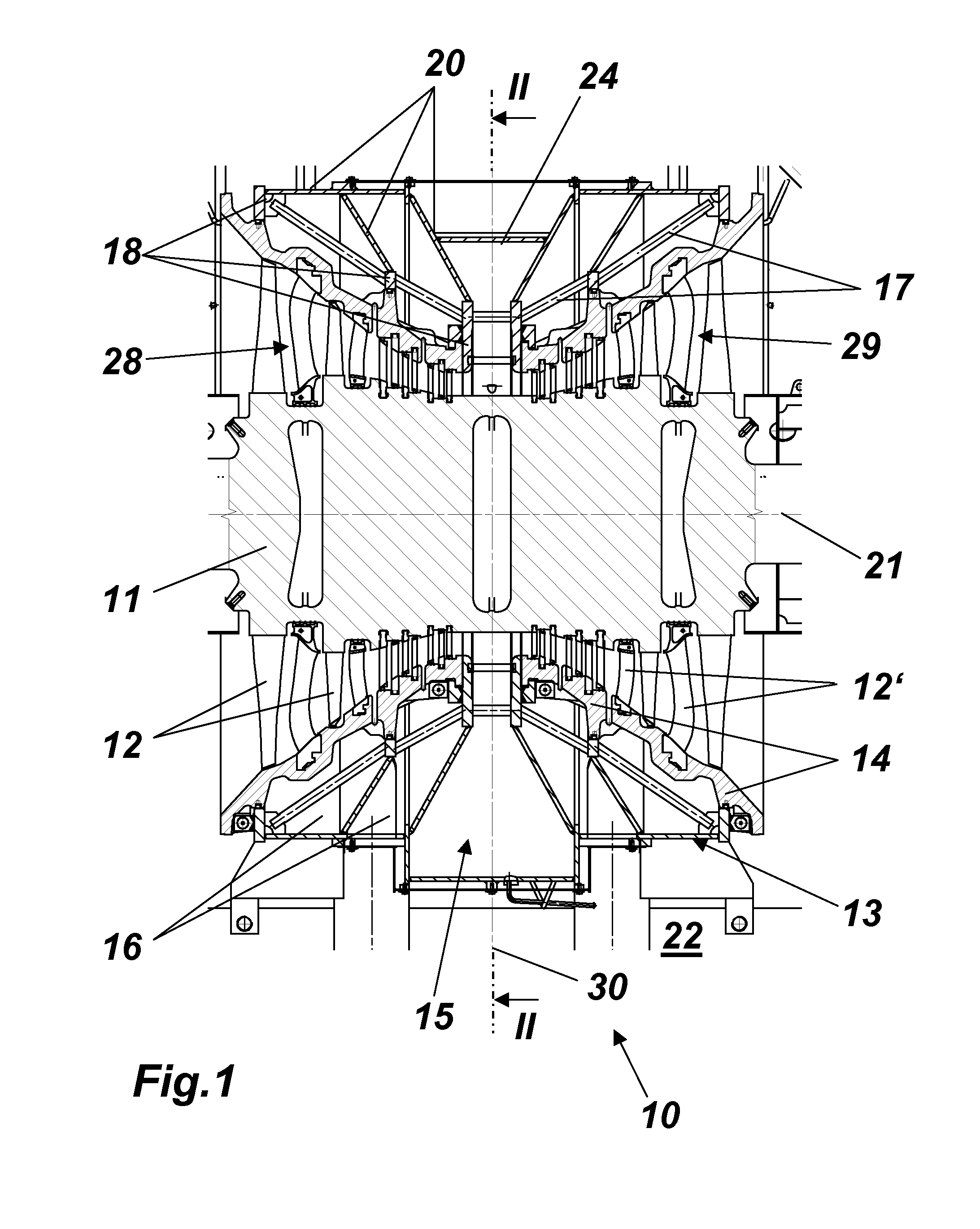

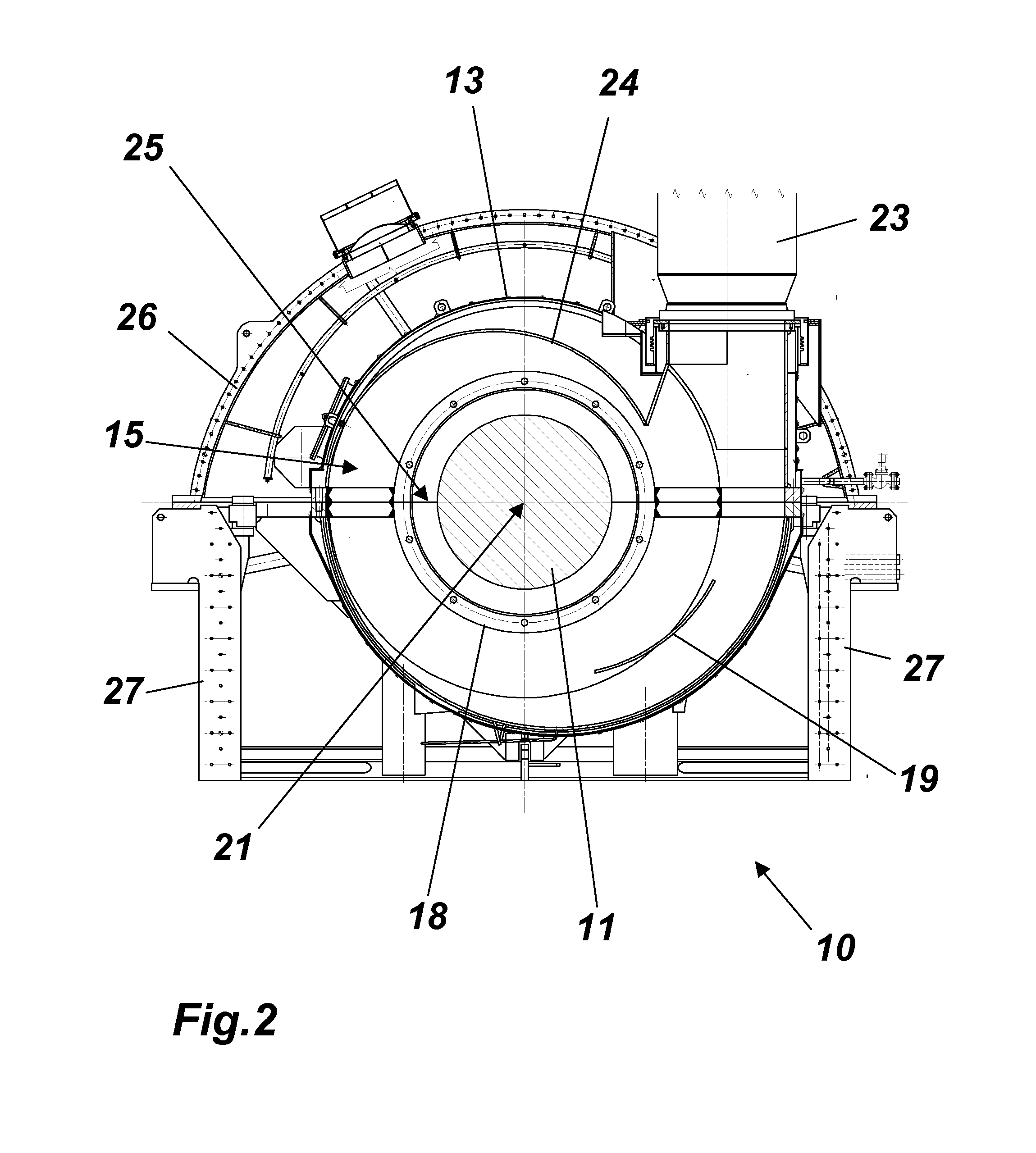

[0021]In FIG. 1, a double-flow low-pressure steam turbine, with its inner casing according to an exemplary embodiment of the invention, is represented in longitudinal section. FIG. 2 shows the section of this turbine in the center plane (plane II-II in FIG. 1). The steam turbine 10 is constructed with its two flows mirror-symmetrical to a vertical center plane 30. It includes a rotor 11, which is rotatable around a horizontal axis 21 and concentrically enclosed with a spacing by an inner casing 13. Outwards widening annular steam passages 28, 29 are formed between the rotor and the inner boundary wall of the inner casing, through which the steam, which is fed radially in the center, flows outwards and, expanding on the rotor blades 12 which are fastened on the rotor 11, performs work.

[0022]Rows of fixed stator blades 12′, which are fastened on blade carriers 14 on the root side, alternate with the rows of rotor blades 12. The blade carriers 14 are cast parts and preferably are forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com